DeFelsko POSITECTOR RTR User manual

Quick Guide v. 1.3

Replica Tape Reader

With the Gage powered down...

1. Clean the probe with the included cleaning card. (pg. 5)

2. Power-up Gage by pressing the center navigation button.

3. Zero the probe. (pg. 6)

4. Verify Gage accuracy (pg. 5)

5. Measure the burnished replica tape (pg. 4)

Introduction

The PosiTector Replica Tape Reader (RTR) is a hand-held

electronic instrument that measures burnished Testex Press-O-

FilmTM replica tape to produce peak-to-valley surface profile height

measurements. It consists of a PosiTector body (Standard or

Advanced) and probe.

This Quick Guide summarizes the basic functions of the Gage.

Download the full instruction manual at: defelsko.com/manuals

Quick Start

The PosiTector RTR powers-up when the center navigation

button is pressed. To preserve battery life, the Gage powers

down after approximately 5 minutes of no activity. All settings are

retained.

To ensure best accuracy, the user will be prompted to zero

the probe every time the Gage is powered-up. It is therefore a

good idea to clean the probe regularly with the included cleaning

card. Cleaning is best performed when the Gage is powered down.

NOTE:

To navigate, use the Up and Down buttons to scroll vertically and

to SELECT.

Menu Operation

Gage functions are menu controlled. To access the Menu,

power-up the gage, then press the center navigation button.

Press the (+)button to switch

pages in a multipage menu.

Press the (

-

)button to return

to the previous menu or page.

Select Exit to exit from any menu.

Previous Page

(Exit) Up Next Page

Access the Menu

(Center/Select)

Down

1

2

Press-O-Film Replica Tape

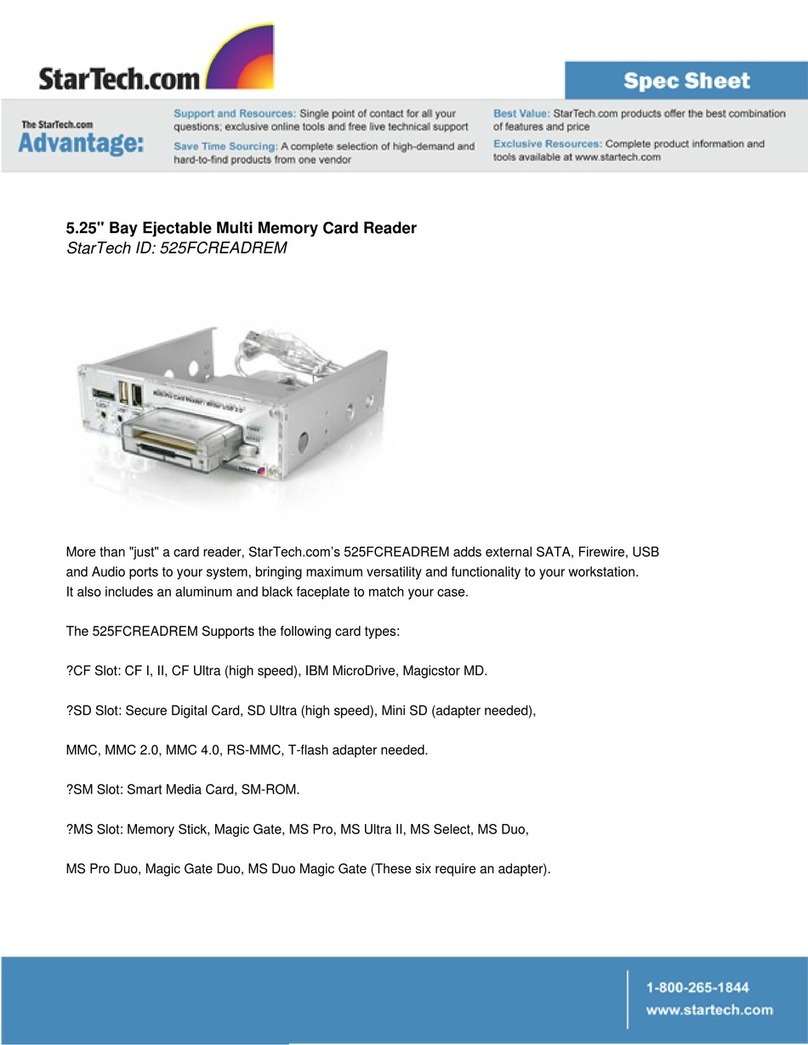

Press-O-Film provides a simple way to obtain an impression of

a surface for analysis. It consists of a layer of crushable plastic

micro foam affixed to a 50.8 µm (2 mil) incompressible polyester

film. When compressed against a roughened surface, the foam

collapses and acquires an accurate impression, or reverse

replica, of the surface. It is available in

Coarse (C) and X-Coarse (XC) grades

to accommodate measurements in

different profile ranges.

Placing the compressed tape (replica) into the PosiTector RTR

gives a measure of the average maximum peak-to-valley height

of the surface roughness profile. The Gage automatically subtracts

the thickness of the polyester film from all measurements.

Probes

When powered-up, the PosiTector automatically

determines which probe is attached and does a self-

check.

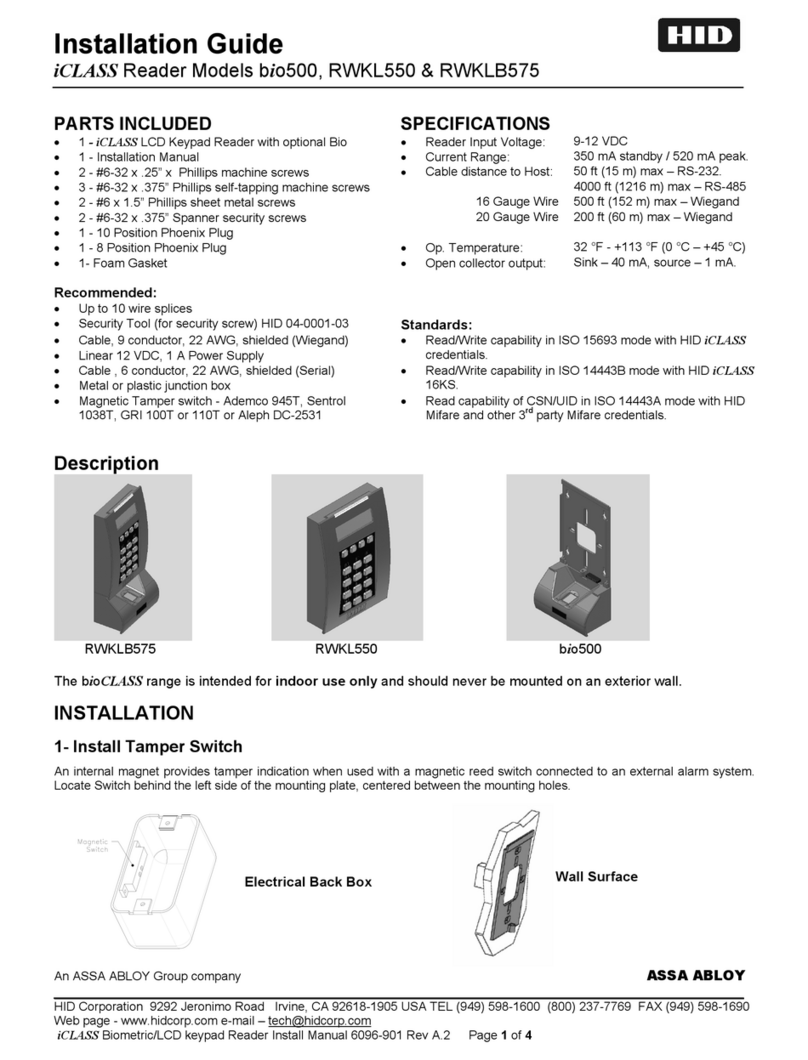

To disconnect a probe from a body, slide the plastic

probe connector horizontally (in the direction of the

arrow) away from the body. Reverse these steps to

attach a different probe. It is not necessary to power-

down the Gage when switching probes.

The PosiTector gage body accepts a wide variety of

probe types including magnetic, eddy-current and

ultrasonic coating thickness, surface profile,

environmental, hardness, salt contamination and

ultrasonic wall thickness probes. See

www.defelsko.com/probes

3

How to Measure

Prepare the test surface

Burnish the replica tape (create a replica)

1. Prepare the test surface

2. Burnish the replica tape

3. Prepare the Gage

4. Measure

Locate a representative site for measurement. Clean

the surface to be tested. DeFelsko recommends the

use of the included putty to remove dust, debris, or

residual blast media from the surface.Firmly press the

putty onto the surface using your fingers, and remove.

Select the appropriate grade of replica

tape based on the target profile. See

tape instructions for assistance.

Pull a single adhesive-backed replica

tape free of its release paper. A “bull’s

eye” circle of paper should remain on

the release paper (it is not used for

measurement).

Apply replica tape to blasted surface. Press the adhesive-

backed ends of the tape to hold it firmly in place during the

burnishing process.

Firmly compress the foam using the rounded

end of the included stainless steel burnishing

tool. Apply sufficient pressure in a circular and

x-y rubbing motion to produce a

replica with a

uniform pebble grain appearance. Excessively

hard rubbing should be avoided because the polyester film

could become

distorted. It normally takes 30 to 60 seconds to

fully compress all parts of the foam on most surfaces. After

burnishing is complete, remove the replica tape from the surface.

Prepare the Gage

Measure

Power-up the Gage by pressing the center navigation button.

An image appears indicating that the probe requires zeroing.

Simultaneously press and hold both probe buttons

firmly until the Gage beeps and the arrows point

outward. Do not place anything in the

measurement opening during this procedure.

Measure the included check shim to verify accuracy (pg. 5).

Ensure the correct grade of replica tape, C or XC, is displayed in

the upper left corner of the gage display (pg. 6).

Insert the burnished replica tape into the

probe opening as far as it will go. Ensure

the tape is properly positioned so that the

burnished region is centered within the

opening with the adhesive (sticky) side down.

To position the tape, align the two dots (printed on replica tape)

with arrows on both sides of the measurement opening.

Align dots with arrows on probe

4

If you are using older tape that does not have the printed dots,

simply align by centering the tape within the measurement opening.

During measurement, a constant anvil pressure is applied to the

replica tape regardless of how hard the two buttons are pressed.

The Gage automatically subtracts the 50.8 µm (2 mil) of

incompressible polyester film. No further adjustments are required.

1. Ensure tape is properly positioned.

2. Firmly press both probe buttons simultaneously and hold until

the Gage beeps and the surface profile height ( )

measurement is displayed. The tape can now be safely

removed.

With the Gage powered-down, clean the measurement surfaces

using the included cleaning card. Swipe the card through the

probe opening a few times while firmly pressing both probe

buttons to remove dust particles and residual tape adhesive.

5

3.

The surface profile height ( ) measurement is immediately

displayed. The tape can now be removed.

The probe contains two measuring surfaces that can become

contaminated with dust particles and residual tape adhesive.

It is therefore a good idea to clean the probe regularly with the

included cleaning card. Cleaning is essential prior to performing

a probe Zero (pg. 6) or a verification of accuracy (pg. 5).

Cleaning is best performed when the Gage is powered off.

With the Gage powered-down, swipe the card through the probe

opening a few times while firmly pressing both probe buttons.

The card can also be used to clean the surfaces of analog spring

micrometers. Replacement cards are available from your dealer.

Cleaning Card

erification of Accuracy

Calibration

Gage calibration is typically performed by the manufacturer or

accredited lab. All PosiTector RTR probes include a Certificate

of Calibration.

Calibration & erification of Accuracy

Ensure that the probe has been cleaned with the included cleaning

card (pg.5) and that the probe has been zeroed (pg. 6).

erify accuracy of the peak height measuring system

Place the PosiTector RTR Check Shim into the probe opening.

The average of several measurements should be within the com-

bined tolerance of both the Gage and the shim. If not, the Gage

may need to be returned to your dealer for service.

The check shim is specifically intended for all PosiTector RTR

probes. The Gage is designed to measure burnished replica tape

within a limited measuring range and automatically subtracts 50.8

µm (2 mil) from height measurements to account for the incom-

pressible polyester film. Therefore plastic shims intended for other

instruments such as coating thickness gages will not be meas-

ured properly.

6

Tape Grade

Cal Settings Menu

The probe should be zeroed regularly to ensure best accuracy.

The user will be prompted to zero the probe every time the Gage

is powered-up. The

Zero

menu item allows the procedure to be

performed at more regular intervals. It is particularly useful during

long measurement sessions.

Important:

Clean the probe with the included cleaning card

(pg. 5) before performing a probe zero.

1. Select

Zero

from the

Cal Settings

menu

2. Simultaneously press and hold both probe buttons firmly until

the Gage beeps and the arrows point outward. Do not place

anything in the measurement opening during this procedure.

Zero

Selects a replica tape grade. Required when

Linearize

mode ( L)

is ON.

C - Coarse

XC - Extra Coarse (default)

Simultaneously press and hold both probe buttons

firmly until the Gage beeps and displays “0”. This can be

performed from the main measurement screen without having to

access the menu.

Coarse Minus and X-Coarse Plus grades are not

supported in Linearize mode since the only function of these two

grades is to improve upon the accuracy of C tape at its low end

and XC tape at its high end, something the

PosiTector

RTR will

automatically do when measuring L. When Linearize mode is

OFF, the

PosiTector

RTR will measure all grades of replica tape

just like a conventional spring micrometer.

NOTE:

S ORTCUT:

Linearize

This is the default measurement mode. Linearize mode is ON when

this box is ticked and the " L" appears on the display.

An undesirable characteristic of replica tape is that measurements

made with analog spring micrometers are most accurate near the

middle of each grade's range and least accurate at the outer ends

of each grade's range. That is why two other grades, Coarse Minus

and X-Coarse Plus, are used to check and, if necessary, adjust

measurements at the lower and upper ends of the primary range of

20-115µm (0.8-4.5 mils).

Inside the primary range, the upper end of Coarse grade’s range

and the lower end of X-Coarse grade’s range share a 38 - 64 µm

(1.5 - 2.5 mil) "overlap" region. Current Testex instructions describe

a relatively complicated and time consuming procedure (the

average of one reading using Coarse grade and one reading using

X-Coarse grade) that is used to knit the Coarse and X-Coarse sub-

ranges together to achieve reasonably accurate readings over the

primary range. This method is a compromise between accuracy and

ease of use.

When the Linearize box is NOT ticked, the PosiTector RTR

displays a height value of comparable to the value an analog

spring micrometer would display after the 50.8 µm (2 mil) of

incompressible polyester film has been subtracted. In other words,

it is the average of the maximum peak-to-valley distances obtained

by measuring the thickness of the replica tape without any

correction.

When the Linearize box IS ticked, the PosiTector RTR displays a

more accurate peak-to-valley height measurement Lthat has

been adjusted for the non-linearity of replica tape. There is no need

to average 2 or more replicas from different grades of tape AND

there is no need to subtract the 50.8 µm (2 mil) of incompressible

polyester film. Ensure the proper tape grade, C or XC, has been

selected (pg. 6) and appears in the upper left corner of the display.

During measurement, if the linearized measurement falls outside

of the selected tape grade's range, the Gage will suggest a more

suitable tape grade to perform the measurement.

7

Selects the type of batteries used in the Gage from a choice of

“Alkaline”, “Lithium”or“NiM ” (Nickel-metal hydride rechargeable).

If NiM is selected, the Gage will trickle charge the batteries while

connected via USB to a PC or optional AC charger. The battery

state indicator icon is calibrated for the selected battery type. No

damage will occur if the wrong battery type is selected. DeFelsko

recommends the use of eneloop (NiM ) rechargeable batteries.

Battery Type

A statistical summary will appear on the

display. Remove the last measurement by pressing the (–) button.

Press (+) to clear statistics.

Statistics

σStandard Deviation

Minimum Value

Average

Maximum Value

x

8

Reset

Reset (menu reset) restores factory settings and returns the Gage

to a known condition. The following occurs:

- All batches and stored datasets, batch names and screen

captures are erased.

- Menu settings are returned to the following:

Memory = OFF

Statistics = OFF

Memory Display = None

Bluetooth = OFF

WiFi = OFF

Date, Time and WiFi are not affected by either Reset.

Units = microns

Flip Display = Normal

Sound = ON

Language = English

Battery Type = Alkaline

Backlight = Normal

USB Drive = ON

Auto Sync = OFF

Setup Menu

Tape Grade = XC

Linearize = ON

NOTE:

Perform a more thorough Hard Reset as follows:

1 Power down the Gage and wait 5 seconds.

2 Simultaneously press and hold the (+) and center

buttons until the Reset symbol appears.

This returns the Gage to a known, “out-of-the-box” condition.

It performs the same function as a menu Reset with the addition of:

- Bluetooth Pairing info is cleared.

- Alarm settings are set to defaults.

- Menu settings are returned to the following:

9

Advanced models store 100,000 readings in up to 1,000 batches.

“New Batch” closes any currently opened batch and creates a

new batch name using the lowest available number. The icon

appears. New batches are date stamped when they are created.

Accessing Stored Measurement Data

DeFelsko offers the following free solutions for viewing, analyzing

and reporting data:

PosiSoft USB Drive - Connect the Gage to a PC/Mac using the

supplied USB cable. View and print readings and graphs using

universal PC/Mac web browsers or file explorers. No software or

internet connection required. USB Drive must be selected in the

Gage’s “Connect > USB” menu (pg. 10).

PosiSoft Desktop - Powerful desktop software (PC/Mac) for

downloading, viewing, printing and storing measurement data.

Includes a customizable, templated PDF Report Generator. No

internet connection required.

PosiSoft.net - Web-based application offering secure, centralized

storage of measurement data. Access your data from any web-

connected device.

PosiTector App - (Advanced model only, /n 784000+) App for

compatible iOS and Android smart devices. Permits users to create,

save and share professional PDF reports. Add images and notes

using the smart device’s camera and keyboard.

Create a new batch

(Advanced only)

The PosiTector RTR has internal memory storage for recording

measurement data. Stored measurements can be reviewed

on-screen or accessed via computers, tablets and smart phones.

Measurements are date and time-stamped.

Standard models store up to 250 readings in one batch.

This Quick Guide summarizes the basic functions of the

Gage. Download the full instruction manual at:

www.defelsko.com/manuals

Memory Management

NOTE:

Scroll through display

modes (Advanced only)

Delete last reading

Access the Menu

Restore brightness

after dimming

10

The above WiFi, USB and Bluetooth menus contain a Sync .net

Now option. When selected, the Gage immediately synchronizes

stored measurement data via its respective communication

method (internet connection required). Alternatively, select Auto

Sync .net from within the USB connect menu to automatically

synchroniz e upon connection to a PC. Additional measurements

added to memory while connected are synchronized only when the

USB cable is disconnected and reconnected, or when the Sync

.net Now option is selected. WiFi connected gages automatically

attempt synchronization upon power-up.

Sync .net Now

Connect Menu

Connect Menu

When USBDrive is checked , the PosiTector gage uses a

USB mass storage device class which provides users with a

simple interface to retrieve stored data in a manner similar to

USB flash drives, digital cameras and digital audio players.

USB Drive is also required to import stored measurements into

PosiSoft Desktop software (pg. 9).

When connected, power is supplied through the USB

cable. The batteries are not used and the body will not

automatically power down. If rechargeable (NiM ) batteries are

installed, the instrument will trickle charge the batteries.

Allows individual datasets to be sent to a computer, printer or

compatible device as they are taken using Bluetooth wireless

technology. See www.defelsko.com/bluetooth

Bluetooth (Advanced model only)

Allows connection to your local wireless network or mobile hot

spot. Ideal for using your network’s internet connection for

synchronizing stored measurements with PosiSoft.net (pg. 9).

See www.defelsko.com/wifi

WiFi (Advanced model only)

NOTE:

USB

PosiSoft Desktop is required when using a USB

connection to synchronize measurements with PosiSoft.net.

NOTE:

11

Determine if a software update is available for your Gage.

See www.defelsko.com/update

Transfers selected batches to the PosiTector App (useful

when switching between devices).

The Send Batches option is visible in the menu when the Gage

is connected to a smart device running the PosiTector App.

Sync Batches

Select batches to flag them for synchronization to the

PosiTector App. New batches created while Bluetooth Smart is

enabled are automatically selected.

With Bluetooth Smart enabled, select Sync Batches to transfer

selected batches to the PosiTector App. This is useful when

switching between smart devices, as only datasets and batches

that have yet to be synchronized with any smart device are

synchronized automatically.

The Gage will perform a Hard Reset (pg. 8) after

an update. All stored measurements will be erased from memory.

Updates

WARNING:

When Enabled , allows communication with a smart device

running the PosiTector App (pg. 9) via auto-pairing Bluetooth

Smart (BLE) wireless technology.

Bluetooth Smart

(Advanced model only, erial number 784000 and greater)

Send Batches

If Bluetooth Smart is disabled, data from batches

selected in the Sync Batches menu are held in a queue until

communication with the PosiTector App is re-established.

NOTE:

12

www.defelsko.com

© 2018 DeFelsko Corporation USA

All Rights Reserved

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole or

part, by any means, without written permission from DeFelsko Corporation.

DeFelsko and PosiTector are trademarks of DeFelsko Corporation registered in the U.S. and in other countries.

Other brand or product names are trademarks or registered trademarks of their respective holders.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not

responsible for printing or clerical errors.

Limited Warranty, Sole Remedy

and Limited Liability

DeFelsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on

its website: www.defelsko.com/terms

Returning for Service

Before returning the Gage for service…

1.Install new or newly recharged batteries in the proper alignment

as shown within battery compartment

2.Clean the measurement opening using the cleaning card (pg. 5)

3.Perform a Hard Reset (pg. 8)

4.Verify accuracy (pg. 5)

5.If issue is not resolved, Update (pg. 11) your PosiTector gage

body and re-attempt measurements.

IMPORTANT:

If you must return the Gage for service, please fill out and

include the Service Form located at www.defelsko.com/support

with the Gage. Be sure to also include the probe, your company

name, company contact, telephone number and fax number or

email address.

Guía Rápida v. 1.0

Lector de cinta de réplica

Con el medidor apagado:

1. Limpie la sonda con la tarjeta de limpieza facilitada. (Pág. 5)

2. Encienda el medidor pulsando el botón central.

3. Ajuste a cero la sonda. (Pág. 6)

4. Mida la galga de comprobación suministrada para verificar la

exactitud (Pág. 5)

5. Mida el perfil de la cinta de réplica (Pág. 4)

1

Introducción

El

PosiTector

Replica Tape Reader (RTR) es un instrumento

eléctrico portátil que mide el perfil de la cinta de réplica Testex

Press-O-Film para producir mediciones del perfil de anclaje de

una superficie. Está formado por un cuerpo (Standard o

Advanced) y una sonda.

Esta guía rápida recoge las funciones básicas del medidor.

Descargue el manual de instrucciones en:

defelsko.com/manuals

Inicio rápido

El PosiTector RTR arrancará cuando se pulse el botón

central. Para ahorrar energía, el medidor se apagará tras unos 5

minutos de inactividad. Se conservarán todas las configuraciones.

Arriba

Abajo

Centro

Para desplazarse utilice los botones Arriba y

Abajo y para SELECCIONAR.

Seleccione Salir para salir de cualquier

menú.

Botón central

El botón central está rebajado a propósito para

evitar que se encienda de manera no intencionada.

Menú de operación

Las funciones del medidor se controlan con un menú. Para

acceder al menú, encienda el medidor y pulse el botón central.

NOTA:

Para garantizar una mayor precisión el usuario deberá

poner a cero la sonda cada vez que encienda el medidor. Por lo

tanto será deseable limpiar la sonda regularmente con la tarjeta

de limpieza incluida. La limpieza se realizará mejor cuando el

medidor esté apagado.

NOTA:

Sondas

2

Para desconectar una sonda de un cuerpo apague el

medidor y deslice el conector de plástico de la sonda en

sentido horizontal fuera del cuerpo (siguiendo la flecha).

Invierta los pasos para conectar una nueva sonda.

Una vez encendido, el PosiTector determinará

automáticamente el tipo de sonda conectado y

realizará una comprobación automática.

Cinta de réplica Press-O-Film

Además, el PosiTector acepta varios tipos de sonda incluyendo

sondas magnéticas para espesores de recubrimiento y por

corrientes de Foucault, para perfiles de superficie, ultrasónicas

para espesores de pared y ambientales.

Para obtener la información más reciente sobre la compatibilidad

de la sonda consulte www.defelsko.com/probes

Press-O-Film ofrece un método simple para obtener una

impresión de una superficie para su análisis. Se trata de una

lámina de plástico recubierta de microespuma plástica deformable

adherida a una película de 50.8 µm (2 mil) incompresible de

poliéster. Al comprimirse contra una superficie rugosa, la espuma

adquirirá una impresión precisa o réplica

inversa de la superficie. Se vende en

diferentes grados para acomodar las

medidas a diferentes rangos de perfil.

Al colocar la cinta comprimida (réplica) en el PosiTector RTR

dará una medida del promedio de la altura máxima entre pico y

valle del perfil rugoso de la superficie. El medidor sustraerá

automáticamente el espesor del sustrato de poliéster de todas

las mediciones.

3

Cómo medir

Preparación de la superficie de prueba

Creación de una réplica

1. Prepare la superficie del área de prueba

2. Perfile la cinta de réplica

3. Prepare el medidor

4. Realice la medición

Encuentre un lugar representativo para la

medición. Limpie la superficie que va a

comprobar. DeFelsko recomienda el empleo de la

masilla suministrada para retirar el polvo, la

suciedad o la granalla residual de la superficie.

Presione con fuerza la masilla sobre la superficie

utilizando los dedos y retírela.

Seleccione el grado apropiado de la cinta de réplica según el

perfil deseado. Consulte las instrucciones de la cinta.

Coloque una cinta de réplica autoadhesiva retirando su papel

protector. Un círculo de "ojo de buey" de papel deberá quedar

en el papel de protección (no se utiliza para la medición).

Aplique la cinta de réplica en la superficie.

Presione los extremos adhesivos del papel

para sujetarlo firmemente en su lugar

durante el proceso de perfilado.

Comprima firmemente la película de réplica utilizando el

extremo redondeado de la herramienta de pulido de acero

inoxidable. Aplique una presión suficiente en círculo y frote en

sentidos transversales para producir una réplica con un aspecto

de grano uniforme. Normalmente se requieren de 30 a 60

segundos para comprimir completamente todas las partes de la

película en la mayoría de las superficies.

En general, el exceso de compresión es más

seguro que demasiado poca. Una vez

finalizado el perfilado retire la cinta de réplica

de la superficie.

4

Preparación del medidor

Con el medidor apagado, limpie las superficies de medición

utilizando la tarjeta de limpieza facilitada. Deslice la tarjeta a

través de la ranura varias veces mientras presiona firmemente

los dos botones de la sonda para eliminar las partículas de polvo

y el adhesivo residual de la cinta.

Encienda el medidor pulsando el botón central. Aparecerá una

imagen que indica que la sonda requiere su puesta a cero.

Pulse y mantenga con firmeza simultáneamente ambos botones

de la sonda hasta que el medidor emita un pitido y las flechas

apunten hacia el exterior. No coloque nada en la ranura de

medición durante este procedimiento.

Mida la galga de comprobación suministrada para verificar la

exactitud (Pág. 5). Asegúrese de que el grado de la cinta de

réplica adecuado (C o XC) se muestra en la esquina superior

izquierda de la pantalla LCD (pág. 6).

Inserte la cinta de réplica pulida en la ranura

de medición. Asegúrese de que la cinta esté

colocada correctamente para que el área

pulida esté centrada en la ranura en la sonda.

Para colocar la cinta, alinee los dos puntos (impresos en la cinta de

réplica) con las flechas en ambos lados de la ranura de medición.

Alinee los puntos con

las flechas en la sonda

Si está utilizando una cinta antigua que no tiene los puntos impresos,

simplemente alinee centrando la cinta en la ranura de medición.

Una vez colocado, presione con firmeza simultáneamente los dos

botones de la sonda y mantenga la sonda hasta que el medidor

emita un pitido y muestre la medición. Durante la medición se

aplicará una presión constante en la cinta de réplica con

independencia de la aplicada en los botones. El medidor restará

automáticamente los 50.8 µm (2 mil) de la película incompresible de

poliéster. No se requieren ajustes adicionales.

Medición

5

Comprobación de la precisión

La precisión del medidor se verificará utilizando la galga de

comprobación suministrada. Asegúrese de que la sonda se ha

limpiado con la tarjeta de limpieza (arriba) y que se ha puesto a

cero la sonda (Pág. 6).

Coloque la galga de comprobación en la ranura de medición. La

media de varias mediciones debería encontrarse entre las

tolerancias combinadas del medidor y la galga. Si no, deberá

devolver su medidor a su distribuidor para reparación.

La galga de comprobación está diseñada de manera especial

para el PosiTector RTR. El medidor está diseñado para medir el

perfil de anclaje de una cinta de réplica en un rango limitado y

automáticamente sustraerá 50.8 µm (2 mil) del perfil para contar

con la película de poliéster incompresible. Por lo tanto las

galgas de plástico destinadas a otros instrumentos tales como

medidores de espesor de recubrimiento no medirán

correctamente.

Calibración

El fabricante o un laboratorio acreditado realizará normalmente

la calibración del medidor. Todas las sondas incluyen Certificado

de Calibración.

La sonda tiene dos superficies de medición que pueden

contaminarse con partículas de polvo y adhesivo residual de la

cinta. Por lo tanto será deseable limpiar la sonda regularmente

con la tarjeta de limpieza incluida. La limpieza es esencial antes

de poner a cero la sonda (Pág.6) o comprobar la precisión

(Pág.5). La limpieza se realizará mejor con el medidor apagado.

Con el medidor apagado, pase la tarjeta por la ranura un par de

veces mientras presiona firmemente los dos botones de la

sonda.

La tarjeta también podrá utilizarse para limpiar las superficies de

micrómetros analógicos de muelle. Su distribuidor dispone de

tarjetas de recambio.

Tarjeta de limpieza

Calibración y comprobación de la precisión

Other manuals for POSITECTOR RTR

2

Table of contents

Languages:

Other DeFelsko Card Reader manuals