Wide-i SeaCam®

Operator’s Manual

5

3. Plug the BNC connector on the topside of the

cable into the monitor or VCR video-in jack (a

BNC-to-RCA adapter may be required by the

monitor/VCR in use).

4. Lubricate the camera bulkhead connector with

an appropriate silicone lubricant (spray type

recommended), and using a linear motion plug

the female inline connector into the male bulkhead

connector on the back of the camera.

5. Screw the locking sleeves together firmly (hand

tight-do not use tools). The camera is now ready

for operation; switch the power supply ON to power

the camera. The camera draws approximately

160 mA of current during operation, and will work

when supplied between 11-30 volts DC.

Camera Output

The Wide-i SeaCam does an exceptional job at giving

a high quality wide angle image even in very low light

conditions. This camera is capable of producing an

incredible 125° (H) x 89° (V) degree field of view under

water. Just like with any wide angle lens, users should

be aware of vignetting effect (black corners).

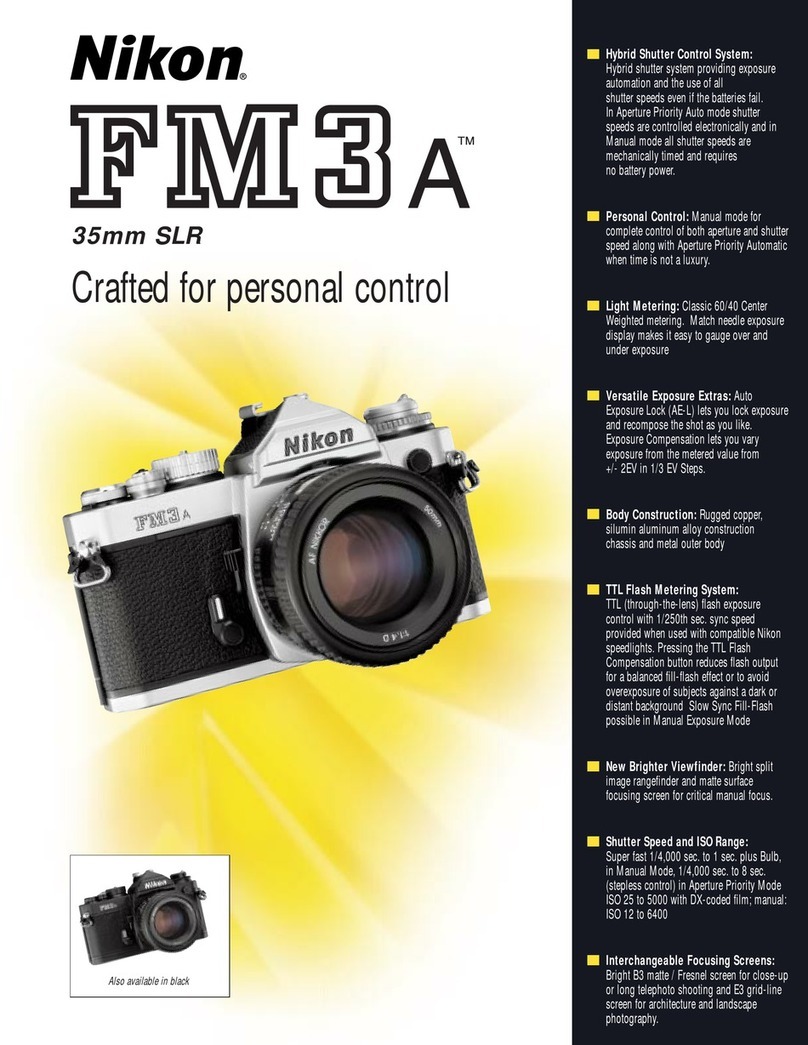

Figure 1

below shows a standard still image taken from the Wide-i

SeaCam clearly showing the vignetting effect on the four

corners of image.

Figure 1: Sample Image

DANGER

After each deployment, carefully check

to make sure the camera has not flooded. It is

possible for the camera to partially flood and then

reseal itself while underwater. Upon surfacing, the

camera can become internally pressurized, which

may be potentially dangerous. Additionally, if the

power remains on when the camera has partially

flooded, it is possible for electrolytic generation of

an explosive mixture of hydrogen and oxygen gases.

If a camera appears flooded upon removal from the

water, it should be treated as potentially dangerous.

Point the camera away from persons and valuable

equipment and make sure that the power is

disconnected. See the Flooding Repair Procedure

for more information.

Flooding Repair Procedure

If the camera stops working while underwater, you

should assume that it has been flooded. When working

on a potentially flooded camera, it is important to use

appropriate personal protective equipment to include, at

a minimum, eye and hand protection.

1. Immediately turn off the power to the unit.

2. Open the housing by removing the rear end cap-

retaining ring. Grasp the rear end cap in one

hand and the camera housing in the other. With

care, separate the two components using a linear

motion. If required gently twist components while

separating.

3. Pour out any water trapped in the housing.

4. If the camera is completely flooded, rinse the

internal components with clean fresh water in order

to minimize contamination and corrosion.

5. Allow parts to dry in air or a convection oven set

at 60° C (190° F). IMPORTANT! DeepSea Power

& Light cannot be responsible for any damage

incurred during emergency field repairs. Such

repairs should be undertaken only as a last resort

and by qualified personnel.

Troubleshooting

1. If the camera stops working while underwater

assume that it has been flooded. See Flooding

Repair procedure.

2. Once it has been determined that the camera is

not flooded, or if it does not turn on during pre-

deployment checks, troubleshoot in the following

sequence:

a. Check the cable/inline connector to make

sure that correct voltage and current are

being supplied, and that the correct sockets

are being used. See page 2 of this manual for

electrical specs and connector pin-outs.

b. Remove the connector. Inspect the assembly

for visual signs of wear. Use a multi-meter

check for continuity or shorts in the connector.

Try a spare connector, if available.

c. Check the wires that go from the power

supply to the camera base for wear. If they

appear worn, replace them.

d. Check to make sure that the power supply

board is securely attached to the camera. If

it is loose, check for damage on the board. If

there appears to be no damage, reattach the

board to the camera. Try using a spare driver

board if available.

e. If the camera still does not work, return it to

DSPL using the RMA Procedure.