decaWave DWM1001 User manual

相关的中文文档请参考 www.decawave.com/china

Overview

The DWM1001 module is based on Decawave's DW1000 Ultra

Wideband (UWB) transceiver IC, which is an IEEE 802.15.4-

2011 UWB implementation. It integrates UWB and Bluetooth®

antenna, all RF circuitry, Nordic Semiconductor nRF52832 and

a motion sensor.

Key Features

•Ranging accuracy to within 10cm.

•UWB Channel 5 printed PCB antenna (6.5 GHz)

•6.8 Mbps data rate

•60 m line-of-sight range typical

•IEEE 802.15.4-2011 UWB compliant

•Nordic Semiconductor nRF52832

•Bluetooth® connectivity

•Bluetooth® chip antenna

•Motion sensor: 3-axis accelerometer

•Current consumption optimised for low power sleep mode: <15μA

•Supply voltage: 2.8 V to 3.6 V

•Size: 19.1 mm x 26.2 mm x 2.6 mm

Key Benefits

•Enables anchors, tags & gateways to quickly get an entire RTLS system up-and-running

•Accelerates product designs for faster Time-to-Market & reduced development costs

•Ready-to-go embedded firmware to minimise software development

•Over-the-air updates

•User API to DWM1001 firmware (available as a library) for user code customisation

•On-board Bluetooth® SMART for connectivity to phones/tablets/PCs

•SPI, UART and Bluetooth® APIs to access DWM1001 firmware from an external device

•Low-power hardware design and software architecture for longer battery life

UWB

Transceiver

Decawave

DW1000

BLE

Microprocessor

Nordic

nRF52832

64 MHz ARM

Cortex M4

SPI M1*

3- Axis Motion

Detector

STM

LIS2DH12TR

BLE Antenna

UART [1:0]

SPI S2* [3:0]

I2C [1:0]

IRQ

UWB Antenna

VCC

2.8 V–3.6 V

DC-DC

Converter

1V8

GPIO

RESET

SWD[1:0]

GPIO

BT_WAKE_UP

GND

READY

4

12

*SPI M1 is nRF52 SPI master 1, SPI S2 is SPI slave 2

High Level Block Diagram

DW1000 Datasheet

Table of Contents

1OVERVIEW ................................................... 5

1.1 UWB TRANSCEIVER DW1000....................... 5

1.2 BLUETOOTH®MICROPROCESSOR NORDIC

NRF52832 ........................................................... 5

1.3 POWER SUPPLY AND POWER MANAGEMENT...... 5

1.4 THREE AXIS MOTION DETECTOR

STMICROELECTRONICS LIS2DH12TR ........................ 5

1.5 SOFTWARE ON BOARD................................... 5

2DWM1001 CALIBRATION ............................. 6

2.1.1 Crystal Oscillator Trim ...................... 6

2.1.2 Transmitter Calibration .................... 6

2.1.3 Antenna Delay Calibration ............... 6

3DWM1001 PIN CONNECTIONS ..................... 7

3.1 PIN NUMBERING.......................................... 7

3.2 PIN DESCRIPTIONS........................................ 7

4ELECTRICAL SPECIFICATIONS ...................... 10

4.1 NOMINAL OPERATING CONDITIONS ............... 10

4.2 DC CHARACTERISTICS.................................. 10

4.3 RECEIVER AC CHARACTERISTICS .................... 10

4.4 RECEIVER SENSITIVITY CHARACTERISTICS ......... 11

4.5 TRANSMITTER AC CHARACTERISTICS .............. 11

4.5.1 Absolute Maximum Ratings ........... 12

5TRANSMIT AND RECEIVE POWER

CONSUMPTION .................................................13

6ANTENNA PERFORMANCE ..........................14

7APPLICATION INFORMATION......................16

7.1APPLICATION BOARD LAYOUT GUIDELINES.......16

8PACKAGE INFORMATION ............................17

8.1 MODULE DRAWINGS................................... 17

8.2 MODULE LAND PATTERN .............................18

8.3 MODULE MARKING INFORMATION ................18

8.4 MODULE SOLDER PROFILE............................ 19

9ORDERING INFORMATION ..........................20

9.1 TAPE AND REEL INFORMATION ......................20

10 GLOSSARY ...............................................21

11 REFERENCES ............................................22

12 DOCUMENT HISTORY ..............................22

13 MAJOR CHANGES ....................................22

14 ABOUT DECAWAVE .................................23

List of Figures

FIGURE 1: DWM1001 PIN DIAGRAM ........................... 7

FIGURE 2: POWER CONSUMPTION DURING TWO WAY

RANGING......................................................... 13

FIGURE 3. ANTENNA RADIATION PATTERN PLANES ......... 14

FIGURE 4: DWM1001 APPLICATION BOARD KEEP-OUT

AREAS ............................................................. 16

FIGURE 5: MODULE PACKAGE SIZE (UNITS:MM)............17

FIGURE 6: DWM1001 MODULE LAND PATTERN (UNITS:

MM)................................................................18

FIGURE 7: DWM1001 MODULE SOLDER PROFILE.........19

FIGURE 8: DWM1001 TAPE AND REEL DIMENSIONS .....20

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 3

List of Tables

TABLE 1: DWM1001 PIN FUNCTIONS ........................... 7

TABLE 2: EXPLANATION OF ABBREVIATIONS..................... 9

TABLE 3: INTERNAL NRF52832 PINS USED AND THEIR

FUNCTION .......................................................... 9

TABLE 4: I2C SLAVE DEVICES ADDRESSI2C....................... 9

TABLE 5: DWM1001 OPERATING CONDITIONS ............ 10

TABLE 6: DWM1001 DC CHARACTERISTICS................. 10

TABLE 7: DWM1001 RECEIVER AC CHARACTERISTICS ... 10

TABLE 8: DWM1001 TYPICAL RECEIVER SENSITIVITY

CHARACTERISTICS .............................................. 11

TABLE 9: DWM1001 TRANSMITTER AC CHARACTERISTICS

...................................................................... 11

TABLE 10: DWM1001 ABSOLUTE MAXIMUM RATINGS. 12

TABLE 11. ANTENNA RADIATION PATTERNS .................. 15

TABLE 12: GLOSSARY OF TERMS.................................. 21

TABLE 13: DOCUMENT HISTORY.................................. 22

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 4

DOCUMENT INFORMATION

Disclaimer

Decawave reserves the right to change product specifications without notice. As far as possible changes to

functionality and specifications will be issued in product specific errata sheets or in new versions of this

document. Customers are advised to check with Decawave for the most recent updates on this product.

The DWM1001 is pre-loaded with firmware, please refer to the "DWM1001 Firmware User Guide" for disclaimer

and license terms.

Copyright © 2017 Decawave Ltd

LIFE SUPPORT POLICY

Decawave products are not authorized for use in safety-critical applications (such as life support) where a

failure of the Decawave product would reasonably be expected to cause severe personal injury or death.

Decawave customers using or selling Decawave products in such a manner do so entirely at their own risk

and agree to fully indemnify Decawave and its representatives against any damages arising out of the use of

Decawave products in such safety-critical applications.

Caution! ESD sensitive device. Precaution should be used when handling the device in order

to prevent permanent damage.

REGULATORY APPROVALS

The DWM1001, as supplied from Decawave, has not been certified for use in any particular geographic region

by the appropriate regulatory body governing radio emissions in that region although it is capable of such

certification depending on the region and the manner in which it is used.

All products developed by the user incorporating the DWM1001 must be approved by the relevant authority

governing radio emissions in any given jurisdiction prior to the marketing or sale of such products in that

jurisdiction and user bears all responsibility for obtaining such approval as needed from the appropriate

authorities.

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 5

1 OVERVIEW

The block diagram on page 1 of this data sheet shows the major sections of the DWM1001. An overview of these

blocks is given below.

1.1 UWB Transceiver DW1000

The module has a DW1000 UWB transceiver mounted on the PCB. The DW1000 uses a 38.4 MHz reference

crystal. The crystal has been trimmed in production to reduce the initial frequency error to approximately 3 ppm,

using the DW1000 IC’s internal on-chip crystal trimming circuit.

Always-On (AON) memory can be used to retain DW1000 configuration data during the lowest power operational

states when the on-chip voltage regulators are disabled. This data is uploaded and downloaded automatically. Use

of DW1000 AON memory is configurable.

The on-chip voltage and temperature monitors allow the host to read the voltage on the VDDAON pin and the

internal die temperature information from the DW1000.

See the DW1000 Datasheet [2] for more detailed information on device functionality, electrical specifications and

typical performance.

1.2 Bluetooth® Microprocessor Nordic nRF52832

The nRF52832 is an ultra-low power 2.4 GHz wireless system on chip (SoC) integrating the nRF52 Series 2.4

GHz transceiver and an ARM Cortex-M4 CPU with 512kB flash memory and 64kB RAM.

See the nRF52832 Datasheet[1] for more detailed information on device functionality, electrical specifications and

typical performance.

1.3 Power Supply and Power management

The power management circuit consists of a switch mode regulator. It is a buck convertor or step down convertor.

The input voltage to the DWM1001 can be in the range 2.8V to 3.6V. Outputs from the convertor provides 1.8V

which is required by the DW1000[2]

1.4 Three Axis Motion Detector STMicroelectronics LIS2DH12TR

The LIS2DH12 is an ultra-low-power high performance three-axis linear accelerometer with digital I2C/SPI serial

interface standard output. The LIS2DH12 has user-selectable full scales of 2g/±4g/8g/16g and is capable of

measuring accelerations with output data rates from 1 Hz to 5.3 kHz. The self-test capability allows the user to

check the functionality of the sensor in the final application. The device may be configured to generate interrupt

signals by detecting two independent inertial wake-up/free-fall events as well as by the position of the device itself.

The LIS2DH12 is guaranteed to operate over an extended temperature range from -40 °C to +85 °C.

See the LIS2DH12TR Datasheet[4] for more detailed information on device functionality, electrical specifications

and typical performance.

1.5 Software on board

The DWM1001 module comes pre-loaded with embedded firmware which provides two-way ranging (TWR) and

real time location system (RTLS) functionality. See the details in the DWM1001 Firmware User Guide [6]. The

module can be configured and controlled via its API, which can be accessed through a number of different

interfaces, allowing flexibility to the product designer. The details of the API are described in the DWM1001

Firmware API Guide [5]. Decawave also provides the module firmware in the form of binary libraries and some

source code. A build environment is provided, so that the user can customise the operation and if required add

their own functions[6].

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 6

2 DWM1001 CALIBRATION

Depending on the end-use applications and the system design, DWM1001 settings may need to be tuned. To

help with this tuning a number of built in functions such as continuous wave TX and continuous packet

transmission can be enabled. See the DW1000 User Manual [3] for further details.

2.1.1 Crystal Oscillator Trim

DWM1001 modules are calibrated at production to minimise initial frequency error to reduce carrier frequency

offset between modules and thus improve receiver sensitivity. The calibration carried out at module production

will trim the initial frequency offset to less than 3 ppm, typically.

2.1.2 Transmitter Calibration

The DWM1001 is calibrated in module production for the on board firmware application.

This is calibrated to meet the power spectral density requirement of less than -41.3 dBm/MHz.

2.1.3 Antenna Delay Calibration

In order to measure range accurately, precise calculation of timestamps is required. To do this the antenna delay

must be known. The DWM1001 allows this delay to be calibrated and provides the facility to compensate for

delays introduced by PCB, external components, antenna and internal DWM1001 delays.

If using the pre-loaded embedded firmware of the DWM1001 module, the Antenna Delay has been pre calibrated

for this configuration. The antenna delay is stored in OTP memory.

If you are creating your own embedded firmware, with a different configuration for the DW1000, then you will

have to calibrate antenna delay. To calibrate the antenna delay, range is measured at a known distance using

two DWM1001 systems. Antenna delay is adjusted until the known distance and reported range agree.

Antenna delay calibration must be carried out as a once off measurement for each DWM1001 design

implementation. If required, for greater accuracy, antenna delay calibration should be carried out on a per

DWM1001 module basis, see DW1000 User Manual [3] for full details. Further details can be found in the

Antenna Delay Application Note [8].

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 7

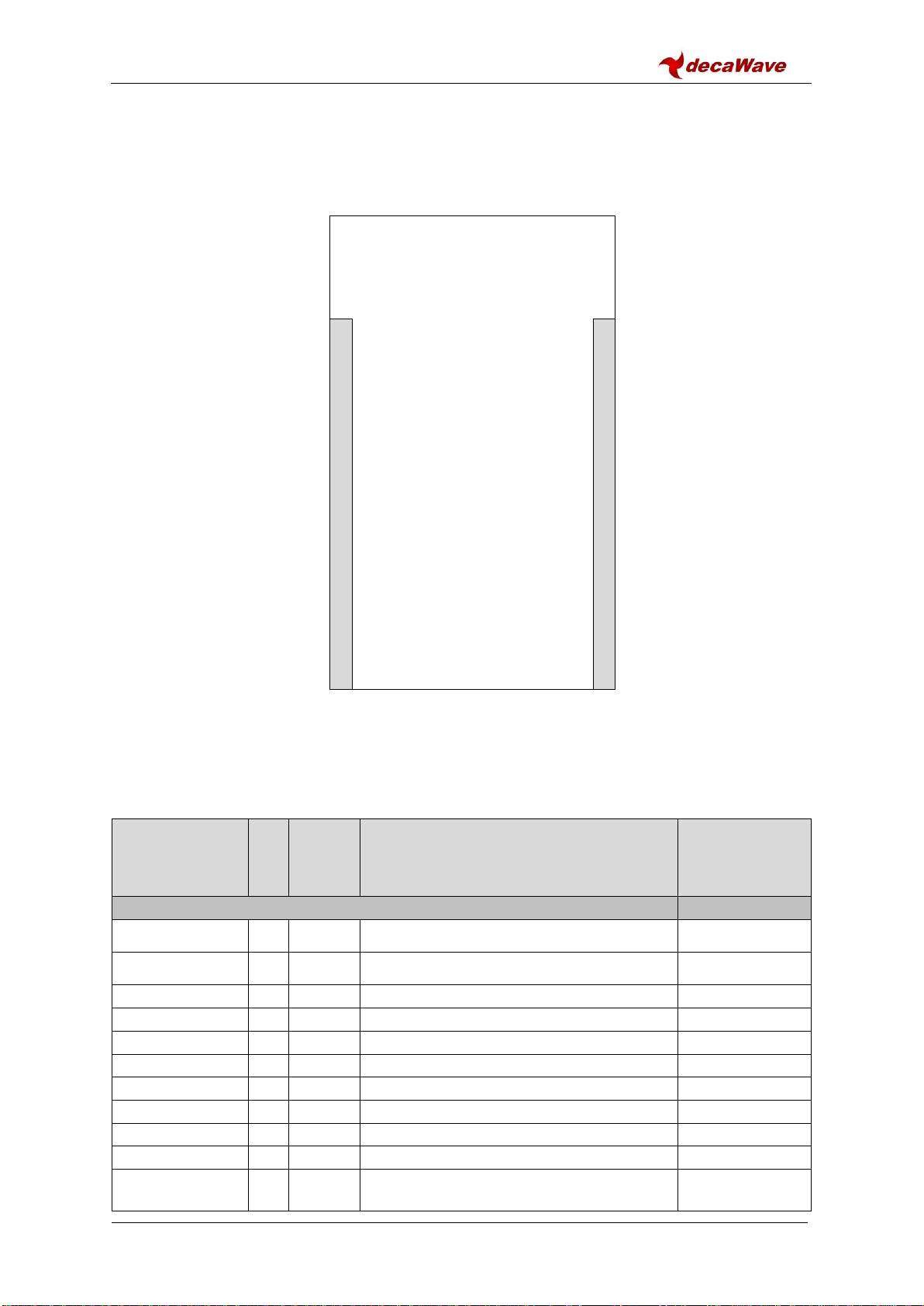

3 DWM1001 PIN CONNECTIONS

3.1 Pin Numbering

DWM1001 module pin assignments are as follows (viewed from top): -

GND

SWD_CLK

SWD_DIO

GPIO_10

GPIO_9

GPIO_12

GPIO_14

GPIO_22

GPIO_31

GPIO_30

GND

VCC

GPIO_27

I2C_SDA

I2C_SCL

GPIO_23

GPIO_13

34 GND

33 RESETn

32 BT_WAKE_UP

31 GPIO_2

30 GPIO_3

29 SPIS_CSn

28 SPIS_CLK

27 SPIS_MOSI

26 SPIS_MISO

25 GPIO_8

24 GND

23 GPIO_15

22 GPIO_0

21 GPIO_1

20 UART_TX

19 READY

18 UART_RX

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Figure 1: DWM1001 Pin Diagram

3.2 Pin Descriptions

Pin details are given in

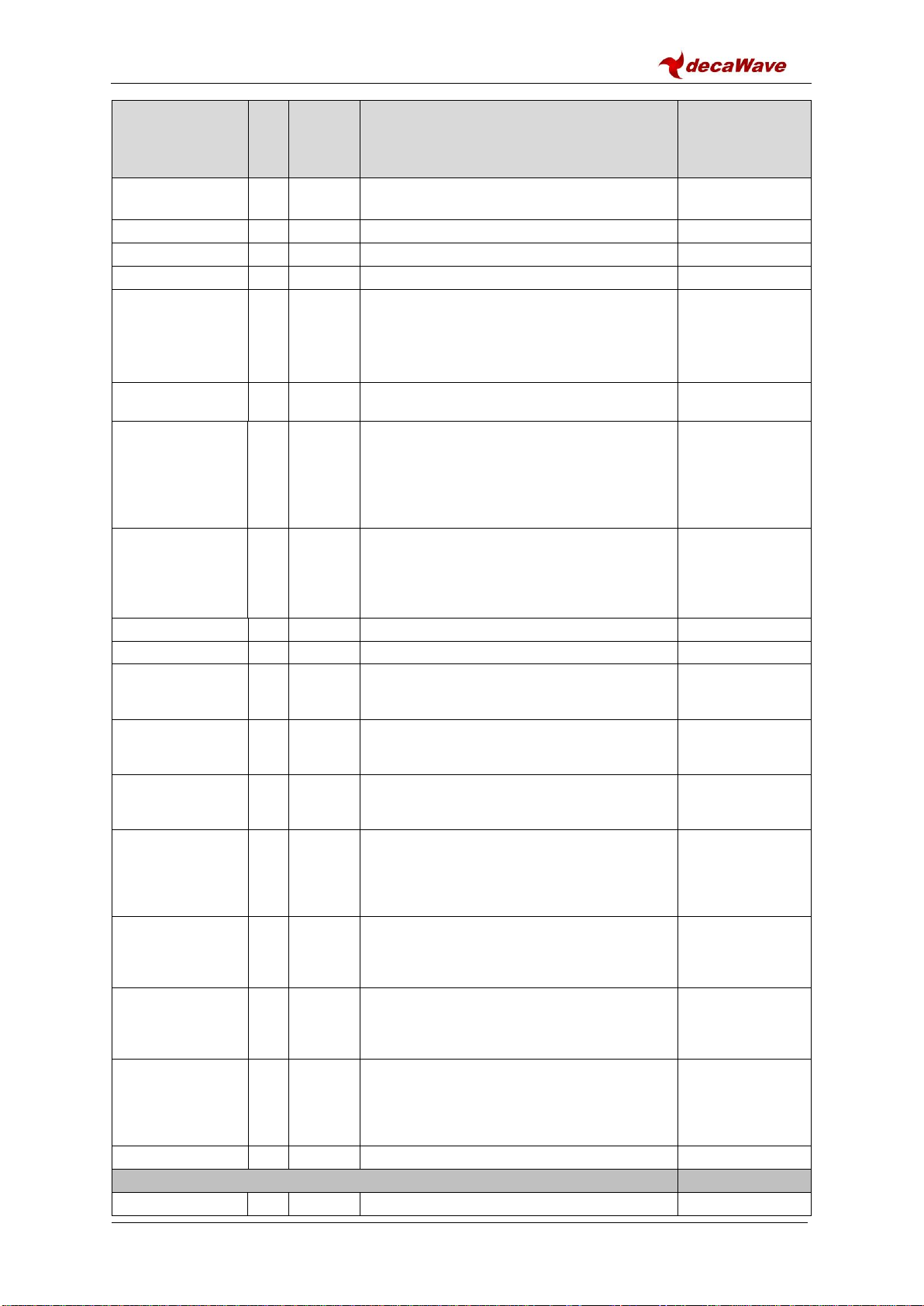

Table 1: DWM1001 Pin functions

SIGNAL NAME

PI

N

I/O

(Default

)

DESCRIPTION

REFERENCE (Pin

designation)

Digital Interface

SWD_CLK

2

DI

Serial wire debug clock input for debug and

programming of Nordic Processor

[N] SWDCLK

SWD_DIO

3

DIO

Serial wire debug I/O for debug and

programming of Nordic Processor

[N] SWDIO

GPIO_10

4

DIO

General purpose I/O pin.

[N] P0.10

GPIO_9

5

DIO

General purpose I/O pin.

[N] P0.9

GPIO_12

6

DIO

General purpose I/O pin.

[N] P0.12

GPIO_14

7

DIO

General purpose I/O pin.

[N] P0.14

GPIO_22

8

DIO

General purpose I/O pin.

[N] P0.22

GPIO_31

9

DIO

General purpose I/O pin. ADC function of nRF52

[N] P0.31

GPIO_30

10

DIO

General purpose I/O pin. ADC function of nRF52

[N] P0.30

GPIO_27

13

DIO

General purpose I/O pin.

[N] P0.27

I2C_SDA

(Master)

14

DIO

Master I2C Data Line.

[N] P0.29

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 8

SIGNAL NAME

PI

N

I/O

(Default

)

DESCRIPTION

REFERENCE (Pin

designation)

I2C_SCL

(Master)

15

DO

Master I2C Clock Line

[N] P0.28

GPIO_23

16

DIO

General purpose I/O pin.

[N] P0.23

GPIO_13

17

DIO

General purpose I/O pin.

[N] P0.13

UART_RX

18

DI

UART_RX

[N] P0.11

READY

19

DO

Generated interrupt from the device.

Indicates events such as SPI data ready, or

location data ready.

See the function dwm_int_cfg() in the DWM1001

Firmware API Guide for details[5].

[N] P0.26

UART_TX

20

DO

UART_TX, This is also the ADC function of the

nRF52

[N] P0.05

GPIO_1

21

DIO

General purpose I/O pin of the DW1000.

It may be configured for use as a SFDLED

driving pin that can be used to light a LED when

SFD (Start Frame Delimiter) is found by the

receiver. Refer to the DW1000 User Manual [1]

for details of LED use.

[DW] GPIO1

GPIO_0

22

DIO

General purpose I/O pin of the DW1000.

It may be configured for use as a RXOKLED

driving pin that can be used to light a LED on

reception of a good frame. Refer to the

DW1000 User Manual [1] for details of LED use.

[DW] GPIO0

GPIO_15

23

DIO

General purpose I/O pin.

[N] P0.15

GPIO_8

25

DIO

General purpose I/O pin.

[N] P0.08

SPIS_MISO

26

DI

Configured as a SPI slave this pin is the SPI

data output. Refer to Datasheet for more details

[1].

[N] P0.07

SPIS_MOSI

27

DO

Configured as a SPI slave this pin is the SPI

data input. Refer to Datasheet for more details

[1].

[N] P0.06

SPIS_CLK

28

DI

Configured as a SPI slave this pin is the SPI

clock. This is also the ADC function of the

nRF52

[N] P0.04

SPIS_CSn

29

DI

Configured as a SPI slave this pin is the SPI

chip select. This is an active low enable input.

The high-to-low transition on SPICSn signals the

start of a new SPI transaction. This is also the

ADC function of the nRF52

[N] P0.03

GPIO_3

30

DO

This pin is configured for use as a TXLED

driving pin that can be used to light a LED

during transmit mode. Refer to the DW1000

User Manual [2] for details of LED use.

[DW] GPIO3

GPIO_2

31

DO

This pin is configured for use as a RXLED

driving pin that can be used to light a LED

during receive mode. Refer to the DW1000

User Manual [2] for details of LED use.

[DW] GPIO2

BT_WAKE_UP

32

DI

When this pin is asserted to its active low state

the Bluetooth device will advertise its availability

for 20 seconds by broadcasting advertising

packets. This is also the ADC function of the

nRF52.

[N] P0.02

RESETn

33

DI

Reset pin. Active Low Input.

[N] P0.21

Power Supplies

VCC

12

P

External supply for the module. 2.8V - 3.6V

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 9

SIGNAL NAME

PI

N

I/O

(Default

)

DESCRIPTION

REFERENCE (Pin

designation)

Ground

GND

1,

11,

24,

34

G

Common ground.

Table 2: Explanation of Abbreviations

ABBREVIATION

EXPLANATION

DI

Digital Input

DIO

Digital Input / Output

DO

Digital Output

G

Ground

P

Power Supply

N

nRF52832

DW

DW1000

Note: Any signal with the suffix ‘n’ indicates an active low signal.

Table 3: Internal nRF52832 pins used and their function

nRF52832 Pin

Function

PO.19

DW_IRQ

PO.16

DW_SCK

PO.20

DW_MOSI

PO.18

DW_MISO

PO.17

DW_SPI_CS

PO.24

DW_RST

PO.25

ACC_IRQ

PO.29

I2C_SDA

PO.28

I2C_SCL

DW1000’s GPIOs 5,6 control the DW1000 SPI mode configuration. Within the DWM1001 module, those GPIOs

are unconnected and will be internally pulled down. Consequently, SPI will be set to mode 0. For more details,

please refer to DW1000 data sheet [2].

Table 4: I2C slave devices address I2C

I2C slave device

Address

LIS2DH12

0X19

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 10

4 ELECTRICAL SPECIFICATIONS

The following tables give detailed specifications for the DWM1001 module. Tamb = 25 ˚C for all specifications

given.

4.1 Nominal Operating Conditions

Table 5: DWM1001 Operating Conditions

Parameter

Min.

Typ.

Max.

Units

Condition/Note

Operating temperature

-40

+85

˚C

Supply voltage VCC

2.8

3.3

3.6

V

Normal operation

Voltage on VDDIO for programming OTP

3.7

3.8

3.9

V

Note that for programming the

OTP in the DWM1001 this

supply is connected to the

VDDIO test point which is

underneath the PCB. (See

Figure 6)

4.2 DC Characteristics

Table 6: DWM1001 DC Characteristics

Parameter

Min.

Typ.

Max.

Units

Condition/Note

Supply current in DEEP SLEEP mode

4

µA

All peripherals in lowest

power consumption mode

Achievable where RTC and

accelerometer are disabled

with custom firmware.

Supply current in DEEP SLEEP mode

12

µA

RTC and accelerometer

operational, all other

peripherals in lowest power

consumption mode*

Supply current in IDLE mode

13

mA

MCU and DW1000 awake

TX peak current

111

mA

TX mean current

82

mA

RX peak current

154

mA

RX mean current

134

mA

Current in Bluetooth® discovery mode

6

mA

Digital input voltage high

0.7 x VCC

VCC

V

Digital input voltage low

GND

0.3 x VCC

V

Digital output voltage high

0.7 x VCC

VCC

V

Digital output voltage low

GND

0.3 x VCC

V

* Using a ranging update rate of 1 Hz

4.3 Receiver AC Characteristics

Table 7: DWM1001 Receiver AC Characteristics

Parameter

Min.

Typ.

Max.

Units

Condition/Note

Frequency range

6240

6739.2

MHz

Centre Frequency 6489.6 MHz

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 11

4.4 Receiver Sensitivity Characteristics

Tamb = 25 ˚C, 20 byte payload. These sensitivity figures assume an antenna gain of 0 dBi and should be modified

by the antenna characteristics, depending on the orientation of the DWM1001.

Table 8: DWM1001 Typical Receiver Sensitivity Characteristics

Packet

Error

Rate

Data Rate

Receiver

Sensitivity

Units

Condition/Note

1%

6.8 Mbps

-98*(-92)

dBm/500 MHz

Preamble 128

Carrier

frequency

offset

±10 ppm

All measurements

performed on

Channel 5, PRF 64

MHz

10%

6.8 Mbps

-99*(-93)

dBm/500 MHz

Preamble 128

*equivalent sensitivity with Smart TX Power enabled. This is enabled in the onboard firmware.

4.5 Transmitter AC Characteristics

Table 9: DWM1001 Transmitter AC Characteristics

Parameter

Min.

Typ.

Max.

Units

Condition/Note

Frequency range

6240

6739.2

MHz

Output power spectral density

-41.3*

dBm/MHz

See DW1000 Datasheet [1]

Output Channel Power

-17

dBm/500MHz

Output power variation with

temperature*

-1

+1

dB

Using on board

compensation.

* If using the pre-loaded embedded firmware of the DWM1001 module, otherwise see the DW1000 datasheet

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 12

4.5.1 Absolute Maximum Ratings

Table 10: DWM1001 Absolute Maximum Ratings

Parameter

Min.

Max.

Units

Supply voltage

2.8

3.9

V

Receiver power

0

dBm

Temperature - Storage temperature

-40

+85

˚C

Temperature –Operating temperature

-40

+85

˚C

ESD (Human Body Model)

2000

V

DWM1001 pins other than VCC, VDDIO and GND

3.6

Note that 3.6 V is

the max voltage

that may be

applied to these

pins

Stresses beyond those listed in this table may cause permanent damage to the device. This is a stress rating

only; functional operation of the device at these or any other conditions beyond those indicated in the operating

conditions of the specification is not implied. Exposure to the absolute maximum rating conditions for extended

periods may affect device reliability.

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 13

5 TRANSMIT AND RECEIVE POWER CONSUMPTION

The following Figures give power profiles for the DWM1001 on a DWM1001-DEV PCB when used for Two Way

Ranging, see Figure 2. Peak values are given.

Figure 2 shows an example of the power consumption of a DWM1001 tag running the factory loaded firmware.

The tag is in low-power mode, and two-way ranging with 3 anchors. The deep-sleep current occurs while the tag

is sleeping with only the RTC and accelerometer active.

Once awake, the tag transmits at its allocated time in the TDMA-slotting, and awaits the anchors responses. This

can be observed as 1 transmission followed by 3 receives, repeated once. After this is completed, the tag spends

some time computing its location, before returning to sleep. The total time awake is dependent on the number of

anchors within range of the tag. For more details on the system operation, see the DWM1001 System Overview

document[9].

Figure 2: power consumption during Two Way Ranging

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 14

6 ANTENNA PERFORMANCE

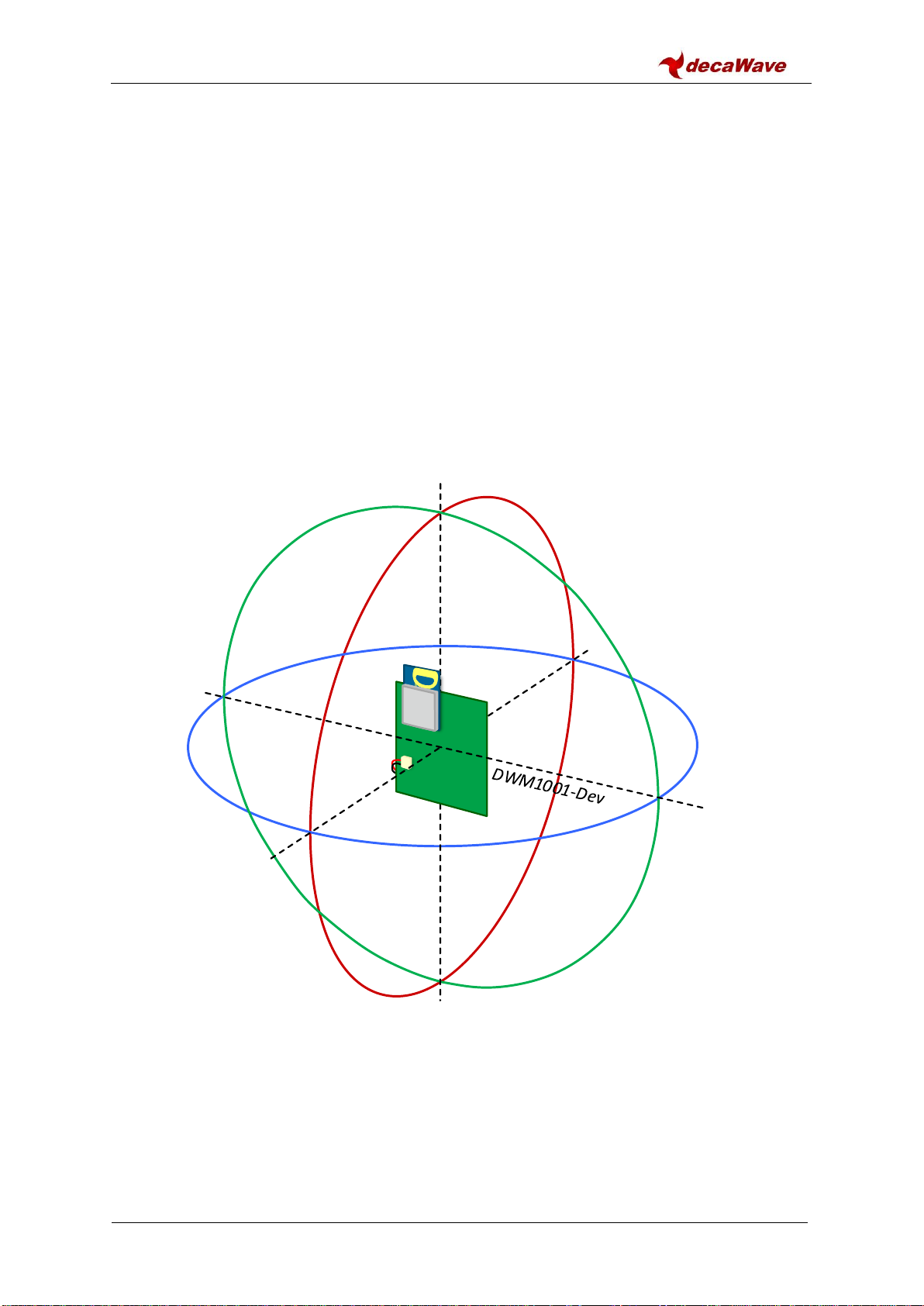

This section details antenna radiation patterns for the DWM1001-Dev board. Figure 3 presents a view of the

measurement planes considered in this document.

Table 11 shows antenna radiation patterns for the DWM1001 module mounted on the DWM1001-Dev board.

Three planes in the spherical space about the centre of the board are measured, with theta and phi plots

representing perpendicular polarisations.

The DWM1001 antenna is vertically polarised, meaning that the module is intended to be positioned vertically

upright when used in an RTLS system. An omnidirectional radiation pattern is seen in the XZ plane when

observed by another antenna which is also vertically polarised. This is shown in the XZ plane antenna patterns,

where the vertically polarised plot, phi, has a circular, or omnidirectional shape.

If the antennas are oriented perpendicular relative to each other, then the polarisation changes. In this case, the

horizontally polarised pattern, theta, applies and there are nulls at certain angles which can limit range and

introduce location inaccuracy.

Figure 3. Antenna Radiation Pattern Planes

x

z

y

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 15

-30

-25

-20

-15

-10

-5

0

5

0816 24 32

40

48

56

64

72

80

88

96

104

112

120

128

136

144

152

160

168

176184

192

200

208

216

224

232

240

248

256

264

272

280

288

296

304

312

320

328 336 344 352

Table 11. Antenna Radiation Patterns

Planes:

Antenna Gain (dBi) vs. Angle (°)

-30

-25

-20

-15

-10

-5

0

5

0816 24 32

40

48

56

64

72

80

88

96

104

112

120

128

136

144

152

160

168

176184

192

200

208

216

224

232

240

248

256

264

272

280

288

296

304

312

320

328 336 344 352

0°

90°

270°

180°

Theta

Phi

XZ Plane:

XY Plane:

YZ Plane:

180°

0°

90°

270°

Theta

Phi

270°

180°

0°

90°

Theta

Phi

-30

-25

-20

-15

-10

-5

0

5

0816 24 32

40

48

56

64

72

80

88

96

104

112

120

128

136

144

152

160

168

176184

192

200

208

216

224

232

240

248

256

264

272

280

288

296

304

312

320

328 336 344 352

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 16

7 APPLICATION INFORMATION

7.1 Application Board Layout Guidelines

When designing the PCB onto which the DWM1001 will be soldered, the proximity of the DWM1001 on-board

antenna to metal and other non-RF transparent materials needs to considered carefully. Two suggested

placement schemes are shown below.

For best RF performance, ground copper should be flooded in all areas of the application board, except

in the areas marked “Keep-Out Area”, where there should be no metal either side, above or below (e.g.

do not place battery under antenna).

The two placement schemes in Figure 4 show an application board with no metallic material in the keep-out

area. The diagram on the right is an application board with the antenna projecting off of the board so that the

keep out area is in free-space. The diagram on the left shows an application board which does not have the

module in free space but has the pcb copper removed on either side (and behind) the module antenna.

(Note: the rectangular area above the shield on the module is the antenna area)

It is also important to note that the ground plane on the application board affects the DWM1001 antenna radiation

pattern. There must be a minimum spacing of 10 mm (d) without metal either side of the module antenna.

Application Board

dd

Application Board

d d

Keep-Out

Area Keep-Out

Area

Figure 4: DWM1001 Application Board Keep-Out Areas

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 17

8 PACKAGE INFORMATION

8.1 Module Drawings

All measurements are given in millimetres.

Figure 5: Module Package Size (units: mm)

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 18

8.2 Module Land Pattern

The diagram below shows the DWM1001 module land pattern.

Figure 6: DWM1001 Module Land Pattern (units: mm)

8.3 Module Marking Information

Each module has a label on the shield with a serial number in the following format:

YY WW 0 SSSSS

Where:

YY indicates the year

WW indicates the week of the year

0 indicates the DWM1001 module

SSSSS indicates the module manufacturing number

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 19

8.4 Module Solder Profile

Figure 7: DWM1001 Module Solder Profile

DWM1001 Datasheet

© Decawave Ltd 2017

Subject to change without notice

Version 1.10

Page 20

9 ORDERING INFORMATION

9.1 Tape and Reel Information

Figure 8: DWM1001 Tape and Reel Dimensions

Table of contents

Popular Control Unit manuals by other brands

Datex-Ohmeda

Datex-Ohmeda B-CPU5 Technical reference manual

Ring Engineering

Ring Engineering AM-1b user manual

FedEx

FedEx SenseAware M4 user guide

Anritsu

Anritsu MT1000A Network Master Pro Operation manual

Texas Instruments

Texas Instruments DS160PR412-421EVM user guide

Opentrons

Opentrons GEN1 instruction manual

weed instrument

weed instrument EOTec 2000 installation instructions

DeZurik

DeZurik APCO CVS-250 instruction manual

Siemens

Siemens SIMOTION Function manual

SolarEdge

SolarEdge ZigBee Plug-in installation guide

Bardiani Valvole

Bardiani Valvole MIXPROOF B915PMO Instruction, use and maintenance manual

Controls

Controls XCAN-AC product manual