DEGREE CONTROLS ROOSTER PRESSURE 100 User manual

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

1 of 30

High Performance Air Pressure

Sensor

with Full-Color Touch Screen Display

Version 1.01

Complete Kit includes:

oSensor Display Module

oPressure Sensor

oPower Supply (optional)

oDoor Switch (optional)

This is proprietary information of Degree Controls Inc., contents are protected under US copyright laws ©

Degree Controls, Inc. 2020.

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

2 of 30

Contents

Product Overview..................................................................................................................................................4

Contents ....................................................................................................................................................................4

Hard Button Overview ...............................................................................................................................................5

Soft Buttons and Home Screen Layout ......................................................................................................................6

Rear Panel Layout for Advanced Connections...........................................................................................................9

Technical Specifications.......................................................................................................................................10

Connection and Wiring Information ....................................................................................................................10

Door Switch Input....................................................................................................................................................11

Unoccupied Room Input ..........................................................................................................................................11

Alarm Output...........................................................................................................................................................11

Mechanical Information ...................................................................................................................................... 12

Display Module Mechanical Drawing......................................................................................................................12

Pressure Sensor Mechanical Drawing .....................................................................................................................12

Template for Pressure Sensor Mounting .................................................................................................................13

External Face Plate Mechanical Drawing ................................................................................................................13

Installation .......................................................................................................................................................... 14

Installation Overview...............................................................................................................................................14

Back Plate Mounting - Display Module ...................................................................................................................15

Installation Example................................................................................................................................................15

Boot Up Procedure .............................................................................................................................................. 19

Access Tier Privileges: USER, EH&S & CERTIFIER .................................................................................................. 20

Set/Change Passwords ........................................................................................................................................20

Calibration...........................................................................................................................................................20

Thresholds ........................................................................................................................................................... 21

Occupied and Unoccupied Thresholds.....................................................................................................................21

Adjust Occupied and Unoccupied Thresholds..........................................................................................................21

Alarms/Sound......................................................................................................................................................22

Alarm Controls.........................................................................................................................................................22

Brightness............................................................................................................................................................ 25

Pressure Resolution............................................................................................................................................. 25

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

3 of 30

I/O Polarity..........................................................................................................................................................26

Data Logging........................................................................................................................................................26

Troubleshooting ..................................................................................................................................................27

Alarm Troubleshooting............................................................................................................................................27

General Troubleshooting.........................................................................................................................................27

USB Field Upgrade Procedure .............................................................................................................................. 28

Factory Reset Procedure...................................................................................................................................... 28

GUI Map ..............................................................................................................................................................29

Warranty ............................................................................................................................................................. 30

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

4 of 30

Product Overview

Congratulations on your purchase of the RoosterTM Pressure100, the next-generation air

pressure sensor and alarm for critical pharmaceutical and clean room applications where

constant positive or negative air pressure differential is required to be viewed, monitored,

alarmed, and even communicated to building and laboratory systems.

Degree Controls Inc. designed the RoosterTM Pressure100 to meet the demand for high

performance room pressure sensing applications with an intuitive, glove-friendly, color

touchscreen interface and best-in-class pressure and humidity sensing module. The

instrumentation class sensors inside require no ongoing factory recalibrations, merely an annual

recertification process. The RoosterTM Pressure100 comes calibrated and with a certificate of

conformance.

The RoosterTM Pressure100 uses a bright, backlit display and contains many simple-to-use

features and configuration capabilities built into an intuitive user interface that requires little to

no training to learn. Password-protected access tiers ensure greater safety in a range of

environments by limiting access to critical functions and system settings for specific, authorized

users.

The RoosterTM Pressure100 is the first pressure sensor with USB-based plug and play firmware

upgrades to keep your product current and operating to the latest standards. Register with us to

receive these product updates at http://www.degreec.com/en/support/register.html.

This manual will guide you through installation, firmware upgrades, alarm control settings, and

the full range of features for the RoosterTM Pressure100.

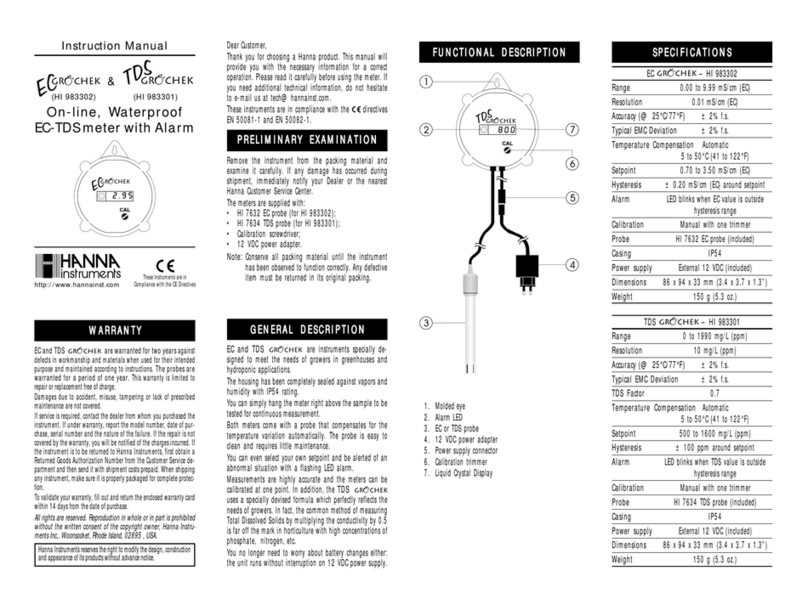

Contents

The RoosterTM Pressure100 consists of:

(1) Display Module

(1) Pressure Module, comprised of:

Pressure Sensor with connected Sensor

Cable, length is 2m [6.6’]

External Face Plate

Flexible Tubing, length is 610 mm [2’]

(1) Power Cable

(4) Sheetrock Anchors

(4) Screws-Phillips Flat Head #6x1”Wood Screw (For

mounting Pressure Sensor & External Face Plate)

(2) Screws–Phillips Flat Head 6-32x1”Machine Screw

(For mounting Display Module Back Plate)

(1) Template for Pressure Sensor Mounting

as well as your power selection and door switch kit option. Available Power Selections are:

Customer Supplied Power with Semi-Flush Mount Back Plate

US Power Supply with Wall Mount Back Plate

European Power Supply with Wall Mount Back Plate

Specify “Included” at time of order to have the optional Door Switch Kit included.

Figure 1 RoosterTM Pressure100 Contents

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

5 of 30

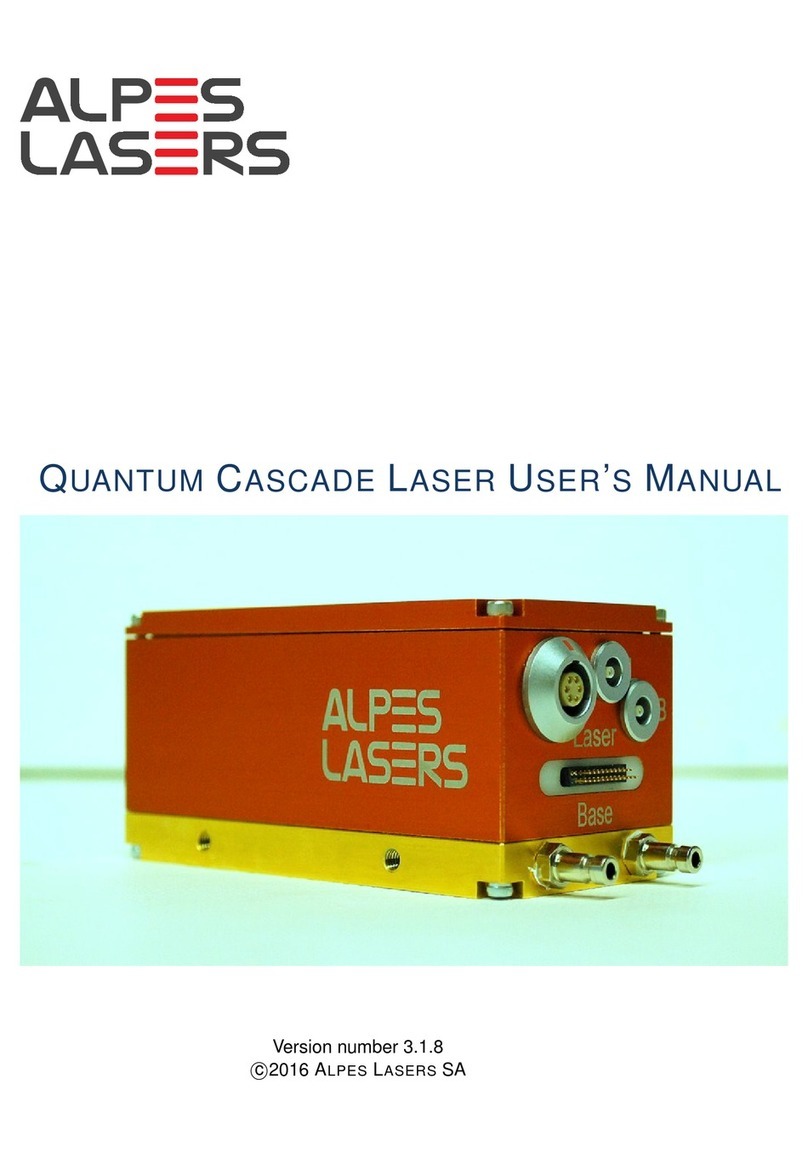

Figure 2 Pressure Module, Cover Removed

Figure 3 External Face Plate with Removable Cover

Hard Button Overview

MUTE

Mutes the audible alarm, any time it is sounding. When the alarm

has been muted, a mute icon [ ] will appear in the top center

portion of the home screen. Just like a snooze button, the

audible alarm will re-sound, when the configurable time-out is

reached if ringback has been enabled.

HOME

Returns the user to the home screen when pushed from any

menu or info screen. * Cannot be used to abort some critical

system functions. *

LED

This red LED will flash while a pressure alarm is active. If the

room is in an Unoccupied state, the alarm will be muted by

default and the LED will flash during a pressure alarm. In all other

cases, this LED will remain off.

Cover

Base

Cover

Base

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

6 of 30

Soft Buttons and Home Screen Layout

PRESSURE MODE

The pressure mode is displayed above the pressure reading on the home screen, Negative

Room, Positive Room.

>Home

TOGGLE AIR PRESSURE UNIT TYPE

Instantly toggle displayed pressure units between Pascals, inches of water, or centimeters of

water by pressing on the displayed room differential pressure reading on the home screen.

>Home

TOGGLE TEMPERATURE UNIT TYPE

Instantly toggle displayed temperature units from Fahrenheit to Celsius or vice versa by

pressing on the displayed temperature reading on the home screen.

>Home

ON-SCREEN ALERT BANNERS

A yellow banner will appear beneath on-screen pressure readings to alert users of the

following scenarios: 1) Uncalibrated Sensor 2) Sensor Module Failure 3) Low/High Room

Pressure. Alarm latched status will also display here.

>Home

USB INTERFACE FOR FIELD UPGRADE PROCEDURE

Firmware upgrades can be installed on-site via USB flash drive.

CUSTOMIZABLE BOOT SCREEN

Our engineers can configure your unit with a custom image or logo file (240x320) in portable

network graphic (.png) format to display on bootup. Contact our sales team to get started:

Room Name

Air Pressure

(touch to toggle units)

% Relative Humidity

Air Temperature

(touch to toggle units)

Settings Menu

USB input for keyboard

and firmware upgrades

Time of Day

Alert Banner

Quick access to current

configuration settings including

alarm thresholds, calibration date,

and firmware version

Status Color (Green, Yellow or Red)

Unoccupied Room/Mute Indicator

Data Logging Indicator (Green Dot)

Pressure Mode

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

7 of 30

ALARM VOLUME

Users can toggle through low, medium or high alarm volumes. If logged in as an EH&S or

Certifier, a global minimum volume threshold can be set. This restricts a standard user from

setting an alarm volume too low for a facility’s safety requirements.

Home> Settings>System>Alarms/Sound>Device Volume

KEYPAD SOUNDS

Users may toggle keypad beep sounds on and off.

Home> Settings>System>Alarms/Sound>Key Beep

ALARM LATCHING

EH&S or Certifier users can set up latched alarms to indicate that a low or high pressure state

has occurred in the “Alarms/Sound

Alarm Controls” menu. Optionally, a password can be required to clear any latched alarms.

Users must then enter EH&S or Certifier passcode to unlatch an alarm.

Home> Settings>System>Alarms/Sound>Alarm Controls>Latch Alarm

ALARM RINGBACK

EH&S or Certifier users can configure the amount of snooze time before an alarm rings again

after being muted in the “Alarms/Sound

Alarm Controls” menu.

Home>Settings>System>Alarms/Sound>Alarm Controls>Alarm Delay Settings>Ringback

BACKLIGHT DIMMING

Users can toggle the brightness setting, as well as the brightness of the screen when set to

“dim”. A “time before dim” option is available that sets the screen to dim after a

predetermined amount of time has expired.

Home> Settings>System>Brightness

PRESSURE RESOLUTION

EH&S or Certifier users can select the resolution of air pressure units displayed in Pascals,

inches of water, or centimeters of water.

Home>Settings>System>Pressure Settings>Pressure Resolution

CLOCK

Users logged in as EH&S or Certifier can set time, date and change clock to display in 12 or 24

hour format.

Home> Settings>System>Time>Date and Time Settings

ADJUSTABLE I/O POLARITY

Users may connect a variety of dry contact relay devices, like wall switches or door sensors, to

indicate whether the room has been accessed in either an Occupied or Unoccupied state. The

way the Rooster Pressure100 interprets the trigger signals from these devices can be adjusted

by changing the I/O polarities from Normally Open or Normally Closed states.

Home> Settings>System>Advanced>I/O Polarity

CUSTOM ROOM NAME

Users logged in as EH&S can change the default “Room Name” to a custom name. This is

useful for naming the sensor in larger distributed systems, or to denote a company asset

number. The user may set a 12-digit numeric room name with the provided on-screen

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

8 of 30

keypad OR plug in a USB interface keyboard to enter a 12 character alphanumeric tag.

Home> Settings>System>Advanced>Configure Room Name

PASSWORD-PROTECTED ACCESS TIERS: CERTIFIER & EH&S

Password protected access tiers enable advanced configuration options and features.

Home> Settings>System>Advanced>Change Passwords

UNOCCUPIED ROOM THRESHOLD

EH&S or Certifier users can configure two convenient modes of operation, Occupied or

Unoccupied, each with their own threshold triggers. This is especially useful when users

desire to mute alarms and/or adjust thresholds when the room is unoccupied, typically for

night service conditions. For more information on setting thresholds, see thresholds section

of manual.

Home> Settings>Thresholds

DATA LOGGING

The RoosterTM Pressure100 features a data logging feature with the ability to export to .csv file

via USB drive. When data logging is active, a green dot will appear at the top of the screen

next to the clock. The default polling rate is 5 seconds, but this can be adjusted from 1

second up to 1 minute.

Home>Settings>System>Data Logging

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

9 of 30

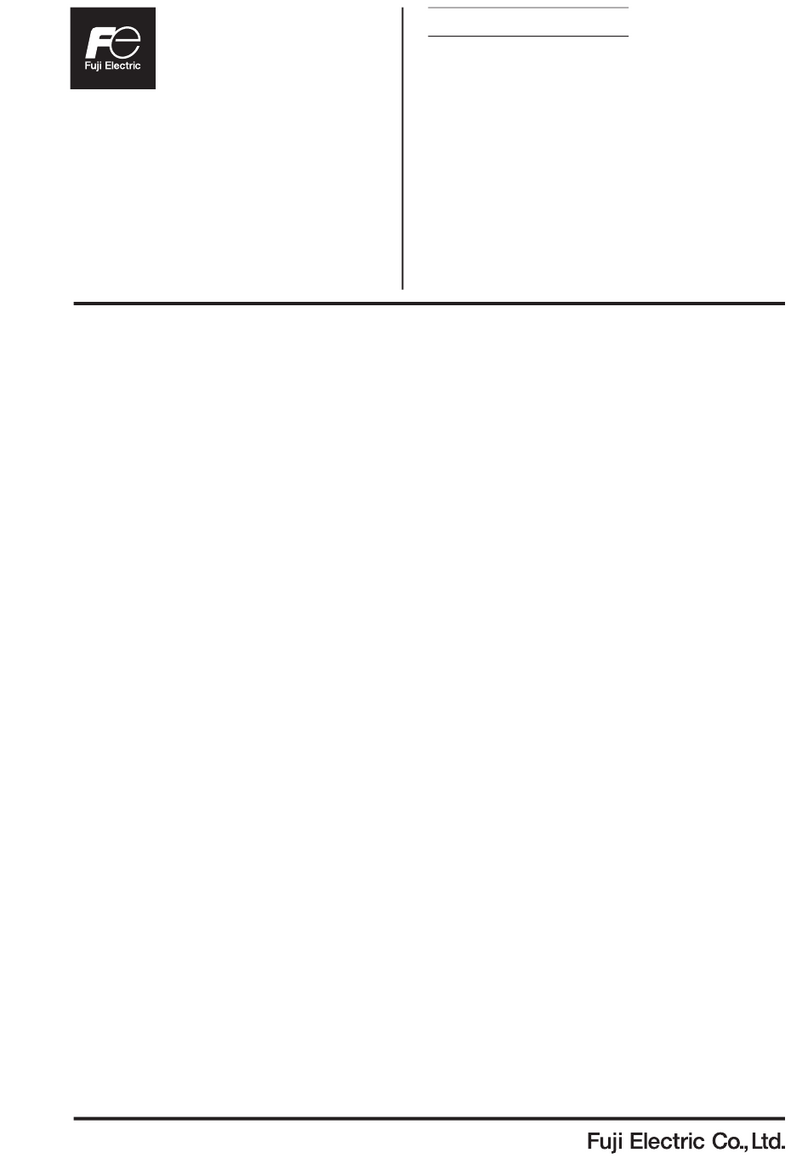

Rear Panel Layout for Advanced Connections

Figure 4 Connections

Connection

Description

Connector Type

Mating Connector

Power Entry

2-pin, polarized,

Phoenix Contact

Included with display module.

RS485

4-pin, push-in

spring connection

Included as part of pressure sensor.

For replacement, Part Number: Phoenix Contact 1778573

Output

Connection

8-pin, polarized,

Phoenix Contact

*2-position

connectors will fit

Not included.

8-position orderable Part Number: Phoenix Contact 1803633

2-position orderable Part Number: Phoenix Contact 1803578

Input

Connection

10-pin, polarized,

Phoenix Contact

*2-position

connectors will fit

Not included.

10-position orderable Part Number: Phoenix Contact 1803659

2-position orderable Part Number: Phoenix Contact 1803578

RJ-11

Connection

RJ-11

Not used.

Table 1 Connections - Rear Panel of Display Module

The Door Switch Kit Option is specified at time of order.

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

10 of 30

Technical Specifications

Connection and Wiring Information

Degree Controls recommends 18-24 AWG wire be used for all wiring connections to the input

and output connectors. The Power Entry connection has been prepared for you, and merely

needs to be pulled through the electrical box knock-out and connected to the Power Entry

connection of the display module.

The supplied sensor cable is terminated both ends and ships connected to the pressure sensor.

It needs to be pulled through the electrical box knock-out and connected to the RS485

connection of the display module.

Note: This manual describes a typical installation where the display module mounts semi-flush to

a standard electrical box. Other installation scenarios are possible.

Alarm Module Size

3.2” x 5.3” x 1.3” (82mm x 135mm x 32mm)

LCD Display Area

2.25”x 2.73” (57mm x 69mm)

Pressure Sensor Size

3.0”x 1.8” (77mm x 46mm)

External Face Plate Size

3.0”x 1.2” (77mm x 31mm)

Differential Pressure Sensing Range

-125 to +125 Pa (-0.5 to +0.5 in H2O)

Air Pressure Accuracy

3% of reading + 0.08 Pa (0.00032 in H2O)

Air Pressure Repeatability

0.5% of reading + 0.04 Pa (0.00016 in H2O)

Response Time

< 1 second

Supply Voltage –Display Module

24 VAC/VDC

Door Switch Input

Dry Contact Closure

Unoccupied Room Input

Dry Contact Closure (0V)

Relay Output

Qty. (1), 1A, 24VDC [Pin 1-2 Differential Pressure Alarm]

Optional Power Adapter

90-250V

Red LED indicator

160° viewing angle

Alarm Volume

0 - 85dB (adjustable)

Operating Relative Humidity

(non-condensing) 5 - 95%

Humidity Sensing Range

0-100% RH; accuracy ±2% at 0-80% RH, ±3% at 100% RH

Operating Temperature

40°F - 140°F (5°C - 60°C)

Storage temperature

-40°F - 185°F (-40°C - 85°C)

Product Weight

1 lb (454g)

Total Packaged Weight

1.5 lbs (680g)

Compliance Standards

RoHS

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

11 of 30

The I/O connectors present on the RoosterTM Pressure100 have some pins deactivated as these

are reserved for future RoosterTM models designed for more advanced control functionality.

Leave these pins non-connected.

Door Switch Input

This door switch input is a digital input, dry contact, and the default I/O polarity of this door

switch input is normally closed. The design intent is that the door switch input be used in

combination with an external sensor to detect whether a door is open or closed:

Switch open means door open, and

switch closed means door closed.

Door switch input logic may be reversed using the I/O Polarity menu on the Rooster™

Pressure100 to achieve a different result.

DegreeC can provide you with an optional Door Switch Kit comprised of (1) dry contact sensor

with screw terminals and (1) 10-position connector which mates to the input connection of the

display module. For this dry contact sensor, the cable length from door switch to display

module can be 30m [100’] or more. If multiple door switches are being used, they should be

wired in series.

Note: Specify “Included” at time of order to have the optional Door Switch Kit included.

Unoccupied Room Input

The RoosterTM Pressure100 provides an additional digital input for room status, and default I/O

polarity of the unoccupied room input is normally open. The purpose of the Unoccupied room

input is to allow the user to use two different sets of alarm thresholds based on whether the

room is in an occupied or unoccupied state. Unoccupied room input logic may also be reversed

using the I/O Polarity menu on the Rooster™ Pressure100.

Once the wiring connections have been made, the user can assert the unoccupied room signal.

Three room profile alarm states can be selected:

Off (default): In this state, when the unoccupied room signal is asserted, the Pressure100

will ignore it.

Muted: In this state, when the unoccupied room signal is asserted, the Pressure100

triggers a muted alarm when pressure moves beyond Unoccupied Thresholds.

Unoccupied Thresholds are independently set.

Audible: In this state, when the unoccupied room signal is asserted, the Pressure100 will

audibly alarm when pressure moves beyond Unoccupied Thresholds.

Alarm Output

The RoosterTM Pressure100 alarms for differential pressure. The Alarm output is a relay output

and available on the output connection of the display module. I/O polarity logic of this output

may be reversed as well. See the I/O Polarity menu of the Rooster™ Pressure100.

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

12 of 30

Mechanical Information

Display Module Mechanical Drawing

Figure 5 Display Module Mechanical Drawing

Pressure Sensor Mechanical Drawing

Figure 6 Pressure Sensor Dimensions

Rear Panel of Display Module

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

13 of 30

Template for Pressure Sensor Mounting

Figure 7 Pressure Sensor Mounting Template Dimensions

External Face Plate Mechanical Drawing

Figure 8 External Face Plate Dimensions

Optional Pre Pilot Drill

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

14 of 30

Installation

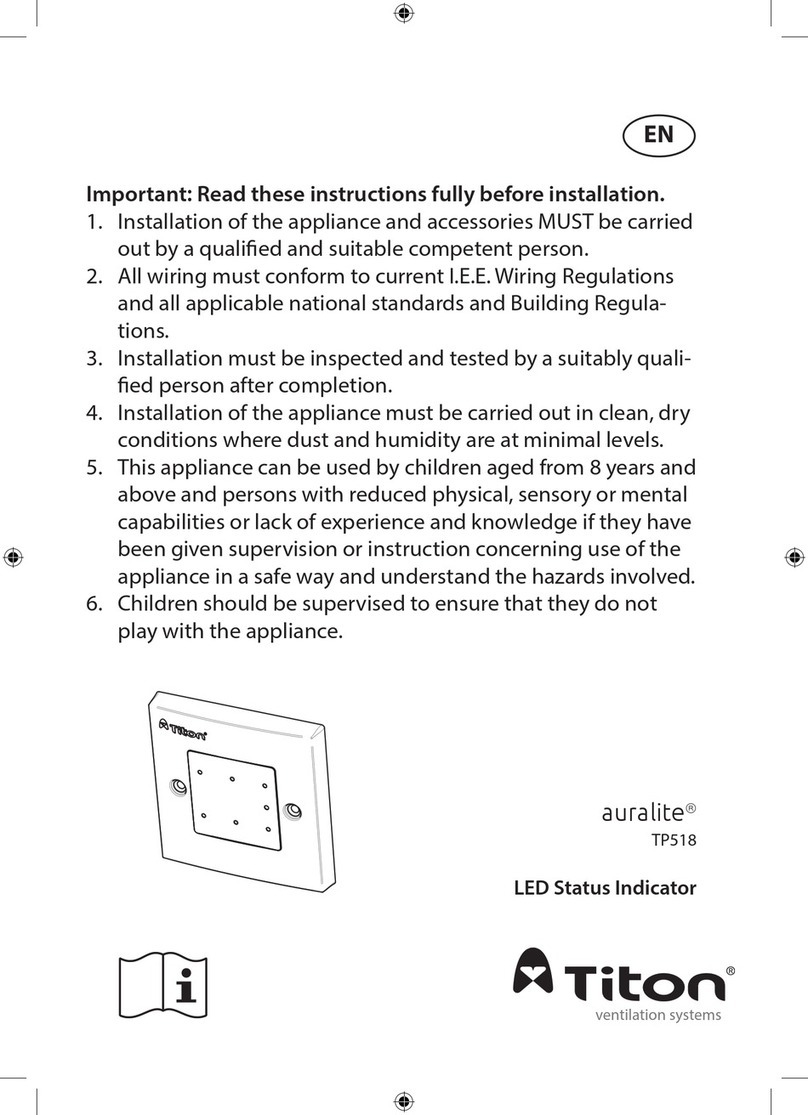

Installation Overview

Installation of the RoosterTM Pressure100 involves selecting and preparing an appropriate location,

wiring and connecting the unit, and then mounting the unit to the wall securely.

Notes:

Typically, the RoosterTM Pressure100 display module is mounted near an access door, at

eye level, and in the controlled room, with the pressure sensor mounted above it.

oIf you choose to mount the display panel in the reference space rather than the

controlled space, or choose some other mounting arrangement, the RoosterTM

Pressure100 will still work.

Customer supplied power with Semi-Flush mount back plate or included power supply

with Wall Mount back plate is specified at time of order. See Back Plate Mounting

section for more information.

It is recommended that the pressure module be located above the display module, and

within the same stud, for efficient wiring.

The pressure sensor should be mounted in an area free from drafts and turbulence.

The external face plate must be mounted opposite the pressure sensor in an adjacent

room or space.

You will need to connect the supplied flexible tubing between the pressure sensor and

the external face plate.

You will need to connect power, sensor and optional door switch & unoccupied room

input wires to the display module.

Be sure to leave enough room so that the display module’s USB port can be accessed.

Only qualified Facilities personnel should install the RoosterTM Pressure100.

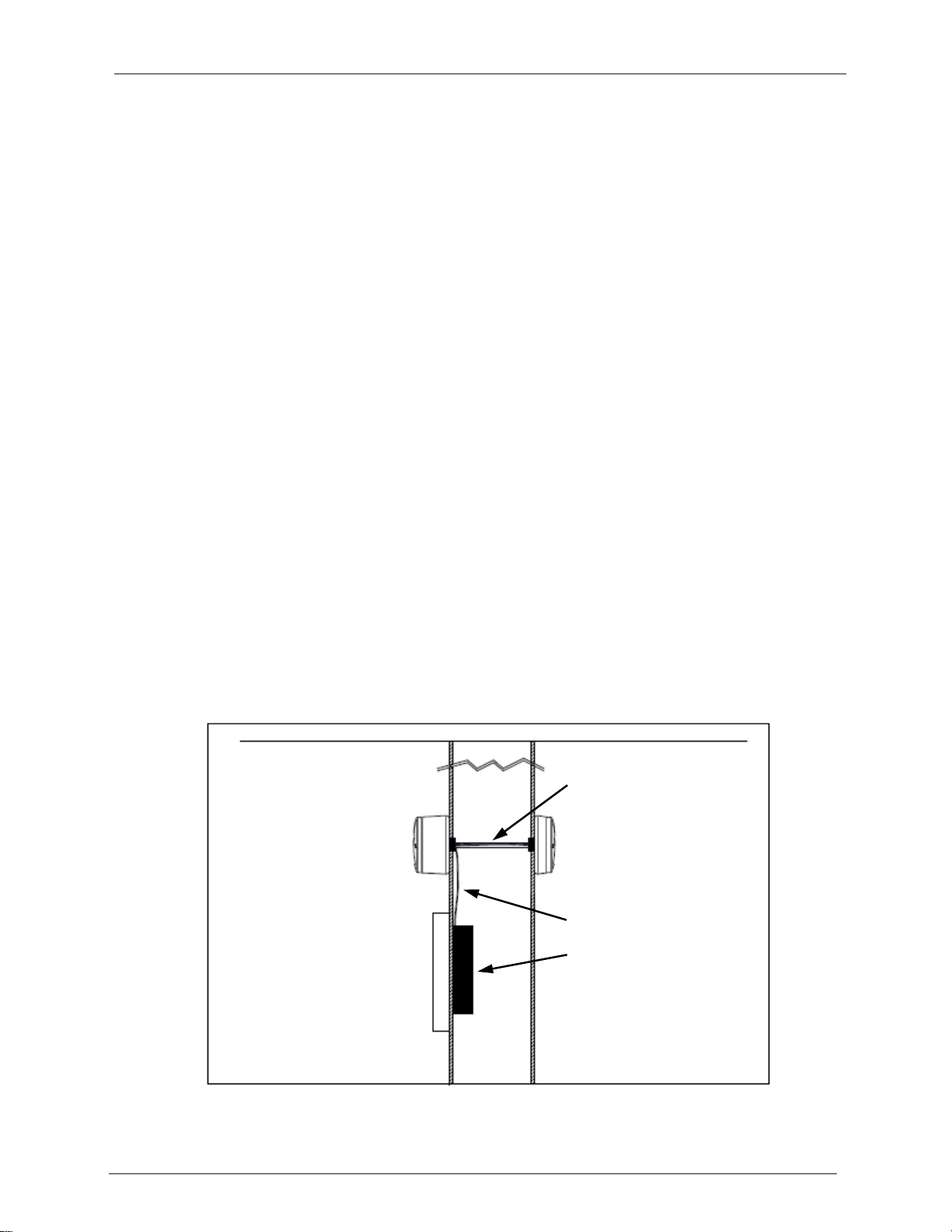

Figure 9 Typical Installation for RoosterTM Pressure100

Pressure Sensor

Electrical Box

Display Module

CEILING

CONTROLLED SPACE

REFERENCE SPACE

External Face Plate

Sensor Cable

Tubing

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

15 of 30

The Rooster Pressure100 is a pre-calibrated device, with stated accuracy performance. It

does not require any special certification process to function properly. However, this

should not imply that industry standard annual laboratory certification processes should

not be adhered to. This should be conducted at the end user discretion.

Back Plate Mounting - Display Module

The display module can be mounted using one of two back plate options:

Semi-Flush: The back plate sits partially inside a standard electrical box and is secured by self-

tapping screws. There is open back access to accept building power.

Wall Mount: The back plate sits directly on a wall or surface and is secured by self-tapping

screws or industrial Velcro. Sensor and control wiring access is at the back, while access for

power in from the wall mount power supply is at the bottom.

Figure 10 Semi-Flush Mount (left), Wall Mount (right) –for Display Module

Installation Example

The installation steps below represent a typical drywall installation with customer supplied power

and semi-flush mount back plate for display module.

Mounting Preparations

1. Determine mounting locations for the RoosterTM Pressure100 display module and

pressure sensor.

Display Module Mounting Preparation

2. Mark the wall for the electrical box where the RoosterTM Pressure100 display module will

be located, and make the cutout.

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

16 of 30

a. The display module is designed to mount semi-flush where the back plate sits

partially inside a standard electrical box. Using this method, the display module

protrudes 15mm [0.6”] from the wall.

Figure 11 Semi-Flush Back Plate Mounting

Pressure Sensor Mounting Preparation

3. Using the enclosed template, mark the wall for pressure

sensor mounting. Take care to orient the template right

side up such that mounting holes are vertical.

4. Use a ¼” drill bit to drill holes for Tubing and Cable.

5. Install (2) drywall anchors.

External Face Plate Mounting Preparation

6. Use a ¾” drill bit to drill the center hole.

7. Drop the base of the external face plate (boss side) in the

hole, and mark the wall for face plate mounting.

Mounting holes should be horizontal.

8. Remove base from wall, and install (2) drywall anchors.

Pressure Sensor Connection and Mounting

The pressure module is comprised of a pressure sensor with connected sensor cable, external

face plate, and flexible tubing to connect the pressure sensor to the external face plate. The

pressure sensor and external plate are mounted on opposite sides of a wall which separates the

controlled environment from the outside, reference space. Inside the sensor are two pitons, one

of which is indicated with a red dot.

Electrical Box

Display Module Back Plate

Cable

Tubing

Mounting (2X)

Figure 12 Tubing & Cable Holes

¾” Drill

Mounting (2X)

Figure 13 Drop In Boss Side of

Base to Locate Mounting Holes

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

17 of 30

The pressure sensor is typically mounted on the side of the wall with the display module.

9. Feed the flexible tubing through the pressure sensor base.

10. Connect the tubing to the appropriate piton on the pressure sensor. Be sure to leave

enough bend radius to ensure that the tubing will not kink, disrupting airflow.

Which piton you connect the tubing to depends on the environment in which the module is

placed:

If the external face plate is in a neutral pressure environment and the display module and

pressure sensor are in a pressurized environment (positive or negative), connect the

tubing to the piton not marked with the red dot.

If the display module and pressure sensor are in a neutral pressure environment and the

external face plate is inside a pressurized environment (positive or negative), connect the

tubing to the piton marked with the red dot.

11. Feed the tubing and sensor cable from the pressure sensor through the wall to the

external face plate and display module mounting locations respectively.

12. Run a bead of laboratory grade caulking, and fasten the pressure sensor securely to the

wall using the included screws.

13. Install cover: Align tabs, push cover onto base, and turn clockwise to lock in place.

Figure 14 Pressure Sensor Mounting

Display Module Connections and Mounting

14. Have a qualified electrician run 24 VAC/VDC to the prepared cutout, and connect to the

supplied power cable.

15. Punch out the appropriate knock-outs on the electrical box that will be secured to

drywall, route power and the sensor cable into the box, and install box to wall.

Note: Optional building management system or laboratory control system wiring should

be completed at this time.

Cover

Base

Screw (2X)

Cable

Tubing

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

18 of 30

16. Secure the display module back plate using

the included screws.

17. Connect power and sensor to the display module.

Make any other optional connections to the

display module.

18. Align right side of display module with tabs on

back plate and snap display module in place.

External Face Plate Connection and Mounting

19. Connect the flexible tubing from the pressure sensor to the

base of the external face plate. You may trim the tubing to

length, but be sure to leave enough slack in the tubing to

prevent any kinks that may disrupt airflow.

20. Run a bead of laboratory grade caulking, and fasten the face plate to the wall using the

included screws.

21. Install cover: Align tabs, push cover onto base, and turn clockwise to lock in place.

Power

Cable

Sensor

Cable

Figure 15 Back Plate Secured to Electrical Box

Figure 16 Power & Sensor Connection

Figure 17 Tubing Connection

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

19 of 30

Figure 18 External Face Plate Mounting

Boot Up Procedure

The RoosterTM Pressure100 does not have a power-on switch and will become

energized as soon as you apply power to it. The RoosterTM Pressure100 boots

to the screen depicted on the right, with a slot for a custom logo. The boot

screen is designed to support a custom image or logo file in portable network

graphic (.png) format with (240x320) dimensions. This feature must be

requested and is not setup for manual configuration.

Once the start procedure has completed, the Home screen will appear with

two system buttons and you will need to setup password-protected access

tiers for advanced system functions. This is explained in the “Access Tier

Privileges” section below.

You can reboot your RoosterTM Pressure100 at any time by pushing the hard “Home”and “Mute”

Buttons simultaneously until the Boot Screen reappears.

Tubing

Base

Cover

Screw (2X)

Rooster™ Pressure100 USER MANUAL 62314MN000-A00

20 of 30

ACCESS TIER PRIVILEGES: USER, EH&S & CERTIFIER

Users have the ability to customize their pressure areas within

a defined set of options for each authorization level. There

are three levels of access to the RoosterTM: User,

EH&S/Facility Manager and Certifier. These are managed by

logging in with a 4-digit numerical passcode. The User access

level does not require a passcode.

Access Privileges Defined

Function

Passcode Required

Adjust Alarm Volume

None

Alarm Latching Settings

EH&S, Certifier

Alarm Ringback Settings

EH&S, Certifier

Mute Live Alarm

None

Set Room Name

EH&S

Set Minimum Alarm Volume Threshold

EH&S, Certifier

Set Time / Clock Format

EH&S, Certifier

Toggle between Fahrenheit or Centigrade Temperature Units on Home

Screen

None

Toggle between Metric or Imperial Pressure Units on Home Screen

None

Toggle ON/OFF Keypad Sounds

None

Calibrate

Certifier

Unlatch Alarm

EH&S

Data Logging

EH&S, Certifier

SET/CHANGE PASSWORDS

To change or set a password, follow this GUI path to trigger the password change sequence:

Home>Settings>System>Advanced>Change Passwords

You will have to enter an EH&S or Certifier passcode to access the “Advanced” menu. To change

either the EH&S or Certifier passcode, you must first re-enter the old passcode. Please note that

if you are authorized to perform both EH&S and Certifier functions, you may set an identical

passcode for both access tiers to make logging in and accessing key functions easier.

Calibration

All RoosterTM Pressure100s are pre-calibrated before leaving the factory,

however we recommend a final recalibration when installation is complete.

Your local certifier should be recalibrating the unit on an annual basis, or

according to your laboratory directives. The calibration menu can be accessed

here:

Home>Settings>Calibration

Manufacturer default passcodes:

EH&S = 6823

Certifier = 1459

Table of contents

Other DEGREE CONTROLS Measuring Instrument manuals