SIGMA SYSTEMS CC-3.5 Owner's manual

CC-3 Manual

.5

SIGMA SYSTEMS

MODEL CC-3.5

PROGRAMMABLE TEMPERATURE CONTROLLER / INTERFACE

INTERIM RELEASE SUPPLEMENT

OPERATING & PROGRAMMING MANUAL

Firmware Release 7.0.0

July 18, 1997

SIGMA SYSTEMS CORPORATION

3163 Adams Avenue

San Diego, California 92116 USA

TEL: (619) 283-3193 WWW.SigmaSystems.Com FAX: (619/283-6526)

CC-3 Manual

.5

Copyright 1997 by

Sigma Systems Corporation

3163 Adams Avenue

San Diego, California 92116 USA

All rights reserved

The manual may be reproduced, in whole, or in part, solely for the purposes of use

and training for the use, of Sigma Systems equipment, or as required to assist in the

sale of new Sigma Systems equipment. No modification of the content is permitted.

CC-3 Manual

.5

TABLE OF CONTENTS

A Model CC-3 Interim Release Upgrade Information ......................S1

.5

A.1 Compatibility with CC-3 and CC-3 Final Release products .........S1

.5

A.2 Final Release Additions .....................................S2

B Hardware & General Revisions .....................................S3

B.1 Firmware downloads .......................................S3

B.2 Release number at startup ..................................S3

B.3 Temp range at startup ......................................S4

B.4 Fahrenheit Operation .......................................S4

B.5 probe out of range shutdown .................................S5

B.6 Internal Error Shutdown Conditions ............................S6

B.6.1 Watchdog Timer ....................................S6

B.6.2 Memory signature checking ...........................S7

B.6.3 Setup parameter integrity checking .....................S7

B.7 Temperature slope/offset adjustment ...........................S7

C Program Mode Revisions ..........................................S9

C.1 Insert/Delete step .........................................S9

C.2 Any step can point to step 100 ..............................S10

C.3 Safer program clear .......................................S10

D Remote Mode Revisions ..........................................S11

D.1 RS232 baud rates 19,200 38,400 ...........................S11

D.2 RS232 bus initialized upon setting to remote ...................S11

D.3 Fault tolerant parser ......................................S11

D.4 QS Query Setpoint Command ...............................S11

D.5 QV Query Version Command ...............................S12

D.6 QU Quit Command .......................................S12

E Setup Mode Revisions ............................................S13

E.1 Fahrenheit and Celsius Modes ..............................S13

E.2 Temperature Correction Entries .............................S13

Final Release Update Instructions .....................................S14

S1

CC-3 Manual

.5

A Model CC-3 Interim Release Upgrade Information

.5

TheSigma Systems Model CC-3 Controller you have received was shipped with

.5

Interim Release, version 7.0.0, firmware. One of the features of the CC-3 is it’s

.5

ability to receive firmware updates via the serial port. Please take the time now to

complete the form at the end of this Interim Release Software section and mail to

Sigma in the enclosed envelope. When the final release firmware is available, we

will use the contact information you supply on this form to contact you. You will

receive the upgrade firmware and a new manual free of charge. Upgrade firmware

will be available to you either as a plug in EPROM chip, or on diskette for serial port

installation from a PC.

The decision to ship the CC-3 with interim release firmware was a made to allow

.5

you to take advantage of the new speed, stability and some of the new features of the

CC-3 earlier than would have been possible if shipment had been delayed until the

.5

final release firmware was available.

A.1 Compatibility with CC-3 and CC-3 Final Release products

.5

The interim release firmware is fully backward compatible with release 5.3 firmware

that has been shipping in Model CC-3 controllers since mid 1994. You should be able

to place a CC-3 in a production environment that has been using model CC-3

.5

controllerswithout incident. However, if you choose to use any of the CC-3 new

.5

features in your remote control programs, existing CC-3 controllers will not respond.

Likewise, the CC-3 fault tolerant parser will correct many small errors in the data

.5

stream that the CC-3 will not tolerate.

The final release of the CC-3 firmware will be a superset of the interim release

.5

firmware with one important exception. The temperature correction feature of the

interim release firmware is implemented through setup entries on a global level such

that the correction is applied after the temperature is read from the each probe into

the control routines. There is therefor only one correction factor, which affects each

probe the same. The final release software will implement temperature correction

at the probe level. There will be two temperature corrections available... one for each

probe. The setup parameters will be numbered differently and it will be possible to

set the correction factors over the bus at run time.

This interim manual was written for use with, and as an addition to, the Release 5.3

manual for the model CC-3 Sigma controller.

S2

CC-3 Manual

.5

A.2 Final Release Additions

The following features, not in the interim release, will be in the final firmware:

Probe level temperature correction

Remote control temperature correction

Average probe temperature control

Direct access to setup parameters

Remote control command queue placement acknowledgment

Remote control command start acknowledgment

Remote control command completion acknowledgment

Nested control loops

User reinitialization of setup parameters to default values

S3

CC-3 Manual

.5

B Hardware & General Revisions

The new CC-3 introduces a number of new improvements to make the controller

.5

faster and more reliable than its predecessor.

TheCC-3 has a completely new digital processing board. The new board has a

.5

much faster processor, more memory, and a much faster IEEE-488 GPIB controller.

Interrupts have been completely restructured to improve stability. The multilayer

design is far more tolerant of both static and power line interference. There is now

a watchdog timer to detect system lockups in the event that something does interfere

with the system. The command stacking and acknowledging that will be included

in the final firmware release, along with the watchdog timer, will allow virtually

seamless recovery from system interruptions, regardless of their source.

The new firmware also monitors the state and integrity of internal memory. Critical

system information is stored in multiple places so that minor errors due to

uncontrollable transients or other causes can be repaired on the fly with no

disruption in process control.

System integrity is further enhanced by a series of successive shutdown processes

that monitor the integrity of the data coming from the sensor probes. In the event

that any probe reports a temperature more than 20°C beyond the limits of the

controller, the controller will shut down all heating and cooling and display a

warning message. Likewise, in the event that a sensor probe reports an extreme

temperature, either hot or cold, the system will assume that a probe has become

compromised and stop applying heat and cooling.

B.1 Firmware downloads

When the final release firmware is sent to you, you can easily download it into the

CC-3 .The procedure requires only a diskette bootable PC and a serial cable and

.5

takes only a couple of minutes. Instructions will be included with the updated

firmware.

B.2 Release number at startup

Upon power up of the controller, the front panel will display c3-5for one second

and will then change to show the current firmware release version in the form of

rEL 7.0.0

S4

CC-3 Manual

.5

B.3 Temp range at startup

Each CC-3 controller is set at the factory for use with a specific device (chamber or

.5

platform). Because the controlled device was made to specific thermal limit

specifications, the controller to be used with each device is set to operate only within

the range of the controlled device. The setting of an operating range involves a

number of internal adjustments and calibrations and the loading of specific control

tables for that range. This setting can only be changed by Sigma Systems service

personnel. We recommend that each controller be kept with the device for which it

was originally configured.

However, if you find that it is necessary to move a controller to another device, it is

important that you check to be sure that the controller that is moved is configured

to operate in the appropriate range for the device it is to control. As of March, 1997,

controllers are supplied for three ranges as follows:

-100 °C to 200°C

-100 °C to 300°C

-100 °C to 350°C

To check the internal range setting of your CC-3 controller, turn the mode switch

.5

from OFF to any other position. During the five seconds that the firmware release

number is shown on the display, press <DISP/TEMP>. The internal range setting will

be displayed for 5 seconds following the version display.

B.4 Fahrenheit Operation

The CC-3 can use either Celsius or Fahrenheit temperature scales. Celsius is the

.5

defaultmode. When the controller is operating in Celsius mode it’s behavior is

identicalto the model CC-3 controller. When the controller is operating in

Fahrenheitmode, both the displays and the bus communications are different.

These differences are intentional and designed to prevent errors that might arise

from a user using setpoints in one scale while the controller is operating in the other

scale. Note, however, that there is no difference in the Program mode programming

operation of the CC-3 when operating in either Fahrenheit or Celsius mode. It is

.5

incumbent upon the user to notice the differences in the temperature displays and

program accordingly.

To change the temperature scale, use SETUP mode (see Section 6 in CC-3 Manual)

to access setup field 16. Select either of these field values:

0 Celsius

1 Fahrenheit

S5

CC-3 Manual

.5

When in Fahrenheit mode, temperature displays have an “F” following the probe

identifier on the left side of the display. Example:

p1f 102.4

Likewise, temperature inquires over the bus (PT command - see Section 5.1.15 in CC-

3 Manual) will return a string with an “F” as the third byte in the string. The string

will therefore be 1 byte longer than the string returned in Celsius mode. This

difference was intentional as it requires a modification of the parsing routine that

will assure that Celsius and Fahrenheit data are recognized properly. Thus, if the

currentprobe 1 temperature is 86.7°F, the result of a Fahrenheit mode get

temperature query for probe 1 (query command = PT1) would be S1F 86.7<CR><LF>.

If the temperature at probe 1 was 55.4°C, the same command in Celsius mode would

return S1 55.4<CR><LF>

For Remote mode operation over the bus, the CC-3 may be queried to determine the

.5

current temperature scale by using the QS, Query Setpoint, command. See Section

D.4.

B.5 probe out of range shutdown

The CC-3 controller frequently checks to be certain that the control temperature, as

.5

reportedby the active control probe, is within the normal operating limits of the

controller. In the event that the temperature reported by the active control probe is

more than 20°C, and less than 50°C, outside the controller’s operating range, then

the controller will presume that an error condition exists that is severe enough to

warrant a system stop. The controller display will show

p1 lo p1 hi

“LO” indicates that the reported temperature was 20-50°C below the operating range

of the controller. “HI” indicates that the reported temperature was 20-50°C above the

operating range of the controller.

In the event that the control temperature reported by the active control probe is more

than 50°C beyond the operating range of the controller, the system will be stopped

and the display will show

p1 err p1 -err

S6

CC-3 Manual

.5

The minus sign in the display indicates that the reported temperature was below the

operating range of the controller and the absence of the minus sign indicates that it

was above the operating range.

Note that because the CC-3 will report a HI or LO condition and stop controlling for

.5

an error of 20-50°C, the only events that will typically trigger an Err or -Err

condition is a failure of the sensing circuit, most likely an open circuit (Err) or short

(-Err).

Note also that any adjustments to the probe readings made by adjustment of the

control temperature slope and offset corrections (See Section B.7) will not affect

system over/undertemp shutdown operations. The raw probe readings for the current

active control probe are used for the system health monitoring.

B.6 Internal Error Shutdown Conditions

The CC-3 monitors system health by keeping track of three additional areas; they

.5

are:

Processor health Tracked by watchdog timer

Memory condition Checked at startup

Setup parameter integrity Checked continuously

B.6.1 Watchdog Timer

Should the system become locked due to corruption that causes the processor to

continuously malfunction, an independent watchdog timer will cause a full system

reset. After a watchdog reset, the display will show

res err

If the controller was operating in Local or Program mode, the mode switch must be

turned to the OFF position, then back to the desired mode to clear the reset message

and continue operation. Internal memory will be the same as it was when the

shutdown condition occurred. If the controller was in Remote mode, operation may

only be continued after the controller is sent a Device Clear (GPIB), or Quit (RS-232).

S7

CC-3 Manual

.5

B.6.2 Memory signature checking

Each time the CC-3 is powered up, the system checks a series of memory signature

.5

bytes to test the integrity of system memory. If the signature bytes are not correct,

the system assumes that memory has been compromised. If this should occur (a

normal event any time a memory chip is replaced) all of system memory is

reinitialized. All program steps for Program mode are reset to their default values,

and all setup parameters are reset to their default values. The display will show

all clr

The mode switch must be subsequently turned to the SETUP position to clear the

display and resume normal operations. Be sure you remember to restore any setup

parameters that have been changed by the system reset.

B.6.3 Setup parameter integrity checking

Each time the system must rely on a system setup parameter the condition of the

setup parameter memory is checked against a replica that the system stores in

memory. If there is any difference between the two copies of the parameter memory,

the system will try to determine which table is correct and restore the incorrect copy.

If restoration is not possible, the system will shutdown, reinitialize the setup

parameters to their defaults, and display

su err

The mode switch must be subsequently turned to the SETUP position to clear the

display and resume normal operations. Be sure you remember to restore any setup

parameters that have been changed by the system reset

B.7 Temperature slope/offset adjustment

The CC-3 will allow you to enter data via the Setup mode that will correct any

.5

anomalies in the temperature readings and control. Such adjustments are sometimes

necessary to optimize accuracy at a particular temperature, or to compensate for

differences between raw probe temperature data and actual temperatures. These

differences can be the result of probe placement, effects of the unit under test on the

temperature data, or other causes.

Temperature adjust is achieved by entering four temperatures into setup parameters

U1, C1, U2, & C2. U1 & U2 are the uncorrected, or displayed, temperatures at two

S8

CC-3 Manual

.5

points. C1 & C2 are the corrected, or actual, temperature at those same two points.

Thus to make a correction using ice water (0°C) and boiling water (100°C) when the

display shows 2.3°C for the ice water and 99°C for the boiling water, the user would

enter the following:

U1 2.3

U2 99

C1 0

C2 100

The CC-3 will then calculate a new slope and offset for the probe curve. All

.5

temperatures reported by either probe will be adjusted by applying this new slope

and offset to the raw temperature data reported by the probe.

Note: In this interim release of the CC-3 , the temperatures reported by both probes

.5

will be adjusted by the same slope and offset correction factors. The final release

firmware for the CC-3 will use 4 entries for each probe and will make separate

.5

corrections.

Sigma uses the highest quality probes and an elaborate data and interpolation

system to achieve the best uniform temperature approximations over a wide range

of temperatures. As a result, there may be small variances between actual and

reported temperatures at any given temperature. To optimize the accuracy of CC-3.5

control at a given temperature, use the adjustment feature to optimize performance

at that and one other point on the curve.

Due to the high accuracy of the CC-3 , Sigma has not offered temperature

.5

adjustment capability in the past. It is the responsibility of the user to be certain

that this feature is used properly. Improper use of this feature can result in the

CC-3 reporting very inaccurate temperature data and then using that data for

.5

temperature control. To minimize the risk from such errors, the following rules have

been adopted.

1. U1 & U2 as well as C1 &C2 must be at least 50°C apart.

2. U1 & C1 as well as U2 & C2 must be within 20°C (Maximum 20°C

correction).

3. The correction values entered must be so constrained that when the

internallycalculated slope and offset are applied to the raw probe

temperatures at the extremes of the CC-3 's current operating range,

.5

the maximum calculated temperature difference (correction) is 20°C.

See Section E.2 for a discussion of the temperature correction setup parameter entry.

S9

CC-3 Manual

.5

C Program Mode Revisions

C.1 Insert/Delete step

Front panel programming of the CC-3 has been made easier by the addition of

.5

program step insert and delete capabilities. In the CC-3, unused program steps that

were in the middle of an existing program could not be deleted. Instead, the next

step pointer of the prior step was changed to point to the next valid step, bypassing

the unused step. This methods works well, but leaves the program with extraneous

unused steps that can be confusing. On the other hand, if an additional step was

needed in the middle of an existing program that had no unused steps, all steps

following the added step had to be reentered. The CC-3 's program step insert and

.5

delete makes programming much easier.

The delete an existing step:

1. Display the step.substep 0 to be deleted.

2. Clear the value of this step by pressing <CLEAR/ENTRY>.

3. Press <CLEAR/ENTRY> again.

The display shows “cl nn”, where nn = step number to be deleted.

4, Press <ENTER> to delete the step and move all higher steps down one step.

To insert a step before an existing step:

1. Display the first (lowest) step.substep 0 to be moved up.

2. Press <ADV>

The display shows “UP nn”, where nn is the new incremented step number

for the current step.

3. Press <ENTER> to move the current and all higher steps up 1 step and

insert a new step at the current step number.

The current step will then be the new step with default values. New

step.substep 0 will be displayed so you can enter your data for that step.

Note that inserting a step pushes old step 99 out of memory.

S10

CC-3 Manual

.5

C.2 Any step can point to step 100

The CC-3 restricted some steps in that they were not permitted to be the last

executable step and in program and point to step 100 (program end). The CC-3 has

.5

no such restrictions. Any step can be the last step and point to step 100, even if

doing so makes no sense.

C.3 Safer program clear

The program clear (reinitialization) in the CC-3 has been made safer by the

.5

addition of a 500 msec required delay between the two presses of <CLEAR/PROG>.

Users accustomed to pressing the key rapidly may need to be a bit more deliberate.

This feature was added to guard against accidental program reinitialization from key

bounce or inadvertent double key presses.

S11

CC-3 Manual

.5

D Remote Mode Revisions

D.1 RS232 baud rates 19,200 38,400

The CC-3 is capable of RS-232 communications at higher baud rates. Setup field

.5

#3 now accepts two additional values:

7 19,200 baud

8 38,400 baud

D.2 RS232 bus initialized upon setting to remote

The CC-3 required that to use the RS-232 port, the port had to be initialized by

switching the mode switch to SETUP before switching to REMOTE mode. The CC-3.5

eliminates this requirement. The RS-232 port is initialized each time the remote

switch is switched to REMOTE mode.

D.3 Fault tolerant parser

The CC-3 uses a very fault tolerant parser. Command strings received over either

.5

the RS-232 or GPIB ports are converted to upper case, extra spaces and tabs are

removed, and line terminators are corrected if necessary. For this reason, programs

that work properly on the CC-3 and not on a CC-3, that use only CC-3 commands,

.5

probably have syntax errors that the CC-3 parser correct.

.5

D.4 QS Query Setpoint Command

This command returns the current setpoint and control probe number as follows:

Sp[-]nnn<CR><LF> For Celsius mode

SpF [-]nnn<CR><LF> For Fahrenheit mode

Where pis the current control probe number and

Where nnn is the current setpoint

S12

CC-3 Manual

.5

D.5 QV Query Version Command

This command returns the current internal firmware release number in the following

format:

QV nnn.nnn.nnn<CR><LF>

Where nnn is the number of each part of the release number, padded on the

left with leading zeros if necessary.

D.6 QU Quit Command

This command causes the CC-3 to stop controlling in the same manner as reaching

.5

step 100, program end, in Program mode. The display will show

p1[-]nnn.n or p1f[-]nnn.n

p2 [-]nnn.n p2f [-]nnn.n

(Celsius mode) (Fahrenheit mode)

Where the 1or 2is the number of the active control probe and nnn.n is the corrected

temperature reported by that probe.

S13

CC-3 Manual

.5

E Setup Mode Revisions

E.1 Fahrenheit and Celsius Modes

To set the CC-3 to run using Celsius or Fahrenheit temperature scale change the

.5

value of setup field 16 to:

0 Celsius mode

1 Fahrenheit mode

E.2 Temperature Correction Entries

The 4 temperature entries for applying slope and offset corrections to the

temperature control data from the probes is entered in setup fields U1, U2, C1, and

C2. The use of these fields is discussed in Section B.7. These fields are accessed by

pressing <DISP/CNTL> to continue advancing through setup fields after field 16 is

reached.

The display will show the 4 fields, U1, C1, U2, and C2 successively after field 16.

Data must be entered in each of the 4 fields during a single entry session. If the

values entered do not comply with the rules as defined in Section B.7, the display will

show cor errand then revert to the U1 entry display so you can try entering the

data in the 4 fields again. The values are not stored and the setup field is not

advanced to field 0 until the entries are within the established limits.

S14

CC-3 Manual

.5

Final Release Update Instructions

When the final release firmware is available for your CC-3 controller, it will be sento you for free.

.5

The firmware is available in two forms, (1) on disk for downloading, or (2) on a PROM chip.

The downloadable version requires that you remove the controller from it’s enclosure, remove the

existing PROM chip and insert the new PROM. This process is not the recommended method for

updating due to the potential for damage from accidental handling errors, static discharge, etc.

The disk version requires that you have a PC type computer available near enough to the CC-3 that

.5

you can connect the PC to the CC-3 with a serial cable. You will need to supply both the PC and the

.5

straight through (modem type)serial cable. The process is quite simple, requiring only that you boot

the PC from the disk we will supply, and then power up the CC-3 and press a special key sequence

.5

during the CC-3 's initialization phase.

.5

Please tell us which type of upgrade you want us to supply (check one):

9Send my upgrade on disk (recommended)

9Send my upgrade on a PROM

Please tell us where to send the upgrade:

Name:

Address:

City/State/ZIP:

Please tell us your name (if different than name above) and how to contact you in case we need to

discuss your upgrade.

Name:

Telephone:

Email:

Controller S/N:

Send to: Sigma Systems CC-3 Upgrade

.5

3163 Adams Ave.

San Diego CA 92116

Table of contents

Other SIGMA SYSTEMS Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

Ranco

Ranco ETC-111000-000 Installation data

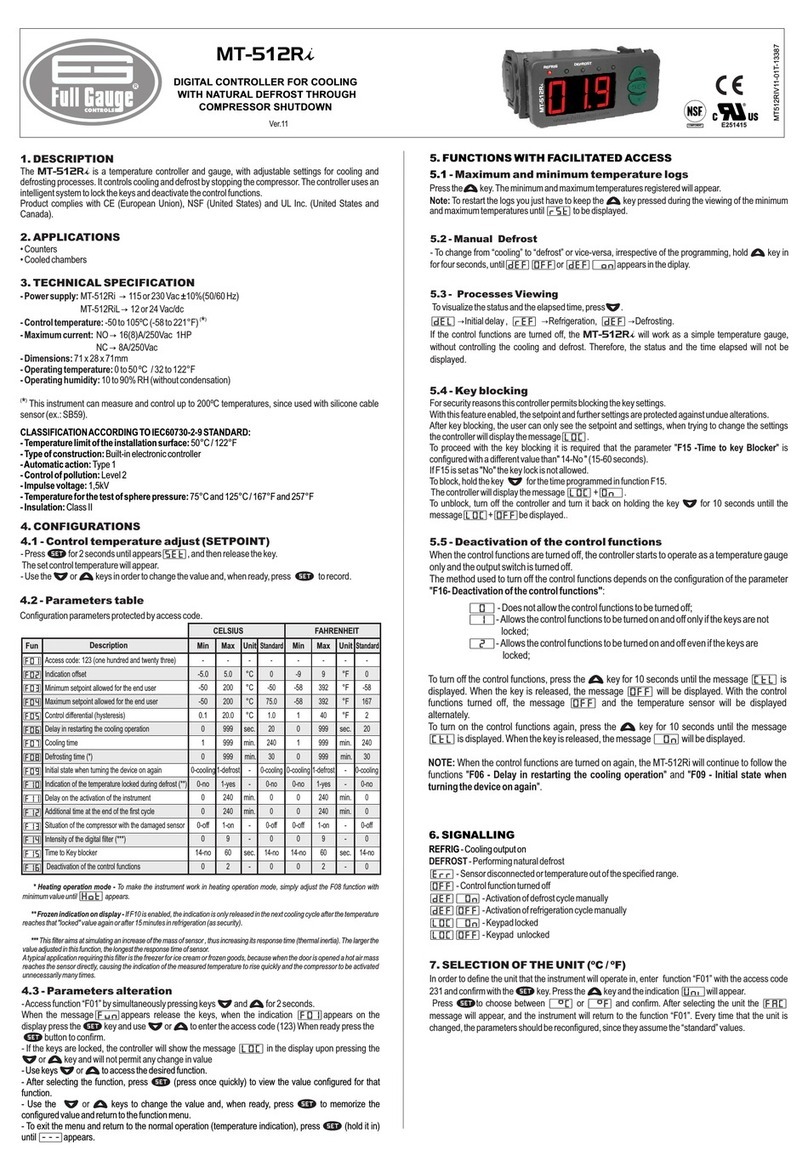

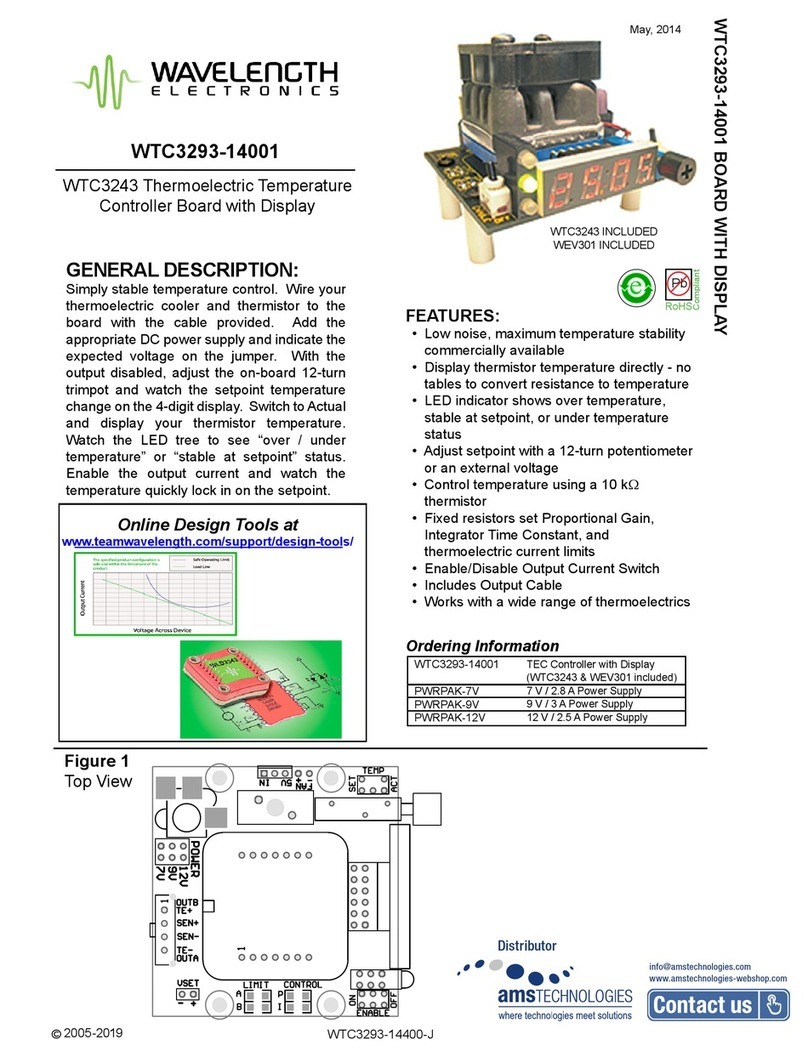

Wavelength Electronics

Wavelength Electronics WTC3293-14001 quick start guide

Danfoss

Danfoss 102E5 Installation and user guide

Delta Controls

Delta Controls RTS-424 installation guide

Polar Electro

Polar Electro 2020 instructions

Klarstein

Klarstein Klimaanlage manual

Ropex

Ropex RESISTRON RES-420 Replacement instructions

Saunum

Saunum AirSolo Instructions for installation and use

Hanyoung

Hanyoung TD500 user guide

Trane

Trane TCONT800AS11AA installation instructions

THERMOSALD

THERMOSALD UPSCR10030-M-V3 Maintenance & Operation Manual

eltherm

eltherm ELTC-W operating manual