2

SVERO Wall-Mounted Winches -61A, -62A

SVERO Wall-Mounted Winches -61A, -62A are used for lifting loads with wire rope which is led

through one or more pulleys. Wire rope and pulleys are not included. Wall-mounted winches are

not intended for lifting persons. Installation must be carried out by specialists. These instructions

must always be available at the work site.

Wall-mounted winches of models 6211A and 6113A may also be used for rope routes

etc. on stage and in studios in accordance with SWEDISH STANDARD SS 767 15 01.

They are also used for high and lowerable light fittings etc. in public buildings such as

churches, exhibition halls, restaurants, sports halls and similar. For important detailed

information see the above Swedish Standard. In these user instructions the special

requirements applying when 6211A and 6113A are used for stage, studio and light

fittings in public buildings are noted in bold italic.

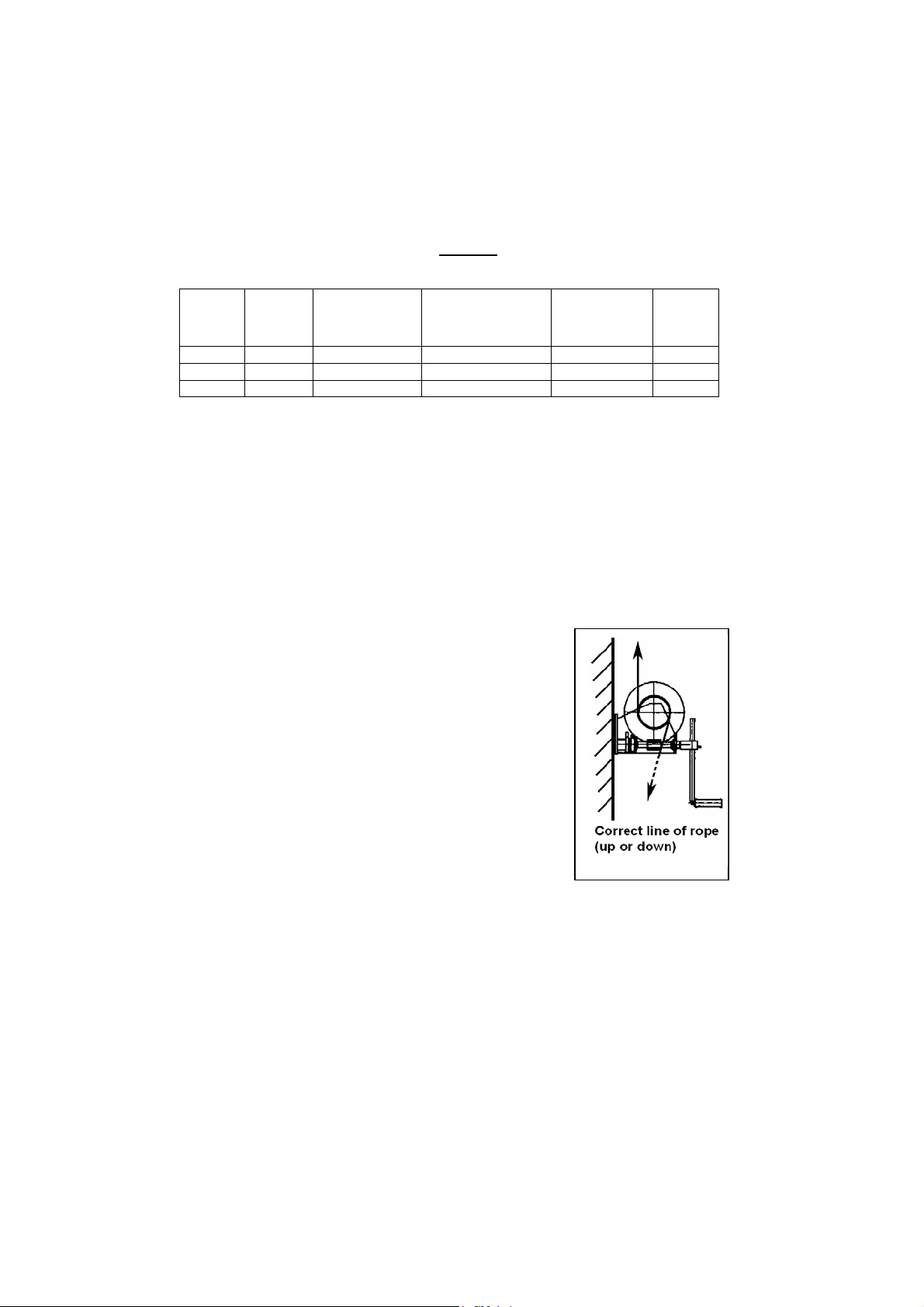

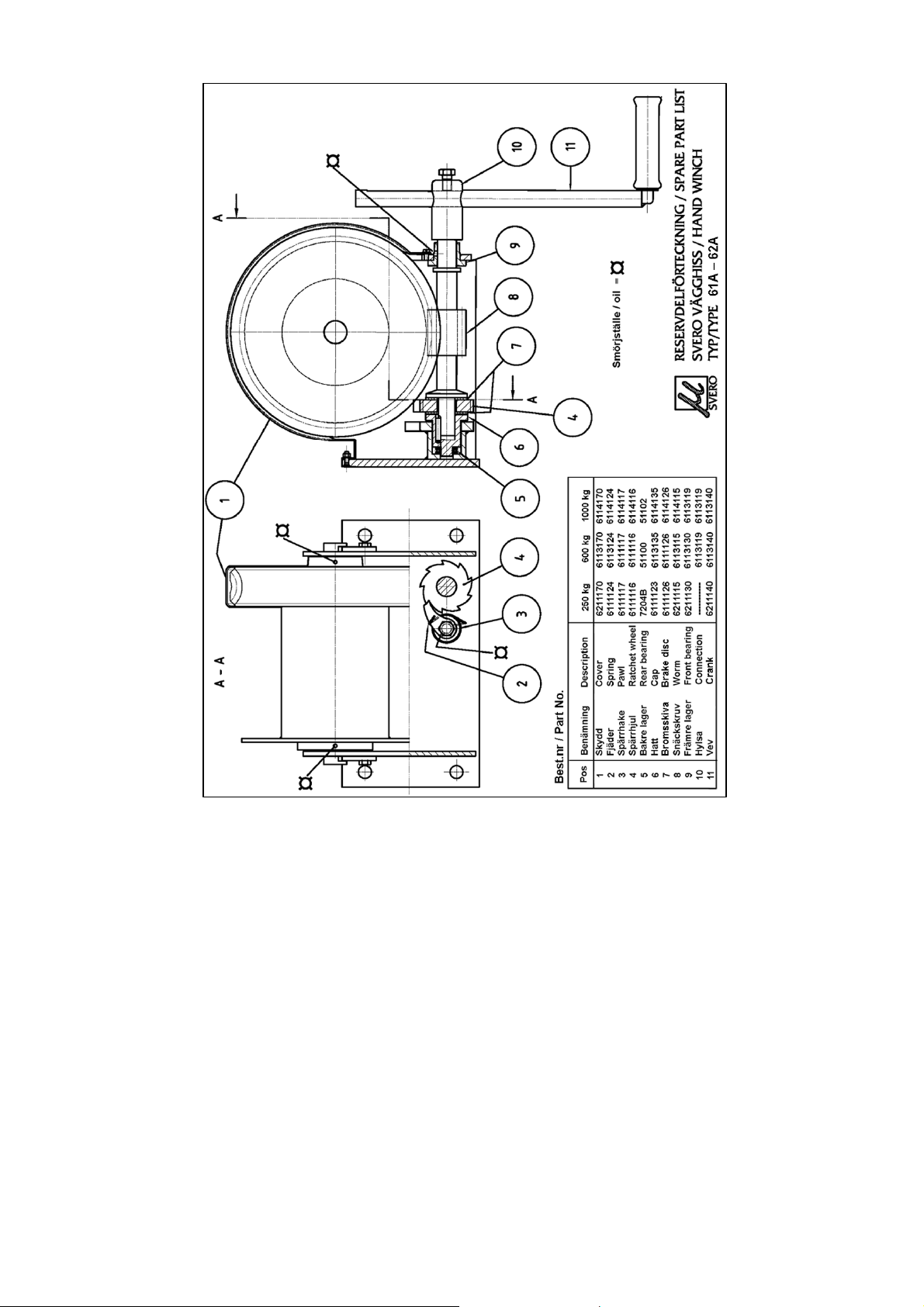

Technical data

Model Max. load

kg Rope diameter *

mm Rope capacity

mCrank

rotations per

m lifting height

Weight

excl.

rope

kg

6211A 250 4, 5, 639, 20, 12 32 12

6113A 600 6,8, 9, 10 36, 17, 11,6 34 27

6114A 1000 8, 10, 12 58, 37, 22 38 36

*The wire rope must be of round strand type with at least 114 wires, or 133 wires with a

steel core or equivalent. It must have a safety factor against breakage of at least 8 – see

also SS 767 15 01.

Mounting of wall-mounted winch

Mount the winch on a flat wall surface of sufficient bearing capacity. This must be particularly

observed in older buildings. Use suitable screws and tighten them equally hard (wood screws must

not be used). Check that the worm wheel and screw are greased and the bearings lubricated.

Tighten the crank with the hexagonal screw. The crank may be kept in an alternative location

protected from the public if this seems appropriate. If a wall-mounted winch is mounted high up

over a floor, it should be ensured that the crank cannot work loose and fall down. Secure the crank

by drilling a hole through the end of the crank shaft and pressing a locking pin of appropriate length

through it.

Outdoors, the wall-mounted winch must be protected from the weather with roof, cover or housing,

with ventilation from below.

Mounting the wire rope

Rope length must be long enough to ensure at least two turns (safety

turns) on the rope drum. Rope ends must be whipped or otherwise

protected from unravelling. Insert one rope end through a hole in the

right-hand flange of the rope drum and then lock as follows: With

press locks according to the Talurit method or by bending the rope

end double and fitting one or preferably two shackle locks.

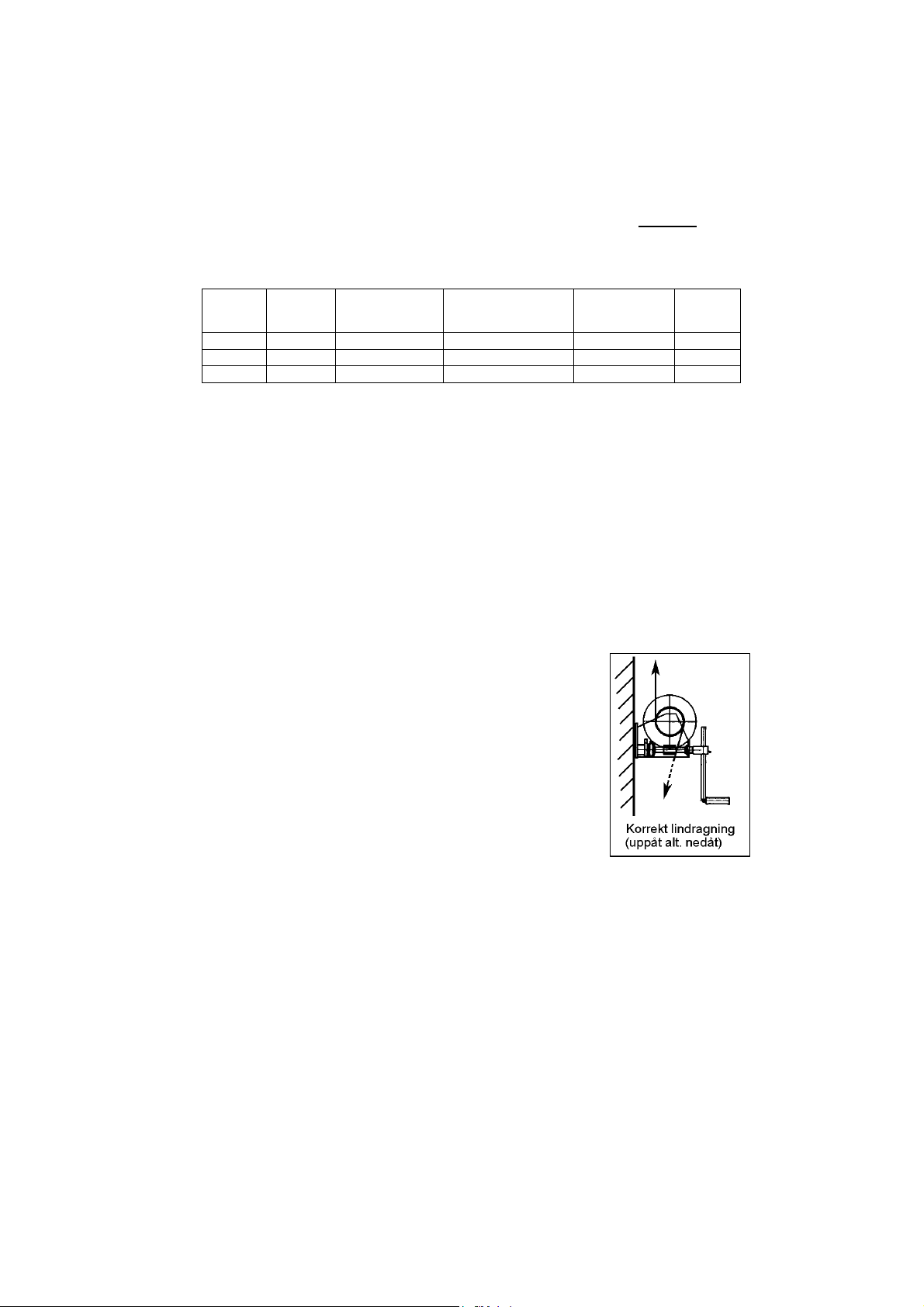

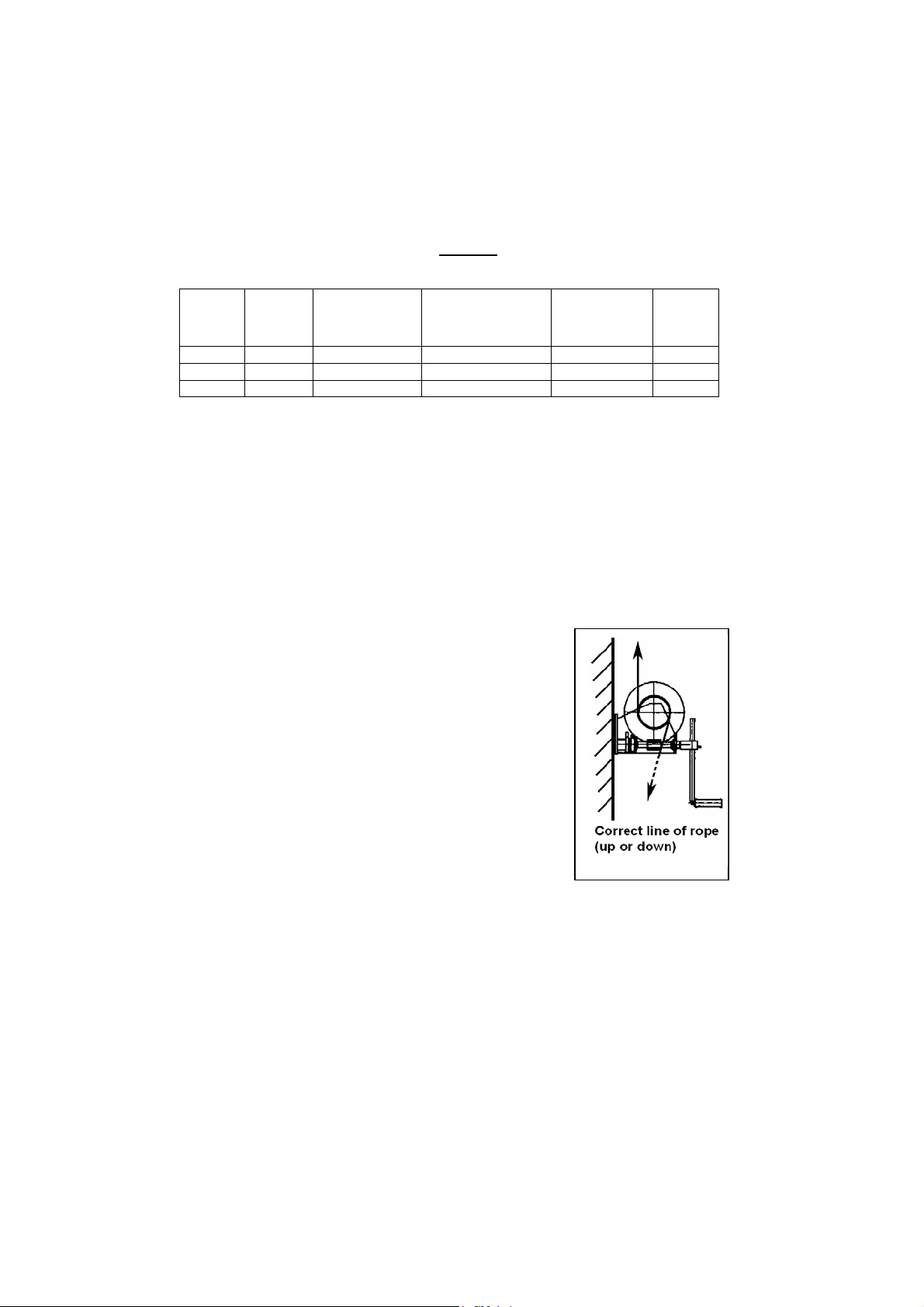

The rope outlet must be such that the torque on the rope drum exerts

pressure on the backpiece and forces the parts of the reaction brake

together. The heavier the load the higher will be the brake friction.

The rope must therefore be pulled upwards from the side of the drum

nearest the wall, or alternatively downwards from the front side of the

drum as in Fig. 1.

Fig. 1 Rope arrangement