Define Instruments PRO-CTR200 User manual

PRO-CTR-MAN-16V03 (0128)Copyright © 2016 Dene Instruments

1

This advanced controller is ideal for a

wide variety of rate monitoring and

batching applications.

It is available with either a single or dual

display, and has a variety of advanced

features, including: batching, batch

count modication, user programmable

input functions, setpoint tracking, set-

point latching and startup inhibit.

Contents

1 - Specications............................. 2

2 - Display & Front Panel................ 3

3 - Wiring ........................................ 5

4 - Input Header Adjustment......... 9

5 - Dimensions & Installation........ 11

6 - Count Modes ........................... 13

7 - Features ................................... 17

8 - Input Setup & Calibration....... 18

9 - Setpoint Setup......................... 26

10 - Setpoint Direct Access ............ 31

11 - Reset PIN Numbers / View

Firmware Version .................... 31

A - Appendix A - Serial Modes ..... 32

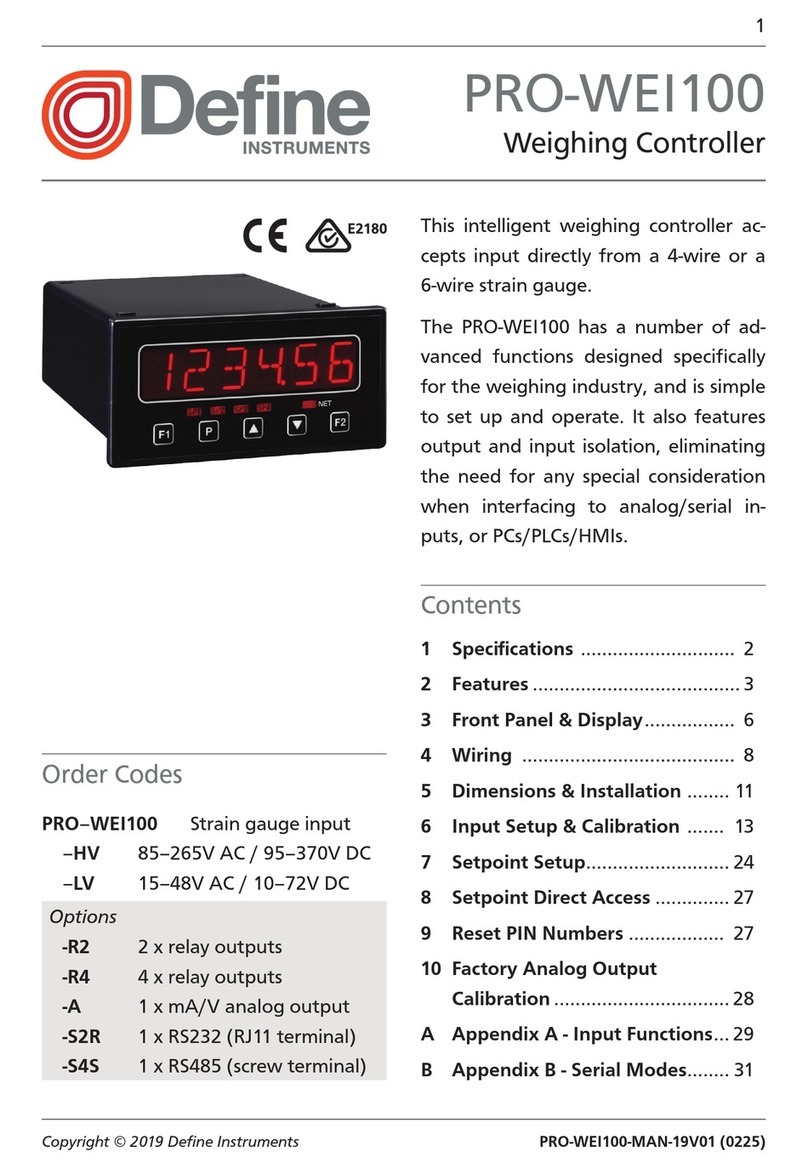

PRO-CTR100/200

Counter/Rate Controller

Order Codes

PRO-CTR100 Single display

PRO-CTR200 Dual display

–HV 85–265V AC / 95–370V DC

–LV 15–48V AC / 10–72V DC

Options

–R2 2 x relay outputs

–R4 4 x relay outputs

–A 1 x mA/V analog output

–S2R 1 x RS232 (RJ11 terminal)

–S4S 1 x RS485 (screw terminal)

PRO-CTR-MAN-16V03 (0128) Copyright © 2016 Dene Instruments

2

1 SPECIFICATIONS

Input

Sensor type Quadrature (x1, x2, x4),

NPN, PNP or TTL

3 x counter inputs available

Input 0–24V DC, 0–30V AC

Power supply HV= 85–265V AC / 95–

370V DC, or LV= 15–48V AC / 10–72V DC

Excitation Default: 24V DC (50mA

max). Optional: 5V DC (200mA max)

Count modes Quad x1/x2/x4,

A+B, A–B, A/B Independent, Up/

Down, C Count, Reset to oset A B,

Reset to oset and start A B

Counter input frequency

10kHz: Quad x4, A+B, A–B, A/B Ind,

Up/Down, RSOFAB, RSOFST

20kHz: Quad x1, Quad x2

38kHz: C Count

Rate input frequency 20kHz max

Minimum pulse width Must be > 5μs

Sampling rate Counter: 10msec

Rate: 100msec

Rate resolution 0.01Hz

Rate accuracy 0.005%

Rate temp. dri Typically 2ppm/°C

Relay Output

Number of relay outputs None, 2 or 4

Relay output type 5A form A (3A 240V

AC max or 3A 30V DC max)

Analog Output

Number of analog outputs None or 1

Analog output type Isolated 16 bit

4–20mA/0–10V

Comm Port

Number of comm ports None or 1

Comm port options

S2R= Isolated RS232, RJ terminal, or

S4S= Isolated RS485, screw terminal

Serial output Custom ASCII, Modbus

RTU slave or Ranger A

Data rate 1200–115k2 baud

Parity Odd, even or none

Programming

Front panel buttons Up, Down, P

(Prog/Enter), plus 2 Menu buttons (F)

Security Input and setpoint setups

are independently accessible and PIN

protected

OPTIONAL

OPTIONAL

OPTIONAL

PRO-CTR-MAN-16V03 (0128)Copyright © 2016 Dene Instruments

3

Display

Display type 14 segment alphanumeric

LED display, 5 buttons

LED indicators 6 setpoint LED's

PRO-CTR100 1 x 6 digits 13mm (0.5")

PRO-CTR200 2 x 6 digits 10mm (0.4")

Display range 0.1 to 99999.9

Construction

Casing Panel mount case

Ingress protection rating IP65 dust/

splash proof (face only)

Dimensions (H x W x D)

48 x 96 x 120mm (1.89 x 3.78 x 4.72")

Panel cutout 45 x 92mm (1.77 x 3.62")

2 DISPLAY & FRONT PANEL

2.1 - Display

Two display types are available for the PRO–CTR controller. Both feature 14 segment

alphanumeric display characters, 6 indicator LEDs and 5 buttons:

PRO-CTR100

›1 x 6 digits 13mm (0.5")

›Customisable display source

(see 8.4B)

›During setup, the text prompt

toggles with selectable

options/values 96mm (3.78")

48mm

(1.89")

PRO-CTR200

›2 x 6 digits 10mm (0.4")

›Customisable display source

for both rows (see 8.4B–D)

›During setup, the top row

displays selectable options/

values, and the bottom row

displays the text prompt

96mm (3.78")

48mm

(1.89")

PRO-CTR-MAN-16V03 (0128) Copyright © 2016 Dene Instruments

4

2.2 - Front panel

SPX /The SP LED's are used to indicate active setpoints.

This button is used to access the Input Setup & Calibration menu (Section 8).

This button is typically used to save your settings and advance to the next step

in the setup process. A custom function can also be programmed (see 8.5B).

This button is typically used to scroll through options or increase values in the

setup menu. Pressing this button from the main display will allow you to view/

reset the Peak value, and view the Rate and Primary Counter values (see 2.3).

This button is typically used to scroll through options or decrease values in the

setup menu. Pressing this button from the main display will allow you to view/

reset the Valley value, and view the B and C Counter values (see 2.3).

This button is used to access the Setpoint Setup menu (Section 9) and the

Setpoint Direct Access menu (Section 10).

2.3 - Up and down button shortcuts

Pressing the and buttons from the main operational display allows instant

access to a number of values held in the controller's memory. These variables will ap-

pear in the order shown in the table below, and will cycle continuously at each press

of the or button. Press at any time to return to normal operating mode.

Up and down button shortcuts

PEAK Maximum measured rate value since the instrument was turned on/reset

PRMCNT Current value of primary counter

RATE Current rate value

VALLEY Minimum measured rate value since the instrument was turned on/reset

B CNT Current value of B counter

C CNT Current value of C counter

PEAK and VALLEY may be reset to zero by pressing the and buttons at the

same time while the variable is being displayed.

PRO-CTR-MAN-16V03 (0128)Copyright © 2016 Dene Instruments

5

2.4 - Display brightness

To adjust the display brightness, press the and buttons together from the

main display. BRI appears on the display with the current brightness setting. Use the

and buttons to adjust the LED backlight, and then press to nish.

3 WIRING

3.1 - Pinouts

C

DEF

A B

Key

3.1A Relay Output (See 3.3)

3.1B Serial Port (See 3.5)

3.1C Analog Output (See 3.4)

3.1D Analog Input (See 3.2)

3.1E Function Pins (See 3.6)

3.1F Power Supply HV/LV

(See 3.7)

3.2 - Wire the analog input module

See 3.1D

IMPORTANT:

The analog input board for the PRO–CTR has adjustable headers for Sensor Type,

Noise Filtering, and Excitation Voltage. Unless you specied otherwise when you or-

dered your PRO–CTR, the headers will be set to:

›Sensor Type = NPN (for all counters)

›Noise Filtering = Off (20kHz)

›Excitation Voltage = 24V

If you need to change these settings, please follow the instructions in Section 4

BEFORE proceeding to wiring your sensor(s).

PRO-CTR-MAN-16V03 (0128) Copyright © 2016 Dene Instruments

6

Quadrature encoder (speed & direction)

SIGNAL A

EXC

GND

SIGNAL B

SIGNAL C

Phase (A)

Supply

Ground

Phase (B)

Index/Marker

Non-quadrature sensor connections

The following diagram shows how multiple sensors can be connected to your input

module. Any combination of NPN, TTL and PNP may be used for sensors A, B and C.

SIGNAL A

EXC

GND

SIGNAL B

SIGNAL C

SENSOR A

SENSOR B

SENSOR C

NPN

Open

collector

output

+ Supply

-- Supply

SIGNAL

+ 24V EXC

GND

PNP

Open

collector

output

+ Supply

-- Supply

SIGNAL

+ 24V EXC

GND

SIGNAL

GND

+ Supply

-- Supply

DC

Supply

TTL

5V

0V

PRO-CTR-MAN-16V03 (0128)Copyright © 2016 Dene Instruments

7

3.3 - Wire the relay outputs (if installed)

See 3.1A

If your controller has relay outputs tted, wire them as shown below. Relays can be

programmed to operate within the total span range of the controller. See Section 9

to configure your setpoints.

SP 2 BCH

SP

–R2

SP 3SP 4 BCH

SPSP 2

–R4

3.4 - Wire the analog output (if installed)

See 3.1C

If your controller has analog output tted, wire it as shown for either

voltage (0–10V) or current (4–20mA).

–V

+V

–mA

+mA

–A

3.5 - Wire the serial port (if installed)

See 3.1B

If your controller has serial port tted, wire it as shown

in the applicable diagram.

›S2R= RS232, RJ11 terminal

›S4S= RS485, screw terminal

N/C

SGND

+5V DC (option)

RXD

TXD

N/C

–S2R

D

-

D +

SGND

–S4S

PRO-CTR-MAN-16V03 (0128) Copyright © 2016 Dene Instruments

8

3.6 - Wire the function pins

See 3.1E

Connect external switches to enable a function to

be executed when its switch is activated.

›User 1–3: Activating one of these function

pins will execute its user-defined function (as

specified in 8.5C–E)

›Test: Activating this pin resets the unit

User 1 TestUser 2 COM User 3

3.7 - Wire the power supply

See 3.1F

DO NOT attempt to wire your controller while the power is on. NEVER connect your

low voltage controller to mains power.

Wire your controller for low or high voltage power supply, as shown in the diagrams

below. Check the label on the unit against the colour of the connector:

›Orange =

High voltage (85–265V AC,

95–370V DC)

›Black =

Low voltage (15–48V AC,

10–72V DC)

High

voltage

(HV)

HV power

supply

−DC

Neutral

AC

+DC

Live

AC

Low

voltage

(LV)

LV power

supply

−DC

Neutral

AC

+DC

Live

AC

Once you have completed the wiring process it is safe to switch on your power

supply. Ensure that your display is functioning before you proceed.

PRO-CTR-MAN-16V03 (0128)Copyright © 2016 Dene Instruments

9

4 INPUT HEADER ADJUSTMENT

Dene Instruments recommends that you specify your sensor type(s) when you

place your order, to avoid unnecessary removal of the input module.

4.1 - Input header settings

The analog input board for the PRO–CTR has adjustable headers for Sensor Type (A),

Noise Filtering (B) and Excitation Voltage (C). Refer to the tables below to determine

whether the default header positions (shown in black) are suitable for your applica-

tion. If required, follow the instructions in 4.2 to adjust the header positions.

Quadrature IP

234K 2006

©

O

On

NC

NPN

PNP

TTL

24V 5V

CH1 CH3CH2

COUNT

FREQ

AB

C

D

Sensor Type (A)

CH1= Primary Ctr, CH2= B Ctr, CH3= C Ctr

NC Not Connected

NPN NPN Sensor (Sink)

PNP PNP Sensor (Source)

TTL TTL Sensor

Excitation Voltage (C)

24V Standard setting

5V May apply to some encoders

Noise Filtering (B)

CH1= Primary Ctr, CH2= B Ctr, CH3= C Ctr

O 20kHz, for high-speed counting

On 1kHz low pass lter, for a noisy

signal or mechanical contact

Mode Header (D) - Do not adjust!

COUNT Always use this setting

FREQ Not used for PRO–CTR

PRO-CTR-MAN-16V03 (0128) Copyright © 2016 Dene Instruments

10

4.2 - How to remove the input module

A If the meter is already installed, remove it from the panel, and unplug all plugs

from the back of the unit.

B Using a small screwdriver or similar implement,

press downward into one of the slots at the

rear of the case. This will disengage one of

the tabs which holds the back plate on, al-

lowing it to be gently levered away at

one corner.

C Holding the loosened corner open

with one hand, disengage the le-

ver on the opposite slot (Fig 1).

E Slide the analog input module out

of the meter case (Fig 2). (See 3.1D

to identify the input module.)

F Position the headers on the input

module as required for your sensor

type, referring to 4.1.

G Slide the input module back into

the meter case.

Fig 1

D You should now be able to remove the back plate. If it does not unclip easily,

you may need to disengage the two remaining tabs by repeating steps 4.2B–C

on the other side of the meter.

Fig 2

Make sure that it is sitting in the tracks on the le and right. Press rmly until the input module

is fully inserted and sits ush with the other boards that are visible from the back of the meter.

H Replace the back plate.

Begin by inserting the two lower tabs into the slots, and then position the upper tabs so that

they will not catch on the top lip of the meter case. Apply rm pressure until the back plate

clicks into place.

I Reconnect the plugs and return the meter to the panel installation.

PRO-CTR-MAN-16V03 (0128)Copyright © 2016 Dene Instruments

11

5 DIMENSIONS & INSTALLATION

5.1 - Case dimensions

Cabling

Allowance

96mm

(3.78")

92mm

(3.62")

120mm (4.72") 39mm (1.54")

155mm (6.10") minimum depth required behind panel

4mm (0.16")

Cabling

Allowance

48mm

(1.89")

45mm

(1.77")

120mm (4.72") 39mm (1.54")

155mm (6.10") minimum de

p

th re

q

uired behind

p

anel

4mm (0.16")

PRO-CTR-MAN-16V03 (0128) Copyright © 2016 Dene Instruments

12

5.2 - Installation instructions

A Prepare the Panel Cutout to

92 x 45mm ±.5 (3.62 x 1.77" ±.02),

as shown below.

Allow at least 155mm (6.10")

depth behind the panel to accom-

modate the meter body, protrud-

ing connectors and cabling.

B Remove the Mounting Clips from

the meter back.

C Slide the Panel Gasket over the

rear of the unit to the back of the

Meter Faceplate.

D From the front of the panel, insert

the meter into the Panel Cutout.

Holding the unit in place, engage

the Mounting Clips so that the tabs

snap into place over the notches on

the case.

E To achieve a proper seal, tighten

the Screws evenly until the unit sits

rmly against the panel. Do not

over-tighten the screws.

Panel Meter Faceplate

Panel

Gasket

Mounting

Clips

Screws 92mm ±.5

(3.62″ ±.02)

45mm ±.5

(1.77″ ±.02)

Panel Cutout

PRO-CTR-MAN-16V03 (0128)Copyright © 2016 Dene Instruments

13

6 COUNT MODES

6.1 - Quad x1 Example: Sha Encoder

This is the most commonly used counter function. Depending on the direction of

rotation, the A signal either leads or lags the B signal.

Pulse Train Direction

Signal A

Signal B

With A and B

signals 90°

out-of-phase

Primary

Counter

Clockwise Primary counter decrements:

On a rising edge A signal when B is low

Pulse Train Direction

Signal A

Signal B

With A and B

signals 90°

out-of-phase

Primary

Counter

Counter-clockwise Primary counter increments:

On a falling edge A signal when B is low.

6.2 - Quad x2 Example: Sha Encoder

In this mode, the angular/linear resolution of the x1 mode is increased by 2. Depend-

ing on the direction of rotation, the A signal leads or lags the B signal.

Pulse Train Direction

Signal A

Signal B

Primary

Counter

Clockwise

With A and B

signals 90°

out-of-phase

Primary counter decrements:

On a rising edge A signal when B is low

On a falling edge A signal when B is high

PRO-CTR-MAN-16V03 (0128) Copyright © 2016 Dene Instruments

14

Pulse Train Direction

Signal A

Signal B

With A and B

signals 90°

out-of-phase

Primary

Counter

Counter-clockwise Primary counter increments:

On a rising edge A signal when B is high

On a falling edge A signal when B is low

6.3 - Quad x4 Example: Sha Encoder

In this mode, the angular/linear resolution of the x1 mode is increased by 4. Depend-

ing on the direction of rotation, the A signal leads or lags the B signal.

Pulse Train Direction

Signal A

Signal B

Primary

Counter

Clockwise

With A and B

signals 90°

out-of-phase

Primary counter decrements:

On a rising edge A signal when B is low

On a rising edge B signal when A is high

On a falling edge A signal when B is high

On a falling edge B signal when A is low

Pulse Train Direction

Signal A

Signal B

Counter-clockwise

Primary

Counter

With A and B

signals 90°

out-of-phase

Primary counter increments:

On a rising edge A signal when B is high

On a rising edge B signal when A is low

On a falling edge A signal when B is low

On a falling edge B signal when A is high

6.4 - A+B

In this mode there is no xed relationship between signals A and B.

Primary

Counter

Signal A

Signal B

Primary

Counter

Signal A

Signal B

Primary counter increments:

On a rising edge A signal On a rising edge B signal

PRO-CTR-MAN-16V03 (0128)Copyright © 2016 Dene Instruments

15

6.5 - A–B

In this mode the A and B signals are linked in a phase relationship. Signal A incre-

ments the primary counter on every rising edge, while signal B decrements the pri-

mary counter on every rising edge.

Signal A

Signal B

Primary

Counter

Primary

Counter

Signal A

Signal B

Primary

Counter

Primary

Counter

Primary counter increments:

On a rising edge A signal

Primary counter decrements:

On a rising edge B signal

6.6 - A&B Independent

In this mode there is no xed relationship between signals A and B. Signal A

increments the primary counter on every rising edge, and signal B increments the

secondary counter on every rising edge.

Signal A

Signal B

Primary

Counter

Secondary

Counter

Signal A

Signal B

Primary

Counter

Secondary

Counter

Primary counter increments:

On a rising edge A signal

Secondary counter increments:

On a rising edge B signal

6.7 - Up/Down

In this mode the A and B signals are linked in a phase relationship. Signal A incre-

ments the primary counter on every rising edge when signal B is low. Signal A also

decrements the primary counter on every rising edge when signal B is high.

PRO-CTR-MAN-16V03 (0128) Copyright © 2016 Dene Instruments

16

Primary Counter

Sig A

Sig B

Primary counter increments:

On a rising edge A signal when B is low

Primary Counter

Sig A

Sig B

Primary counter decrements:

On a rising edge A signal when B is high

6.8 - Count

This mode is particularly useful for multi-input systems.

Signal C

Primary

Counter

Primary counter increments:

On a rising edge C signal only

6.9 - RSOFAB - Reset to oset A, B mode

In this mode the primary and secondary counters are reset to the values stored in

the meter's reset oset registers, and they continue counting aer being reset. This

is useful for setting a position to a known reference position.

Signal C

Index

/

Marker

Primary

reset oset

register

Secondary

reset oset

register

Primary Counter

Continues counting

afer being reset

Secondary Counter

Continues counting

afer being reset

RESET RESET

On a falling edge C signal:

Primary counter is reset to the value stored in

primary reset offset register

Secondary counter is reset to the value stored

in secondary reset offset register

Both counters continue to count after being

reset

PRO-CTR-MAN-16V03 (0128)Copyright © 2016 Dene Instruments

17

6.10 - RSOFST - Reset to oset and start A, B mode

In this mode the primary and secondary counters are reset to the values stored in

the meter's reset oset registers, and they continue counting aer being reset.

Signal C

Primary

reset

oset

register

Primary Counter

Reset to primary

reset oset value

Secondary Counter

Reset to secondary

reset oset value

RESET RESET

Secondary

reset

oset

register

BEGIN

COUNTING

BEGIN

COUNTING

On a rising edge C signal:

Both counters begin counting

On a falling edge C signal:

Primary counter is reset to the value stored in

primary reset offset register

Secondary counter is reset to the value stored

in secondary reset offset register

Both counters continue to count after being

reset

7 FEATURES

7.1 - Batching feature

The PRO–CTR has a Batching function, which is used to maintain the total count,

as well as the current Batch Value. The Batch Value is calculated using the following

formula:

Batch Value = Primary Count – Batch Tare

The Batch Tare value is reset to the Primary Count value via the setpoint reset func-

tion RST BT, which can be executed by setpoint logic (see 9.2M) or manually by

activating an appropriately congured user input pin (see 3.6 & 8.5). (Batch Tare is a

hidden register used only for this calculation.)

The controller also includes a Batch Counter function associated with SP 1. The 'Batch

Count Modier' value (see 9.2P) is added to the Batch Count register each time

SP 1 activates, allowing the user to count how many completed batches have been

processed.

PRO-CTR-MAN-16V03 (0128) Copyright © 2016 Dene Instruments

18

8 INPUT SETUP & CALIBRATION

Setup menu display note:

If you are using a single display (PRO-CTR100), the menu title or text prompt will

scroll across the display, and toggle with the currently selected option. If you are

using a dual display (PRO-CTR200), the menu title or text prompt will scroll across the

bottom row, and the currently selected option will appear in the top row.

8.1 - Enter CAL PIN number

A Enter the calibration mode by pressing the button.

_ _ _ ENTER CAL PIN NUMBER scrolls across the display, and 0appears. Use the

and buttons to enter your security code (factory default 1). Then press

. If the correct PIN is entered, setup is started at 8.2.

If an incorrect PIN number is entered, _ _ _ INCORRECT PIN NUMBER – ACCESS

DENIED scrolls across the display, and it returns to normal operating mode.

You will have the opportunity to change your PIN number at the end of this section

(8.8). If you have forgotten your PIN number, see Section 11.

8.2 - Counter setup

There are 3 counter inputs available on the input module:

›Count A input (drives the primary counter)

›Count B input

›Count C input

When the primary counter mode is set to AB IND (A & B independent) the A input

drives the primary counter and the B input drives the secondary counter. In other

count modes, the A and B inputs are both used to drive the primary counter, so the

B counter options are not available. IT IS THEREFORE ADVISABLE TO SET UP THE

PRIMARY COUNT MODE FIRST.

PRO-CTR-MAN-16V03 (0128)Copyright © 2016 Dene Instruments

19

A _ _ _ COUNTER SETUP scrolls across the display, and SKIP appears. Press to

skip to 8.3, or use the and buttons to select: PRM CT (primary counter),

B INPT (B input) or C INPT (C input), and then press to enter setup for the

selected counter.

If you selected PRM CT or C INPT, continue to 8.2B now.

If you selected B INPT, skip to 8.2C now.

Note that the B INPT counter cannot be independently congured unless the count mode for

PRM CT is set to AB IND (see 8.2B). If you attempt to enter the B INPT counter setup when the

above condition has not been met, an error message will scroll across the display, and you will

not be allowed to continue.

B _ _ _ COUNT MODE scrolls across the display, and the current count mode ap-

pears. Use the and buttons to select an option from the list. (Options

will vary depending on which counter you are editing.) When you have made a

selection, press to accept and continue.

If you are currently editing PRM CT, the menu options will be:

QUADX1, QUADX2, QUADX4, A+B, A–B, AB IND (AB independent) or

UP/DN (up/down).

If you are currently editing C INPT, the menu options will be:

COUNT, RSOFAB (reset to oset A, B mode) or RSOFST (reset to oset

and start A, B mode).

For more information on count modes, please see Section 6.

C _ _ _ DECIMAL POINT POSITION scrolls across the display, and the current

decimal point position appears. Use the and buttons to select NO DP,

0.1, 0.12, 0.123, 0.1234 or 0.12345, and then press to accept and continue.

D _ _ _ PULSES PER UNIT OF MEASUREMENT scrolls across the display, and the

current number of pulses appears. Adjust this value using the and but-

tons, and then press .

For example, if an encoder outputs 1,500 pulses/metre, set this value to 1500.

E _ _ _ ENTER DISPLAY VALUE FOR X PULSES scrolls across, and the current

display value appears. ('X' is the number of pulses selected in 8.2D.) Adjust this

value using the and buttons, and then press .

For example, if you selected 1,500 pulses in 8.2D, and 1,500 pulses = 1 metre, then enter 1

PRO-CTR-MAN-16V03 (0128) Copyright © 2016 Dene Instruments

20

here. (Enter this value with reference to your decimal point position - the controller will auto-

matically calculate the correct scale factor for you.)

F _ _ _ RESET AT POWER UP scrolls across the display, and the current setting

appears. Use the and buttons to select: NO (count value will be retained

at power up), ZERO (count value will be set to zero at power up), or LD VAL

(count value will be set to a user dened load value at power up - see 8.2G).

Then press to accept and continue.

G _ _ _ LOAD VALUE scrolls across the display, and the load value appears. (This

value will loaded into the selected counter at power up when LD VAL is selected

in 8.2F.) Use the and buttons to adjust your load value as desired, and

then press .

This value is also used for the C input reset functions RSOFAB (see 6.9) and RSOFST (see 6.10).

H _ _ _ COUNTER SETUP scrolls across the display, and SKIP appears. You are

now back at 8.2A. To set up another input channel, follow the instructions from

8.2A–H again. If you do not wish to set up another input channel, press now

to skip to 8.3.

8.3 - Rate display setup

A _ _ _ RATE DISPLAY SETUP scrolls across the display, and SKIP appears. Press

to skip to 8.4, or the button and then to ENTER.

The rate value is taken from the primary count input (signal A).

B _ _ _ DECIMAL POINT POSITION scrolls across the display, and the current

selection appears. Use the and buttons to select NO DP, 0.1, 0.12, 0.123,

0.1234 or 0.12345, and then press .

C _ _ _ ROUNDING scrolls across the display, and the currently selected rounding

setting appears. Using the and buttons, select either: NONE, 2, 5or 10.

Then press .

Rounding is quoted in display counts and is not inuenced by decimal point position. For exam-

ple, if your input signal is 5.3, the display will show: 5.3 (for rounding=None), 5.4 (for round-

ing=2), 5.5 (for rounding=5) or 5.0 (for rounding=10).

This manual suits for next models

1

Table of contents

Other Define Instruments Controllers manuals

Popular Controllers manuals by other brands

Datakom

Datakom DKG-319 user manual

Mitsubishi Electric

Mitsubishi Electric MELSEC Q Series user manual

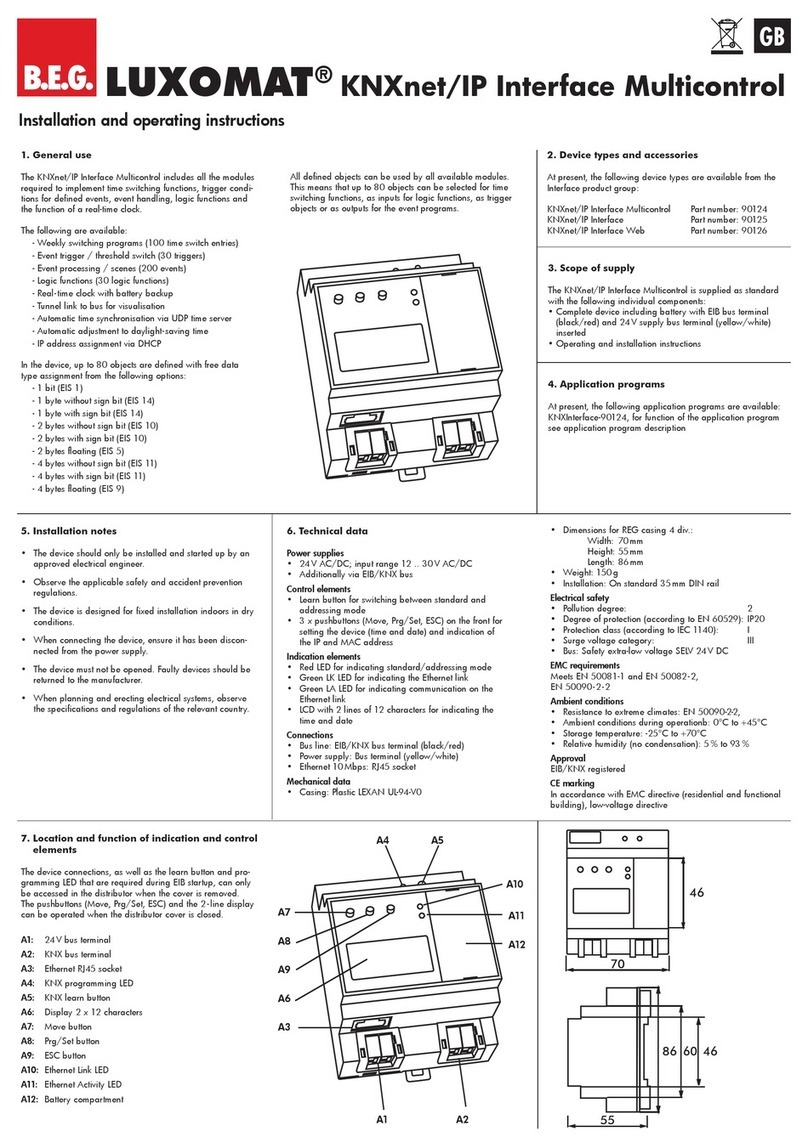

B.E.G.

B.E.G. LUXOMAT Installation and operating instructions

Pressure Tech

Pressure Tech MF-414 Series Operating and service manual

MR

MR TAPCON 230 basic operating instructions

Mitsubishi Electric

Mitsubishi Electric MELDAS C6 Programming manual