6270A

Service Manual

ii

G- and B-Series Valves..................................................................... 39

Remove and Inspect the B-Series Valves..................................... 40

Install the B-Series Valves............................................................. 43

Remove and Inspect the G-Series Valves..................................... 44

Install the G-Series Valves ............................................................ 44

Power Supply and Fan.......................................................................... 45

Remove the Power Supply................................................................ 46

Remove the Fan................................................................................ 48

Remove the Power Entry Module...................................................... 49

Front Panel and Display Assembly ....................................................... 50

Remove Front-Panel Assembly......................................................... 50

Remove Keypad PCA and Knob from the Front-Panel Assembly..... 52

Remove Display Components from the Display Panel Shell............. 54

Remove the Module Bay Latch Assembly......................................... 57

PCM Assembly...................................................................................... 59

Replace the Control Valves............................................................... 62

Inspect the Control Valves................................................................. 64

PCM Supply, Test, Exhaust Sensor Alignment ................................. 66

Calibrate the Sensors........................................................................ 67

Supply Port (ATM and 3,000 psi) ...................................................... 68

Exhaust Port (Hard Vacuum then ATM)............................................ 70

Calibration Sled and PMM..................................................................... 70

PM200 and PM600 Modules................................................................. 72

PM600 Digital Barometer Optimization ................................................. 73

Setup ................................................................................................. 73

Return to Service – Safety Validation Recommendations..................... 75

Electrical............................................................................................ 75

Pressure ............................................................................................ 75

Calibration Adjustment .......................................................................... 76

PM200 ............................................................................................... 76

PM600 ............................................................................................... 77

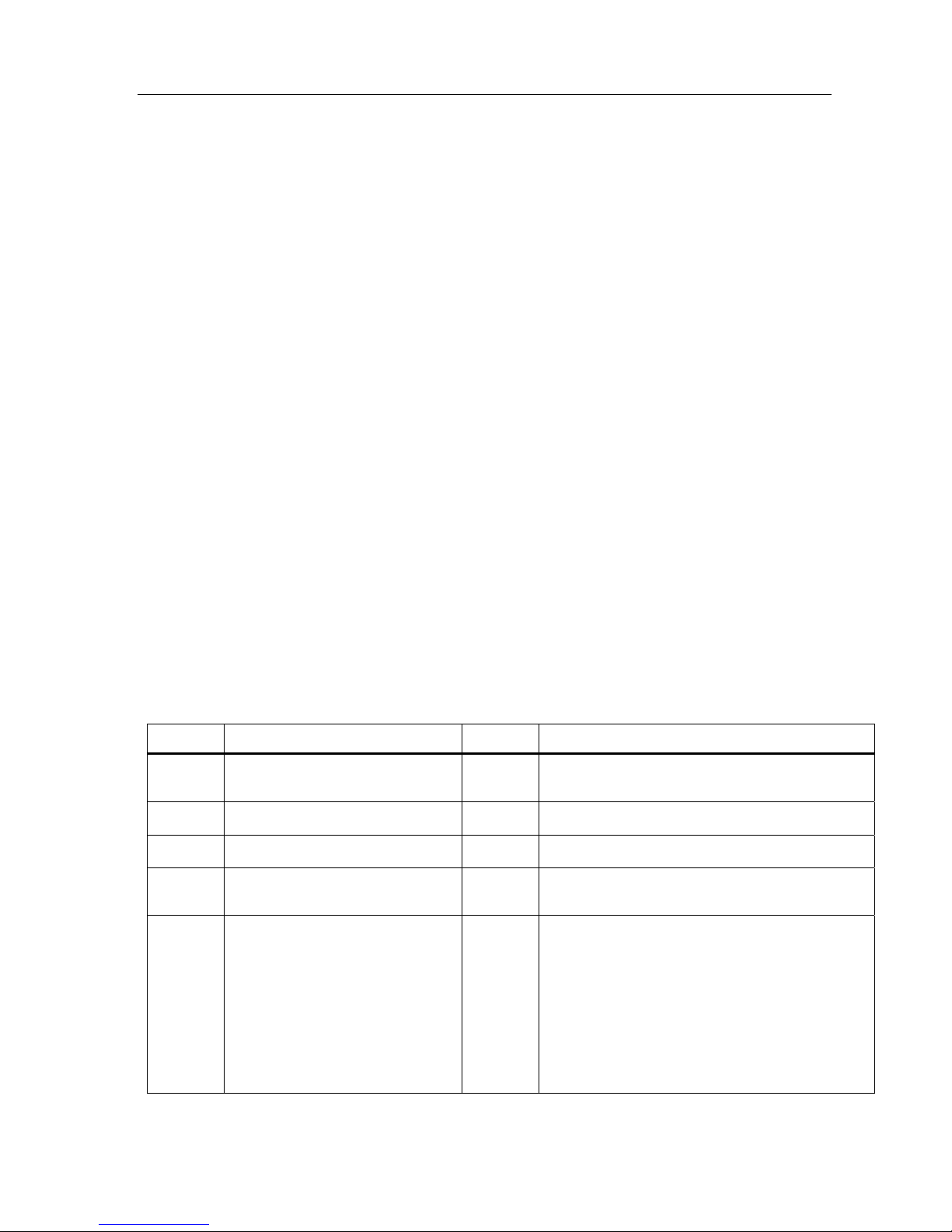

Calibration and Adjustment Procedures................................................ 78

Required Equipment.......................................................................... 78

Preliminary Operations...................................................................... 80

Setup ................................................................................................. 81

Module Calibration ................................................................................ 84

Calibration of Modules in Chassis ..................................................... 84

Calibration of Modules in Calibration Sled......................................... 85

Calibration Tables ................................................................................. 88

PM200 Calibration Definition ............................................................. 88

PM600 Calibration Definition ............................................................. 89

PM200 Test Definition Matrices......................................................... 90

PM600 Test Definition Matrices......................................................... 102

Calibration with COMPASS for Pressure .......................................... 110

Troubleshooting..................................................................................... 111

Reset Controller Settings................................................................... 113

Diagnostics........................................................................................ 113

System............................................................................................... 114

Measure............................................................................................. 114

Control............................................................................................... 115

Leak Test........................................................................................... 115

Remote Interface............................................................................... 116

Contamination Prevention System (CPS) ............................................. 116

CPS Cleaning and Inspection............................................................ 116

Separate the Lower and Upper Housing ....................................... 120