DefenderCab Kawasaki Teryx 750 User manual

1

Owner’s Manual

Model:

Kawasaki Teryx 750™

Caution:

Before using this

product, read this

manual and follow all

Safety Instructions.

Kawasaki Teryx 750 Cab Kit*

Safety Instructions

Cab Kit Contents

Hardware Assembly

Panel Assembly

Operation

*DefenderCab™and accessories are in no way affiliated

with Kawasaki Heavy Industries Ltd™. Any use of the name is only

to identify their utility vehicle as it pertains to our accessories.

Kawasaki and teryx are registered trademarks of Kawasaki heavy

industries Ltd.

2

Warning: Failure to heed all safety and operating instructions and

warnings regarding use of this product can result in serious bodily

injury.

SAFETY INSTRUCTIONS

Read entire assembly instructions

before beginning work.

Install all parts indicated in assembly

instructions. Failure to fully assemble

product before use could result in

personal injury.

Assembly of product requires use of hand

or power tools. If you are not experienced

in using these types of tools, have product

dealer do the installation for you.

Some parts contain sharp edges as

indicated in the manual. Wear protective

gloves if necessary.

Dress for safety. DO NOT wear loose

clothing, gloves, neckties or jewelry if

using power tools to assemble this

product.

Always keep your assembly area clean,

uncluttered and well lit.

Keep visitors and children a safe distance

away from the assembly area. Visitors

should wear the same safety equipment

described above.

Never operate your ATV with the cab

doors open. Failure to properly latch

the doors before moving the vehicle

could result in serious injury.

3

CAB KIT CONTENTS

Your DefenderCab™should contain the parts listed below. Separate all parts from

packing materials. Do not discard packing material until assembly is complete. Item

quantities are listed in parenthesis below.

Panels, Doors and Brackets

(1) Plastic Roof Panel

(1) Plastic Rear Panel

(1) Steel Windshield Panel

(1) Plastic Driver Side Panel

(1) Plastic Passenger Side Panel

(1) Steel Driver Door Assembly

(1) Steel Passenger Door Assembly

(2) Polycarbonate Door Window

(1) RH Hinge Mounting Bracket

(1) LH Hinge Mounting Bracket

(1) RH Striker Mounting Bracket

(1) LH Striker Mounting Bracket

(2) Upper Panel Bracket

(4) Door Adjuster Plate

(1) Baton Strip

(1) Rubber Dust Shield

Hardware

(2) RH Lift Off Hinge

(2) LH Lift Off Hinge

(2) Striker Plate

(14) Plastic Knobs

(1) 25ft Roll, Hard Gasket

(1) 25ft Roll, Soft Gasket

(6 ft.) Small Edge Trim

(2) M6 x 10mm Hex Bolt

(16) ¼-20 x 5/8” Flat Head Screw

(2) #10-32 x ¾” Screw, Nyloc, Washer

(38) ¼-20 x 5/8” Screw, Nyloc,

Washer

(4) ¼-20 HEAVY Nyloc Nut

(4) ¼-20 x 3/8” Screw

(6) U-Type Speed Clip

(2) Anti-Vibration Mount

(6) #8-32 Self Tapping Screw

TOOLS REQUIRED FOR ASSEMBLY

Ensure that you have the following tools available before you begin the assembly of your

DefenderCab™kit. Note: Assembly requires an assistant.

Phillips & Flat Screwdrivers

1/4” Wrench / Socket

1/2” Wrench / Socket

7/16” Wrench / Socket

5/32”Allen Wrench

10, 14 & 19mm Wrench / Socket

Electric drill

3/16” drill bit

1/4” drill bit

Utility knife

Utility Clamps or Locking Pliers

Rubber Mallet

4

C

Vehicle Preparation

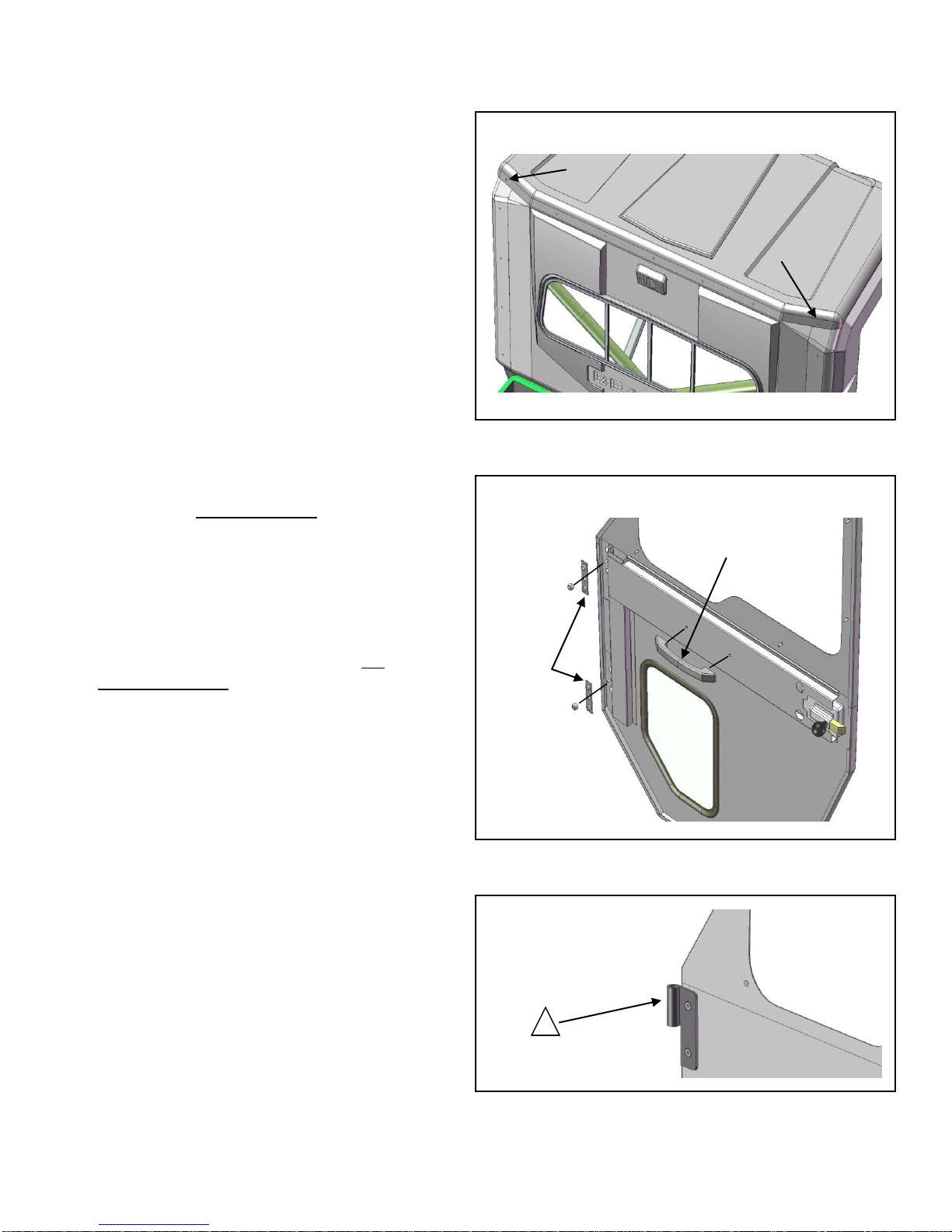

1. Forward Bracketery

i) Remove seats and set aside for

better access to vehicle interior.

Refer to Owner’s Manual for

instructions.

ii) Remove lower foot guardrails and

set shoulder screws aside for later

use. Loosen 19mm bolts (Ain

Fig.1) until 3/16” gap can be

achieved.

iii) Loosely fasten anti-vibe mount (B

in Fig.1) to Hinge Mounting

Brackets using 6mm bolts. Mount

brackets to vehicle as shown in

Fig.1 and hand tighten 19mm bolts.

iv) Align lower bracket hole to

existing foot guard mounting hole

and fasten with OEM shoulder

screw (Cin Fig.1). NOTE: Apply

pressure to screwdriver in order

catch threads on nuts.

v) Adjust upper edge of brackets

with mallet to make bracket edge

flush to roll bar edge (Fig.2).

Tighten 19mm bolts. Adjust and

tighten rubber mounts.

FLUSH

A

B

Fig.2

Fig.1

5

2. Rear Bracketery

i) Remove 14mm bolts from lower

mounting points on rear crossbar.

Install Striker Mounting Brackets as

shown (Fig.3). Reinstall bolts and

hand tighten only. Attach Striker

Plates using (4) ¼-20 x 3/8” screws,

keep loose for later adjustment.

ii) Remove 14mm bolts from upper

crossbar and install Upper Rear

Panel Brackets as shown (Fig.4).

Tighten 14mm bolts back into place.

(Driver side shown from vehicle

exterior)

3. Panel Installation

i) Install low density foam to interior

of panels as shown (Fig.5.) Approx.

(8) 3” long strip are required on each

side panel. Install low density foam

to entire door / panel interface.

ii) Mount side panels to roll cage and

temporarily clamp to top roll bar.

Loosely insert remaining (2) shoulder

screws to each foot well. Adjust each

panel to obtain proper alignment at

front, top and lower rear.

iii) Ensure hinge mounting bracket

edges are flush with inside door

frame and transfer hinge bolt hole

locations onto plastic panels.

Remove panels and drill holes using

¼” bit. Re-install panels and

shoulder screws onto vehicle.

iv) Mount hinges as shown (Fig.6)

with (8) ¼-20 x 5/8” Lg. Flat Head

screws. DO NOT OVER TIGHTEN.

Fig. 3

Fig. 4

Fig. 5

Fig.6

UP

Interior

6

v) Hold lower side panel sections

firmly against vehicle body and

pierce (3) 3/16” holes through side

panel and underside of vehicle

rocker panel. Slide U-Type speed

clips onto rocker panel and fasten

side panels with (3) #8-32 screws

each.

4. Windshield Installation

i) Temporarily install windshield

panel onto vehicle; ensure panel is

horizontal and is aligned identically

on both sides of vehicle. Use an

erasable marker to transfer bottom

edge of panel to hood surface

(Fig.8). Remove panel when done.

ii) Adhere high density foam strip to

hood using marker line as centerline

guide to ensure windshield panel will

sit squarely onto foam after

installation. Install small edge trim to

side edges of windshield and cut to

suit. Install small edge trim to lower

edge of windshield.

iii) Re-install windshield panel onto

vehicle and have an assistant hold

and press windshield panel down

onto foam strip as tightly as possible.

Line up small side edges of plastic

panels (Din Fig.9) to outer wind-

shield panel edges and transfer

holes (Ein Fig.9) onto plastic panels

using 1/4” drill bit. Secure panel with

(10) ¼-20 x 5/8” Lg. screws, washers

and nyloc nuts.

Fig.8

D

E

Fig.9

Clip onto rocker panel

Fig. 7

7

5. Back Panel Installation

i) With help from an assistant, mount

rear panel inside plastic side panels.

If needed, use temporary clamps to

hold and align bends and edges to

ensure a clean fit (Fin Fig.10). Using

a ¼”drill bit, transfer holes onto back

panel (Gin Fig.10). Secure panels

with (8) ¼-20 x 5/8” Lg. screws,

washers and nyloc nuts.

ii) Center and clamp Rubber Dust

Shield and Baton Strip to lower edge

of back panel. Transfer baton strip

holes to rubber shield and back

panel using a ¼” drill bit (Fig.11).

Secure with (7) ¼-20 x 1” Lg.

screws, washers and nyloc nuts.

Note: Baton Strip should be located

above or below panel bend line to

avoid hardware interference with box

tilt operation.

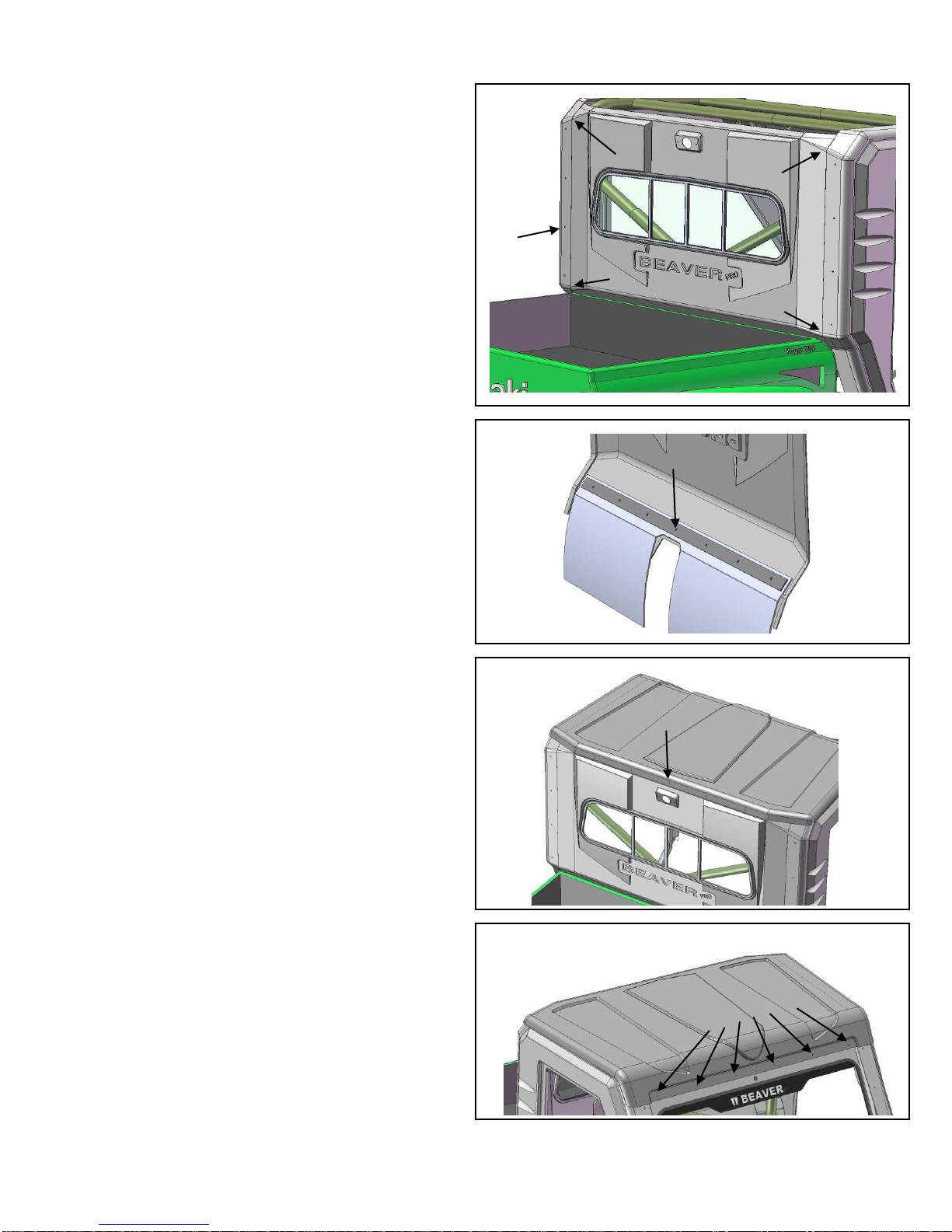

6. Roof Panel Installation

i) Install roof panel and note roll bar

contact points. Adhere foam strips if

desired. Press down onto rear center

section of roof and line up panel

edge to back panel bend line.

Transfer middle hole to back panel

and secure temporarily. (Fig.12)

ii) Have an assistant hold down and

level the front portion of the roof

panel. Stand away from the vehicle

and ensure that the roof looks level

from all angles. Once satisfied with

the look, transfer windshield panel

holes from inside of vehicle to roof

panel with ¼” drill bit. Secure with

1/4-20 x 5/8” Lg. screws, washers

and nyloc nuts. (Fig.13)

Fig.10

Fig.11

F

F

F

F

G

Fig. 12

Fig. 13

8

iii)Align remainder of roof panel to

back panel and transfer remaining

holes onto rear and side panels.

(NOTE: A proper finish at corners is

better achieved by firmly holding

panels from interior while drilling

through [Hin Fig.14]). Secure with

(7) ¼-20 x 5/8” Lg. screws, washers

and nyloc nuts.

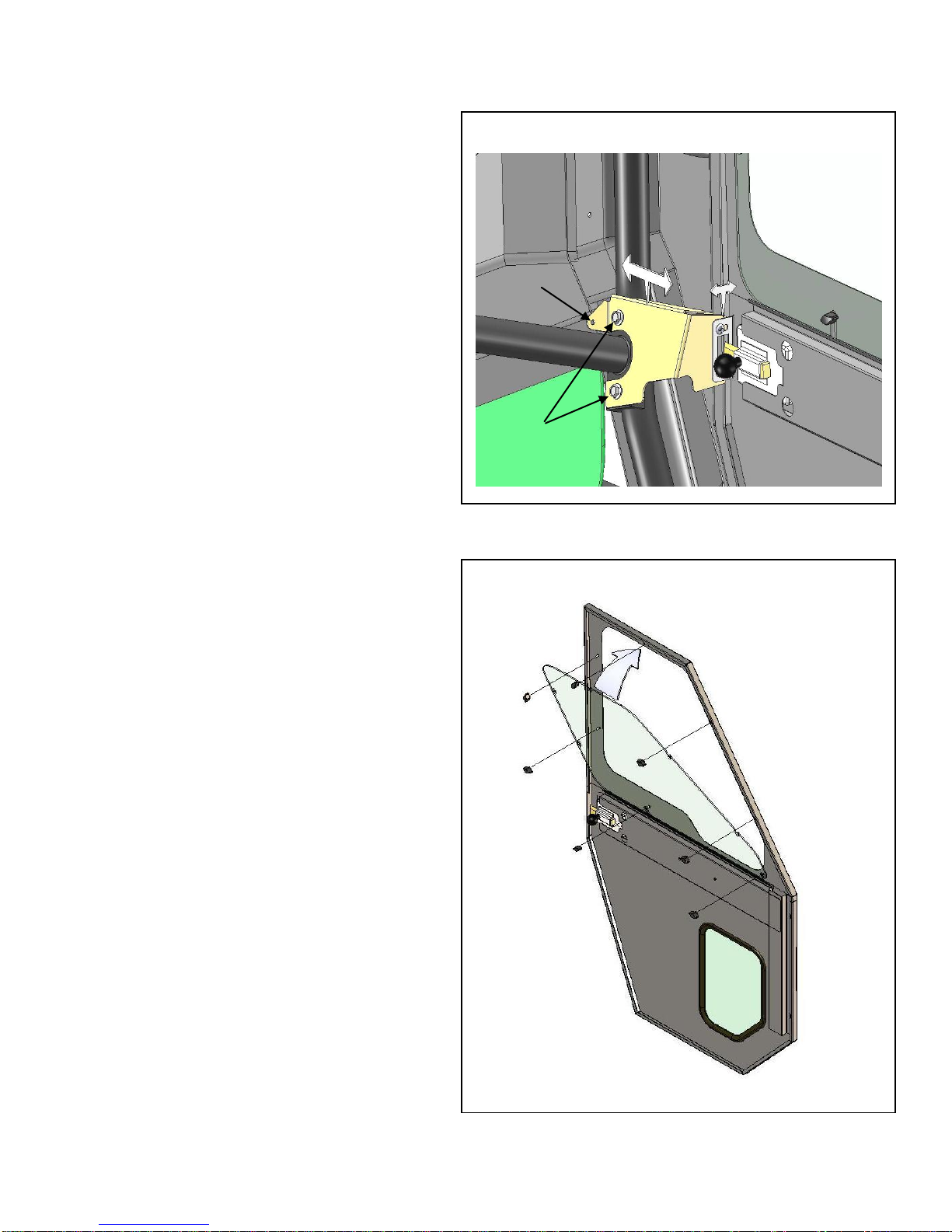

6. Door Preparation / Installation

i) Mount door adjuster plates (Jin

Fig. 15) to inside of door (2 plates

per door) with heavy (large) ¼-20

Nyloc nuts. Do not tighten. Install

inside door handle with #10-32 x ½”

screws. (Kin Fig.14)

ii)Install proper hinges (Fig.16) to

door panels using (8) remaining ¼-

20 x 5/8” Lg. Flat Head screws. Do

not fully tighten.

iii) Mount doors to vehicle. Shim

bottom edge of door as required in

order to obtain equal spacing at top,

bottom and back edges. Reach

through window opening and tighten

¼” nuts followed by exterior hinge

screws –DO NOT OVER TIGHTEN.

Ensure door swings freely within

frame; adjust if necessary.

iv) Push door into frame until flush

with plastic panel surface in latch

area. Reach inside and adjust striker

plate depth (Lin Fig.17)

Fig. 14

H

H

J

Fig.15

K

Driver door shown

!

Fig. 16

9

v) Open and close door. Adjust

amount of latch / striker plate

interface by moving striker mounting

bracket towards front or back of

vehicle until door closes firmly (Min

Fig. 17). Tighten rear lower cross

brace 14mm bolts (Nin Fig.17).

(NOTE: Plastic panel door frame

may require trimming on some

units.)

vi) -Optional-Transfer bracket hole

(Pin Fig.17) to back panel and install

#10-32 x ¾” Lg. screw, washer and

nyloc.

vii) Install seats and ensure proper

door operation.

7. Window Operation

i) Install windows onto doors by

sliding bottom edge in first. Secure

window with (7) plastic knobs per

door.

L

M

N

Fig. 17

Fig. 18

P

10

OPERATION

The DefenderCab™with removable doors is very useful for work or play. It is perfect for

the hunting, farming, fishing, commercial and recreational enthusiast. The cab and optional

heater allow the full enjoyment of the vehicle in all weather conditions.

Removing the doors

In warm weather or to load your ATV on a

trailer, the doors of your hard cab can be

easily removed by opening the door and

carefully lifting it off the hinges.

Removing the windows only

In warm weather, the windows of your

hard cab can be removed to provide

ventilation.

Cleaning your DefenderCab™

Use same mild soap and techniques used

to clean your ATV

To order replacement parts, contact the Parts Department at:

LB Manufacturing Inc.

247 Arsenault Road,

Dieppe, N.B Canada

E1A 7J5

Ph: (506) 388-9334 Fax (506) 388-3325

www.defendercab.com

Manual Revision: 2.0 Date: 26 October, 2012

This manual suits for next models

1

Table of contents

Popular Automobile Accessories manuals by other brands

Safe Fleet

Safe Fleet RVS G Series instruction manual

Phonocar

Phonocar 5/030 Mounting instructions

Motorola

Motorola MTP6000 SERIES installation guide

Whispbar

Whispbar K987W Fitting instructions

BTCPower

BTCPower L3S2-50-400 Series Installation and user manual

NORAUTO

NORAUTO 2274266-NO0531-608 owner's manual

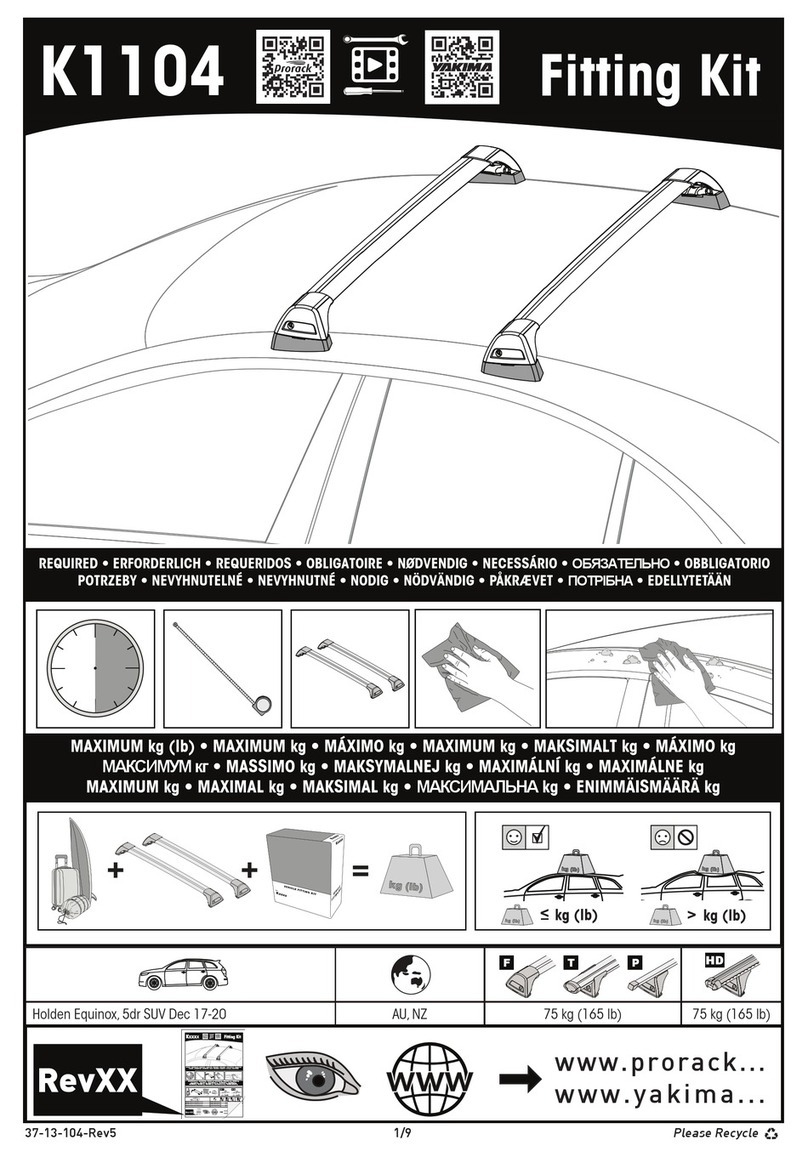

Prorack

Prorack K1104 manual

Ironman4x4

Ironman4x4 IUP002E installation instructions

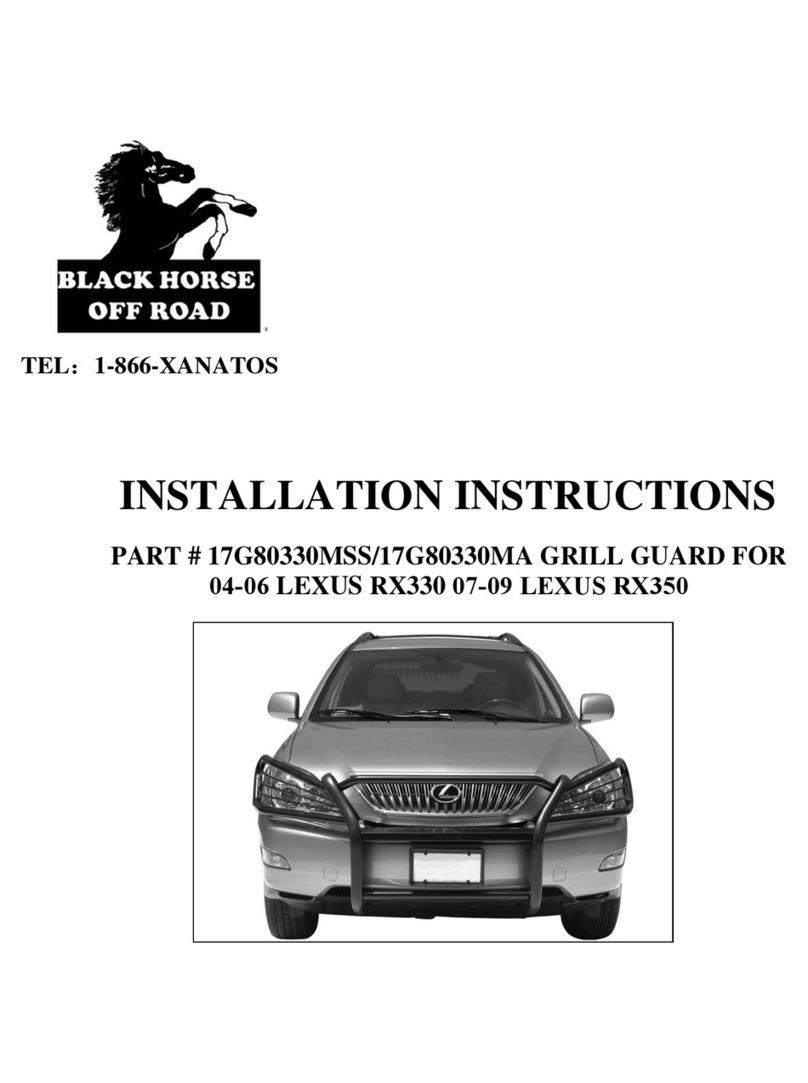

Black Horse Off Road

Black Horse Off Road 17G80330MSS installation instructions

Metra Electronics

Metra Electronics 955822 installation instructions

Roadmaster

Roadmaster 76515 installation instructions

Thetford

Thetford SANICON TURBO 300 manual