Dectron LH Series User manual

DEHUMIDIFIERS

LH SERIES

Dectron.com

OPERATION AND MAINTENANCE MANUAL

Dectron LH Series OMM 2April 2022

Contents

General Information .....................................................................................................................................4

Operating Safety (Warnings, Cautions, and Notes)..................................................................................... 4

Reference and Additional Information........................................................................................................ 5

Contact Us.................................................................................................................................................... 5

Basic Information..........................................................................................................................................6

Dehumidifier View and Options................................................................................................................... 7

Dehumidifier External Systems Connection ................................................................................................ 8

Dehumidifier Optional Arrangement........................................................................................................... 9

Air Conditioning Options –Outdoor Air Fluid Coolers (OAFC).................................................................. 10

Equipment Specific Data............................................................................................................................ 12

Layout and Components.............................................................................................................................13

Dehumidifier Main Components ............................................................................................................... 13

Layout and Components (continued)........................................................................................................ 15

Control System............................................................................................................................................16

Outdoor Air Fluid Coolers Layout and Components...................................................................................17

Sequence of Operation ...............................................................................................................................18

Set Points.................................................................................................................................................... 18

Ventilation.................................................................................................................................................. 18

Cooling........................................................................................................................................................ 18

Cooling with Outside Air .....................................................................................................................18

Cooling with Evaporator coil...............................................................................................................18

Cooling with Chilled water coil ...........................................................................................................19

Dehumidification........................................................................................................................................ 19

Dehumidification with Outside Air .....................................................................................................19

Dehumidification with Evaporator coil ...............................................................................................19

Purge Mode................................................................................................................................................ 19

Heat Recovery............................................................................................................................................ 19

Space Heating............................................................................................................................................. 20

Compressor(s) If applicable. ...................................................................................................................... 21

Compressor Circuit Operation ................................................................................................................... 21

Outdoor Fluid Cooler Operation................................................................................................................ 22

Interface and Communication ....................................................................................................................23

April 2022 3Dectron LH Series OMM

Touch Display Operator Panel ................................................................................................................... 23

Alarms .................................................................................................................................................24

Remote Communication............................................................................................................................ 25

WebSentry...........................................................................................................................................25

BMS (Building Management System) ........................................................................................................ 25

Basic Maintenance......................................................................................................................................26

Maintenance and Safety ............................................................................................................................ 26

Maintenance Key Points ............................................................................................................................ 26

Routine Maintenance Program ................................................................................................................. 27

Specific Components Maintenance........................................................................................................... 28

Special Maintenance Tasks. Fluid Cooler Winterization. ........................................................................... 28

Pools –Equipment Warranty......................................................................................................................30

Dectron LH Series OMM 4April 2022

General Information

This manual provides basic information about the applicable Dectron dehumidifier and its operation.

Important information regarding installation, maintenance, and start up as well as additional and auxiliary systems

and devices (outdoor condenser, communication interfaces, etc.) is normally provided with the dehumidifier and

can also be obtained from the manufacturer (see Contact Us below).

Operating Safety (Warnings, Cautions, and Notes)

FOR YOUR SAFETY: READ BEFORE PERFORMING ANY OPERATIONS, MAINTENANCE OR SERVICE TASKS!

Only qualified technicians should install, operate, maintain or service mechanical equipment

including current dehumidification system.

Make sure to read this manual before performing any tasks to familiarize yourself with the

equipment as well as with any potential hazards. Always exercise caution!

Beware of electrical power and high electrical voltage!

•Follow proper safety procedures –lockout, tagout, and other respective procedures

•Failure to follow safety procedures can result in serious injury or death

Beware of moving parts and hot surfaces!

•Make sure to stop all moving parts (fans, blowers, etc.) before accessing the equipment’s

internal space

•Be aware of hot surfaces (hot refrigeration, space heating pipes, coils, heaters, etc.)

Beware of high pressures and chemicals!

•Dehumidifiers, equipped with compressors, contain refrigerant under high pressure; oil is

also contained in the compressor and refrigeration circuit(s)

•Some dehumidifiers may also contain other liquids such as glycol mixtures

The following warnings, cautions, and notes appear throughout this manual and referenced documentation

whenever special care must be taken to avoid potential hazards that could result in equipment malfunction or

damage, personal injury, or death.

WARNING

Indicates a potentially hazardous

situation which could result in

serious injury or death if handled

improperly.

CAUTION

Indicates a potentially hazardous

situation which could result in

moderate injury or equipment

damage if handled improperly.

Note

Indicates a situation that could

result in equipment damage or

improper/ineffective operation if

handled improperly.

April 2022 5Dectron LH Series OMM

Reference and Additional Information

For safe, efficient and problem-free operation, it is critical to handle the dehumidifier (as well as related systems

and components) properly at each step - from receiving and storage to installation and start up. Relevant

information can be found in the respective documents (like Installation Manual) provided with the dehumidifier.

This manual and other related documents could be obtained from the manufacturer (see Contact Us below).

Contact Us

Dectron

5685 Rue Cypihot,

Saint-Laurent, QC

H4S 1R3

Dectron.com

1-833-DAS-POOL (327-7665)

Schedule / Modify a Start-up:

Startups@DehumidifiedAirServices.com

Inquire about Warranty:

Warrant[email protected]

Order Parts:

Parts@DehumidifiedAirServices.com

All Other Product Support:

Start-up Requests: Start-ups@dehumidifiedairservices.com

Miscellaneous Inquiries: Support@dehumidifiedairservices.com

Parts Requests: Parts@dehumidifiedairservices.com

Warranty: Warranty@dehumidifiedairservices.com

Attention: Installation and Service Contractors

WARNING! Any work (installation, start up, service, maintenance, repair, etc.) on any mechanical

equipment (dehumidifier, outdoor condenser, fluid cooler, etc.) must be performed in accordance with

respective manufacturer’s recommendations as well as submittal documentation, local Codes and Regulations,

and appropriate field practices. Failure to do so could result in personal injury, equipment damage or

malfunction, and will void equipment warranty. Only qualified and properly trained individuals should perform

tasks on this equipment.

Attention: Maintenance Team

CAUTION. To ensure equipment longevity and proper and efficient operation, the dehumidifier and its

auxiliary systems and devices (outdoor condenser, fluid cooler, etc.) should be maintained properly and regularly.

Failure to do so could negatively affect natatorium comfort levels and people’s health. It could also lead to

equipment damage, malfunction, premature tear and ware and may void equipment warranty.

Dectron LH Series OMM 6April 2022

Basic Information

Pic. C.1

April 2022 7Dectron LH Series OMM

Dehumidifier View and Options

Standard NH series dehumidifiers are semi-custom: while basic concept and layout is the same, options and

specific systems and components layout and location may vary from one dehumidifier to another. One of the

typical dehumidifier arrangement is shown on Pic.C.1.

Dehumidifier Options

•Indoor or outdoor installation.

oNote: Pic. C.1. shows outdoor model, equipped with louvers (to protect air intake and discharge

openings from elements). Indoor model would have ducts connected to respective openings, no

louvers would be needed.

•Refrigeration Capacity (compressorless ’00’ model or cooling capacity in tons) –zero to three compressors

(see Dehumidifier Optional Arrangement below for more details):

oZero-compressor dehumidifier option (6,000 to 64,000 CFM Supply cabinet, models NH000).

oTwo-compressor dehumidifier option (18 to 80 tons, models NH018 to NH080).

oThree-compressor dehumidifier option (90 to 120 tons, models NH090 to NH120).

•Airflow/ductwork connection *. Pic. C.1 shows some options only; each option location availability depends on

the dehumidifier installation (indoor or outdoor) and other options:

oReturn Air (RA) ductwork connection - top, bottom, end, sides.

oSupply Air (SA) ductwork connection –top, bottom, sides.

oOA1ductwork connection/termination –top, sides.

oEA1 and optional EA2 ductwork connections/terminations –end, sides.

oOptional OA2 ductwork connection/termination - top, sides.

•Optional Space Heating - hot water coil, electric or gas heater **.

•Heat Recovery (HR) circuit.

•Air Conditioning (AC)* –compressorless can have a chilled water coil option; cooling refrigeration has external

water cooling or fluid cooler (packaged or separate) options.

oNote: Pic. C.1 shows outdoor model without a packaged fluid cooler.

o“Packaged’ AC option is available for outdoor models only; alternatively, indoor and outdoor models

could be fitted for separate/remote AC option –remote fluid cooler or other external cooling media

source.

* Some available options (tonnage, ductwork connections, AC options etc.) are shown. Refer to the submittal

and other relevant documentation for your dehumidifier’s options.

** For specific details on space heating (hot water, gas, electric) option, refer to the submittal and other

documentation:

Attention! Equipment Clearances and Dimensions!

CAUTION! For equipment proper operation, maintenance and service, respective clearances should be

maintained. Generally, 30” clearances to the equipment must be kept for the maintenance and service purposes.

For the specific required clearances information, as well as dehumidifier overall dimensions, distances to pipe

connections, duct connections etc., refer to the submittal documentation.

Dectron LH Series OMM 8April 2022

Dehumidifier External Systems Connection

Pic. C.1 shows provisions for external systems connections, including ductwork, electric power and various piping

connections.

✓Except for the condensate, all other piping systems are optional and may not be present in each

dehumidifier

•Condensate Drain Line –bottom, side (through the dehumidifier base).

•Air Conditioning (AC) Connection.

oChilled water coil option –bottom, side.

oPackaged AC option (outdoor dehumidifier with outdoor fluid cooler (OAFC) incorporated with the

dehumidifier), does not require piping connection to external AC system or device.

▪Packaged outdoor models typically have the OAFC mounted at the end of the dehumidifier;

alternatively, if requested, OAFC could be mounted on the roof of the dehumidifier.

oRemote (“split”) AC option (indoor or outdoor dehumidifier, connected to external cooled

water/glycol system or remote fluid cooler) –side or end (through the compressor compartment

wall) connection.

•Space heating (Hot Water connection) –bottom, side.

•Space Heating (Gas Heater connection, gas line).

•Electric Power and Control Connection. Typically the power lines are to be brought directly to the main

electric panel. However, if applicable the electric power could be brought to the dehumidifier disconnect,

which is normally incorporated with main electric panel.

WARNING! Gas Line. The gas line must be installed in accordance with respective device documentation

(boiler, furnace, etc.) and local codes and regulations.

CAUTION! Current manual shows general/default connections’ location. For details regarding specific

dehumidifier’s connections (actual location, piping sizes and position dimensions, circuit type and flow direction

etc.), refer to the dehumidifier’s submittal documentation as well as dehumidifier’s labels and stickers.

NOTE. Dehumidifier MUST be equipped with a P-trap at the condensate connection for proper operation! If

dehumidifier is requested from the factory without P-trap, one MUST be installed on site prior to dehumidifier

being commissioned. Refer to the Installation Manual for details.

April 2022 9Dectron LH Series OMM

Dehumidifier Optional Arrangement

Multi-Compressor Arrangement and Compressor Compartment Layout

NH series dehumidifier, depending on required capacity, could have two or three compressors. Pic.C.2 shows

options of dehumidifier supply air (SA) end and compressor compartment arrangement, based on number of

compressors and overall tonnage of the unit.

The end compressor compartment location is used for all tonnages in the NH series.

2

2

2

1

1

3

1

1

1

1

Dectron LH Series OMM 10 April 2022

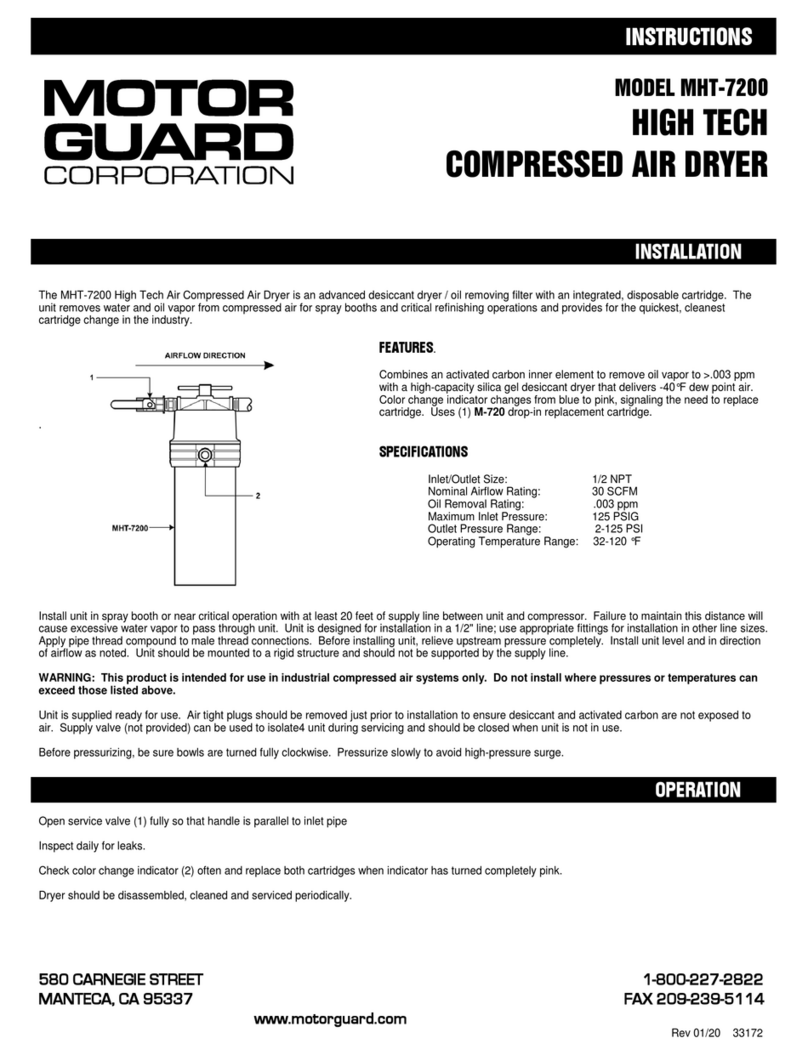

Air Conditioning Options –Outdoor Air Fluid Coolers (OAFC).

Basic views of standard air conditioning options are shown on Pic.C.4 (below); standard combinations of the

dehumidifier and respective fluid cooler (based on their capacities) are shown in Table C.1. Note, that depending

on number of factors, dehumidifier may have different cooler provided with it - refer to the dehumidifier’s

submittal documentation for more details.

Standard fluid coolers used with this model of dehumidifier is NG-V series, composed of number of “two-coils-two-

fans” blocks, based on required capacity of the cooler:

•Fluid Cooler NG-V-22 (Fig.1) composed of two such blocks etc. The largest single fluid cooler, NG-V-62

(Fig.3) composed of six such blocks.

Pic. C.2

2

1

1

1

April 2022 11 Dectron LH Series OMM

Attention! Equipment Clearances!

Proper clearances should be maintained for adequate airflow and heat rejection! Generally, up to 36” side and

96” top clearances are required. For more information on clearances as well as equipment dimensions and other

details, refer to the submittal documentation.

Pic. C.4

Dectron LH Series OMM 12 April 2022

Equipment Specific Data

Specific information for individual dehumidifiers is provided in the following methods:

Main Label (Pic. C.5):the manufacturer tag attached

to the front of the dehumidifier includes the

dehumidifier’s most critical data:

✓General data including:

oSerial number

oDehumidifier model (nomenclature)

oDesign room conditions (air

temperature and humidity)

✓Operational data, including:

oRefrigeration (refrigerant type, charge,

etc.)

oElectrical/airflow (dehumidifier

voltage, CFM, etc.)

oOther applicable data (space/auxiliary

heating features, etc.)

Labels and Stickers: attached when applicable to

the exterior and interior of the dehumidifier to

show:

✓External systems connections location/direction

(pool/space heating, cooling circuits,

condensate)

✓Air filter locations, quantity, and size.

✓Additional Info (warning, caution stickers, etc.)

Wiring Diagrams: attached to the interior side of the

dehumidifier, depict dehumidifier control and power

wiring.

Remotely installed condenser or cooler would have its specific information provided in similar manner (labels etc.).

Attention! Glycol Circuits.

Unless otherwise indicated, equipment fluid circuits (except for refrigeration) such as heat recovery loop,

compressor glycol loop, fluid cooler etc., are normally filled/to be filled with water/glycol mixture; normally, rust

inhibitor-infused food-grade propylene glycol is used.

Glycol mixture concentration is normally shown on Main Label –refer as needed.

Note: The main label shown above is just an example.

Pic. C.5

April 2022 13 Dectron LH Series OMM

Layout and Components

The general layout and components location is the same for all dehumidifiers of current type, however some may

vary, based on the dehumidifier’s specific options –refer to submittal documentation. Pic. D.1 below shows most

available options, some of which may not be present on your dehumidifier.

Dehumidifier Main Components

•Main Blower(s) (1) is a supply fan array located at the supply air end of the unit.

Number of blowers may vary based on airflow requirements. Supply fans are

mounted within the fan boxes, in the fan wall (see pic D.1A for illustration).

Allowing built-in redundancy, a failed fan can temporarily be blanked off to allow

continued operation of the unit. Spare blank-off panel is also found in the supply

section of the unit.

•Main Electric Panel (2) is located at the supply air end of the unit. Either in the

compressor vestibule section, if the unit has compressors, or at the supply end of

the unit, outside of the airstream in their own dedicated vestibule.

•Outdoor Air (OA1) Opening (4) has a motorized damper, HR coil(s) and filter(s).

OA1 is also fitted with a modulating actuator for automatic adjustment of outdoor air intake.

oOutdoor-installed dehumidifier would have a louver(s) installed at the OA opening.

oIndoor-installed dehumidifier would have a Filter Box(s) installed at the OA opening.

•Exhaust Fan Blowers (5) also use fan array which is located on the dehumidifier’s return air side. Exhaust Air

opening in outdoor-installed dehumidifier is equipped with louver(s). Number of blowers may vary based on

Pic. D.1A

Pic. D.1

1

7

3

2

5

6

4

9

8

Dectron LH Series OMM 14 April 2022

airflow requirements. Exhaust fans are mounted within the fan boxes in the fan wall (see pic D.1A for

illustration). Allowing built-in redundancy, a failed fan can temporarily be blanked off to allow continued

operation of the unit. Spare blank-off panel is also found in the return air section of the unit.

•Exhaust air opening(s) EA1 (6) are equipped with HR coils and dampers. All Hybrid units are equipped with HR

on the EA1 and OA1 openings, and HR pump, installed in the return air compartment.

•Motorized Return Air (RA) damper (8) would be located between return air side and OA2 opening(s).

oOutdoor- installed dehumidifier would have louvers installed at the EA2 opening and OA2 Air

openings.

•If dehumidifier is equipped with OA2 (Additional Airflow) option (due to Dehum OA CFM exceeding OA1 max),

OA2 equipped with motorized dampers, would be located directly upstream of filter wall.

•If equipped, Evaporator coils (7) & reheat coil (if applicable) are located directly downstream of the Main

Filter Rack (9).

oMotorized Evaporator Bypass Damper is located next to the evaporator coils; it by-passes portion of

air around evaporator, thus adjusting compressor circuit operation. Some dehumidifiers, based on

airflow requirement, could be equipped with additional manual by-pass damper also.

oEach compressor circuit has its own evaporator coil(s) set (one or two coils per circuit, depending on

capacity), while all reheat coils, generally, are manifolded together and serve both compressor

circuits together.

•If equipped, Cooling Chilled water coils are located directly downstream of the Main Filter Rack (9).

•Space heater location, if the dehumidifier is equipped with one, depending on the heater type: Hot water coil

or Electric heater is usually located directly downstream of the reheat coil; Gas heater (not shown) is usually

located downstream of the main blower(s).

April 2022 15 Dectron LH Series OMM

Layout and Components (continued)

*If dehumidifier is equipped with compressors: Compressor Compartment and Main Electric Panel (detailed; see

Pic.D.1C).

•Compressor(s) (13), Receiver(s) (14) and other components are located within the Compressor Compartment

(3):

oEach compressor circuit has glycol-to-refrigerant plate heat exchanger (16) and, common to both

circuits, glycol pump (16a), that circulates water/glycol to reject compressor-generated heat.

oMotorized water/glycol Reheat (79) and AC (80) valves’ opening position determines how much fluid

is diverted to respective coil(s) (reheat and fluid cooler or external heat sink).

oControl sub-panel with Main Control

Board (17) and Operator Panel (18) is

normally mounted on the compressor

stand frame.

•Main Electric Panel (2) contains main

blower(s) VFD (variable frequency drive)

(if applicable) (78), main Disconnect (77),

if one is installed, and other electrical and

control components (contactors, fuses,

control transformer etc.).

•Packaged Outdoor Fluid Cooler (19), if

dehumidifier is equipped with it, is

normally mounted at the end of the

dehumidifier supply air end (see Pic.

D.1D).

19

Pic. D.1D

79

13

14

18

17

77

78

16

16a

13

27

28

25, 26

80

Pic. D.1C

Dectron LH Series OMM 16 April 2022

Control System

The dehumidifier control system is composed of sensors, spread throughout the dehumidifier, Main Control

Board, Operator Panel and other electric components, located in the Main Electric Panel.

Temperature Sensors (Pic. D.2):

a) Temperature sensors (thermistors) are used to monitor

various temperatures (air, water, compressor, etc.);

b) Combo sensor is used to monitor air temperature and

humidity.

Compressor operation is monitored with pressure sensors (Pic. D.3):

c) Pressure Transducers (as main operational control and safety) and

d) Pressure Switches (fast-reacting backup safety).

Note. Sensors and safeties approximate location is shown on Pic. D.1B and

D.1C –refer as needed.

•RA Combo Sensor measures temperature and humidity of the pool room air (Return Air) entering the

dehumidifier. It is located at the return air ductwork connection to the dehumidifier.

•OA Combo Sensor measures temperature and humidity of the Outdoor air (OA1 & OA2 if applicable) entering

the dehumidifier; it’s located at the OA filter rack.

•OA Air Velocity Sensor, Measures incoming OA CFM located in the OA opening.

•ET (EvapT) Temperature Sensor measures the temperature of air leaving evaporator coil. It’s located directly

downstream of the evaporator coil(s) (one sensor per each compressor circuit).

•Chilled Water Coil Temperature Sensor measures the temperature of air leaving chilled water coil. It’s located

directly downstream of the chilled water coil.

•SA temperature sensor measures the temperature of the air leaving the dehumidifier (supplied to the

natatorium). It must be located downstream of the space heater:

oSA temperature sensor of dehumidifier, equipped with gas heater, would be composed of four

regular temperature sensors, installed in different points at supply duct connection, averaging

temperature reading.

•The compressor’s discharge line (high pressure side) is equipped with Temperature and Pressure sensors set -

Discharge Temperature Sensor, High Pressure Transducer and High Pressure Switch (27) - to protect the

compressor and control its operation. A similar function is performed by Suction Temperature Sensor, Low

Pressure Transducer and Low Pressure Switch (28) located at compressor’s suction line (low pressure side).

oSaid safeties/sensors are installed on each compressor.

•Pressure Transducers measure Exhaust CFM(eCFM) , the maximum exhaust CFM(mCFM) is based on the

quoted value. When the air velocity exceed what the HR Filter/coil can handle (~600 FPM) the EA2 damper will

begin to open. EA2 Damper modulates from 0-100%. These pressure tranducers ensure a negative pressure is

maintained within the natatorium.

•Having the mandatory Heat Recovery on EA1, it will also have Exhaust Air (EA) Temperature Sensor, installed

downstream of exhaust-side located heat recovery glycol coil.

b

a

c

d

Pic.D.3

Pic. D.2

April 2022 17 Dectron LH Series OMM

Main Electric Panel, apart from devices listed above (control board, OP, etc.) also contains Voltage Monitor; some

optional control sensors and devices such as an air pressure differential sensor, current sensor(s). It may also be

located in main electrical panel or in the dehumidifier in general.

Outdoor Air Fluid Coolers Layout and Components.

The general layout of AC options is shown on Pic.D.5 below with the outdoor fluid and NG-V-32 (Fig.2) has been

displayed as an example. While layout and main components are similar for all applicable AC options, there are

some deviations (number of fans, composition, etc.). Refer to AC Options Basic View (Basic Information chapter)

for additional information.

•Cooling (AC) coils (31) (where heat from glycol mixture is rejected to the ambient air) is mounted onto metal

frame, upstream (before) the fans (32), that pulls the air through the coils to absorb the heat.

oNormally, fluid cooler would have multiple coils and fans. Cooler NG-V-32 (Fig.2), comprised of six

coils, mounted on the angle to each other, and six fans, with two fans and two coils presenting a

single block. Depending on the capacity, cooler could be comprised of up to six such single blocks,

stacked side by side on the same frame and manifolded together.

•Cooler piping connections (33) are identified respectively (IN –OUT);

oPiping connection location may vary –refer to particular cooler labels, stickers, submittal and other

documentation.

•Electric power is brought to disconnect (35) which feeds it to the electrical box (36), that contains cooler

power and control apparatuses.

oDepending on fluid cooler specifics, location of electrical box may slightly differ.

Pic. D.5

32

35

33

36

31

Dectron LH Series OMM 18 April 2022

Sequence of Operation

The dehumidifier’s ventilation system achieves the pre-set airflow through the dehumidifier. The control system

compares air temperature and humidity to their desired values (set points) and proceeds to dehumidify, cool or

heat the recirculating air. Outdoor air is used preferentially to dehumidify or cool the natatorium over all other

options providing the OA conditions are acceptable.

Set Points

The control system is constantly adjusting unit operation to achieve and maintain pre-defined parameters within

couple degrees/percent of the set point. Refer to the dehumidifier’s main label for the design value of control

parameters, as well as the following note.

Ventilation

The main blowers run continuously, establishing required CFM. The main blowers speed is pre-set via adjustable

variable signal.

Exhaust Air Fan Banks direct a portion of the return air outdoors, through a HR coil & dampered opening EA1, and

in higher EA CFMs through the motorized damper EA2. Like the main blowers, exhaust fan(s) speed is also

controlled via adjustable (pre-set) variable signal, that varies based on scheduled ventilation mode (Occupied,

Non-Occupied and Spectator). Exhaust fan speed is adjusted to ensure a constant pre-set CFM differential

between OA & Exhaust Air, this maintains the negative pressure in the natatorium.

OA1 damper, opens to introduce fresh outdoor air into the natatorium. OA1 damper is equipped with modulating-

controlled actuator(s).

Cooling

When natatorium air temperature goes over (exceeds) its set point, the dehumidifier control system issues a call

for cooling Mode.

Cooling with Outside Air

Sensors responsible for measuring OA1 & OA2 (if applicable), RH and Temperature, feedback the relevant values to

the controller. If outdoor air conditions are suitable, it is used preferentially to cool the natatorium over all other

options. More OA is brought in if space temperature is not reaching the dead band within the pre-defined setting.

The control system does so by increasing exhaust fan(s) speed, with the return air damper being controlled inverse

proportionally to the OA dampers.

Cooling with Evaporator coil

If the cooling requirements of the space cannot be satisfied by just the OA, or the OA conditions are unsuitable,

and the unit is equipped with compressors, the compressors start to operate enabling the evap coil (in conjunction

with OA) to cool space.

Note: To ensure the dehumidifier’s most economical operation, we recommend maintaining the following

relationship between pool water and room air temperatures:

Room Air T = Pool Water T + 2˚F

April 2022 19 Dectron LH Series OMM

Cooling with Chilled water coil

If the cooling requirements of the space cannot be satisfied by just the OA, or the OA conditions are unsuitable,

and the unit is equipped with chilled water coils, the valves supplying chilled water to the coils will open and

modulate to cool until set points are achieved.

Dehumidification

Respectively, when natatorium air humidity goes over (exceeds) its set point, the dehumidifier control system

issues a call for Dehumidification Mode. To execute Dehumidification mode, control system, depending on current

conditions, would resort to available means of dehumidification.

Dehumidification with Outside Air

Sensors responsible for measuring OA1 & OA2 (if applicable) CFM, RH and Temperature, feedback the relevant

values to the controller. If outdoor air conditions are suitable, it is used preferentially to dehumidify the

natatorium over all other options. More OA is brought in if relative humidity is not reaching the dead band within

the pre-defined setting. The control system does so by increasing exhaust fan(s) speed, with the return air damper

being controlled inverse proportionally to the OA dampers.

Dehumidification with Evaporator coil

If the dehumidification requirements of the space cannot be satisfied by just the OA (OA conditions being

unsuitable), the compressors start to operate enabling the evap coil (in conjunction with OA) to dehumidify space.

Purge Mode

Along with EA1 and OA1 damper, dehumidifier could have additional EA dampers and OA dampers (EA2 and OA2

respectively). EA2 and OA2 damper(s) function is to allow for higher exhaust and fresh air influx.

EA2 and OA2 damper(s) are controlled in the same fashion as EA1 and OA1, and open when the Exhaust CFM

requirement surpasses the upper limit for EA1. Dehumidifiers are equipped with additional Return Air damper: it

closes fully in event of complete air changeover, separating return air side of dehumidifier from supply side (refer

to Layout and Components chapter, as needed, for respective devices’ location).

Purge Mode, triggered manually, ramps up all exhaust fans and OA dampers to their max capacities, until the pre-

set time expires or supply air gets too cold. In this mode only fresh air from outdoors is being taken in and air from

inside the room is being expelled.

Heat Recovery

Hybrid units, by default have a Heat Recovery (HR) closed-loop glycol system, between the EA1 and OA1

dampered openings. Some dehumidifiers may have HR coils on OA2 and EA2 as well, if applicable.

Heat Recovery loop (see Pic. E.1 below) typically consists of two coil banks (air-to-glycol heat exchangers) and a

pump, establishing glycol circulation between them. One coil bank, installed at exhaust air opening, recovers

portion of exhausted air energy, another coil bank, installed at outdoor air intake, transfers this captured energy to

entering outdoor air.

Table of contents

Other Dectron Dehumidifier manuals