1. Before working on your LED Multi-SeaLite®, be sure that you have a clean,

dry, at work area available.

2. Unscrew the connector/socket assembly from the back of the light body

using your hand or a 1 3/8” wrench. Gently pull the connector/socket assembly

away from the light body and unscrew the lamp base (the thing with wires run-

ning to it) from the socket in the connector/socket assembly. Remove the o-ring

(2-213 NO674-70) from the connector/socket assembly. Place all items in a

clean, dry place.

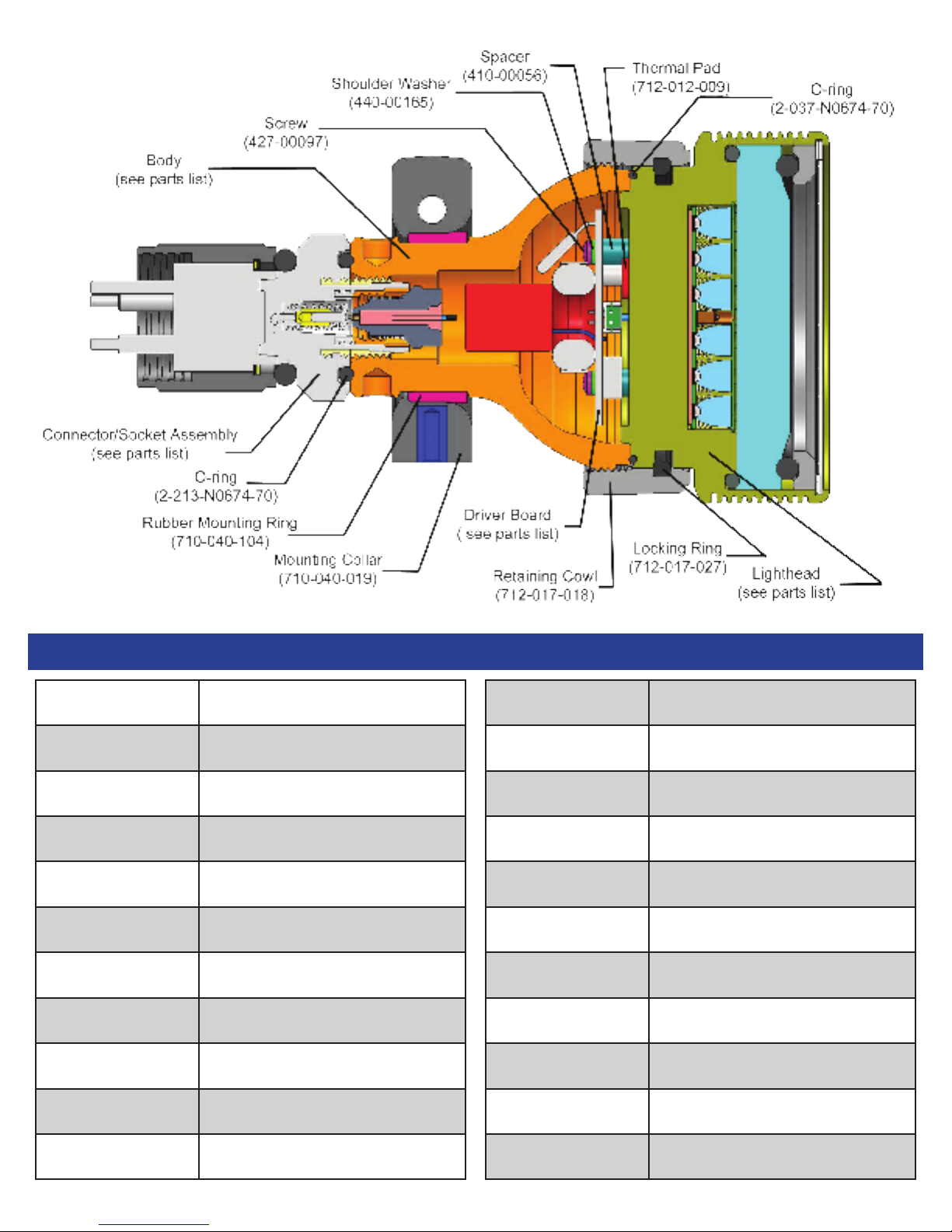

3. Unscrew the retaining cowl using a large size spanner wrench to hold the

cowl and a small size spanner wrench to hold the light body.

4. Optional: If you wish to remove the retaining cowl and locking ring, do so

before separating the lighthead from the body. Once the retaining cowl is loos-

ened, retighten it so that it is just hand tight. This gives the locking ring some

resistance to hold it out of the way during removal of the retaining cowl. Using a

small allen wrench or screwdriver, press in on the locking ring through the small

sight holes in the retaining cowl. Work your way around the cowl until the lock-

ing ring has bottomed out in the groove in the lighthead. Pull the lighthead di-

rectly away from the body and cowl to separate it. This process may need to be

repeated several times before the lighthead releases. This process takes some

practice, and care should be taken not to damage or force any of the parts.

5. Carefully separate the lighthead from the body making sure that the lamp

base passes through the connector/socket assembly hole. The retaining cowl

will remain connected to the lighthead, if you have not removed it already.

6. Remove the o-ring (2-037-NO674-70) from the back side of the lighthead.

Place in a clean dry place.

7.

8. Optional: If you wish to replace the driver board, remove it by unscrewing the

four screws that hold it to the light engine. Carefully unplug the green connec-

tor that attaches the lighthead to the driver board. Place all parts in a clean dry

place.

9. Optional: If you wish to remove the mounting collar, unscrew the allen head

screw at the top of the collar. With your thumbs on the rear of the light body

and your ngers on the collar, pull back on the collar while you push on the light

body. It may take considerable force to remove the collar. Once the collar has

been removed, remove the rubber mounting ring.

1. Inspect all o-rings to make sure that there are no nicks or cuts present, and

that they are still supple and exible. Clean with a lint free wipe and reagent

grade alcohol.

2.

The front window of the lighthead is made of acrylic plastic and will

cloud and craze if exposed the alcohol.

3. Clean the o-ring groove on the back of the lighthead with a lint free wipe.

Check the wires that connect the lamp base to the driver board for nicks or

wear.

4. Inspect the light body to make sure that it is clean, and that the sealing sur-

faces on the front and back are smooth and free of scratches or rough spots.

Check the entire body for evidence of corrosion.

5. Inspect the retaining cowl for cracks or chips.

6. Inspect the connector/socket assembly for wear. Clean the o-ring groove

with a lint free wipe and reagent grade alcohol. This is also a good time to

check the continuity of the connector/socket assembly.

7. If any of the above parts show signs of wear or damage they should be

replaced. If there appears to be anything wrong with the lighthead, it should be

returned to DSPL for evaluation and repair using the RMA procedure.

1. If you removed the mounting collar from the light body, reinstall the rubber

mounting ring rst, making sure that the rounded corner of the ring is on the

outside and facing the rear of the body. Place the light body face down on a at

surface. Loosen or remove the allen head screw in the collar. Place the collar

over the light body making sure that the ridge on the inside edge of the collar is

on top. Press rmly on the collar until it is seated over the rubber mounting ring.

Tighten the allen head screw.

2. Place the lighthead/driver assembly face down on the at surface.

3. If you separated the driver board from the lighthead, reinstall the driver board

by plugging the green connector back into the driver board. Make sure that the

thermal pad is sitting on top of the FET (black, D shaped component on the

driver board) and that it contacts the lighthead body when the driver board is

seated.. Reinstall the 4 screws, shoulder washers and spacers that hold the

board to the light engine.

4. If you removed the retaining cowl and locking ring, reinstall them by com-

pressing the locking ring in the groove in the lighthead with your hand while

lowering the retaining cowl onto the lighthead.

5. Lubricate the o-ring (2-037-NO674-70) with Dow 111 and place it into the

groove in the back of the lighthead.

6. Lower the body onto the lighthead and sh the lamp base through the hole

where the connector/socket assembly will go using tweezers or needle-nose

pliers.

7. Tighten the retaining cowl, rst by hand, and then using the spanner wrench-

es until it feels snug and no threads remain visible.

Look through the larger sight holes in the retaining cowl to

make sure that the lighthead and body are in contact all the way around.

8. Lubricate and reinstall the o-ring (2-213-NO674-70) into the groove in the

connector/socket assembly.

9. Screw the lamp base into the socket in the connector/socket assembly. Ro-

tate the connector/socket assembly three full revolutions in a counterclockwise

direction to preload the wires that connect the lamp base to the driver board.

Screw the connector/socket assembly into the back of the light body until hand

tight.

10. It is recommended that the light be pressure tested once reassembled. If

pressure testing facilities are not available, soak the light in clean, fresh water

for several hours to insure that the light is sealed.

If the light stops working while underwater, you should assume that it has been

ooded. When working on a potentially ooded light, it is important to use

appropriate personal protective equipment to include, at a minimum, eye and

hand protection.

1. Place the light face down on a table making sure that the connector side is

facing up.

2. Slowly unscrew the connector/socket assembly to allow any internal pres-

sure to be equalized.

3. Once it is determined that the light is not internally pressurized, it is recom-

mended that the light be returned to DeepSea Power & Light (DSPL) for evalu-

ation and repair using the RMA Procedure.

4. In case of emergency, you may attempt to repair the ooded light by follow-

ing the steps listed in the Disassembly, Inspection and Assembly procedures.

Any parts that were exposed to saltwater should be cleaned with de-ionized

water to remove any salt residue before reassembly. Make sure that all parts

are completely dry before reassembly by baking them in an oven at 140°F for

30 minutes.

1. If the light stops working while underwater assume that it has been ooded.

See Flooded Light Repair procedure.

2. Once it has been determined that the light is not ooded, or if it does not turn

on during pre-deployment checks, troubleshoot in the following sequence:

a. Check the power cable/inline connector to make sure that correct voltage

and current are being supplied, and that the correct sockets are being used.

See the back of this manual for electrical specs and connector pinouts.

b. Remove the connector/socket assembly (see step 1 in the Disassembly

procedure). Inspect the assembly for visual signs of wear. Using a multi-meter

check for continuity or shorts in the connector. Try a spare connector/socket

assembly if available.

c. Disassemble the rest of the light using the Disassembly procedure (steps 2

through 7).

d. Check the wires that go from the driver board to the lamp base for wear. If

they appear worn, replace the driver board.

e. Check to make sure that the driver board is securely attached to the

lighthead. If it is loose, check for damage on the board. If there appears to be

no damage, reattach the driver to the lighthead (see step 3 in the Assembly

procedure). Try using a spare driver board if available.

f. If the light still does not work, return it to DSPL using the RMA Procedure.