formlabs Fuse 1 User manual

Manual Fuse 1

Installation and Usage Instructions

Fuse 1

Benchtop Selective Laser Sintering (SLS)

3D printer

Original English instructions

Read this manual carefully and keep it for future reference.

January 2021

REV 01

© Formlabs

1 Table of Contents

1Preface ..................................................................6

1.1 Read and retain instructions ................................................6

1.2 Obtaining documentation and information ...................................6

2Introduction ..............................................................8

2.1 Intended use..............................................................8

2.2 Technical specifications ....................................................8

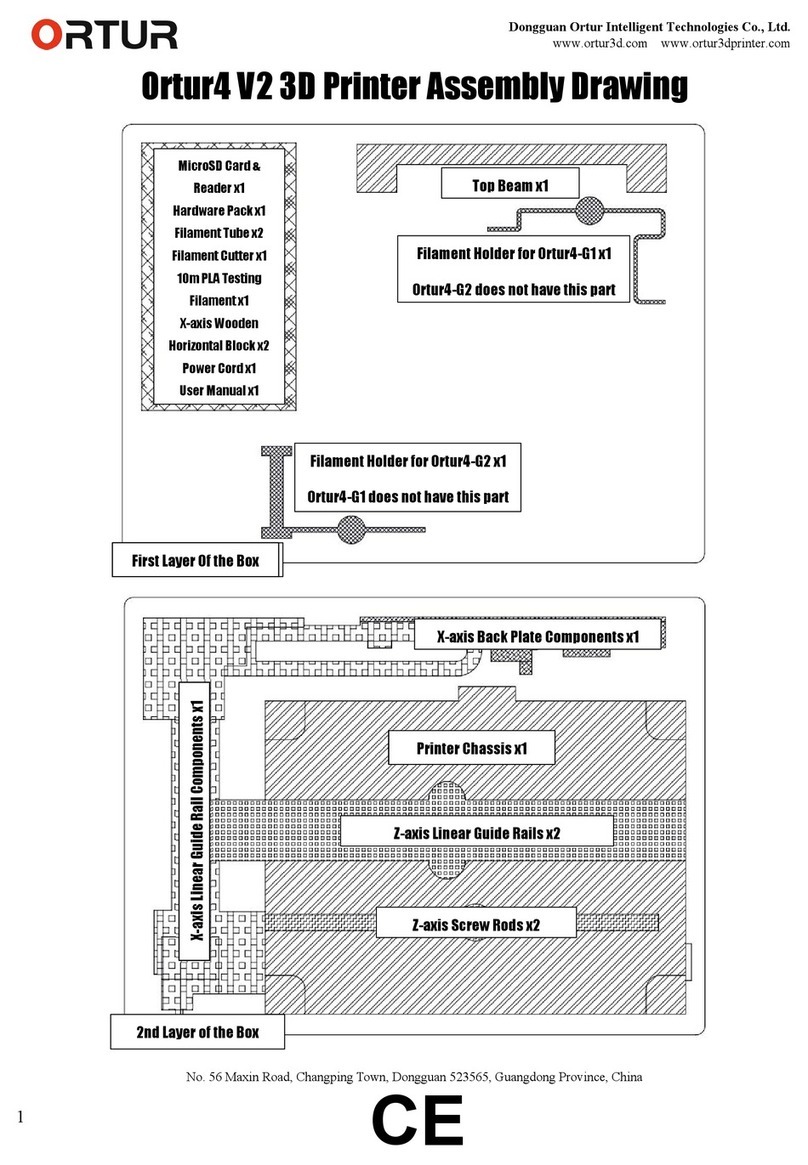

2.3 Product components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Fuse 1 user interface ......................................................13

3Safety...................................................................14

3.1 Component and subsystem safety .........................................15

3.2 Personal protective equipment (PPE) .......................................18

3.3 Specification of tools to be used ...........................................18

3.4 Sensitive components ....................................................19

3.5 Emergency and exceptional situations ......................................19

4Preparation and setup....................................................21

4.1 Location and environs ....................................................21

4.2 Power and networking ................................................... 22

4.3 Unboxing the machine ................................................... 22

4.4 Accessing the serial name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.5 Installing the machine.................................................... 24

4.6 Setting up a network connection .......................................... 25

4.7 Updating firmware....................................................... 26

4.8 Registering powder credit ................................................ 26

4.9 Preparing the optical cleaning kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.10 Transporting the machine ................................................ 29

5Printing ................................................................ 32

5.1 Operational environment................................................. 32

5.2 Designing for SLS ....................................................... 32

5.3 Setting up a print .........................................................33

5.4 Preparing for a print ......................................................34

5.5 Retrieving and cleaning prints with the Fuse Sift .............................37

5.6 Managing the machine................................................... 38

6Maintenance ........................................................... 39

6.1 Tools and supplies....................................................... 39

6.2 Inspection and maintenance.............................................. 40

6.3 Tasks between uses ..................................................... 40

6.4 Periodic maintenance.....................................................43

6.5 Intermittent maintenance ................................................. 48

7Troubleshooting .........................................................51

7.1 Collecting diagnostic logs .................................................51

7.2 Performing a factory reset .................................................51

7.3 Cleaning after a failed print ................................................51

7.4 Troubleshooting errors or abnormal activity ................................ 52

8Disassembly and repair.................................................. 54

8.1 Tasks................................................................... 54

9Recycling and disposal ..................................................55

9.1 Disposal of powder ...................................................... 55

9.2 Recycling of powder ..................................................... 55

9.3 Disposal of cleaning agents .............................................. 55

9.4 Recycling of solvent ..................................................... 55

9.5 Disposal of electronic components........................................ 56

9.6 Disposal of packaging waste ............................................. 56

10 Index................................................................... 57

11 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

12 Product compliance ......................................................61

Disclaimer | 5

Read and understand this manual and its safety instructions before using the Fuse 1.

Failure to do so can result in serious injury or death.

DISCLAIMER

Formlabs has made every eort to make these instructions as clear, complete, and correct

as possible. The information provided in this documentation contains general descriptions

and/or technical characteristics of the performance of the products contained herein. This

documentation is not intended as a substitute for and is not to be used for determining

suitability or reliability of these products for specific user applications. It is the duty of any

such user or integrator to perform the appropriate and complete risk analysis, evaluation, and

testing of the products with respect to the relevant specific application or use thereof. Neither

Formlabs nor any of its aliates or subsidiaries shall be responsible or liable for misuse of the

information that is contained herein. Notify us if you have any suggestions for improvements

or amendments or have found errors in this publication.

Copyright © 2020 by Formlabs. All rights reserved.

support.formlabs.com

TRADEMARKS

All product names, logos, and brands are property of their respective owners. All company,

product, and service names used in this manual are for identification purposes only. Use of

these names, logos, or brands does not imply endorsement.

DOCUMENT REVISIONS

Date Version Document changes

Jan 2021 REV 01 Initial publication

WARNING

6

1 Preface

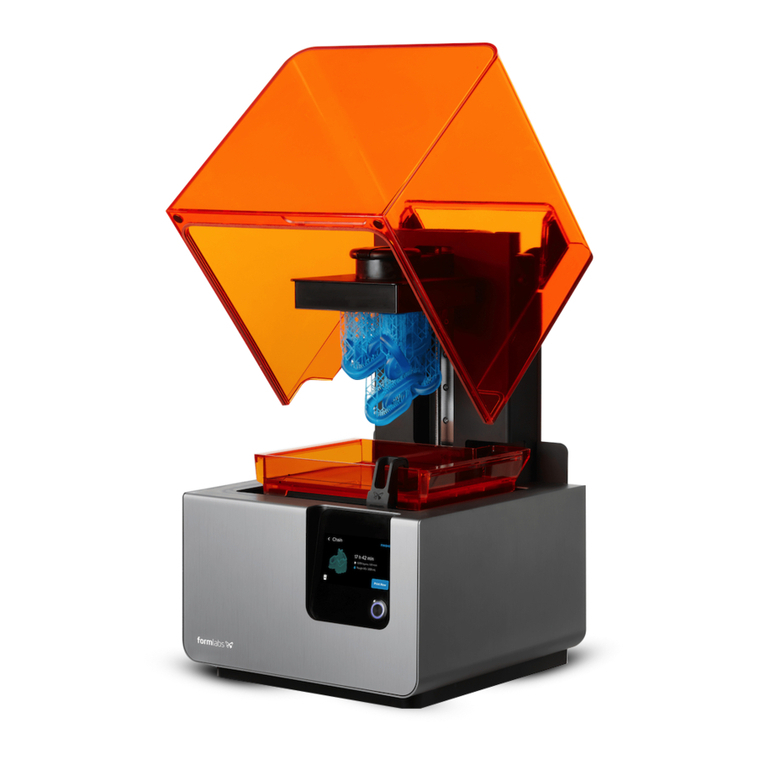

Congratulations on purchasing the Fuse 1. On behalf of the Formlabs team, we thank you for

your purchase. The Fuse 1 is a Selective Laser Sintering (SLS) 3D printer.

The Fuse 1 fabricates fully-supported parts by heating powdered thermoplastic to just below

its melting point, then solidifies it by sintering layers (2D cross sections) together with a laser.

These 110 micron thick layers are stacked on top of each other to create 3D parts.

This manual explains how to set up, use, and properly maintain the Fuse 1, as well as provides

design guidance for optimizing print results.

The manual is intended for anyone who is installing, operating, maintaining, or otherwise

interacting with the Fuse 1. Supervise young or inexperienced users to ensure enjoyable and

safe operation.

1.1 Read and retain instructions

Read and understand this manual and its safety instructions before using the Fuse 1. Failure

to do so can result in serious injury or death. Keep all safety information and instructions for

future reference and provide them to subsequent users of the product.Follow all instructions to

avoid fire, explosions, electric shocks, or other hazards that may result in damage to property

and/or severe or fatal injuries. The Fuse 1 shall only be used by persons who have fully read

and understand the contents of this manual. Ensure that each person who uses the Fuse 1

has read these warnings and instructions and follows them. Formlabs is not liable for cases of

material damage or personal injury caused by incorrect handling or non-compliance with the

safety instructions. In such cases, the warranty will be voided.

1.2 Obtaining documentation and information

Visit formlabs.com to:

• Access your Formlabs store (formlabs.com/store) and Dashboard accounts (formlabs.

com/dashboard).

• Find certified service providers in your region (formlabs.com/company/partners).

•

Access the Terms of Service (formlabs.com/terms-of-service) and the Privacy Policy

(formlabs.com/privacy-policy).

Visit support.formlabs.com to:

• Access the latest version of all Formlabs product documentation.

•

Contact Formlabs Support to request documentation, manuals, repair guides, and

technical information.

• Submit any comments or feedback regarding what is good and what can be improved.

Formlabs values comments from its users.

• Request additional training.

1.2.1 Support and service

Retain a record of the original purchase to request warranty services. Service options depend

on the status of the specific product’s warranty. Include the serial name of the product when

contacting Formlabs Support or a certified service provider for product support.Instead of a

serial number, Formlabs products have a serial name, which is a unique identifier to track the

history of manufacturing, sales, and repair, and to distinguish usage when connected to a

Preface | 7

network. The serial name is on the back panel of the machine in the format AdjectiveAnimal.

Service providers of Formlabs products also provide support and service. To the extent that

Formlabs or a certified service provider oers other or extended warranties, the terms of the

separate oer may apply.

For products purchased from certified service providers, contact the original service provider

for assistance before contacting Formlabs Support.

For any support or service requests, including product information, technical assistance, or

assistance with instructions, contact Formlabs Support:

support.formlabs.com USA

Formlabs, Inc.

35 Medford St.

Somerville, MA, USA, 02143

Germany

Formlabs GmbH

Nalepastrasse 18

12459 Berlin, Germany

1.2.2 Warranty

This product is protected under warranty. Formlabs oers a warranty for all Formlabs branded

hardware. Unless otherwise expressly stated, the Terms of Service, including the Warranty,

constitute the entire agreement between you and Formlabs with respect to the Service and

any product you purchase from Formlabs and supersedes all prior or contemporaneous

communications, proposals, and agreements, whether electronic, oral, or written, between

you and Formlabs.

Read the warranty for more details on the Formlabs warranty for your region:

US formlabs.com/support/terms-of-service

EU (EN) formlabs.com/eu/terms-of-service

EU (DE) formlabs.com/de/support/terms-of-service/eu

EU (FR) formlabs.com/fr/support/terms-of-service/eu

EU (ES) formlabs.com/es/terms-of-service/eu

EU (IT) formlabs.com/it/terms-of-service/eu

8

2 Introduction

2.1 Intended use

The Fuse 1 is a commercial, precision tool intended for use in the additive manufacture of

end-user supplied designs from SLS powder. The final performance characteristics of sintered

SLS powder may vary according to your compliance with the instructions for use, application,

operating conditions, material combined with, end use, or other factors.

In some cases, the additive manufacturing process may inherently result in variable

performance characteristics between manufacturing runs or within a specific part.

Such variances may not be apparent and may result in unexpected defects in

additively fabricated parts.

You shall independently verify the suitability of additive manufacturing, Selective

Laser Sintering (SLS), the Fuse 1, and any specific designs or materials employed

for the application and intended purpose before use. In no event shall Formlabs be

liable for any loss, death, or bodily injury that you suer, or that you cause to any third

party, in connection with your use of Formlabs products. To the fullest extent legally

permitted Formlabs EXPRESSLY DISCLAIMS ANY IMPLIED OR EXPLICIT WARRANTY

OF FITNESS for a particular usage, the particular nature and circumstances of said

usage being unforeseen and unforeseeable to Formlabs.

Formlabs is not a manufacturer of medical devices. Formlabs provides tools and

materials that may be used in many applications, but makes no claims as to the

safety or eectiveness of any specific devices made using Formlabs products.

Certain Formlabs products, such as those commonly known in the industry as

“biocompatible” materials, have been engineered to comply with relevant industry

standards. The specific standards and most relevant technical specifications may be

identified within the technical data sheets and have been tested according to relevant

testing protocols for those standards and specifications. Biocompatible materials are

a speciality product, developed for use by medical professionals, and should be used

in accordance with the instructions for use.

Do not modify. The Fuse 1 is intended for use as-is. Modifying the machine without

explicit approval and directions from Formlabs or a certified service provider will void

your warranty, and could potentially ruin the machine and cause you bodily harm.

2.2 Technical specifications

Parameter Unit

Printer Fuse 1

NOTICE

WARNING

WARNING

WARNING

Introduction | 9

Parameter Unit

3D printing technology Selective Laser Sintering (SLS)

Minimum dimensions for convenient

access (W × D × H)

125.5 × 149.5 × 187.0 cm | 49.4 × 59.0 × 73.6 in

Printer dimensions (W × D × H) 64.5 × 68.5 × 107 cm (165.5 cm with stand)

25.4 × 27.0 × 42.0 in (65.0 in with stand)

Printer weight 114 kg (without build chamber or powder)

251.3 lb (without build chamber or powder)

Build chamber dimensions (W × D × H) 27.9 × 34.2 × 48.9 cm | 11.0 × 13.5 × 19.3 in

Build chamber weight 11 kg (17.6 kg, full with 20% packed powder)

24.3 lb (38.8 lb, full with 20% packed powder)

Build volume (W × D × H) 16.5 × 16.5 × 30.0 cm | 6.5 × 6.5 × 11.8 in

Material refresh rate Print with up to 70% recycled powder

Startup time 60 minutes

Build speed 10 mm/hour | 0.39 in/hour

Hopper capacity 9 kg powder | 19.8 lb powder

Operating environment 20–27 ºC | 68–81 ºF

Operating temperature 200 ºC | 392 ºF

Temperature control Quartz tube heating elements

Positive temperature coecient (PTC) cartridges

Air handling Pressure-controlled two-stage filtration (Replaceable HEPA

and carbon mediums)

Power requirements EU: 230 VAC, 7.5 A (dedicated circuit)

US: 120 VAC, 15 A (dedicated circuit)

Laser specifications EN 60825-1: 2014

Class 1 laser product

1065 nm

Maximum 10 W

4.01 mrad beam divergence (nominal, full angle)

Laser spot size (FWHM) 200 μm | 0.0079 in

Radiation information The Fuse 1 is a Class 1 laser product. Accessible radiation is

within Class 1 limits.

Connectivity Wi-Fi: 2.4 GHz

Ethernet: 1000 Mbit

USB: 2.0

Wi-Fi connectivity Protocol: IEEE 802.11 b/g/n

Frequency: 2.4 GHz

Supported security: WPA/WPA2

Ethernet connectivity RJ-45 Ethernet (10BASE-T/100BASE-TX/1000BASE-T) LAN port

Connect with a shielded Ethernet cable (not included):

minimum Cat5, or Cat5e or Cat6 for 1000BASE-T.

USB connectivity USB (rev 2.0) B port with a USB A-B cable

Printer control Interactive touchscreen

Powder dispensing system Automated

Alerts Touchscreen alerts, SMS/email via Dashboard

Print preparation PreForm desktop software

File type STL or OBJ

10

2.3 Product components

2.3.1 Fuse 1

Print enclosure door: Provides access to the print enclosure and optical cassette tray.

IR sensor door: Provides top-down access to the IR sensor and powder card reader.

Touchscreen: The LCD capacitive touch user interface displays print information, settings,

and error messages.

Hopper lid: Prevents debris from entering and powder from leaving the hopper.

Hopper: Stores up to 9 kg (19.8 lb) of powder for printing.

Hopper window: Allows for visual check of powder level in the hopper.

Door handle: A grab slot to help close the door.

Cassette tray: Holds the optical cassette in place.

Build chamber latch: Secures a build chamber.

Print enclosure: Houses the build chamber and optics system for printing.

Build chamber socket: Connects the build chamber’s plug.

Filter cabinet door: Sealed door for accessing the intake and exhaust filters.

1

2

3

4

5

6

7

8

9

10

1 1

12

Introduction | 11

2.3.2 Build chamber

Print bed: The moving surface (Z-axis) on which

powder is deposited and sintered.

Front handle: Silicone handle for loading and

unloading the build chamber.

Side handles: Silicone handles on each side for

moving the build chamber.

Plug holster: A retainer to keep the plug secure

when moving or storing the build chamber.

Build chamber plug: Main connector for the build

chamber’s heaters and temperature sensors.

2.3.3 Powder cartridge

Cartridge wings: Two brackets for locking the

cartridge to the mixer.

Cartridge valve: The primary opening for filling and

depositing powder.

Valve knife: Used to close and open the cartridge valve.

Handles: For holding and lifting the cartridge.

2.3.4 IR sensor

Sensor window: The exposed surface that allows

infrared radiation to enter the sensor.

Ethernet socket: Used to connect the sensor to the

printer and disconnect for cleaning.

Status light: Indicates if the sensor is seated

correctly (green) or incorrectly (yellow).

2.3.5 Optical cassette

Laser window gasket: Seals the top of the laser

window from the print enclosure.

Camera window gasket: Seals the camera window

from the print enclosure.

Tray catch: Two hooks that align the optical cassette

to the cassette tray.

Laser window: Protects the laser during printing.

This side requires cleaning after each print.

Camera window: Protects the camera lens during

printing. This side requires cleaning after each print.

1

2

3

4

5

1

2

3

4

1

2

3

1

2

3

4

5

12

2.3.6 Additional Fuse 1 package components

Power cable: Compatible with both the Fuse 1 and the Fuse Sift.

Stand: Freestanding platform for the Fuse 1.

Optical cassette: A set of gasketed windows that protect the laser and camera. Each Fuse

1 includes an optical cassette packaged with the printer.

Build chamber: The compartment in which powder is deposited and sintered into parts.

Thermal-insulated silicone gloves: For removing the build chamber while it’s still hot.

Push-top dispensers: For dispensing Alconox, deionized water, and ethanol to clean the

optical cassette.

Polyester swabs: For cleaning the upper laser window, the IR sensor and the IR

sensor housing.

PEC*PADs: For cleaning the cassette’s optical windows.

Telescoping mirror: For inspecting the upper laser window and roof of the print enclosure.

Lifting straps: For two individuals to lift and move the Fuse 1.

1

2

3

4

5

6

7

8

9

10

Introduction | 13

2.4 Fuse 1 user interface

For detailed guidance and visual assistance, visit support.formlabs.com.

The touchscreen displays print information (print job name, time remaining, layers printed),

settings, and error messages. The touchscreen serves as the user interface for the printer.

Tap the home icon in the left sidebar to

access the Home screen. A status card on

the right indicates if the Fuse 1 is idle, printing,

or cooling. Below the status card is the Next

Job card, which presents the next print job

in the queue. The slider to unlock the print

enclosure is located in the bottom-right corner

of the touchscreen.

Tap the printer icon in the left sidebar to access

the printer status screen. Readouts of the bed

temperature, hopper level, powder type, and

available credits can be found here.

The Fuse 1 requires periodic maintenance and

notifies users when a procedure is due. Each

procedure is accompanied by written and

visual instructions and organized in a checklist

with due tasks highlighted red. When a task is

completed, the Fuse 1 keeps track of procedure

intervals in the background.

14

3 Safety

Read and understand this manual and its safety instructions before using the Fuse 1.

Failure to do so can result in serious injury or death.

Supervise young or inexperienced users to ensure enjoyable and safe operation.

The instructions contain warnings and safety information, as explained below:

DANGER indicates a hazard with a high level of risk which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard with a medium level of risk which, if not avoided, could result in death or

serious injury.

CAUTION indicates a hazard with a low level of risk which, if not avoided, could result in minor or

moderate injury.

NOTICE indicates information considered important, but not hazard-related.

DANGER: Ethanol is a flammable chemical.

DANGER: CLASS 4 INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED AVOID

EYE OR SKIN EXPOSURE TO DIRECT OR SCATTERED RADIATION

WARNING: Class 1 laser product. Only remove the exterior paneling of the printer with authorization

from Formlabs Support or a certified service provider.

ENVIRONMENTAL HAZARD: Unsintered SLS powder is classified as a microplastic, a group of

plastics that are hazardous to aquatic life..

MANDATORY ACTION: Refer to instruction manual/booklet.

MANDATORY ACTION: Wear a respirator (N95 or better).

MANDATORY ACTION: Wear thermal-insulating silicone gloves when handling hot build chambers.

MANDATORY ACTION: Disconnect before carrying out maintenance or repair.

MANDATORY ACTION: Grounding required.

WARNING

DANGER

WARNING

CAUTION

NOTICE

Safety | 15

3.1 Component and subsystem safety

3.1.1 General

The Fuse 1 requires a 230 VAC (50 Hz), 7.5 A power supply (EU) or 120 VAC (60

Hz), 15 A power supply (US) for nominal operation. Unless explicitly instructed by

Formlabs Support or a certified service provider, do not disassemble or tamper with

the product beyond what is explicitly outlined for typical maintenance. Tampering

with, or disassembling the Fuse 1 prior to disconnecting the power cable and waiting

approximately ten minutes can subject users to potentially fatal electrical hazards.

The Fuse 1’s print enclosure is designed to operate at up to 200 °C (392 °F) and

incorporates high-intensity heaters. Do not open the print enclosure or any other

access doors on the printer during or immediately after a print. Do not handle parts

from a build chamber without allowing the entire print enclosure to cool for several

hours, or until the print bed temperature has reached ≤ 45 ºC (113 °F). Use the

provided thermal-insulating silicone gloves when removing a build chamber that

has not been allowed to cool down. Failure to follow these procedures will result in

serious injuries, including burning and/or scalding of skin.

Due to its size and weight, do not move or reposition the Fuse 1 alone. If the machine

needs to be moved, at least two or more individuals should use the lifting straps

provided with the printer.

Do not lift or reposition the Fuse 1:

• By grabbing or pulling on the print enclosure door, hopper, hopper lid, filter

compartment, filter door, power cable, or any components inside the print

enclosure.

• By pushing on any side of the unit while stationary.

• When the build chamber from a previous print is loaded or still cooling in the print

enclosure.

• When the print enclosure is still hot from a previous print.

The Fuse 1 requires an operating environment that is low in ambient humidity and

static electricity. Due to the sensitive nature of its components and the printing

mediums, system reliability and print quality may fluctuate if the ambient temperature

and moisture are outside the recommended ranges. Refer to section 4.1 Location and

environs for the recommended operating environs. When performing maintenance or

testing with the exterior paneling of the machine removed, ground equipment to the

grounding stud marked with this protective earth symbol.

DANGER

WARNING

CAUTION

NOTICE

NOTICE

16

3.1.2 Laser

The above Class 4 laser warning label is also located in the Fuse 1. It can be seen on the laser module

heatsink. It is visible when the rear cover of the printer is opened by an authorized technician.

Class 1 laser product. The laser beam is extremely harmful to the eyes and skin,

capable of causing permanent blindness. Avoid direct contact at all times. The Fuse

1 contains redundant interlock systems to automatically shut o the laser when the

print enclosure door is open, or if the IR sensor is out of place. If these systems are

tampered with or fail, there is a risk of exposure to Class 4 laser light. Use of controls

or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure. Only remove the exterior paneling of the

machine with authorization from Formlabs Support or a certified service provider.

Accessible radiation is within Class 1 limits. The laser diode used inside the device has the

following specifications:

Parameter Unit

Diode 1065 nm

Maximum output 10 W

Beam divergence 4.01 mrad (nominal, full angle)

Certification ISO 11553-1:2020

ISO 11252:2013

ISO 11554:2017

3.1.3 Powder

Dust deposits should not be allowed to accumulate on surfaces. Clean dust residues at regular

intervals. Do not use brooms or compressed air hoses to clean surfaces. Only use a compliant

vacuum that is grounded and bonded, such as a Class II, Division 2 vacuum, for dust collection.

Use only non-sparking tools. Keep powder containers tightly closed when not in use.

Use appropriate personal protective equipment when handling loose or unsintered powder.

Wear non-reactive nitrile gloves and safety glasses. Wear a respirator (N95 or better) if the

occupational threshold limit value for airborne particle concentration has been exceeded, if

you are sensitive to dust or pollen, or you are concerned about your respiratory health. Refer to

section 3.2 Personal protective equipment (PPE) for more information. Handle loose powder

only with adequate ventilation. Avoid breathing mist/vapor/spray/dust. Do not eat, drink, smoke,

or use personal products when handling powder. Avoid contact with skin, eyes, and clothing.

DANGER

WARNING

Safety | 17

In case of powder inhalation, swallowing, or contact with eyes, follow these

instructions:

• AFTER INHALATION: If inhaled, remove person to fresh air and place in a position

comfortable for breathing. Keep person at rest. If breathing is dicult, administer

oxygen. If breathing has stopped, provide artificial respiration. If symptoms develop

or persist, seek medical advice/attention.

• AFTER SKIN CONTACT: Remove contaminated clothing and shoes. Rinse

skin with copious amounts of water [shower] for several minutes. Launder

contaminated clothing before reuse. If symptoms develop or persist, seek

medical advice/attention.

• AFTER SWALLOWING: If swallowed, DO NOT induce vomiting unless told to do

so by a physician or poison control center. Rinse mouth with water. Never give

anything by mouth to an unconscious person. If spontaneous vomiting occurs,

place on the left side with head down to prevent aspiration of liquid into the lungs.

If symptoms develop or persist, seek medical advice/attention.

Consult the safety data sheet (SDS) as the primary source of information to

understand safety and handling of Formlabs powders. Respect Formlabs powder

like any household chemical. Follow standard chemical safety procedures and

Formlabs powder handling instructions. In general, Formlabs powder is not

approved for use with food, drink, or medical applications on the human body. Refer

to the safety data sheet (SDS) for each specific powder as well as support.formlabs.

com for more detail.

3.1.4 Radio interference

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at their own expense.

Changes or modifications to this product not authorized by Formlabs could void the

electromagnetic compatibility (EMC) and wireless compliance and negate your authority to

operate the product.

This product has demonstrated EMC compliance under conditions that included the use

of compliant peripheral devices and shielded cables between system components. It is

important that you use compliant peripheral devices and shielded cables between system

components to reduce the possibility of causing interference to radios, televisions, and other

electronic devices.

WARNING

NOTICE

18

3.1.5 Ethanol

Ethanol is a flammable chemical. Keep away from ignition sources, including open

flames, sparks or concentrated sources of heat.

Formlabs does not manufacture ethanol. Consult the chemical manufacturer or

supplier for detailed safety information. Carefully follow the safety instructions

provided with the ethanol that you purchase. Ethanol can be flammable, even

explosive, and should be kept away from heat, fire, or sparks. Any containers

holding ethanol should be kept closed or covered when not in use. We also

recommend that you wear protective gloves and have good ventilation when

working with ethanol.

3.2 Personal protective equipment (PPE)

Safe operation of the Fuse 1 can be achieved by implementing the following equipment:

• Particulate filtering respiratory protection (N95 or better)

Wear a respirator (N95 or better) if the occupational threshold limit value for airborne

particle concentration has been exceeded, if you are sensitive to dust or pollen, or you

are concerned about your respiratory health.

• Non-reactive nitrile gloves

Recommended when handling loose or unsintered powder, as it may draw moisture and

oils out of skin. If powder is handled at room temperature, it is not necessary to wear

protective gloves.

• Safety glasses

Required when performing maintenance on the Fuse 1, as well as handling loose or

unsintered powder at any time. Polycarbonate-based lenses, including prescription glasses,

are acceptable so long as they provide peripheral protection.

3.3 Specification of tools to be used

The Fuse 1 shall only be used with supplied accessories and additional tools recommended

by Formlabs or a certified service provider. Third-party accessories and materials may cause

damage. Refer to sections 3.2 Personal protective equipment (PPE) and 6.1 Tools and

supplies for more information.

Purchase additional supplies:

• Alconox

The recommended cleaning agent for removing deposits of laurolactam and other o-

gassing stains from the printer’s optical components. It is the first cleaning agent to be used,

followed promptly by distilled water and ethanol.

• Compliant vacuum that is grounded and bonded (e.g., Class II, Division 2 vacuum)

Certified for use with materials whose fine particles present an explosive risk when in the

vicinity of potentially malfunctioning electrical equipment.

NOTICE

Table of contents

Other formlabs 3D Printer manuals

formlabs

formlabs Form Wash User manual

formlabs

formlabs Fuse Sift User manual

formlabs

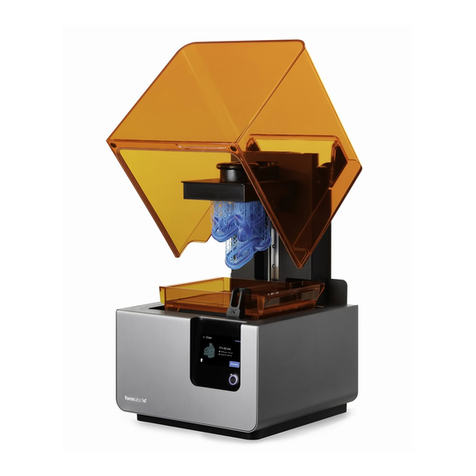

formlabs Form 2 Setup guide

formlabs

formlabs Form Wash L User manual

formlabs

formlabs Form Cure User manual

formlabs

formlabs Form 3 User manual

formlabs

formlabs Form 2 User manual

formlabs

formlabs Form 2 User manual

formlabs

formlabs IBT Flex Resin User manual

formlabs

formlabs Form 3BL User manual