Content

For your safety..................................................................................................................................................................................3

Technical data and information........................................................................................................................................................3

Operational conditions .....................................................................................................................................................................4

Terminology ......................................................................................................................................................................................4

Product desciption............................................................................................................................................................................5

Instalation, assembly and disassembly of the transmitter...............................................................................................................6

1. Assembly of the transmitter .................................................................................................................................................6

2. Replacement of the sensor module......................................................................................................................................6

3. Replacement of the battery..................................................................................................................................................6

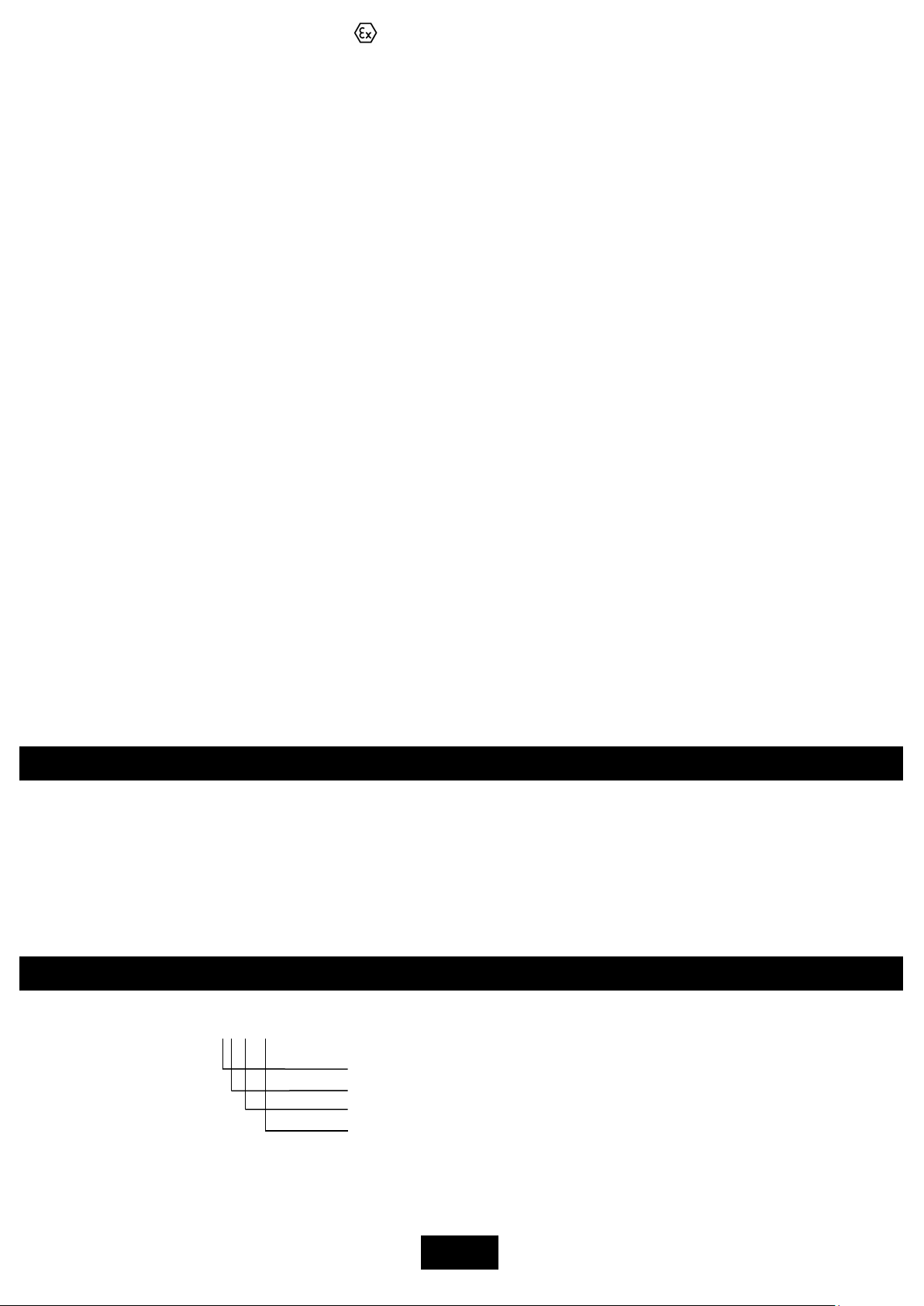

4. Connecting the transmitter via current loop to the controler DEGA UPA II DEGA UPA III a DEGA UDA III..........................6

5. Connecting the sensor via RS485 to the controller DEGA UPA III/UDA III............................................................................7

6. Installation of wiring for RS485.............................................................................................................................................7

Selecting the appropriate type of cable depends on the fire report and the protocol for determining external influences. ....7

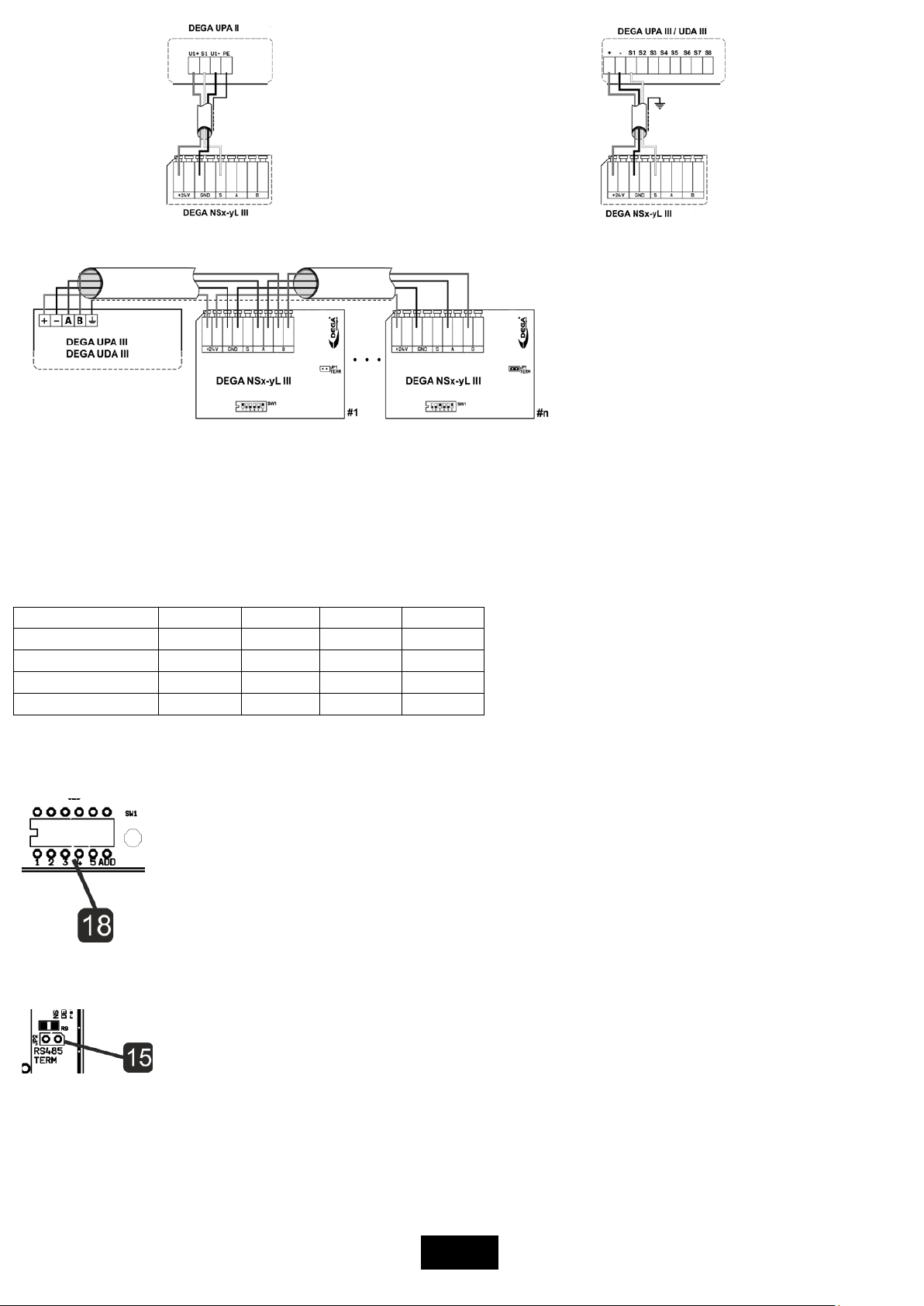

7. Setting the RS485 adress of the transmitter.........................................................................................................................7

8. Terminating resistor..............................................................................................................................................................7

9. Communication protocol switch DEGA/MODBUS................................................................................................................8

Transmitter functions .......................................................................................................................................................................8

1. Turning on the transmitter ...................................................................................................................................................8

2. Gas detection........................................................................................................................................................................8

3. Malfunction...........................................................................................................................................................................8

4. Monitoring the calibration periods.......................................................................................................................................8

5. Reading the record of measured concentrations and alarms ..............................................................................................8

Operation, maintenance, inspection and service of the transmitter ...............................................................................................8

1. Usage limits...........................................................................................................................................................................8

2. Operation..............................................................................................................................................................................9

3. Operation/Maintenance.......................................................................................................................................................9

Accessories and basic types of transmitters.....................................................................................................................................9

1. Calibration adapter/connection to the gas pump DEGA GAS INLET ....................................................................................9

2. Cover against splashing water DEGA WATER CAP..............................................................................................................10

3. Funnel for gas collection DEGA COLLECT CAP ....................................................................................................................10

4. Additional Ex „d“ bushing DEGA VÝVODKApro NSxIII.........................................................................................................10

Basic types of transmitters .............................................................................................................................................................10

1. Transmitters with a catalytic sensor NSx-CL III...................................................................................................................10

2. Transmitters with an electrochemical sensor NSx-EL III.....................................................................................................10

3. Transmitters with an infrared sensor NSx-IL III...................................................................................................................12

4. Transmitters with a semiconductor sensor NSx-SL III.........................................................................................................13

5. Transmitters with a PID sensor NSx-PID III .........................................................................................................................13

Attachments....................................................................................................................................................................................13

1. Chart for setting the transmitter adress.............................................................................................................................13

2. Signalization transmitted by the current loop 4-20mA ......................................................................................................13

General warranty terms and conditions.........................................................................................................................................14