2.14

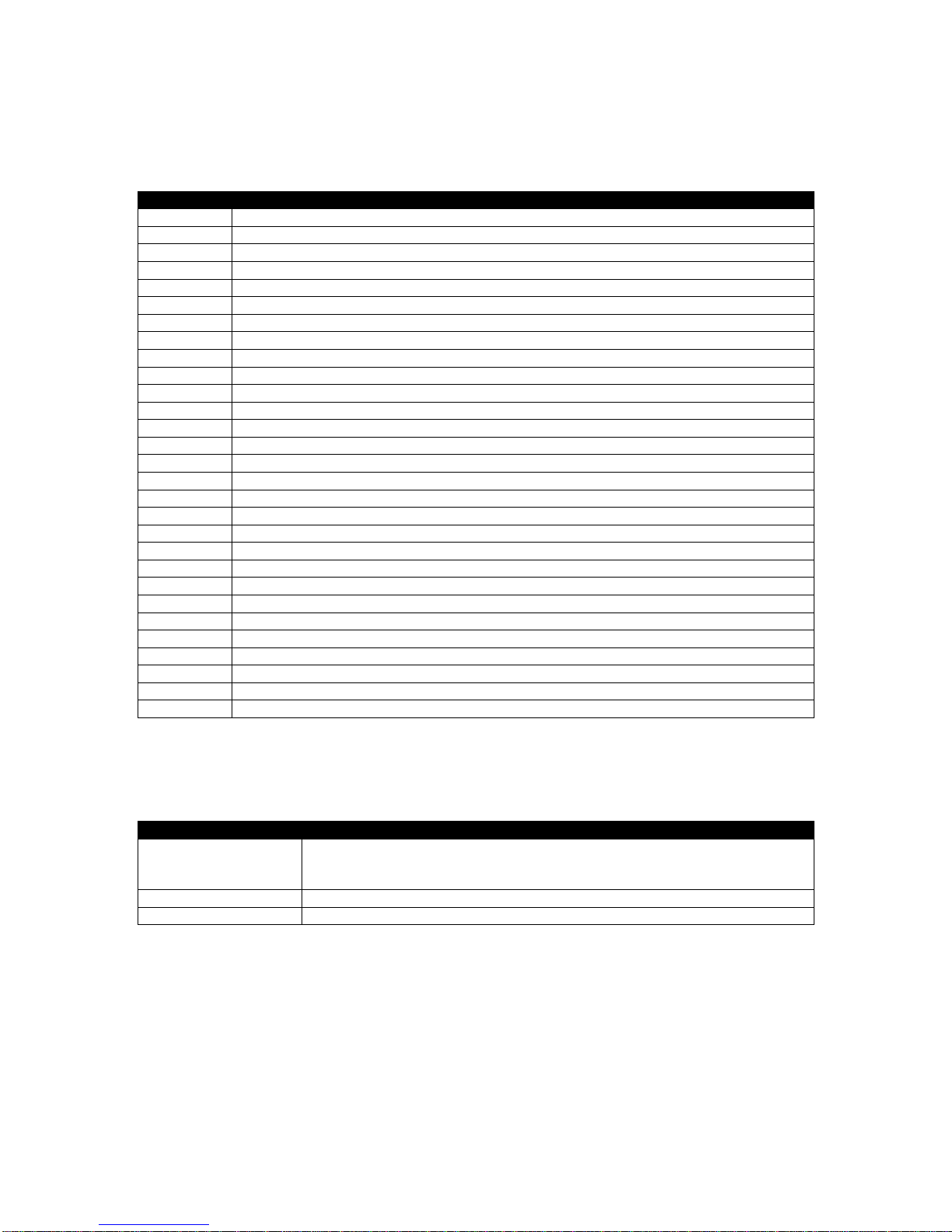

APPLICABLE STANDARDS......................................................................................... 36

2.14.1

ENCLOSURE CLASSIFICATIONS............................................................................. 38

2.14.1.1

IP CLASSIFICATIONS......................................................................................... 38

2.14.1.2

NEMA CLASSIFICATIONS.................................................................................. 38

3

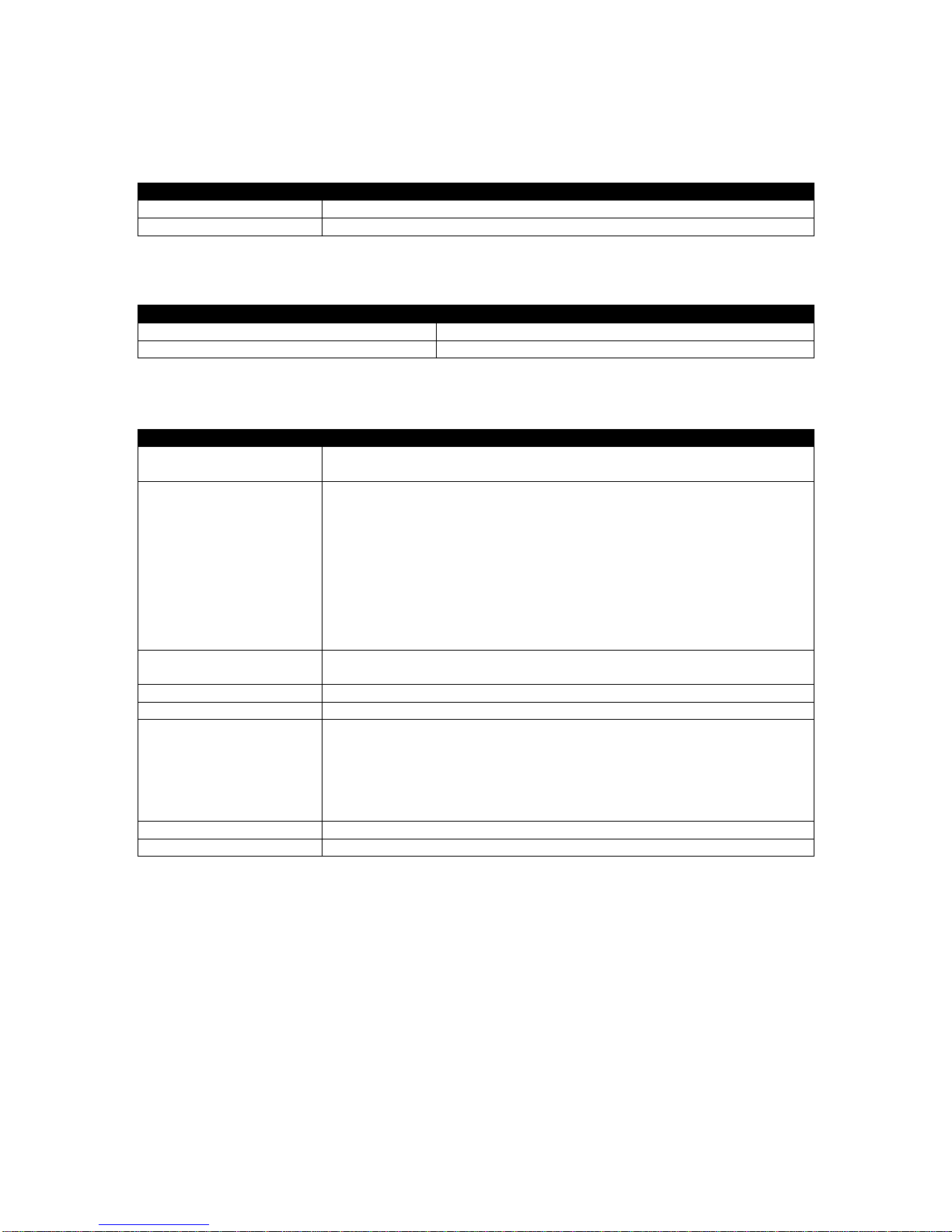

INSTALLATION.................................................................................................39

3.1

USER CONNECTIONS..................................................................................................... 39

3.2

CONNECTION DESCRIPTIONS....................................................................................... 40

3.2.1

DC SUPPLY & DC OUTPUTS.................................................................................... 40

3.2.2

MSC & DSENET

®

....................................................................................................... 41

3.2.3

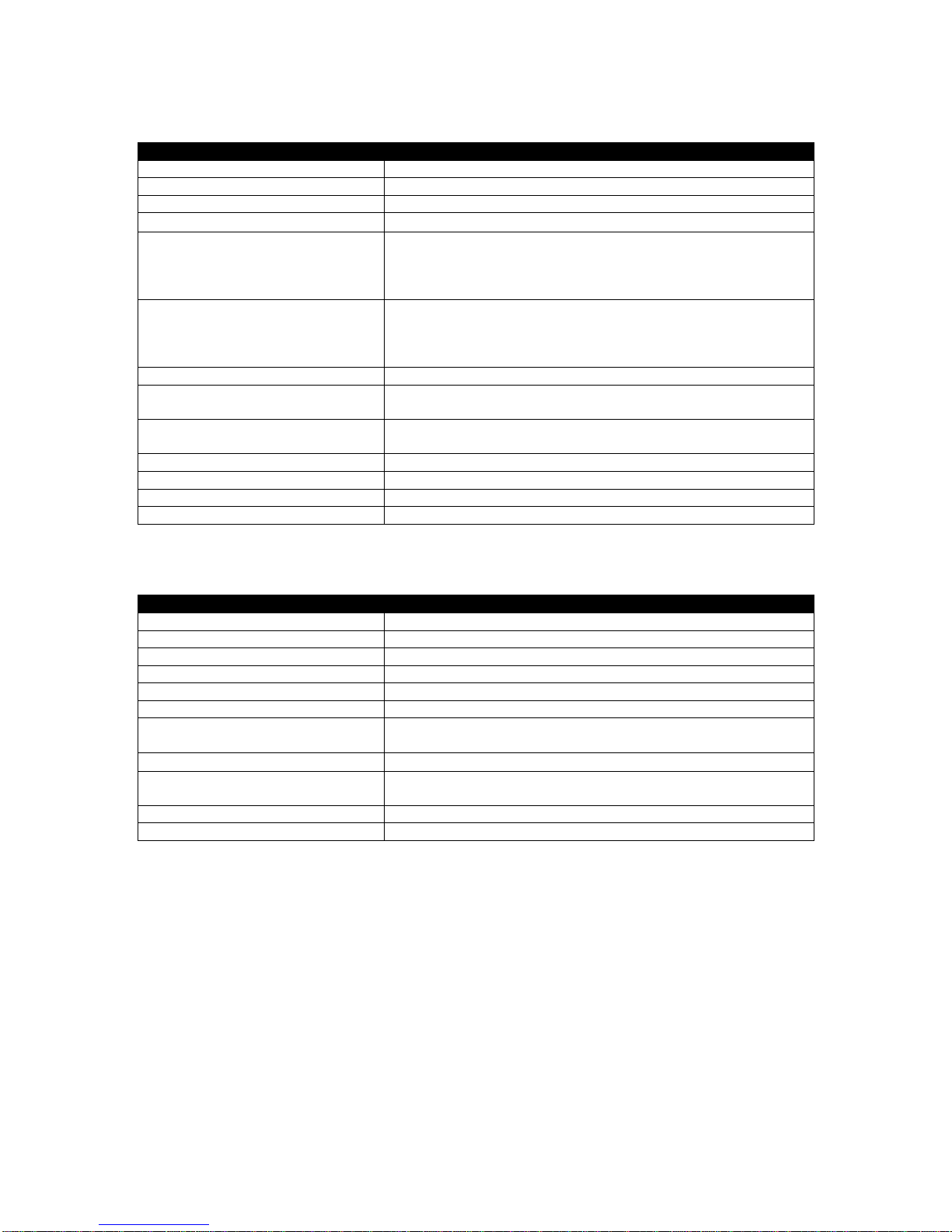

OUTPUT C & D & V1 (MAINS) VOLTAGE & FREQUENCY SENSING ....................... 42

3.2.4

V2 (BUS) VOLTAGE & FREQUENCY SENSING........................................................ 42

3.2.5

MAINS CURRENT TRANSFORMERS........................................................................ 43

3.2.6

BUS/LOAD CURRENT TRANSFORMER................................................................... 44

3.2.6.1

ADVANTAGES OF BUS/LOAD CT...................................................................... 44

3.2.7

DIGITAL INPUTS ....................................................................................................... 45

3.2.8

RS485........................................................................................................................ 46

3.2.9

RS232........................................................................................................................ 47

3.2.10

USB SLAVE (PC CONFIGURATION) CONNECTOR.................................................. 48

3.2.11

USB HOST (DATA LOGGING) CONNECTOR............................................................ 48

3.3

TYPICAL WIRING DIAGRAM (3 PHASE, 4 WIRE STAR)................................................. 49

3.4

ALTERNATE TOPOLOGY WIRING DIAGRAMS.............................................................. 50

3.4.1

3 PHASE 3 WIRE DELTA........................................................................................... 50

3.4.2

SINGLE PHASE (L1 & N) 2 WIRE .............................................................................. 51

3.4.3

SINGLE PHASE (L1 & L2) 3 WIRE............................................................................. 52

3.4.4

SINGLE PHASE (L1 & L3) 3 WIRE............................................................................. 52

3.4.5

2 PHASE (L1 & L2) 3 WIRE........................................................................................ 53

3.4.6

2 PHASE (L1 & L3) 3 WIRE........................................................................................ 53

3.4.7

BUS AND LOAD CURRENT TRANSFORMER POSITION ......................................... 54

3.4.7.1

3 PHASE, 4 WIRE WITH A BUS CURRENT TRANSFORMER............................ 54

3.4.7.2

3 PHASE, 4 WIRE WITH A LOAD CURRENT TRANSFORMER.......................... 55

3.5

TYPICAL ARRANGEMENT OF DSENET

®

........................................................................ 56

3.6

TYPICAL ARRANGEMENT OF MSC LINK....................................................................... 57

3.7

TYPICAL SINGLE LINE APPLICATION DRAWINGS....................................................... 58

3.7.1

MULTI GENERATORS FOR PRIME POWER............................................................. 58

3.7.2

MULTI GENERATORS FOR PRIME POWER WITH BUS COUPLERS ...................... 59

3.7.3

MULTI GENERATORS WITH SINGLE SYNCHRONISING TRANSFER SWITCH....... 60

3.7.4

MULTI GENERATORS WITH TWO SYNCHRONISING TRANSFER SWITCHES....... 61

3.7.5

MULTI GENERATORS & SYNCHRONISING TRANSFER SWITCHES ...................... 62

3.7.6

MULTI GENERATORS & TRANSFER SWITCHES WITH BUS COUPLER................. 63

3.7.7

SINGLE GENERATOR EXPORTING (BASE LOADING) POWER.............................. 64

3.7.8

MULTI GENERATORS EXPORTING (BASE LOADING) POWER.............................. 65

3.7.9

EARTH SYSTEMS..................................................................................................... 66

3.7.9.1

NEGATIVE EARTH ............................................................................................. 66

3.7.9.2

POSITIVE EARTH............................................................................................... 66

3.7.9.3

FLOATING EARTH.............................................................................................. 66

4

DESCRIPTION OF CONTROLS........................................................................67

4.1

CONTROL PUSH BUTTONS............................................................................................ 68

4.2

VIEWING THE INSTRUMENT PAGES.............................................................................. 72

4.2.1

STATUS..................................................................................................................... 73

4.2.1.1

ELECTRICAL TRIP ............................................................................................. 73

4.2.2

MAINS........................................................................................................................ 74

4.2.2.2

SYNCHROSCOPE OPERATION......................................................................... 75

4.2.3

BUS ........................................................................................................................... 76

4.2.3.1

COMMISSIONING SCREENS............................................................................. 77

4.2.4

EXPANSION.............................................................................................................. 78

4.2.5

ALARMS.................................................................................................................... 79

4.2.6

EVENT LOG............................................................................................................... 80

4.2.7

SERIAL PORT............................................................................................................ 81

4.2.7.1

RS232 SERIAL PORT......................................................................................... 81