2ENGLISH

Contents Page

Table of contents UK

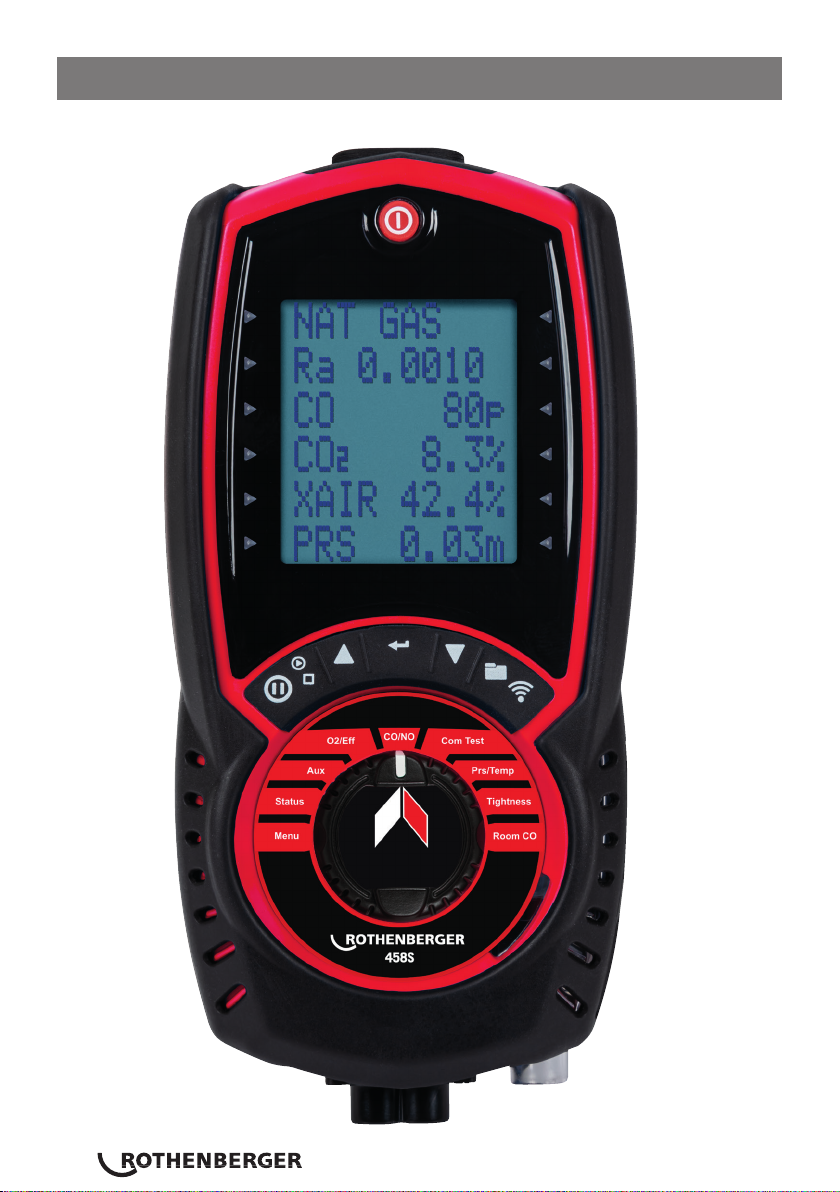

1 RO 458s Overview 4

2 Analyser Features and Keypad 6

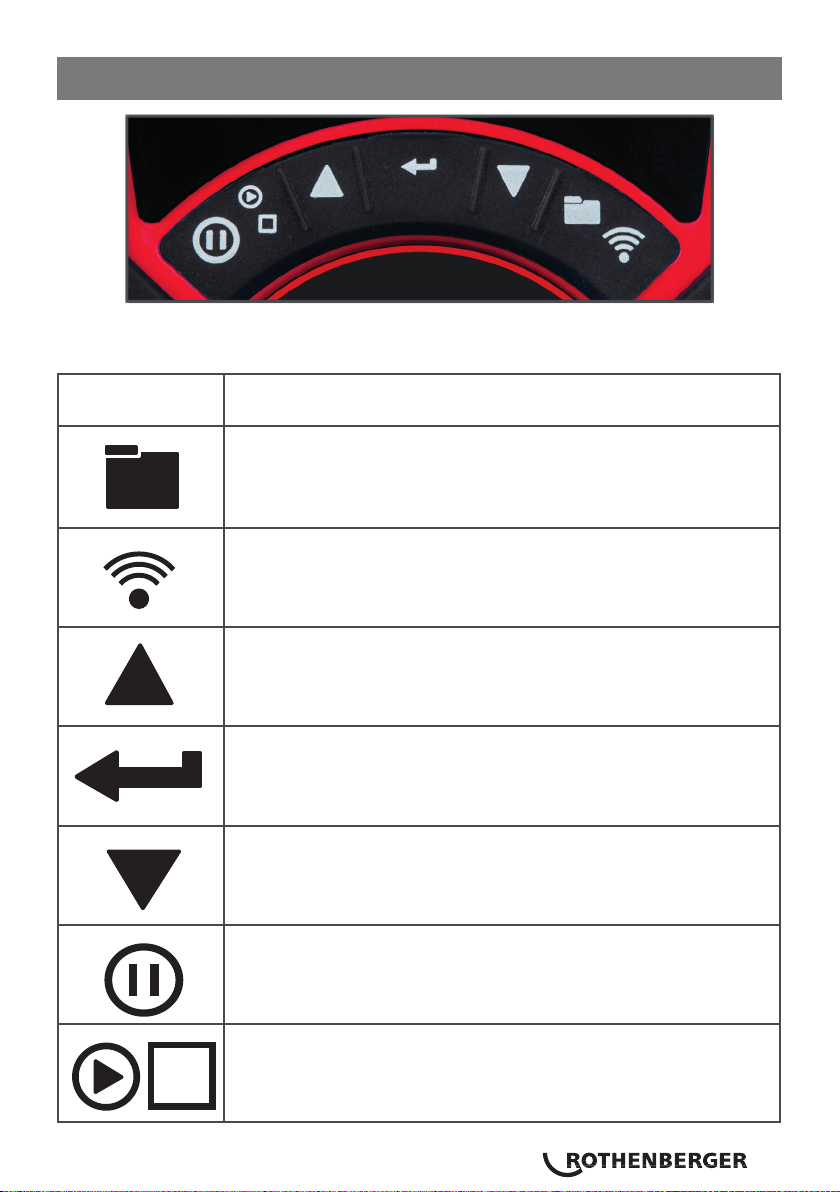

2.1 RO 458s Buttons 7

2.2 Analyser Layout 8

3 Batteries 10

3.1 Replacing batteries 10

3.2 Time & date 10

3.3 Charging NIMH batteries 10

3.4 Battery disposal 10

4 General Safety 11

4 Using your RO 458s for the first time 12

4.1 Using your RO 458s every time 12

4.2 Fresh air purge switch on 12

5 Using the menu 14

6 Measuring flue gasses 16

7 CO protection pump operation 17

7 CO protection pump operation 17

8 Using your analyser 17

8.1 Combustion tests 17

8.2 Ratio display 18

8.3 O2/Eff display 18

9 Transferring results 19

8.4 AUX display 19

9.1 To view/print a logged report 19

9.2 Viewing/printing a logged combustion test 20

9.3 Kane infrared printer 20

9.4 Printouts 21

10 Commissioning test 22

11 Pressure & temperature testing 23

11.1 Pressure measurement good practice 24

11.2 Large bore tubing issues 24

1 RO 458S OVERVIEW..............................................4

2 ANALYSER FEATURES AND KEYPAD ....................6

2.1 RO 458S BUTTONS..........................................................7

2.2 ANALYSER LAYOUT ........................................................8

3 BATTERIES ...........................................................10

3.1 REPLACING BATTERIES .................................................10

3.2 TIME & DATE.................................................................10

3.3 CHARGING NIMH BATTERIES .......................................10

3.4 BATTERY DISPOSAL......................................................10

4 GENERAL SAFETY ...............................................11

5 USING YOUR RO 458S FOR THE FIRST TIME ......12

5.1 USING YOUR RO 458S EVERY TIME..............................12

5.2 FRESH AIR PURGE SWITCH ON ....................................12

6 USING THE MENU ...............................................14

7 MEASURING FLUE GASSES.................................16

8 CO PROTECTION PUMP OPERATION ..................17

9 USING YOUR ANALYSER.....................................17

9.1 COMBUSTION TESTS.....................................................17

9.2 RATIO DISPLAY.............................................................18

9.3 O2/EFF DISPLAY............................................................18

9.4 AUX DISPLAY ................................................................19

10 TRANSFERRING RESULTS ...................................19

10.1 TO VIEW/PRINT A LOGGED REPORT............................19

10.2 VIEWING/PRINTING A LOGGED COMBUSTION TEST .....20

10.3 KANE INFRARED PRINTER ............................................20

10.4 PRINTOUTS ...................................................................21

11 COMMISSIONING TEST .......................................22

12 PRESSURE & TEMPERATURE TESTING ................23

12.1 PRESSURE MEASUREMENT GOOD PRACTICE ..............24

12.2 LARGE BORE TUBING ISSUES.......................................24

13 LET-BY & TIGHTNESS TESTING ...........................25

14 ROOM CO TESTING .............................................27