SeeMeCNC Rostock Max v3 User manual

Other SeeMeCNC 3D Printer manuals

SeeMeCNC

SeeMeCNC Artemis 300 User manual

SeeMeCNC

SeeMeCNC Rostock Max v3 User manual

SeeMeCNC

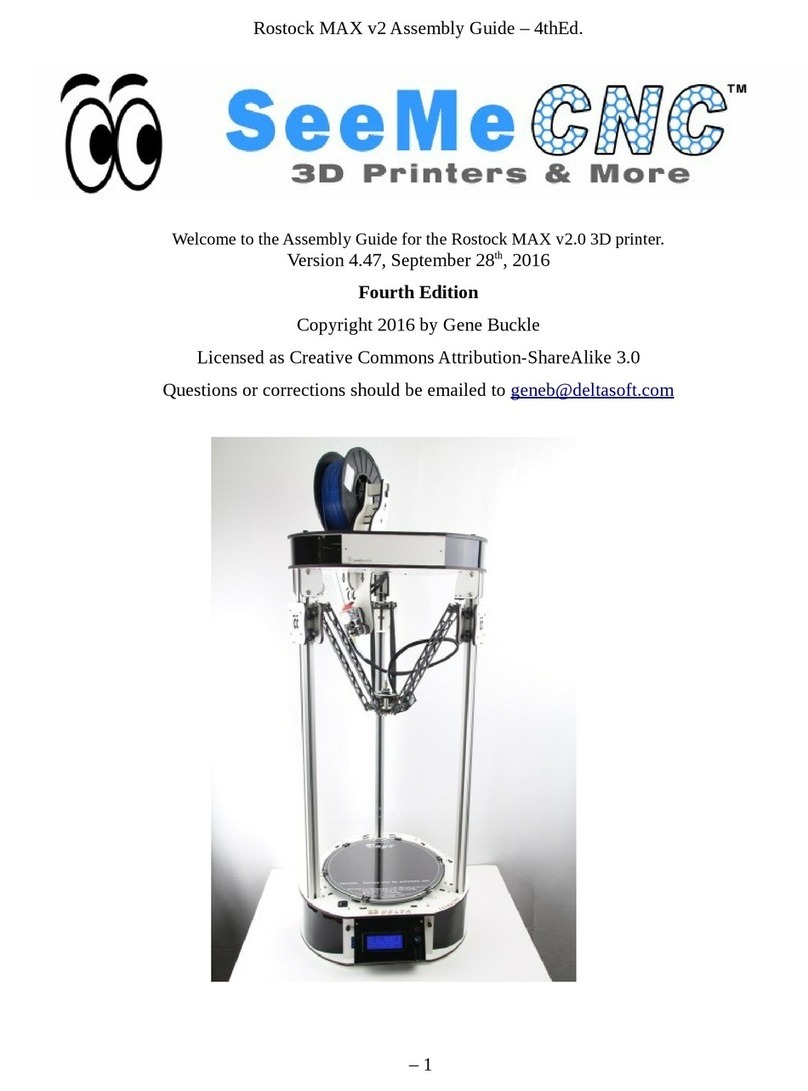

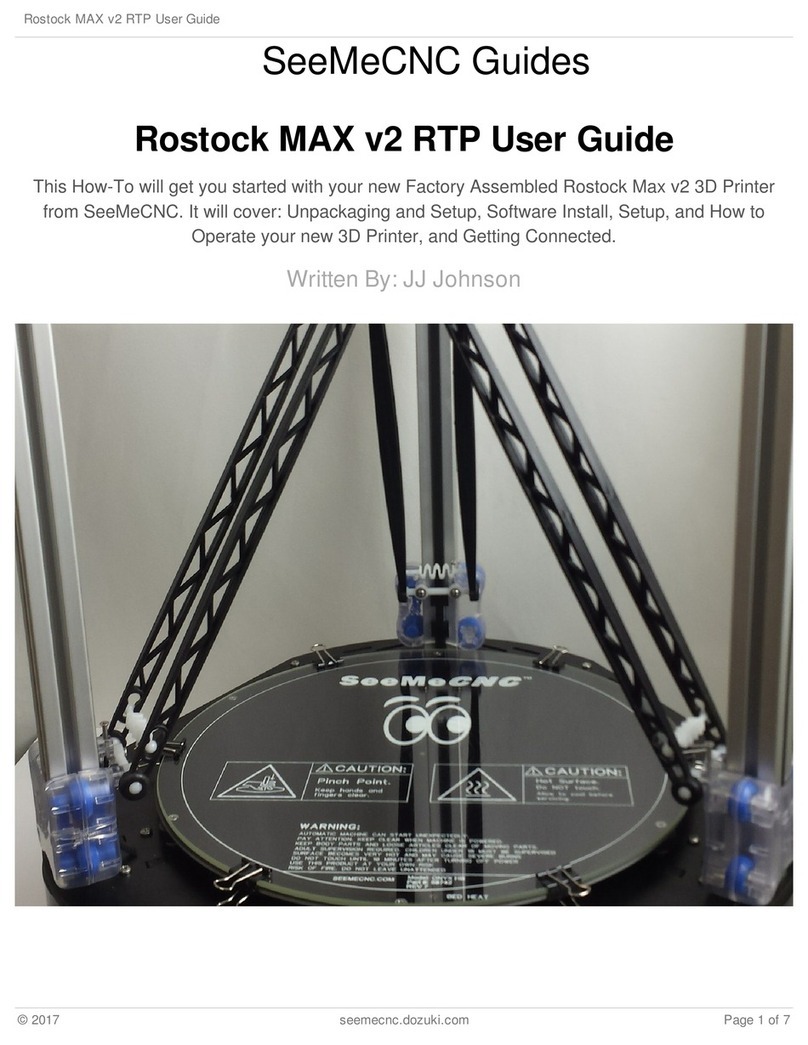

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC DropLit User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

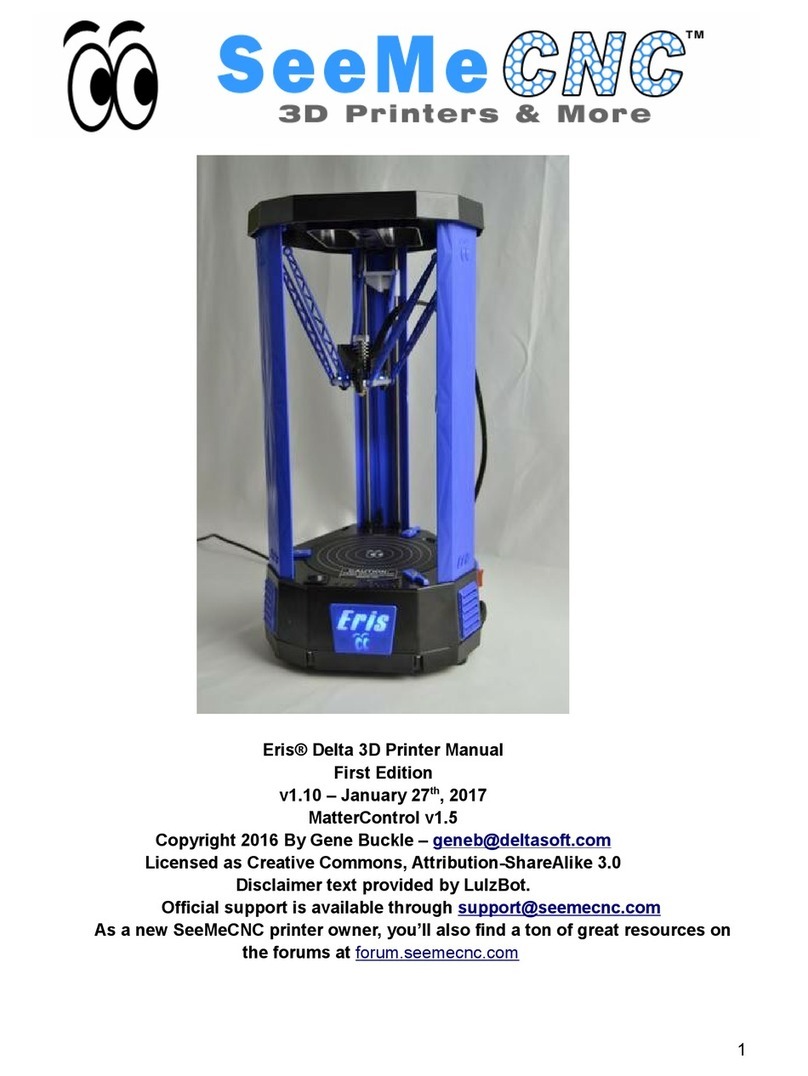

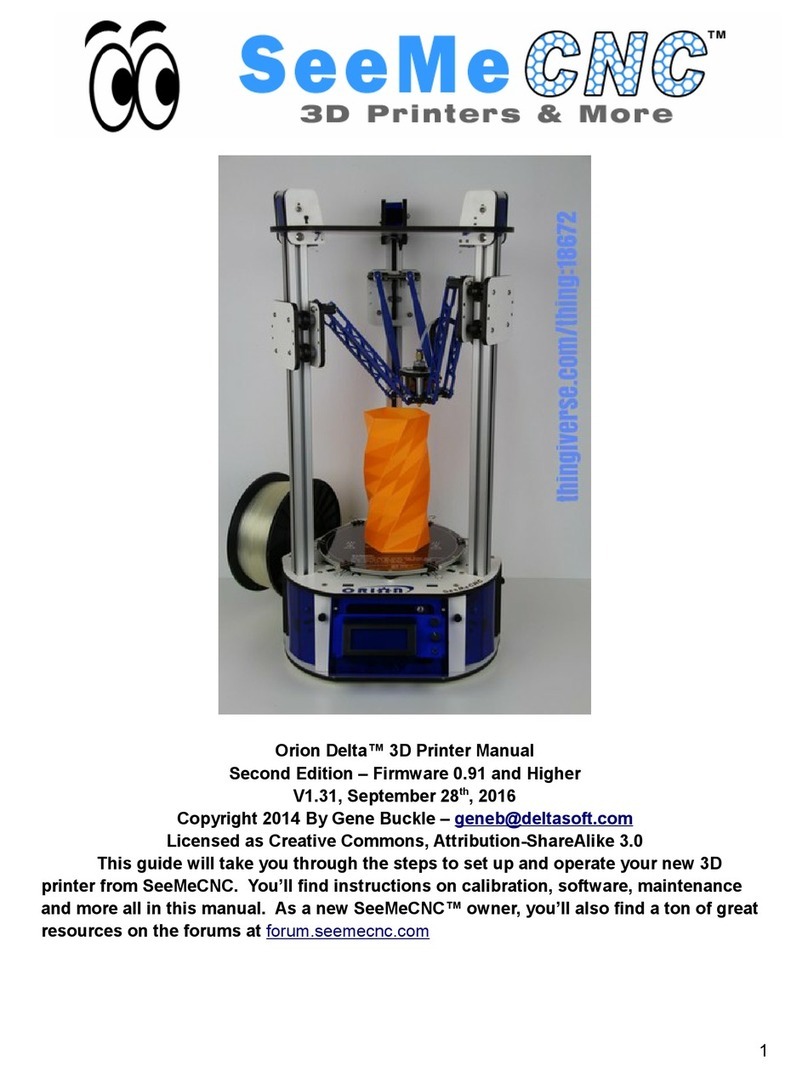

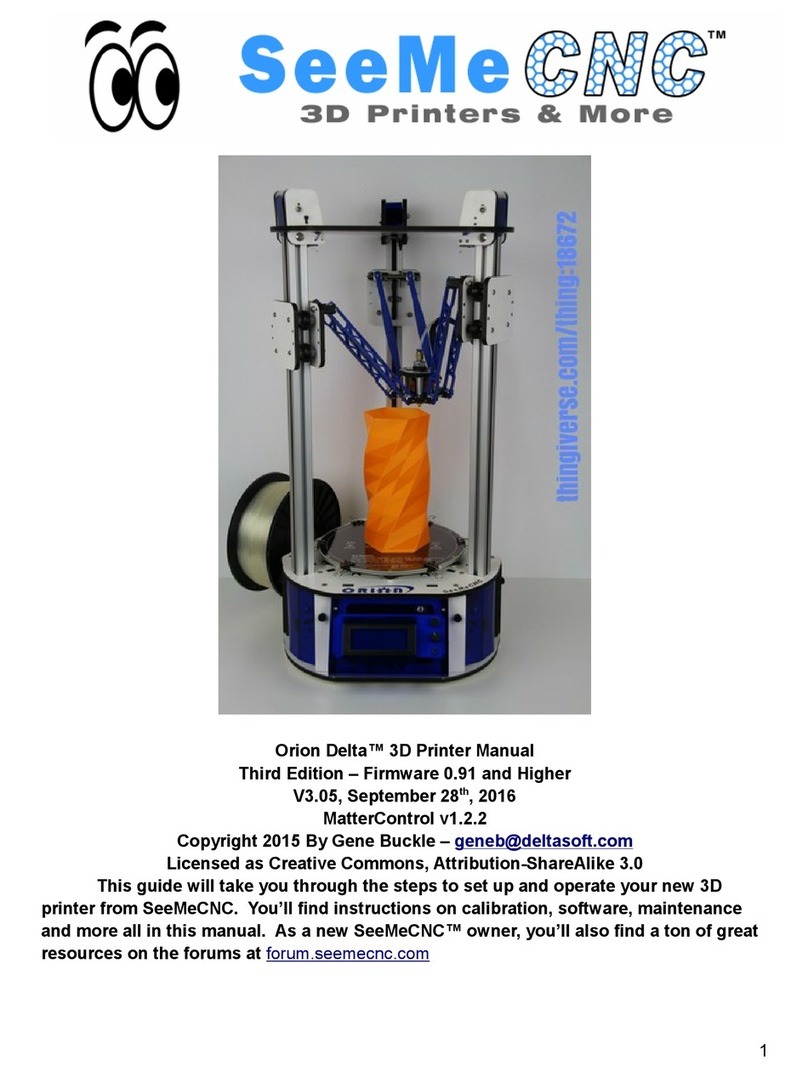

SeeMeCNC orion delta User manual

SeeMeCNC

SeeMeCNC Artemis User manual

SeeMeCNC

SeeMeCNC orion delta User manual

SeeMeCNC

SeeMeCNC Rostock Max User manual