3/ 10

Contents

1. Safety Tips ...................................................................................................................................................................... 4

1.1 Explosion May Result In Death or Serious Injury. ...................................................................................... 4

1.2 Process Leaks Can Cause Serious Injury or Death..................................................................................... 4

1.3 Failure to Follow Safe Installation Guidelines May Result In Death or Serious Injury.................... 4

2. Product Manual............................................................................................................................................................ 4

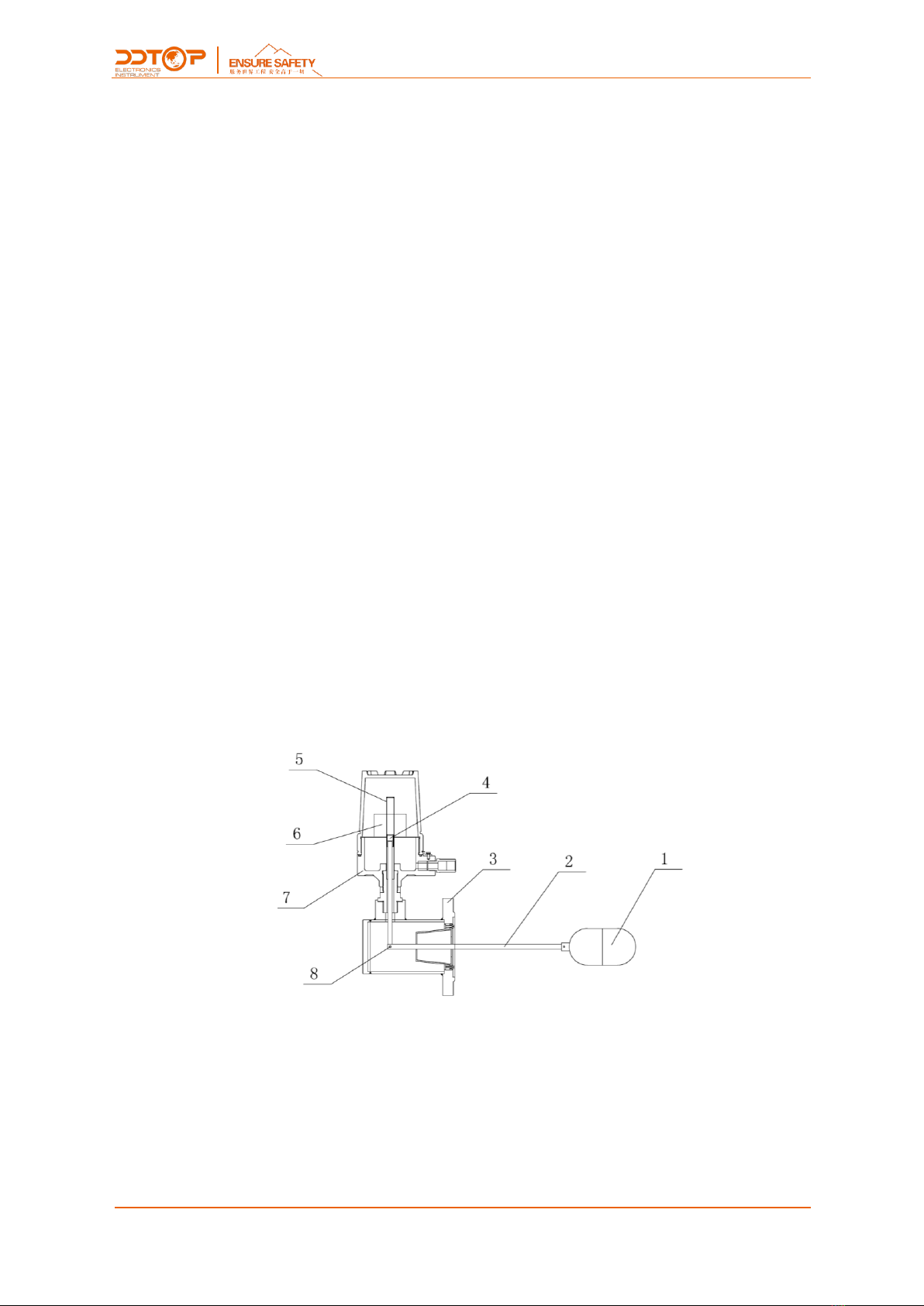

2.1 Main Structure of Product -Figure 1.............................................................................................................. 4

2.2 Operating Principle –Figure2............................................................................................................................ 5

2.3 Packing..................................................................................................................................................................... 5

2.4 Transporting........................................................................................................................................................... 5

2.5 Warehousing.......................................................................................................................................................... 5

3. Technical Characteristics............................................................................................................................................ 5

3.1 Main Performance................................................................................................................................................ 5

3.2 Main Parameters................................................................................................................................................... 5

4. Dimensional Schematic -Figure 2.......................................................................................................................... 6

5. Unpacking and Inspection ........................................................................................................................................ 6

5.1 Unpacking Inspection Notice ........................................................................................................................... 6

5.2 Check Content....................................................................................................................................................... 6

6 Installation ....................................................................................................................................................................... 7

6.1 Installation Tool..................................................................................................................................................... 7

6.2 Installation Technical Requirements............................................................................................................... 7

c6.3 Installation Process............................................................................................................................................. 7

7. Debugging ..................................................................................................................................................................... 7

7.1 Preparation for Commissioning....................................................................................................................... 7

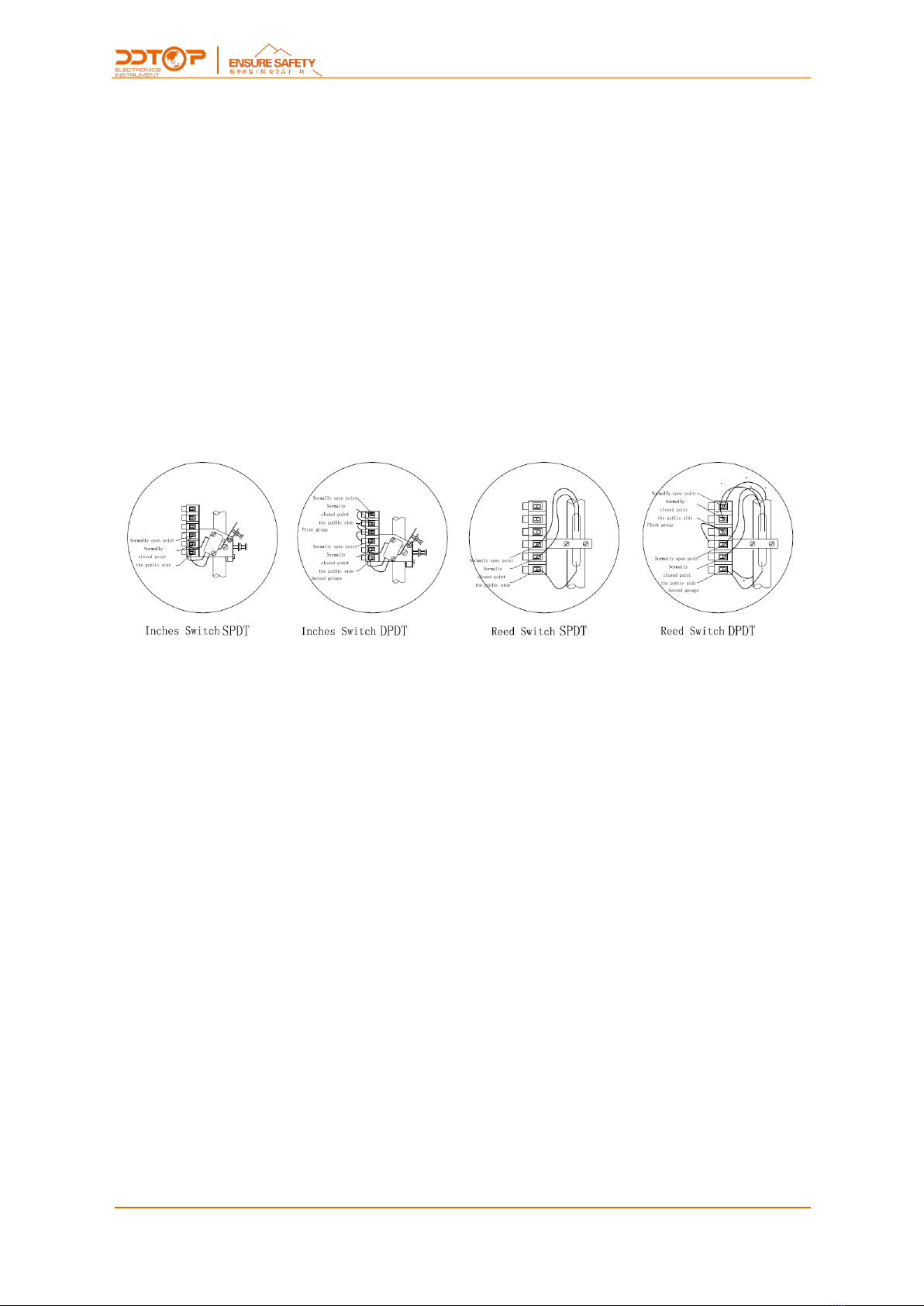

7.2 Electrical Wiring..................................................................................................................................................... 7

7.3 Debugging Operation Process......................................................................................................................... 8

8 Precautions...................................................................................................................................................................... 8

9 Fault Analysis and Elimination .................................................................................................................................. 9

10.Disassembly .................................................................................................................................................................. 9

10.1 Warning................................................................................................................................................................. 9

10.2 Waste Removal ................................................................................................................................................... 9

11 Product Certification.................................................................................................................................................. 9