DEGREE CONTROLS Rooster Sensor200 User manual

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A001 of 40

User Manual

High Performance Air Velocity and Temperature Sensor

with Full-Color Touch Screen Display

BACnet® MS/TP Capable

Version 1.06

Complete Kit includes:

oSensor Display Panel

oSensor Probe and Mounting Clamp

oPower Supply

This is proprietary information of Degree Controls Inc., contents are protected under US copyright laws ©Degree Controls, Inc. 2022.

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A002 of 40

Contents

Product Overview..............................................................................................................................................................................................................................3

Hard Button Overview................................................................................................................................................................................................................4

Soft Buttons and Home Screen Layout ..................................................................................................................................................................................4

Feature Overview.........................................................................................................................................................................................................................4

Rear Panel Layout for Advanced Connections ....................................................................................................................................................................7

Technical Specifications ..................................................................................................................................................................................................................8

Connection and Wiring Information...........................................................................................................................................................................................9

Sash Input ......................................................................................................................................................................................................................................9

Night Setback Input.................................................................................................................................................................................................................. 10

Auxiliary Input ........................................................................................................................................................................................................................... 11

Outputs ........................................................................................................................................................................................................................................ 11

Mechanical Information............................................................................................................................................................................................................... 13

Alarm Module ............................................................................................................................................................................................................................ 13

Installation........................................................................................................................................................................................................................................ 13

Back Plate Mounting Options - Alarm Module ................................................................................................................................................................ 13

Installation Procedure.............................................................................................................................................................................................................. 14

Probe Sensor............................................................................................................................................................................................................................... 15

Boot Up Procedure........................................................................................................................................................................................................................ 16

Access Tier Privileges: USER, EH&S & CERTIFIER................................................................................................................................................................ 17

Set/Change Passwords................................................................................................................................................................................................................. 18

Calibration –Sash Height............................................................................................................................................................................................................ 18

Sash Readings............................................................................................................................................................................................................................ 18

Alarm Threshold Configuration................................................................................................................................................................................................. 19

Alarm Troubleshooting............................................................................................................................................................................................................ 19

Alarm Controls ................................................................................................................................................................................................................................ 20

Night SetBack............................................................................................................................................................................................................................. 20

Alarm Ringback......................................................................................................................................................................................................................... 20

Alarm Delay................................................................................................................................................................................................................................ 21

Startup Delay ............................................................................................................................................................................................................................. 21

Splash Screen ............................................................................................................................................................................................................................. 22

Latch Alarm ................................................................................................................................................................................................................................ 22

Alarm Tone Settings................................................................................................................................................................................................................. 22

Backlight Dimming ........................................................................................................................................................................................................................ 23

Airflow Settings............................................................................................................................................................................................................................... 23

Airflow Sensitivity...................................................................................................................................................................................................................... 23

Airflow Resolution..................................................................................................................................................................................................................... 23

Volumetric Flow Settings ........................................................................................................................................................................................................ 24

Air Changes Per Hour.............................................................................................................................................................................................................. 25

BACnet® MS/TP............................................................................................................................................................................................................................. 25

BACnet® Protocol Network Settings................................................................................................................................................................................... 25

BACnet® MS/TP Objects ........................................................................................................................................................................................................ 26

I/O Configuration........................................................................................................................................................................................................................... 34

Relay Outputs ............................................................................................................................................................................................................................ 34

Accessory Buttons ..................................................................................................................................................................................................................... 34

Links to Relay Outputs............................................................................................................................................................................................................. 34

I/O Polarity................................................................................................................................................................................................................................. 35

Import/Export.................................................................................................................................................................................................................................. 35

EEPROM....................................................................................................................................................................................................................................... 35

Event Log..................................................................................................................................................................................................................................... 35

USB Field Upgrade Procedure.................................................................................................................................................................................................... 36

Soft Reboot from Info Screen................................................................................................................................................................................................. 37

Power Cycle Procedure............................................................................................................................................................................................................ 37

Factory Reset Procedure.............................................................................................................................................................................................................. 37

GUI Map............................................................................................................................................................................................................................................ 39

Warranty............................................................................................................................................................................................................................................ 40

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A003 of 40

Product Overview

Congratulations on your purchase of the RoosterTM Sensor200, the first the BACnet® MS/TP

capable air velocity and temperature sensor with color touch panel display for facility managers

to achieve local and remote communications simultaneously.

The Rooster™Sensor200 is delivered calibrated and ready to deploy with a probe-style sensor

to monitor ducted airflow. Sensor200 comes with NIST certification, and the instrumentation-

class sensor provides best accuracy across a wide velocity range, 0.15 –20.0 m/s (30 –4000

fpm). Rooster™ provides real-time audible and visual notification at the display module, and

concurrent communication to a building controller over RS485 with the BACnet® MS/TP

communication protocol. Physical and digital configuration programming also work together, as

users may configure Sensor200 using its own touch screen display, or remotely, through

BACnet®.

The Rooster™ Sensor200 is feature-rich, delivering maximum flexibility and control to duct

airflow monitoring applications. Alarm output behavior is fully configurable, and dual password

protection allows users to personalize operational experience, but not override safety features

set by facility managers. Volumetric flow is easily enabled by entering duct information, and

ACH (air changes per hour) functionality is available to measure the air volume added to, or

removed from, spaces within buildings. Sensor200’s built-in USB port allows for in-the-field

firmware updates to future-proof investments in airflow monitoring. Advanced controls include

I/O to drive fans, lighting, or a hard-wired alarm separate from the distributed control system

(DCS). In addition, Sensor200’s PI output may be applied for setpoint control.

This manual will guide you through installation, alarm control settings, firmware upgrades, and

the full range of features for the BACnet®-capable RoosterTM Sensor200.

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A004 of 40

Hard Button Overview

MUTE

Mutes the audible alarm, any time it is sounding. When the alarm has

been muted, a mute icon [ ] will appear in the top center portion

of the home screen. Just like a snooze button, the audible alarm will

re-sound, when the configurable time-out is reached, and if ringback

has been enabled.

HOME

Returns the user to the home screen when pushed from any menu or

info screen. *Cannot be used to abort the calibration procedure and

some critical system functions.*

LED

A red LED will flash while an airflow alarm is active. The red LED will

also flash if Sash and Night Setback alarms are active. In all other

cases, this LED will remain off.

Soft Buttons and Home Screen Layout

Feature Overview

CUSTOM ASSET TAG

Users logged in as EH&S can change default “Asset Tag” to a custom tag. This is useful

for naming the sensor in a larger distributed system, or to denote a company asset

number. A 12-digit numeric asset tag can be set with the provided on-screen keypad, OR

plug in a USB interface keyboard to enter a 12-character alphanumeric tag. Users can

enable or disable display of the Asset Tag.

Home>Settings>System>Advanced>Configure Asset Tag

Startup Delay Indicator, Night

Setback/Mute Indicator

Asset Tag

Face Velocity

(touch to toggle units)

Air Temperature

(touch to toggle units)

Time of Day

Alert Banner

Status Color

(Green, Yellow or Red)

Settings

Menu

Quick access to current

configuration settings including

alarm thresholds, calibration

date, and firmware version

USB input for keyboard

and firmware upgrades

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A005 of 40

CLOCK

Users logged in as EH&S or Certifier can set time, date, and change clock to display in 12

or 24-hour format.

Home>Settings>System>Date & Time>Date & Time Settings

KEYPAD AND BUTTON SOUNDS

Users may toggle keypad and button beep sounds on and off.

Home>Settings>System>Alarms/Sound>Key Beep

DEVICE VOLUME

Users can toggle through low, medium, or high alarm volumes. If logged in as EH&S or

Certifier, a global minimum volume threshold can be set. This restricts a standard user

from setting an alarm volume too low for particular facility safety requirements.

Home>Settings>System>Alarms/Sound>Device Volume

ON-SCREEN ALERT BANNERS

A yellow banner will appear beneath on-screen velocity readings to alert users regarding

various scenarios such as low airflow or power failure.

Home

TOGGLE VELOCITY UNIT TYPE

Instantly toggle displayed velocity units from m/s to fpm, or vice versa, by pressing on the

displayed velocity reading on the home screen. A third touch toggle of CFM is accessible

if volumetric flow is enabled, or ACH if air changes per hour is enabled.

>Home

TOGGLE TEMPERATURE TYPE

Instantly toggle displayed temperature units from Fahrenheit to Celsius, or vice versa, by

pressing on the displayed temperature reading on the home screen.

>Home

PASSWORD-PROTECTED ACCESS TIERS: CERTIFIER & EH&S

Password protected access tiers enable advanced configuration options and features.

Home> Settings>System>Advanced>Change Passwords

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A006 of 40

USB INTERFACE FOR UPGRADES AND DATA IMPORT/EXPORT

Firmware upgrades can be installed on-site via USB flash drive. See the USB Field Upgrade

section for more information. Users may also import/export Rooster™ settings and export

the event log through the USB interface.

CUSTOMIZABLE BOOT SCREEN

Our engineers can configure your unit with a custom image or logo file (240x320) in

portable network graphic (.png) format to display on boot up. Contact our sales team to

get started: sales@degreec.com

NIGHT SETBACK

EH&S or Certifier users can configure 3 convenient modes (Audible, Muted, or Off) of

operation. The RoosterTM Sensor200 is a normally open device. To trigger audible or

muted night setback, the dry contact relay must be closed. See the Alarm Threshold

Configuration section for instructions on how to setup night setback alarm thresholds.

Home>Settings>System>Alarms/Sound>Alarm Controls>Night Setback

ALARM LATCHING

EH&S or Certifier users can setup latched alarms to indicate that a low airflow state has

occurred in the “Alarm Controls” menu. User must then enter a EH&S or Certifier

passcode to unlatch an alarm.

Home> Settings>System>Alarms/Sound>Alarm Controls>Latch Alarm

ALARM RINGBACK

EH&S or Certifier users can configure the amount of snooze time before an alarm rings

again after being muted in the “Alarm Controls” menu. Optionally, the audible alarm can

be turned off completely.

Home>Settings>System>Alarms/Sound>Alarm Controls>Ringback

BACKLIGHT DIMMING

Users can toggle the brightness setting, as well as the brightness of the screen when set

to “dim”. A “time before dim” option is available that sets the screen to dim after a

predetermined amount of time has expired.

Home>Settings>System>Brightness

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A007 of 40

AIRFLOW RESOLUTION

EH&S or Certifier users can select the resolution of air velocity units.

Home>Settings>System>Airflow Settings>Airflow Resolution

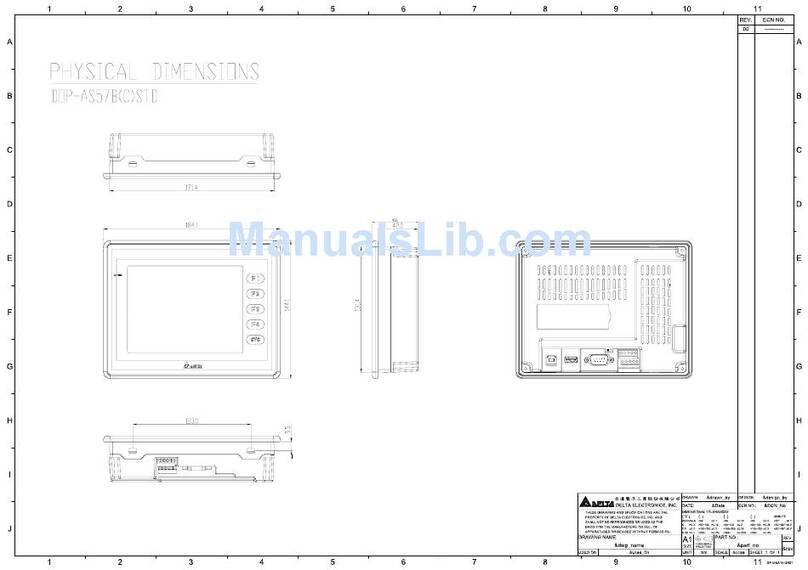

Rear Panel Layout for Advanced Connections

Figure 1 Connections

Connection

Description

Connector Type

Mating Connector

Power Entry

2-Pin, polarized, Phoenix

Contact

Included and attached to AC/DC power supply

Sensor Connection

RJ-11

Included as part of sensor assembly

BACnet® Connection

3-pin, push-in spring

connection

Not included

3-position orderable Part Number: Phoenix Contact 1778845

Output Connection

8-pin, polarized, Phoenix

Contact

*2-position connectors will fit

Not included

8-position orderable Part Number: Phoenix Contact 1803633

2-position orderable Part Number: Phoenix Contact 1803578

Input Connection

10-pin, polarized, Phoenix

Contact

*2-position connectors will fit

Not included

10-position orderable Part Number: Phoenix Contact 1803659

2-position orderable Part Number: Phoenix Contact 1803578

Table 1 Connections - Rear Panel of Display Module

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A008 of 40

Optional Sash Switch Kit, Degree Controls Part#: 62310AS004 includes 10-postion Phoenix

Contact connector. This is for digital sash sensor mode.

Optional Sash Position Sensor Kit, Degree Controls Part#: 62310AS008 includes 10-postion

Phoenix Contact connector. This is for analog sash sensor mode.

Technical Specifications

Alarm Module Size

82mm x 135mm x 19mm (3.2” x 5.3” x 0.7”)

(without back plate)

LCD Display Area

57mm x 70mm (2.3” x 2.7”)

Airflow Velocity Range

0.15- 20.0 m/s (30-4,000 fpm)

Response Time

< 1 second

Supply Voltage

24VAC/VDC

Sash Switch Input

Pin 1 = +15V Power (For Proximity SW)

Pin 2 = SASH (Contact or Proximity)

Pin 3 = GND (Contact or Proximity)

Night-Set Back Input

Dry Contact Closure

Pins 5-6

Auxiliary Input

(BACnet®Monitored)

Dry Contact Closure

Pins 7-8

Analog Input

0 –10V Analog

Pin 9 = A IN

Pin 10 = GND

Relay Outputs

Qty. (3), 1A, 24VAC/DC

Pins 1-2 Relay1

Pins 3-4 Relay2

Pins 5-6 Relay3

Analog Output

0 –10V Analog

Pin 7 = A OUT

Pin 8 = GND

Power Adapter

90-250V

Red LED indicator

160° viewing angle

Alarm Volume

0 - 85dB (adjustable)

Relative Humidity

(non-condensing) 5 - 95%

Operating temperature

5°C - 60°C (40°F - 140°F)

Storage temperature

-40°C - 85°C (-40°F - 185°F)

Weight

<170g (<6oz)

Compliance Standards

CE, RoHS

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A009 of 40

Connection and Wiring Information

Degree Controls recommends 18-24 AWG wire for all wiring connections to the input and

output connectors. The sensor and power entry connections have been prepared for you, and

merely need to be pulled through the openings and connected to the display module. If the

Sash Switch option (digital sash operation) is purchased, this is pre-connectorized for you as

well.

The RoosterTM Sensor200 has additional input and output capabilities for night setback and

application specific controls. These cable harnesses should be prepared by the client, using the

orderable mating connectors listed above.

Sash Input

The RoosterTM Sensor200 provides you with the ability to select one of two sash input settings:

1. Digital sash sensor or

2. Analog sash sensor

The default value is Digital, and users can toggle between a digital or analog sash sensor input

by navigating to:

Home>Settings>Sash Settings

Digital Sash

The default I/O polarity of the digital sash position input is normally open. The design intent is

as follows:

The sash setting is set to Digital.

When the sash is in a safe position, the proximity sensor should not detect a metallic

object/strip.

Sash position input logic may be reversed using the I/O configuration menu on the Sensor200

to achieve a different result, and any proximity sensor may be implemented.

Degree Controls can provide you with an optional Sash Switch comprised of (1) inductive

proximity sensor and (1) 10-position connector which mates to the input connection of the

display module. This inductive proximity sensor switches state when it contacts metal surfaces.

This sash sensor is a normally open device, meaning it closes upon sensing metallic objects.

The DegreeC Sash Switch (Part# 62310AS004), comes with three stripped and tinned wire leads:

Brown = +15V

Black = Sash

Blue = GND

Wire these in their respective positions 1, 2, and 3 on the input connection block.

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0010 of 40

Analog Sash

With the sash input configured as Analog, the Sensor200 monitors the sash position as detected

from the 0-10V analog signal on the analog input.

The design intent is as follows:

The sash setting is set to Analog.

The Sensor200 monitors sash position as detected from a 0-10V analog signal on the analog

input.

The sash height calibration routine records the sash sensor's resistance in the Open, Normal

and Closed positions.

If the sash reading is within 1% of full scale of the recorded closed position, the sash is

considered to be in the closed position.

If the sash reading is 1% of full scale greater than the normal position, the sash is considered

to be in the open position.

If sash readings are between the closed and open positions, the sash is considered to be in the

normal position.

The Sensor200 will alarm for unsafe sash position whenever the sash is in the open position.

The DegreeC Sash Position Sensor Kit (Part# 62310AS008) uses pin 1 for 15V and analog input

pins 9 and 10 on the input connector marked as Analog In:

Pin 1 = +15V

Pin 9 = A IN

Pin 10 = GND

See the sash height calibration section for additional calibration detail. See the I/O configuration

section to configure a relay output for Sash Alarm.

Note: For implementation support, or for users preferring to use a micro-switch for sash alarm

activation, please contact Degree Controls.

Night Setback Input

The RoosterTM Sensor200 allows the user to connect to a digital input, dry contact, on positions

5 & 6 of the Input connector, for night setback. The purpose of the Night Setback input is to

provide the user with the ability to send a remote signal to all RoosterTM Sensor200s

simultaneously, to change their behavior during low flow conditions. This signal is normally

initiated by a Laboratory or Building Management System (BMS).

Once the wiring connections are made, the user can assert, and also remove, the night setback

signal via the BMS. Three Sensor200 night setback states can be selected.

Audible: In this state, when the night setback signal is asserted, the Sensor200 will still

audibly alarm when airflow drops below the NSB trip threshold. Note: NSB threshold is

independently set.

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0011 of 40

Muted: In this state, when the night setback signal is asserted, the Sensor200 will alarm

(screen will display a red background, and the LED will flash) when airflow drops below

the NSB trip threshold, but the alarm will be muted.

Off (default): In this state, when the night setback signal is asserted, the Sensor200 will

ignore it.

Auxiliary Input

The RoosterTM Sensor200 provides a BACnet® MS/TP monitored auxiliary input for specialized

application. For example, a human presence sensor may be connected to the auxiliary input and

monitored via BACnet® communication in order to shut off room lights or reduce the number

of air changes per hour when no persons are detected. The auxiliary input is a digital input, dry

contact closure with default I/O polarity of normally open. See the BACnet® section for auxiliary

input object information.

Outputs

Relay Outputs

Three relay outputs are available on the output connector of the RoosterTM Sensor200 alarm

module. Default I/O polarity is normally open, and output polarity logic may be changed via the

Output Configuration menu of the Rooster™ Sensor200.

The RoosterTM Sensor200 alarms for airflow and sash position and allows users to enable on-

screen buttons for accessory lamp and accessory fan. Relay outputs are configurable and linked

to alarms and accessory buttons from the output configuration grid. See the I/O Configuration

section for additional detail.

Analog Output

Analog output can be enabled to produce an analog control signal on the analog output pins in

order to maintain the desired face velocity or volumetric flow, or to indicate the flow. Analog

output pins are 7 and 8 on the output connector and marked as Analog Out:

Pin 7 = A OUT

Pin 8 = GND

Users can toggle analog output mode between Control Output, Scale Output, and Disabled.

Home>Settings>System>Advanced>Analog Out>Output Mode

Control Output

Control Output implements a proportional and integral control loop to maintain a specified

velocity setpoint. A control signal is calculated using the error, or difference, between current

face velocity, or volumetric flow, and the setpoint. The Control Output is typically used to

regulate a fan or damper.

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0012 of 40

Once Control Output is enabled, the user needs to enter or select:

1. Setpoint, desired face velocity or volumetric flow (if volumetric flow is enabled) and

2. Output

a. 0-20 mA

b. 4-20 mA

c. 0-5 V

d. 0-10 V

Proportional and integral terms are also available for the user to tune the output control loop.

The proportional gain, P term, determines the ratio of the output response to the error signal.

The user can adjust this value based on stability of the airflow. Proportional gain can be any

decimal value between 0 and 9999, and the default value for P term is 0.50.

The primary purpose of the integral term is to eliminate the small steady-state error between

process flow and the setpoint. It produces a correction based on the error over time. The

integral term can be any decimal value between 0 and 9999, and the default value for I term is

0.20.

Scaled Output

Scaled Output provides a control signal proportional to the face velocity or volumetric flow.

Scaled Output is typically used to change the position of a damper in a VAV (variable air

volume) system or control fan speed. Once Scaled Output is enabled, the user needs to enter or

select:

1. Output

a. 0-20 mA

b. 4-20 mA

c. 0-5 V

d. 0-10 V

2. Max Scale, upper limit of scale

For example, with:

▪Output set to 0-5 V,

▪Max Scale set to 10 m/s, and

▪flow in the cabinet set such that 5 m/s is displayed on the RoosterTM

the analog out voltage will be 2.5 volts.

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0013 of 40

Mechanical Information

Alarm Module

Figure 2 Alarm Module with Wall-Mount Back Plate

Installation

Installation of the RoosterTM involves selecting and preparing appropriate locations for the alarm

module and sensor, wiring, and connecting the unit, and then mounting both the alarm module

and sensor securely.

Back Plate Mounting Options - Alarm Module

The RoosterTM is mountable to a cabinet or wall panel by first securing the back plate. Once this is

complete, the RoosterTM is easily aligned to the back plate and secured with bottom captive screw.

Two back plate versions are available:

1. Wall Mount: This back plate sits directly on the wall or cabinet surface, and is secured by

self-tapping screws, or industrial Velcro. Sensor and control wiring access is at the back,

while access for power in from the wall mount power supply is at the bottom of the back

plate.

2. Semi-Flush: This back plate sits partially inside a standard electrical gang box, allowing the

RoosterTM to be recessed and sit approximately 15mm [0.6”] proud of the mounting surface.

Self-tapping screws secure it, and there is open back access to accept building power.

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0014 of 40

Figure 3 Wall Mount (left), Semi-Flush Mount (right) - for Alarm Module

Installation Procedure

1. Determine mounting locations for the RoosterTM alarm module and sensor.

2. Choose alarm module mounting method: Wall Mount or Semi-Flush.

3. Mark the surface where the RoosterTM alarm module will be located, and make the

necessary drills/cutout.

4. Secure back plate.

5. Mount the sensor. See below for sensor installation.

6. Feed power and sensor wire harnesses through the opening(s) and make connections to

the RoosterTM alarm module. Make any other optional connections to the alarm module.

7. Align top of alarm module with tabs on back plate, and secure in place with captive

screw at bottom of alarm module.

Figure 4 Wall Mount Back Plate Mounting

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0015 of 40

Figure 5 Semi-Flush Back Plate Mounting

Probe Sensor

The probe sensor should be located in your duct system in the best laminar (stable) flow

possible. Good sensor placement and ASHRAE best practices should be followed. The sensor

should be placed at least two duct diameters away from duct elbows and constrictions. Please

see below for °C Clamp specifications and installation instructions.

°C Clamp and Sensor Installation:

1. Mark the sensor hole, and screw positions, per Step 1 of °C Clamp installation figure,

below.

2. Drill a 17/32” (14mm) hole through the surface where you wish to install the sensor.

3. Drill two pilot holes for the °C Clamp fastening screws. (°C Clamp, Degree Controls P/N:

64500AS011)

4. Secure the °C Clamp with two screws (not provided).

5. Insert the sensor into the °C Clamp and adjust the sensor’s insertion depth (use the

printed ruler on the sensor’s body for reference), ensuring that the airflow indicators

(arrows on the blue or orange head; see Airflow Direction below) are facing in the

intended direction.

6. Using the provided screw, tighten and cinch the sensor into place.

Back View

Front View

Figure 6 °C Clamp

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0016 of 40

Figure 7 °C Clamp Installation

Figure 8 Airflow Direction

Ensure that the sensor head is aligned correctly, by positioning the arrow in the direction of

airflow.

Boot Up Procedure

The RoosterTM does not have a power-on switch and will become energized as

soon as it is plugged in. The RoosterTM boots to the screen depicted on the

right, with a slot for a custom logo. The boot screen is designed to support a

custom image or logo file in portable network graphic (.png) format with

(240x320) dimensions. This feature must be requested and is not setup for

manual configuration. Once the start procedure has completed, the Home

screen will appear with two system buttons.

Step 1

Step 2

Step 3

Step 4

Step 5

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0017 of 40

The RoosterTM can be rebooted at any time by pushing the hard “Home”and “Mute”buttons

simultaneously until the boot screen reappears.

Access Tier Privileges: USER, EH&S & CERTIFIER

Users have the ability to customize their containment

cabinets within a defined set of options for each

authorization level. There are three levels of access to the

RoosterTM: User, EH&S/Facility Manager and Certifier.

These are managed by logging in with a 4-digit

numerical passcode. The User access level does not

require a passcode.

Access Privileges Defined

Function

Passcode Required

Adjust Alarm Volume

None

Set Minimum Alarm Volume Threshold

EH&S, Certifier

Alarm Ringback Setting

EH&S, Certifier

Alarm Delay Setting

EH&S, Certifier

Startup Delay Setting

EH&S, Certifier

Alarm Latching Setting

EH&S, Certifier

Alarm Tones Settings

EH&S, Certifier

Mute Live Alarm

None

Perform Calibration

Certifier

Set Asset Tag

EH&S

Set Time / Clock Format

EH&S, Certifier

Import / Export

EH&S, Certifier

Toggle between Fahrenheit or Centigrade Temperature Units on Home Screen

None

Toggle between Metric or Imperial Air Velocity Units on Home Screen

None

Toggle ON/OFF Keypad Sounds

None

Unlatch Alarm (if Alarm Latching is set to Password)

EH&S

Manufacturer default passcodes:

EH&S = 8377

Certifier = 6425

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0018 of 40

Set/Change Passwords

To change or set a password, follow this GUI (graphical user interface) path to trigger the

password change sequence: Home>Settings>System>Advanced>Change Passwords

You will have to enter an EH&S or Certifier passcode to get access to the “Advanced” menu. To

change either the EH&S or Certifier passcode, you must first re-enter the old passcode. Please

note that if you have authorization to perform both EH&S and Certifier functions, you may set

an identical passcode for both access tiers to make logging in and accessing key functions

easier.

Calibration –Sash Height

The sash height calibration routine calibrates sash position, to scale, to a given input voltage.

Sash height calibration is available for analog sash operation and describes sash position as

Closed, Normal or High. The sash height calibration steps are as follows:

1. Navigate to the Calibrate Sash Position screen by following this path:

Home> Settings>Calibrate Sash Position

2. Press the “Calibrate” button.

3. In order to proceed, you will need to enter your “Certify” password. If

you have not set a custom password, the factory default is “6425”.

4. Move the sash to the fully closed position, then select “Continue” to

initiate the calibration.

Note: The Sensor200 displays actual sash input voltage level as you

step through the calibration routine. Voltage levels should change as

you move the sash position from Closed to High to Normal.

5. Move the sash to the fully open position, then select “Continue”.

6. Move the sash to the normal operating position, then select “Continue”.

7. Once the Closed, High and Normal sash positions are defined, sash position is calibrated

to scale, and the calibration sequence will end with a “Calibration Successful!” message

and the sash calibration date will be displayed.

Note: The sash height position routine records position.

Sash Readings

▪If the sash reading is within 1% of full scale of the recorded closed position, the sash is

considered to be in the closed position.

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0019 of 40

▪If the sash reading is 1% of full scale greater than the normal position, the sash is

considered to be in the open position.

▪If sash readings are between the closed and open positions, the sash is considered to be

in the normal position.

▪The Sensor200 will alarm for unsafe sash position whenever the sash is in the open

position.

Alarm Threshold Configuration

1. To set your alarm threshold, follow the menu path below:

Home>Settings>Thresholds>Adjust Normal Thresholds

2. Select “Low Threshold”to set low threshold alarm trip and clear

points. Select “High Threshold” to set high threshold alarm trip and

clear points. Use of low threshold alarm trip and clear points is most

common.

The alarm trip point is the air velocity value that will trigger an alarm.

The alarm clear point is the air velocity value that will clear an alarm

state. Once you have defined these values, the alarm will trip and clear

based on your settings. You may return to this menu at any time to

adjust these values as needed.

3. By default, no values are set for the NSB (Night Setback) mode of

operation. Depending on your application or setup, an active alarm

during Night Setback may not be required. Specific alarm trip and

clear points for Night Setback mode may be entered. First, define an

alarm trip point and an alarm clear point. The alarm trip point is the

air velocity value that will trigger an alarm. The alarm clear point is

the air velocity value that will clear an alarm state. Once thresholds are

assigned for Night Setback, the alarm may be set as "Audible" or

"Muted" in the alarm controls menu.

Home>Settings>System>Alarms/Sound>Alarm Controls>Night Setback

4. To quickly glance at threshold settings, follow this menu path:

Home>Settings>Thresholds>Threshold Info

Alarm Troubleshooting

If an alarm is failing to sound or clear as intended, first verify that the alarm threshold values are

valid. For both normal and NSB modes of operation, the “Alarm Trip” or “NSB Trip” point must

be a lower value than the “Alarm Clear” or “NSB Clear” point to properly trigger and clear an

alarm.

80

85

Rooster™ Sensor200 USER MANUAL

Rooster™ Sensor200 USER MANUAL 62360MN000-A0020 of 40

The RoosterTM Sensor200 offers an array of customization options for alarm behaviors. The

following section provides a detailed overview on how to customize alarm behavior to meet

individual needs and preferences.

Alarm Controls

To provide our users with full customization of the alarm behaviors that are best suited for their

facilities and unique conditions, the RoosterTM Sensor200 allows authorized users (Certifier &

EH&S) to set night setback, ringback, alarm delay, startup delay, latching, alarm tone and airflow

resolution preferences.

Night SetBack

The RoosterTM Sensor200 supports Night Setback (NSB) for energy savings and greater HVAC

system integration in building automation systems. Users can toggle between three modes of

operation detailed below:

*The crescent moon icon [ ] will appear on the top portion of the home screen when Night Setback is active*

Home>Settings>System>Alarms/Sound>Alarm Controls>Night Setback

Note: The definitions in the table below are with the I/O Polarity of the NSB input set as

normally open.

Night Setback

Modes

Definition

Audible

Enters Night Setback mode whenever relay is closed and audibly triggers an

alarm when airflow drops below the NSB trip point. To adjust Night Setback

alarm thresholds, navigate to:

Home>Settings>Thresholds>Adjust Thresholds

Muted

Enters Night Setback mode whenever relay is closed and triggers a muted alarm

when airflow drops below the NSB trip point. (LED will still flash during an alarm

event). This is the default setting. To adjust Night Setback alarm thresholds, you

must go to the Calibration menu and select “Adjust Thresholds”.

Disabled

Disables Night Setback mode. Device does not enter Night Setback mode when

relay is closed.

Alarm Ringback

When an active alarm state is muted, ringback is a useful safety feature to remind the user that

the muted alarm is still active. Whenever there is an active alarm state, the red LED will flash for

the entire duration of the alarm. There are seven ringback durations available:

Home>Settings>System>Alarms/Sound>Alarm Controls>Ringback

Table of contents

Popular Temperature Controllers manuals by other brands

Winland Electronics

Winland Electronics ENVIROALERT EA200 quick start guide

Vostermans Ventilation

Vostermans Ventilation Mf Net AEW-6.3N Installation and operation manual

AutomiX

AutomiX Automix 10 Mounting and operating instructions

Gatekeeper Systems

Gatekeeper Systems ITSS Desktop Mount Installation Guide

netvox

netvox R720C user manual

Carrier

Carrier Sensitech TempTale GEO Ultra Instructions for use