SAFE INFORMATION

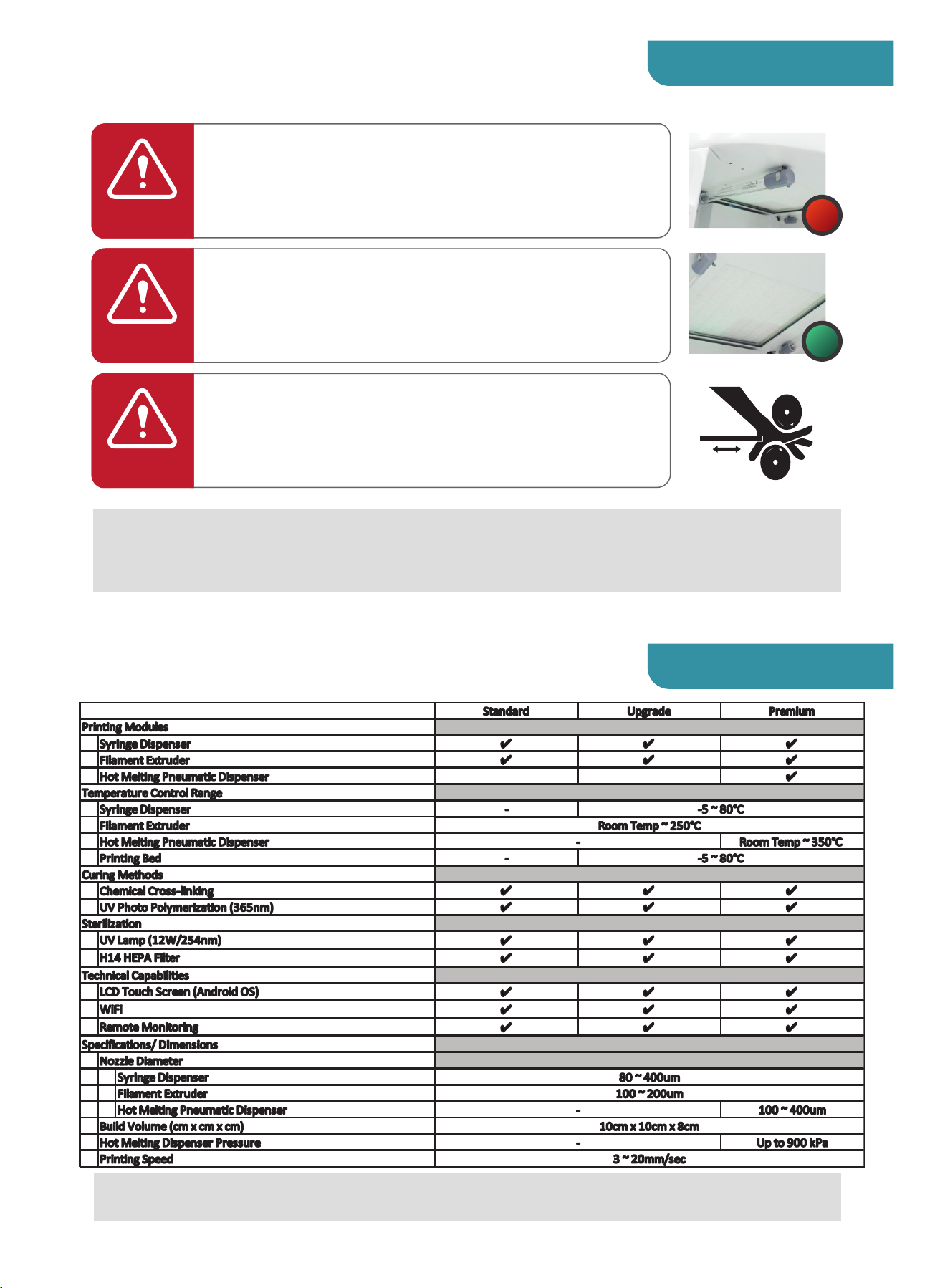

SPECIFICATION

Printing System

LCD

Resolution

Hepa Filter

UV Lamp

UV LED

Extruder

Bio Dispenser

Bio Dispenser Function

Bed Plate Function

Nozzle

Pneumatic

Dispenser

Build Volume

Printing Speed

Polymer Extruder + Bio Dispenser Polymer Extruder + Bio Dispenser

+ Hot Melt Pneumatic Dispenser

LCD Touch Screen / Android OS

Extruder 0.2mm / Dispenser 0.08mm

H14 Hepa Filter

Sterilizing UV Lamp(12W/254nm)

UV LED(365nm)

Detachable Nozzle / Tube System

Screw type of Bio Dispenser to avoid Contamination

12ml Syringe

Extruder: 0.2mmØ,0.4mm Ø

Bio Dispenser: 0.08~0.2mm Ø

-

-

-

Temperature Control System(-4℃~80℃)

Temperature Control System(-4℃~80℃)

High Temperature

Melting System(~350℃)

100X100X80mm

3~20mm/sec

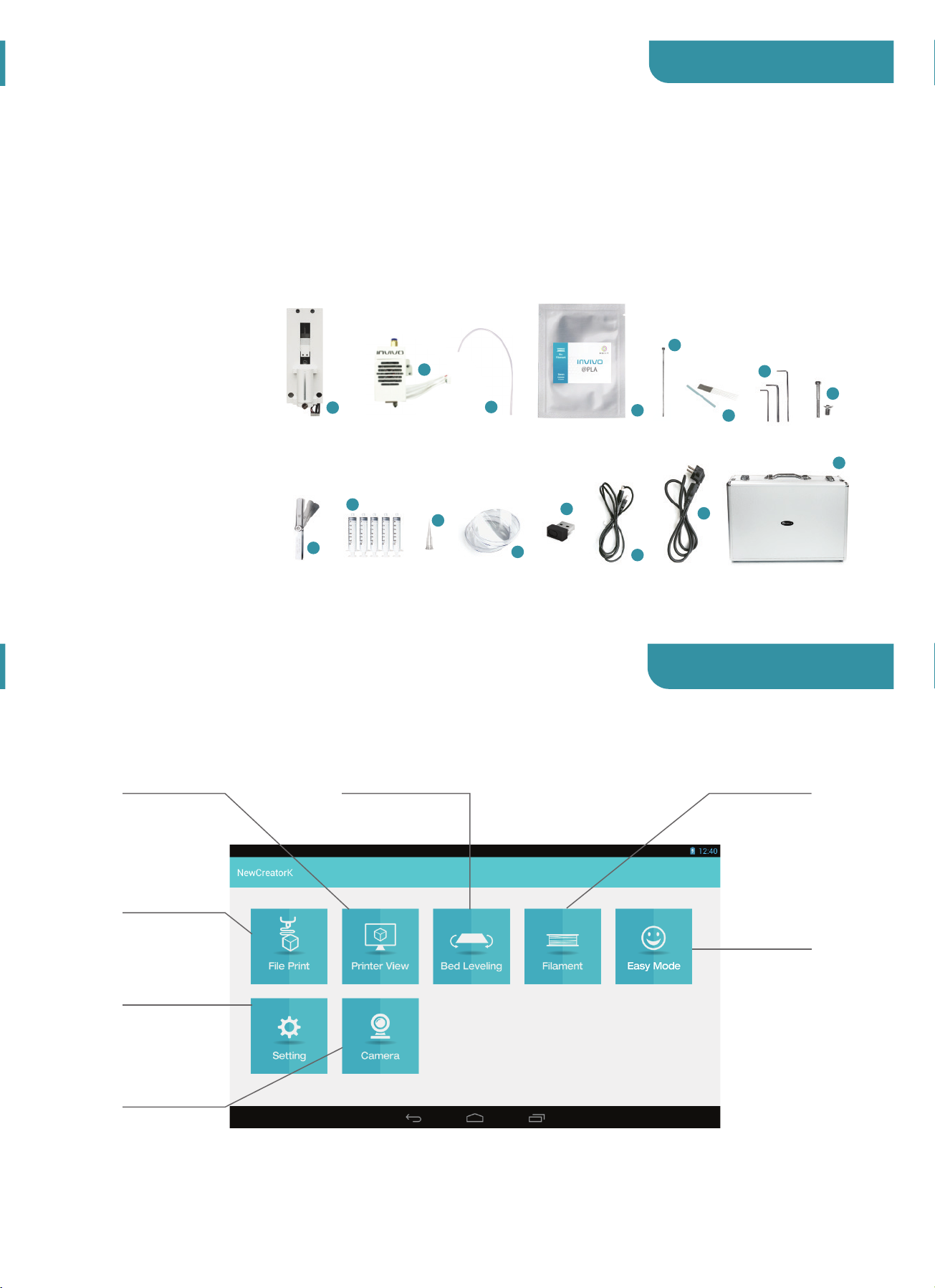

NOTE :

Do not operate on the deck while UV lamp on. It might cause burns or injury to eyes.

NOTE :

Above specifications can be changed without notice.

Extruder: 0.2mmØ,0.4mm Ø

Bio Dispenser: 0.08~0.2mm Ø

Pneumatic Dispenser: 0.1~0.5mm Ø

Use caution when turning on the UV lamp

- Do not use a work bench when a UV lamp is on.

- It may irritate or burn skin and eyes.

- Use a red switch on the upper right side of the machine to turn on/off the UV lamp.

- Turn off the UV lamp before opening

- It requires replacement every 14 months. (24hours a day)

NOTE :

Keep away from flammable substances. It may result in a fire.

Do not touch a power cord with wet hands. It may cause electric shock.

Do not plug in multiple devices to one consent. This may cause a fire.

For sterilization, change filter regularly.

Use caution when turning on the HEPA filter

- Use a green switch on the upper right side of the machine to turn on/off the HEPA filter.

- Turn on the HEPA filter before use the printer, and the UV lamp should be turned off.

- It requires replacement every 8 months

(It varies depending on the operating environment)

- In the clean bench, turn off the filter and print.

Hazardous moving parts

- Keep fingers and other body parts away

- Open the door carefully or insert your hands while the device is running.

ON

OFF

ON

OFF

Caution

Caution

Caution