DeFelsko PosiTector RTR 3D User manual

Instruction Manual v.1.0

Replica Tape Reader

3D

3D

1

Table of Contents

Introduction 2

Quick Start 2

PosiTector Body 3

Probes 4

Certification 4

Press-O-Film Replica Tape 5

How to Measure 6

Cleaning the Probe

Opening (Anvils) 9

Calibration & Verification

of Accuracy 10

Menu Operation 11

Cal Settings Menu 12

Zero 12

Tape Grade 12

Linearize 12

Setup Menu 13

Reset 13

Gage Info 13

Peak Density (Spd) 22

2D Images 14

3D Images 14

Sound 15

Units 14

Language 15

Memory Management 16

Standard Models 16

Advanced Models 17

Annotate 18

Display 19

Summaries 19

Screen Capture 19

Save SDF 20

Accessing Stored

Measurement Data 24

PosiSoft.net 24

PosiSoft 4.0 Desktop Software 24

PosiTector App 24

Connect Menu 24

WiFi 24

Access Point 25

USB 26

USB Serial Streaming 26

Sync.net Now 27

Bluetooth Smart 27

Bluetooth 28

Updates 28

Technical Data 30

Power Supply / Battery Indicator 29

Returning For Service 30

Warranty 30

2

Introduction

The PosiTector Replica Tape Reader (RTR-3D) is a hand-held

electronic instrument that measures burnished Testex Press-O- FilmTM

replica tape and uses a light intensity versus thickness algorithm to

produce three-dimensional (3D) images of the replicated surface.

Images generated within the gage are analyzed to produce 2D and 3D

parameters that represent specific characteristics of a surface.

Quick Start

The PosiTector RTR-3D powers-up when the center navigation

button is pressed. To preserve battery life, the Gage powers

down after approximately 5 minutes of no activity. All settings are

retained.

To ensure best accuracy, the user will be prompted to zero the probe

every time the Gage is powered-up. It is therefore good practice to clean the

probe regularly with the included cleaning card and microfiber cloth. Cleaning is

best performed when the Gage is powered down.

NOT :

Measurement RTR-3D

Peak Height H & Linearized Peak Height HLl

2D/3D Parameters* l

2D/3D images (pg. 14)* Advanced model only

Save SDF surface data file (pg. 20)* Advanced model only

With the Gage powered down...

1. Clean the probe with included cleaning card and microfiber

cloth. (pg. 9)

2. Power-up Gage by pressing the center button.

3. Zero the probe. (pg. 12)

4. Verify Gage accuracy. (pg. 10)

5. Measure the burnished replica tape. (pg. 8)

* Optical Grade Replica Tape is required for measuring 2D/3D parameters (pg. 5)

Tape Selection (pg. 5)

Tape Grade Height Measurement 2D/3D Parameters

Coarse (C) l

X-Coarse (XC) l

Optical Grade

Coarse (C) l

Optical Grade

X-Coarse (XC) l l

3

Typical Display

By Default, the PosiTector

RTR-3D displays a three-

dimensional (3D) image of

the replicated surface, HL,

Spd, Ra and Sa parameters.

Displayed parameters and

images may be modified from

the Analysis Setup (pg. 21)

and Setup (pg. 13) menus.

PosiTector body

PosiTector bodies accept all interchangeable probes including

surface profile (RTR/SPG), coating thickness (6000/200),

environmental (DPM), Shore Hardness (SHD), soluble salt (SST), and

ultrasonic wall thickness (UTG) probes.

Updates: Keep your PosiTector current with software updates

containing the latest features, functionality and

probe compatibility (see Updates pg. 28).

Wrist Strap: We recommend attaching and

wearing the supplied wrist strap.

Protective ens Shield: The PosiTector display is covered with a

thin plastic film for protection against fingerprints and other marks

during shipment. This film, while usually removed before using the

Gage, can be left in place to protect against paint overspray or debris.

Replacements can be purchased.

USB Port

Display

Probe

connector

Connected probe

type is displayed

during power-up

1

2

Tape Grade

Areal Peak

Density

3D Image

Linearized

Peak Height

Roughness

Average 3D Roughness

Average 2D

Default Display

T

4

When powered-up, the PosiTector automatically determines which

probe is attached and does a self-check.

To disconnect a probe from a body, slide the plastic probe connector

horizontally (in the direction of the arrow) away from the body.

Reverse these steps to attach a new probe.

Probes

It is not necessary to power-down the gage when

interchanging probes.

NOT :

Probe

Connector

Measurement

Opening

(Anvils)

Camera

Button-Operated

Spring Micrometer

applies constant

anvil pressure

PosiTector RTR 3D probe

Certification

PosiTector RTR probes include a Certificate of Calibration.

For organizations with re-certification requirements, instruments may

be returned at regular intervals for calibration.

DeFelsko recommends that customers establish calibration intervals

based upon their own experience and work environment. Based on

our product knowledge, data and customer feedback, a one year

calibration interval from either the date of calibration, date of

purchase, or date of receipt is a typical starting point.

5

Press-O-Film Replica Tape

Press-O-Film provides a simple way to obtain an impression of a

surface for analysis. It consists of a layer of crushable plastic micro

foam affixed to a 50.8 µm (2 mils) incompressible polyester film. When

compressed against a surface, the foam collapses and acquires an

accurate impression, or reverse replica, of the surface.

Several grades of replica tape are available:

Tape Grade H Range 2D/3D Range Order Code

Coarse (C) 20 to 64 µm

0.8 to 2.5 mils ---------- R-PR SS

X-Coarse (XC) 40 to 115 µm

1.5 to 4.5 mils ---------- R-PR SSX

Optical Grade

Coarse (C)

20 to 64 µm

0.8 to 2.5 mils R-PR SSOG

Optical Grade

X-Coarse (XC)

40 to 115 µm

1.5 to 4.5 mils

10 to 115 µm

0.4 to 4.5 mils R-PR SSXOG

If only the maximum peak-to-valley height is needed, then

conventional Coarse or X-Coarse can be used. Placing the

compressed tape (replica) into the PosiTector RTR-3D gives a

measure of the average maximum peak-to-valley height (H) of the

surface roughness profile. The Gage automatically subtracts the

thickness of the polyester substrate from all measurements. Press-

O-Film is available in Coarse (C) and X-Coarse (XC) grades to

accommodate measurements in different profile ranges.

Optical Grade Press-O-Film Replica Tape for 2D/3D Measurements:

When measuring 2D and 3D parameters, it is recommended to use

optical grade Press-O-Film. Optical grade tape provides higher

resolution images than conventional Press-O-Film replica tape. It is

available in both Coarse (C) and X-Coarse (XC). Choose the tape

grade that most closely matches the intended maximum peak to

valley height of the surface being measured.

6

Operating Principle

The PosiTector RTR-3D uses two measurement principles: a digital

micrometer to measure the overall height of the burnished replica

tape, and an optical system that projects light through the replica tape

and captures a two-dimensional black and white image.

The digital micrometer is used to measure the overall thickness of the

burnished replica tape. After subtracting the thickness of the

incompressible polyester film and linearizing the result (pg.12), this

thickness corresponds to the average maximum peak-to-valley height

(H).

It is known that replica tape transmits light proportionally to the degree

to which it is compressed. Peaks in the surface profile compress the

replica tape and result in bright spots, while valleys compress the

replica tape less, and result in dark spots. By recording the amount

of light transmission at each point on the burnished replica tape, a

precise 3D map of the surface can be generated. 2D and 3D surface

profile parameters can be measured.

The PosiTector RTR-3D uses a light intensity versus thickness

algorithm to produce three dimensional (3D) images of the replicated

surface burnished using Replica Tape. The image sensor produces a

1024x1024 pixel image that represents an approximate 3.8 mm x 3.8

mm image area. Images generated within the gage are analyzed to

produce 2D and 3D parameters that represent specific characteristics

of a surface.

How to Measure

1. Prepare the test surface

2. Burnish the replica tape

3. Prepare the Gage

4. Measure

1. Prepare the Test Surface

Locate a representative site for measurement. Clean the surface to

be tested. DeFelsko recommends the use of the included putty to

remove dust, debris, or residual blast media from the surface. Firmly

press the putty onto the surface using your fingers, and remove.

nsuring a clean surface is especially important when using

the PosiTector RTR-3D to measure 2D and 3D parameters or

generating SDF files for post processing.

NOT :

7

2. Burnish the replica tape (create a replica)

Select the appropriate grade of replica tape based on the target pro-

file. See tape instructions for assistance (pg. 5).

Pull a single adhesive-backed replica tape free of its release paper.

A “bull’s eye” circle of paper should remain on the release paper (it

is not used for measurement).

Apply replica tape to the surface. Press the adhe-

sive-backed ends of the tape to hold it firmly in

place during the burnishing process.

Firmly compress the foam using the rounded end of the included

stainless steel burnishing tool. Apply sufficient pressure in a

circular and x-y rubbing motion to produce a

replica with a uniform appearance.

Excessively hard rubbing should be avoided

because the polyester film could become

distorted. It normally takes 30 to 60 seconds to

fully compress all parts of the foam on most surfaces. After

burnishing is complete, remove the replica tape from the surface.

It is important to clean the anvils and camera lens before

each measurement of 2D and 3D parameters or generating SDF files.

(pg. 9).

NOT :

3. Prepare the Gage

Power-up the Gage by pressing the center navigation button. An

image appears indicating that the probe requires zeroing.

Simultaneously press and hold both probe buttons

firmly until the Gage beeps and the arrows point

outward. Do not place anything in the measurement

opening during this procedure.

nsure the correct grade of replica tape, C or XC, is

displayed in the upper left corner of the display (pg. 12).

8

4. Measure

Insert the burnished replica tape into the

measurement opening. nsure the tape is

properly positioned so that the burnished

region is centered within the opening in the

probe with the adhesive (sticky) side down.

To position the tape, move the tape to the back of the probe and align

the two dots (printed on replica tape) with arrows on both sides of the

measurement opening.

If you are using older tape that does not have the printed dots, simply

align by centering the tape within the measurement opening.

During measurement, a constant anvil pressure is applied to the

replica tape regardless of how hard the two buttons are pressed.

1. a) Firmly press both probe buttons simultaneously and hold

until the Gage beeps and the arrows point outward.

b) Remove your fingers from the tape and release both

probe buttons (do not hold or remove tape from gage).

c) Hold the gage steady while the probe measures the

compressed foam until the following graphic disappears.

Several images of the foam surface are captured during

each measurement. Image blurring will occur if the tape is

touched or removed during this time.

2. The surface profile height (HL) measurement is

immediately displayed. The tape can now be removed.

An hour glass will display while 2D and 3D parameters

are calculated.

Align dots with arrows on probe

9

Cleaning the probe opening (anvils)

The probe contains two measuring surfaces (anvils) and a camera

lens that can become contaminated with dust particles and residual

tape adhesive. It is therefore recommended to clean the probe

regularly with the included cleaning card and microfiber cloth. Cleaning

is essential prior to performing a probe zero (pg. 12) or a verification

of accuracy (pg. 10). It is best performed when the Gage is powered

down.

With the Gage powered-down, swipe the card through the opening a

few times while pressing both probe buttons. Then insert the included

microfiber cloth and gently wipe the surfaces of the anvils several

times by sliding the cloth back and forth with the probe buttons

pressed.

The cleaning card can also be used to clean the surfaces of analog

spring micrometers. Replacement cards and microfiber cloths are

available.

Cleaning the anvils is especially important when using the

PosiTector RTR-3D to measure 2D and 3D parameters or generating

SDF files.

xample of a 2D surface image taken with a PosiTector RTR-3D

Advanced before and after cleaning the anvils with the cleaning card

NOT :

Bef re Cleaning After Cleaning

10

Calibration & Verification of Accuracy

Calibration

Gage calibration is typically performed by the manufacturer or

accredited lab. All probes include a Certificate of Calibration.

Verification of Accuracy

nsure that the probe has been cleaned with the included cleaning

card (pg. 9) and that the probe has been zeroed (pg. 10).

Verify accuracy of the digital micrometer measuring system

Place the P siTect r RTR Check Shim into the probe opening. The

average of several measurements should be within the combined

tolerance of both the Gage and the shim. If not, the Gage may need

to be returned to your dealer for service.

The check shim is specifically intended for all PosiTector RTR

probes. The Gage is designed to measure burnished replica tape

within a limited measuring range and automatically subtracts 50.8

µm (2 mils) from height measurements to account for the

incompressible polyester film. Therefore plastic shims intended for

other instruments such as coating thickness gages will not be

measured properly.

Verify the optical measuring system

Place the Peak Density Check Tape into the probe opening. The peak

density (Spd) result should be within tolerance specified on the tape.

If not, the Gage may need to be returned to your dealer for service.

Ignore the peak height (H) result when using the Peak Density Check

Tape.

11

Menu Operation

Gage functions are menu controlled. To access the Menu, power-up

the Gage, then press the center navigation button.

Below is a sample menu for a PosiTector RTR-3D Advanced model:

RTR

Memory

Cal Settings

Setup

Analysis Setup

Connect

Power Off

Exit

Memory

Statistics

Cal Settings

Setup

Connect

Power Off

Exit

Sync Now

USB Drive

Auto Sync

Bluetooth

WiFi

Powder Probes

Updates

Exit

To navigate, use the Up and Down buttons to scroll vertically and

to SE ECT.

Press the (+)button to switch

pages in a multipage menu.

Press the (

-

)button to return to

the previous menu or page.

Select Exit to exit from any menu.

Previous Page

( xit) Up Next Page

Access the Menu

(Center/Select)

Down

Current selection is displayed

with white background

Some buttons have a tick box

to their right to indicate current

status. An empty box indicates

that feature is not active.

12

Tape Grade

Cal Settings Menu

The probe should be zeroed regularly to ensure best accuracy. The

user will be prompted to zero the probe every time the Gage is

powered-up. The

Zero

menu item allows the procedure to be

performed at more regular intervals. It is particularly useful during

long measurement sessions.

Important:

Clean the probe with the included cleaning card (pg. 9)

before performing a probe zero.

1. Select

Zero

from the

Cal Settings

menu

2. Simultaneously press and hold both probe buttons firmly until the

Gage beeps and the arrows point outward. Do not place anything in

the measurement opening during this procedure.

Zero

Selects a replica tape grade. Required when

inearize

mode (HL) is ON.

C - Coarse XC - xtra Coarse (default)

Simultaneously press and hold both probe buttons

firmly until the Gage beeps and displays “0”. This can be performed

from the main measurement screen without having to access the menu.

SHORTCUT:

inearize

nWhen the Linearize box IS ticked, the PosiTector RTR displays a

more accurate peak-to-valley height measurement HLthat has been

adjusted for the non-linearity of replica tape. There is no need to

average 2 or more replicas from different grades of tape AND there is

no need to subtract the 50.8 µm (2 mils) of incompressible polyester

film. nsure the proper tape grade, C or XC, has been selected (pg.

12) and appears in the upper left corner of the display.

nWhen the Linearize box is NOT ticked, the PosiTector RTR

displays a height value of H comparable to the value an analog

spring micrometer would display after the 50.8 µm (2 mils) of

incompressible polyester film has been subtracted. In other words, it

is the average of the maximum peak-to-valley distances obtained by

measuring the thickness of the replica tape without any correction.

During measurement, if the linearized measurement falls outside of

the selected tape grade's range, the Gage will suggest a more

suitable tape grade to perform the measurement.

13

Reset

Reset (menu reset) restores factory settings and returns the Gage to

a known condition. The following occurs:

- All batches and stored datasets, batch names and screen

captures are erased.

- Menu settings are returned to the following:

Memory = OFF

Memory Display = ON

2D* = ON

Bluetooth = OFF

WiFi = OFF

3D* = ON

Date, Time and WiFi are not affected by either Reset.

Units = microns

Flip Display = Normal

Sound = ON

anguage = nglish

Battery Type = Alkaline

Backlight = Normal

USB Drive = ON

Auto Sync = ON

Setup Menu

Tape Grade = XC

inearize = ON

NOT :

*PosiTector RTR-3D models only

Perform a more thorough Hard Reset as follows:

1. Power down the Gage and wait 5 seconds.

2. Simultaneously press and hold the (+) and center

buttons until the Reset symbol appears.

This returns the Gage to a known, “out-of-the-box” condition.

It performs the same function as a menu Reset with the addition of:

- Bluetooth Pairing info is cleared.

- Alarm settings are set to defaults.

- Menu settings are returned to the following:

Gage Info

Displays gage body/probe details including serial numbers,

PosiSoft.net registration key, remaining memory capacity for storage

of readings, date and time and software packages.

For security purposes, the serial number and registration key are

required to add the Gage to your PosiSoft.net account.

14

2D

Displays a two-dimensional (2D) black and white image of the

replicated surface. When Memory is on, this thumbnail image is

stored with each reading for inclusion into inspection reports.

Advanced models only

3D

Displays a low-resolution color three-dimensional (3D) image of the

replicated surface. When Memory is on, this thumbnail image is

stored with each reading for inclusion into inspection reports.

Advanced models only

Press the Up navigation button to toggle between 2D and

3D images if the image does not automatically appear on the

display.

NOT :

Units

Converts the display from inch to metric or vice versa. Stored

measurements in memory are not converted. Switching units will turn

off Statistics view and closes Memory.

15

Flip Display

This option causes the display to rotate 180°. Ideal for right-side

up viewing when the sensors are pointed away from the user.

Backlight

Selects display brightness (Sun, Normal or Night). All settings will dim

slightly after a period of no activity to conserve battery life.

Press the Down button to brighten the display.

Sound

When checked (default), the gage will emit various sounds for

activities such as successful measurement and for button presses.

Untick to turn sound off.

Set Clock

All measurements are date and time stamped (24 hour format) when

stored into memory. It is therefore important to keep both the date and

time current using this menu option. Use the Up and Down buttons

to scroll, and the (-) and (+) buttons to adjust a value. The Gage’s

date and time can also be viewed in Gage Info (pg. 13).

Selects the type of batteries used in the Gage from a choice of

“Alkaline”, “Lithium”or“NiMH” (Nickel-metal hydride rechargeable).

If NiMH is selected, the Gage will trickle charge the batteries while

connected via USB to a PC or optional AC charger. The battery

state indicator icon is calibrated for the selected battery type. No

damage will occur if the wrong battery type is selected.

Battery Type

DeFelsko recommends the use of eneloop (NiMH)

rechargeable batteries.

NOT :

anguage

Converts displayed and printed words to the selected language.

16

Memory Management

The PosiTector RTR has internal memory storage for recording

measurement data. Stored measurements can be reviewed on-

screen or accessed via computers, tablets and smart phones.

Measurements are date and time-stamped.

Button functions with Memory ON:

Create a new batch

(Advanced only)

Restore brightness

after dimming

Scroll through display

modes (Advanced only)

Delete last reading

Access the Menu

# of readings

in memory

Current Batch

Tape Grade Cutoff FilterShort Filter

Spd - Areal

peak densitiy

Ra - Roughness

Average 2D

H - Average

maximum peak-

to-valley height

Sa - Average

Roughness 3D

Default Memory Screen

17

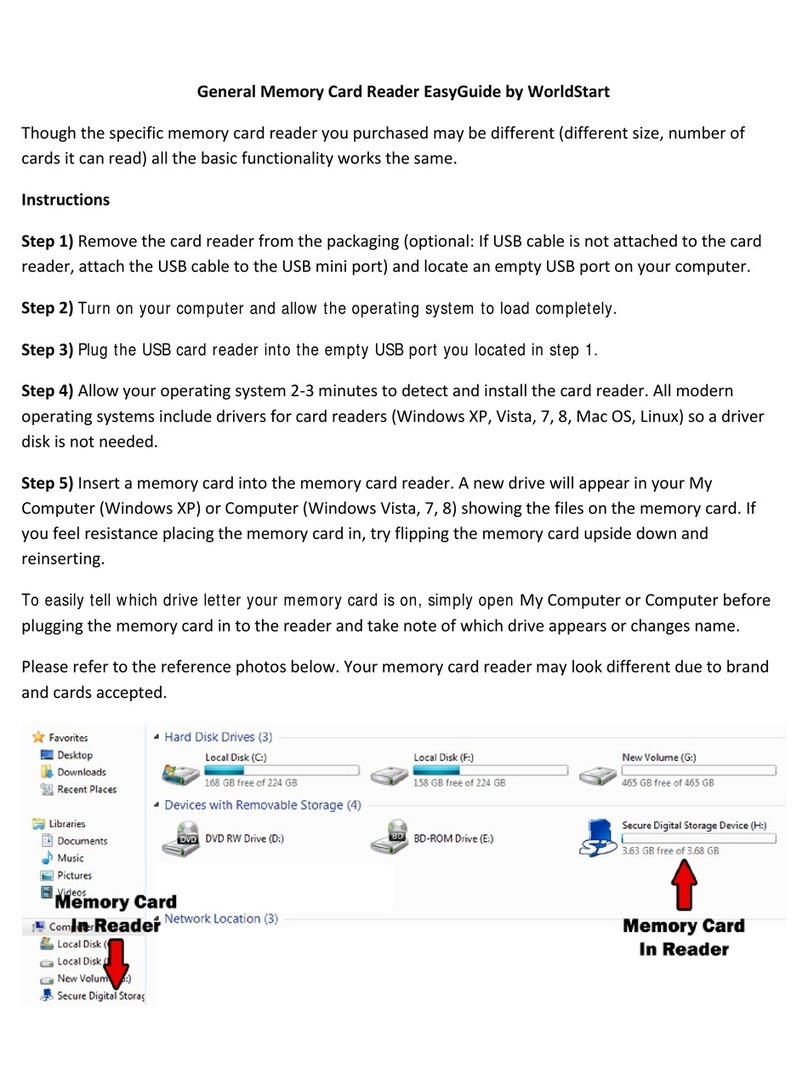

Standard models store up to 250 readings in one batch. The

Memory Menu includes the following options...

On: turns memory on and begins recording

Off: stops recording (stored readings remain in memory)

Clear: removes all readings from memory

View: lists group statistics and all stored readings on the display. It

will begin by showing statistics based on all readings in memory. Use

the Up and Down buttons to scroll through all readings. Press

to exit.

Advanced models store 100,000 readings in up to 1,000 batches.

2D/3D images are stored if checked within the Setup menu. The

Memory Menu includes the following options:

New Batch

Closes any currently opened batch and creates a new batch name

using the lowest available number. For example, if only Batch 1 and

Batch 3 exist, then Batch 2 would be created and made the current

batch. The icon appears. ach measurement will be displayed

and stored into this new batch. New batches are date stamped when

they are created. ach reading is also data/time stamped.

When a batch is open, press (+) to create a new batch

SHORTCUT:

lRemove the last reading from the current open batch by pressing (-).

lIf memory is ON, continuous measurements can be taken and stored

in memory.

lach batch can contain a maximum of 10,000 readings.

NOT :

18

Open

Selects a previously created batch name to open and make current.

If it contains measurements, onscreen statistics will immediately

reflect values calculated from this batch.

Close

Stops the recording process, closes the current batch, and removes

batch information from the display.

Delete

Permanently removes a batch from Gage memory. The name is

deleted and all measurements are erased.

View

Scroll using the Up or Down buttons through information, statistical

summary, and a list of each reading in the currently opened batch.

Press to exit.

Annotate

Create meaningful batch names and enter

notes directly on the Gage using a familiar

onscreen QWERTY keyboard.

Use the Gage’s navigation and (-)(+)

buttons to enter annotations.

Annotations can be synchronized with

PosiSoft.net and are included in all PosiSoft

reports (see Accessing Stored

Measurement Data, pg. 24).

Annotations can also be created using PosiSoft.net (pg. 24)

or the PosiTector App (pg. 24).

NOT :

Other manuals for PosiTector RTR 3D

1

Table of contents

Languages:

Other DeFelsko Card Reader manuals

Popular Card Reader manuals by other brands

Welch Allyn

Welch Allyn SCANTEAM 6920 user guide

Rosslare

Rosslare AY-K6255 Installation and user manual

G4S

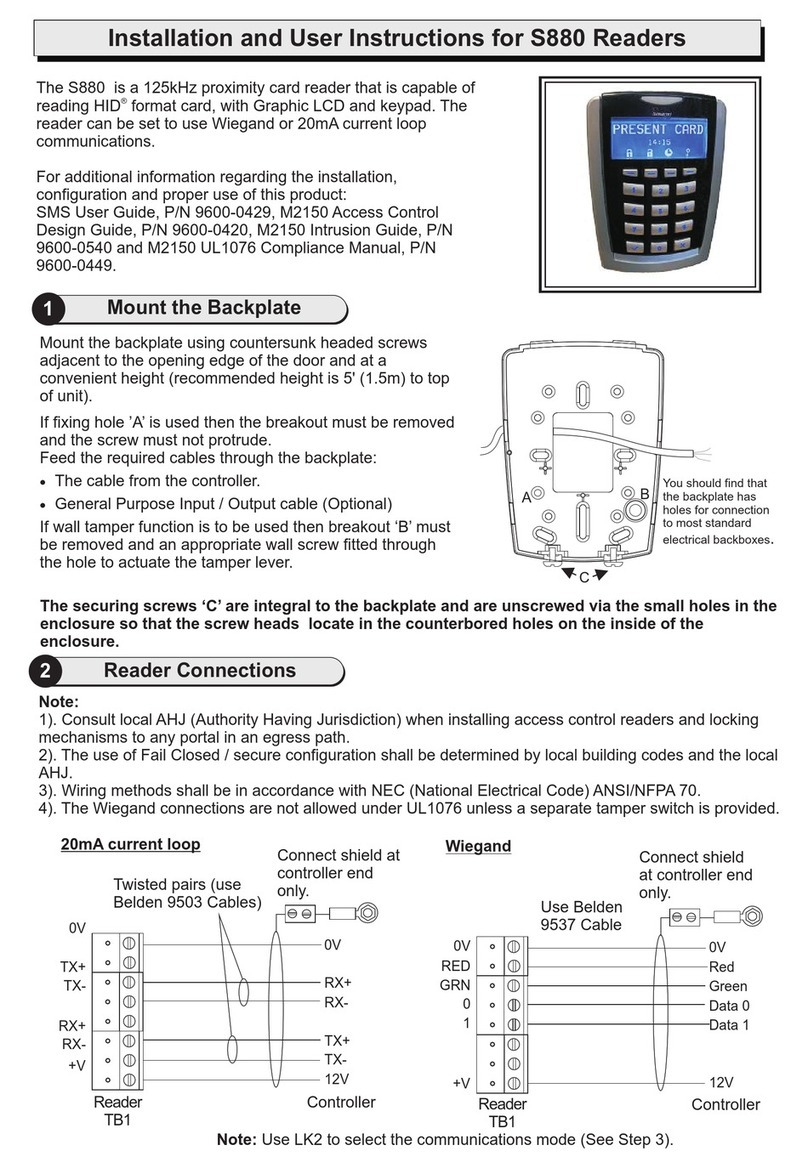

G4S S880 Installation and user instructions

Dot Origin

Dot Origin VTAP100 installation guide

Clas Ohlson

Clas Ohlson MCR20I52D0S quick start guide

Magtek

Magtek IntelliStripe 60 Technical reference manual