3/ 14

CONTENTS

1 Safety Tips ....................................................................................................................................................................... 4

1.1 Explosion may result in death or serious injury.................................................................................4

1.2 Process leaks can cause serious injury or death................................................................................4

1.3 Failure to follow safe installation guidelines may result in death or serious injury................4

2 Product Manual............................................................................................................................................................. 4

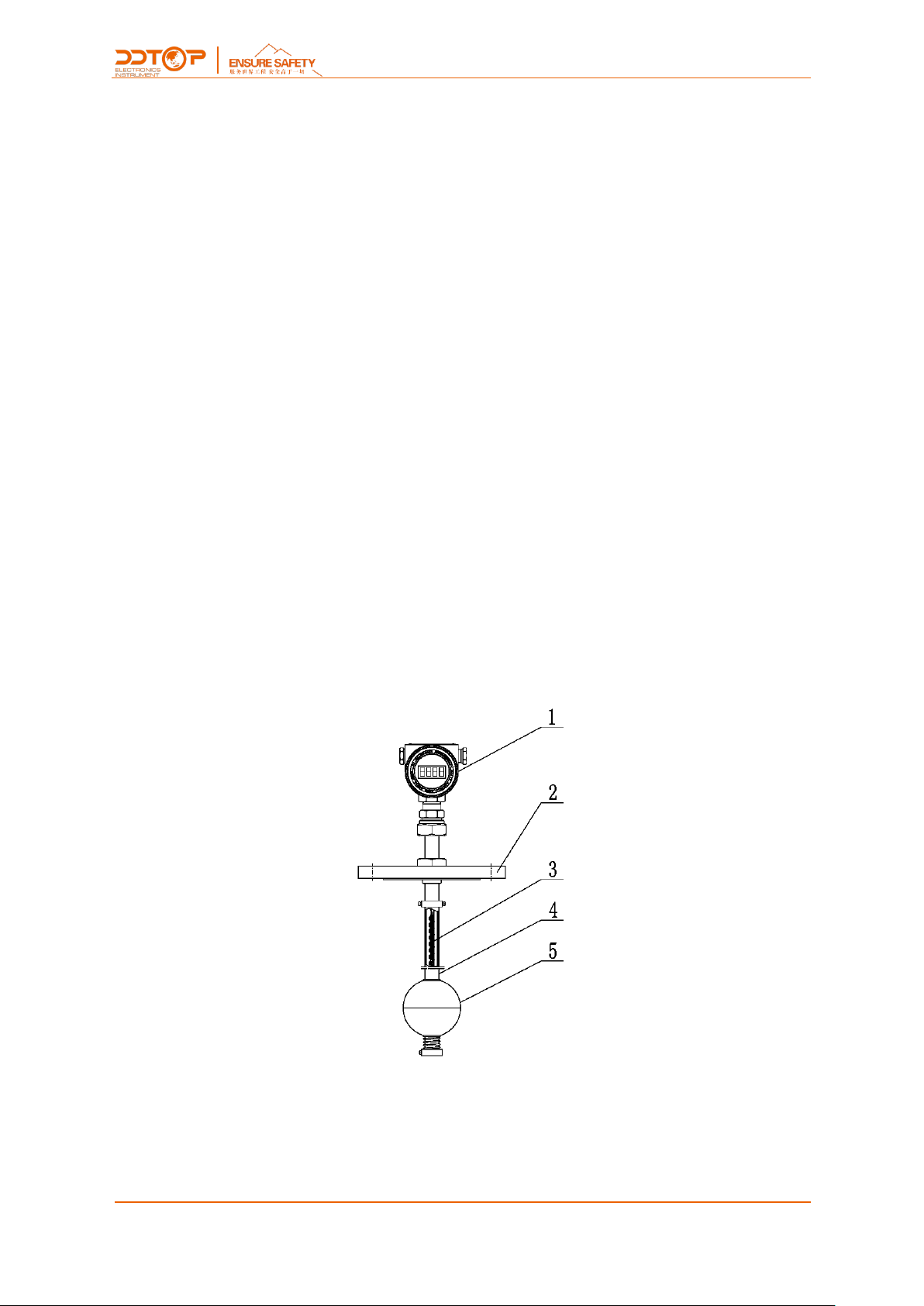

2.1 Product Basic Structure..............................................................................................................................4

2.2 Operating Principle .....................................................................................................................................5

2.3 Packing............................................................................................................................................................5

2.4 Hoisting and Transporting........................................................................................................................5

2.5 Storage............................................................................................................................................................5

3 Technical Characteristics............................................................................................................................................. 5

3.1 Product Features..........................................................................................................................................5

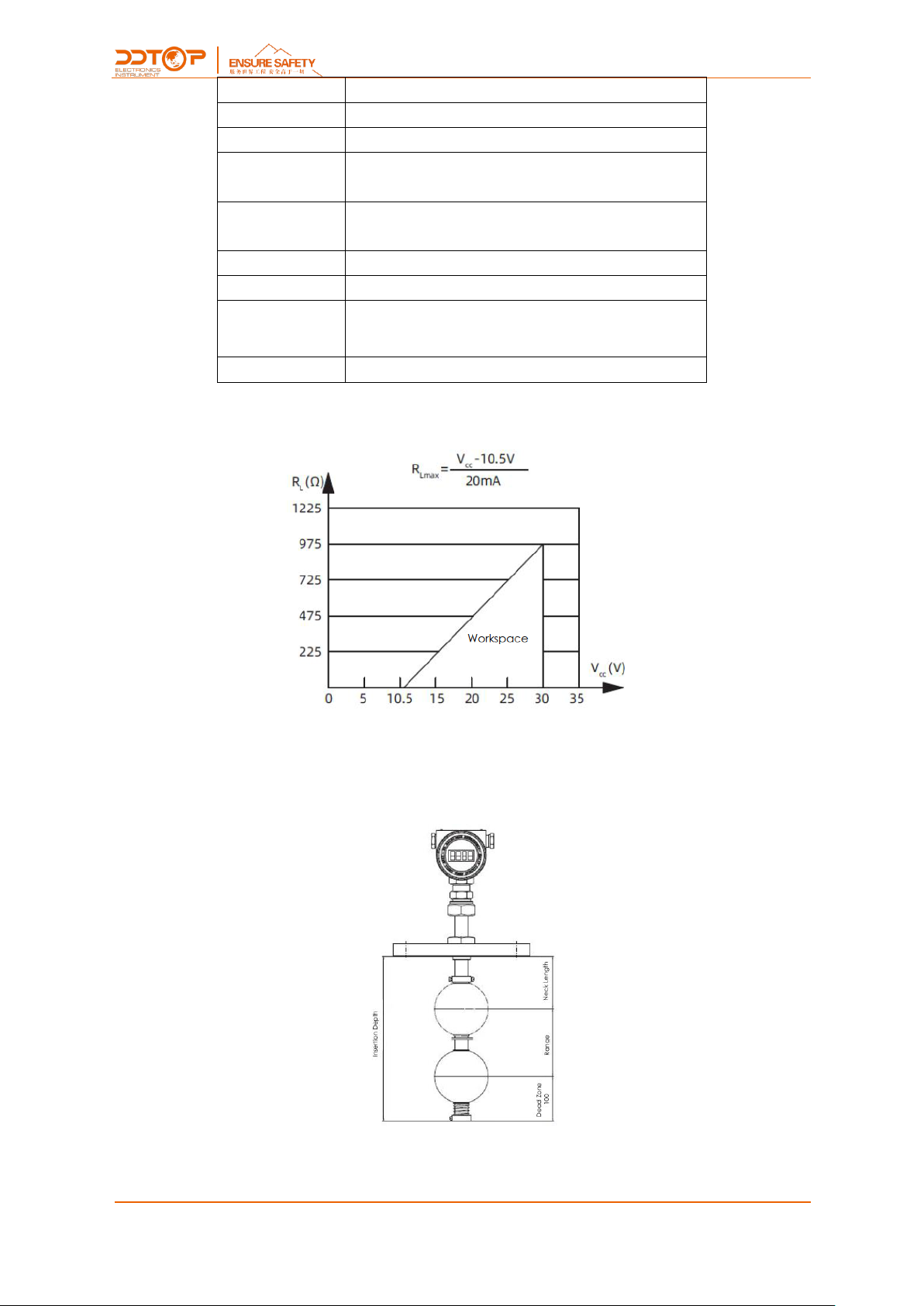

3.2 Main Parameter............................................................................................................................................5

4 Dimension Schematic.................................................................................................................................................. 6

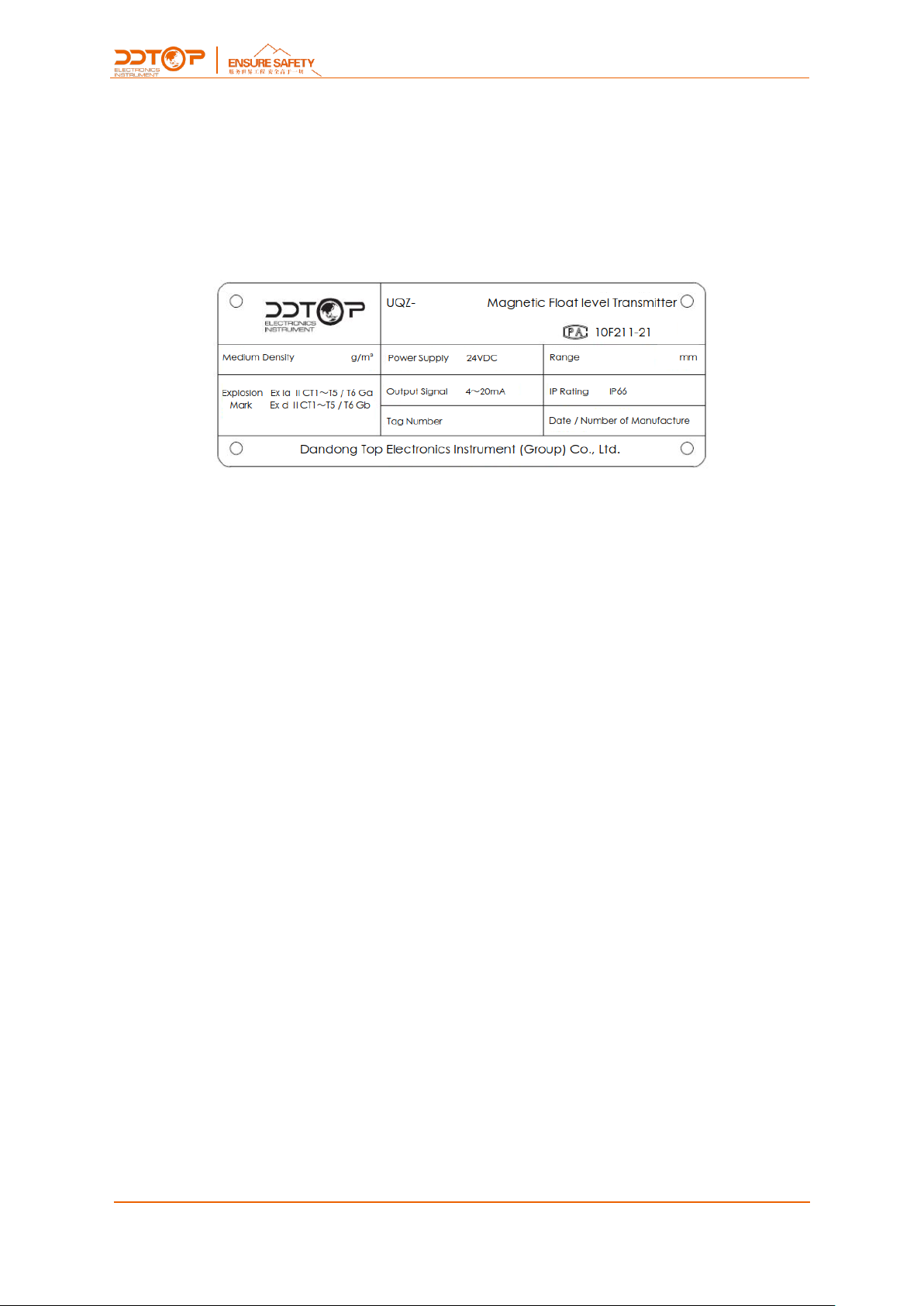

5 Unpacking and Inspection ......................................................................................................................................... 7

5.1 Matters needing attention in unpacking and inspecting goods..................................................7

5.2 Check Content..............................................................................................................................................7

6 Installation....................................................................................................................................................................... 7

6.1 Installation Tool............................................................................................................................................7

6.2 Installation Technical Requirements......................................................................................................7

6.3 Installation Procedure ................................................................................................................................7

7 Debugging ...................................................................................................................................................................... 8

7.1 UQZ Magnetic Float Level Transmitter Debugging .........................................................................8

8 Precautions....................................................................................................................................................................13

9 Fault Analysis and Elimination ................................................................................................................................14

10 Disassembly................................................................................................................................................................14

10.1 Warning......................................................................................................................................................14

10.2 Waste Removal ........................................................................................................................................14

11 Product Certification................................................................................................................................................14