DEHACO DSG User manual

DSG

Hydraulic demolition and sorting grabs

Operation and

maintenance manual

DSG-V2.0/31-01-2022

English

3

© 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Preface

© Copyright 2022, Dehaco B.V.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording

or otherwise, without express written permission from Dehaco B.V. This also applies to any accompanying drawings and diagrams. Dehaco B.V. reserves the right to revise sections of

this document at any time and without prior or direct notice to the customer. The contents of this manual can also be changed without prior notice. For information regarding setting,

maintenance or repairs not included in this user manual, please contact your supplier’s technical department. This user manual has been prepared with the utmost care, however Dehaco B.V.

can not accept responsibility for any errors in this user manual or the consequences thereof.

PREFACE

Thank you for choosing for a demolition and sorting grab from Dehaco!

Dehaco was established in 1985 and has since gained a leading position in the European demolition industry. With our complete product

range, we are the ideal complete supplier for the demolition, recycling and asbestos remediation industry in the Benelux.

We are not only leading in the eld of selling all imaginable requirements for these markets, our large rental eet and modern test centre

for equipment items and asbestos tools also contribute to Dehaco’s unique market position. Dehaco is a market leader in the Benelux in

the eld of asbestos remediation products, dust control products and hydraulic equipment units for the demolition sector.

Dealers

Dehaco works with a network of global dealers for the sale of demolition equipment, asbestos removal and dust control products. These

dealers are also qualied to service and maintain your equipment.

Demolition and sorting grabs

Dehaco demolition and sorting grabs include a CE mark and comply with all relevant European safety regulations. Safety instructions

provided in the maintenance and user manual must be followed. The safety and operating instructions for the excavator as well as

regulations in the vicinity of where the demolition and sorting grab is used, maintained or repaired must also be observed.

Modications to the demolition and sorting grab may only be performed with written permission of the manufacturer! Only then shall the

warranty conditions and CE liability apply.

Operation and maintenance manual

The purpose of this operation and maintenance manual is to familiarise you with the safe and eective operation of the demolition and

sorting grab. Maintenance instructions are also included in this document.

Read these instructions carefully before attaching and using the demolition and sorting grab.

Any comments, requests or omissions may be directed to Dehaco B.V. Contributions to improve this manual are always welcome. We hope

you enjoy your purchase.

Dehaco B.V.

Kruisbaak 25

2165 AJ Lisserbroek (NL)

T +31 (0) 252 41 79 50

F +31 (0) 252 41 85 31

I www.dehaco.nl

Dealer

54 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

CE-Certicaat fabrikant Inhoudsopgave

INDEX

1. PRECAUTIONS AND SAFETY INSTRUCTIONS 6

1.1 Signal words 6

1.2 Qualication 6

1.3 Intended use 6

1.4 Use other than specied 6

1.5 Protective equipment 6

1.6 Transport, precautions 7

1.7 Hydraulic equipment, precautions 7

1.8 Consumables, precautions 7

1.9 Explosions and re, precaustions 7

1.10 Elektric shock, precautions 8

1.11 Falling rocks, precautions 8

1.12 Emissions, precautions 8

1.13 Operating machines, precautions 8

1.14 Modications or changes, precautions 8

1.15 Environmental contamination, precautions 8

2. OVERVIEW 10

2.1 Description of the equipment 10

2.2 Operation 10

2.3 Nameplate 11

2.4 Applications 12

2.5 Warranty 12

2.6 Removing the packaging 12

2.7 Scope and content of the delivery 12

3. TRANSPORT 13

3.2 Transport with a fork-lift truck 13

3.3 Transport by lorry 13

4. INSTALLATION 14

4.1 Hydraulic uids 14

4.2 Attaching to the excavator 15

4.3 Detaching the demolition and sorting grab from the excavat16

4.4 Detaching the adapter plate 17

5. OPERATION 18

5.1 Preparations for starting 18

5.2 Switching the demolition and sorting grab on and o 18

5.3 Function test 18

5.4 Proper use 19

5.5 Prohibited use 21

6. MAINTENANCE 25

6.1 Daily maintenance 26

7. TROUBLESHOOTING 28

7.1 The demolition and sorting grab does not work 28

7.2 Insucient closing force 28

7.3 The rotate function does not work 28

7.4 The operating temperature is too high 29

7.5 Oil leaks at hydraulic connections 29

7.6 Insucient lubrication 29

8. REPAIR 30

8.1 Repair service for the demolition and sorting grab 30

9. STORAGE 31

9.1 Demolition and sorting grab 31

9.2 Grease cartridges 31

10. DISPOSAL 32

10.1 Demolition and sorting grab 32

10.2 Hydraulic hoses 32

10.3 Hydraulic oil 32

10.4 Grease and grease cartridges 32

11. TECHNICAL SPECIFICATIONS 33

Hydraulic demolition and sorting grabs 33

without rotation

Hydraulic demolition and sorting grabs 34

with rotation

76 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

1. Precautions and safety instructions1. Precautions and safety instructions

1. PRECAUTIONS AND SAFETY

INSTRUCTIONS

This chapter describes the safety regulations. These must be

observed before installing, using or maintaining the demolition

and sorting grab. Retain this operation and maintenance manual

carefully for the entire life of the demolition and sorting grab.

Any person transporting, installing, removing, operating,

maintaining, repairing, storing or disposing of this demolition and

sorting grab must read this operation and maintenance manual.

Following these safety instructions will:

◊ prevent the risk of injury and fatal accidents.

◊ protect the demolition and sorting grab from physical

damage.

◊ protect the environment against environmental damage.

All safety instructions in this manual comply with the laws and

regulations of the European Union. Additional national/regional

regulations must also be observed.

Outside the European Union, the demolition and sorting grab

must be used in accordance with the laws and regulations of the

relevant country. Observe any other more stringent regional

regulations and legislation.

1.1 Signal words

This manual includes safety indicators that can be identied as

follows:

DANGER

Indicates a hazardous situation where the user can (seriously)

injure himself or (severely) damage the product.

WARNING!

Indicates potential damage to the product should the

user not perform the procedures carefully.

CAUTION!

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury.

ATTENTION

The signal word ATTENTION is used to provide additional

information and alert the user to potential problems.

1.2 Qualication

Transport of the demolition and sorting grab is only permitted

when carried out by persons who:

◊ are authorised to operate a forklift in accordance with

applicable federal laws;

◊ are familiar with all relevant national/regional safety and

accident prevention regulations.

◊ have read this operation and maintenance manual.

Installation, maintenance, storage and disposal of

demolition and sorting grab is only permitted when carried

out by persons who:

◊ are familiar with all relevant national/regional safety and

accident prevention regulations.

◊ have read this operation and maintenance manual.

Operation of the demolition and sorting grab is only

permitted when carried out by qualied excavator operators.

Operators are qualied if they:

◊ have been trained in accordance with federal regulations

to operate an excavator.

◊ are familiar with all relevant national/regional safety and

accident prevention regulations.

◊ have read this operation and maintenance manual.

Testing the installation of the demolition and sorting grab is

only permitted when carried out by persons authorised to do

so.

Repair of the demolition and sorting grab is only permitted

when carried out by persons under the instruction of Dehaco.

1.3 Intended use

The demolition and sorting grab should only be attached to an

excavator with a capacity suitable for use with the demolition

and sorting grab. Read the manual from the excavator

manufacturer thoroughly before installing and using the grab.

Follow all instructions closely.

The demolition and sorting grab may only be used for the

following activities:

◊ Demolition of timber structures

◊ Demolition of masonry

◊ Sorting

◊ Loading work

1.4 Use other than specied

Never use the demolition and sorting grab to:

◊ pull on/demolish girders, brackets, walls and partitions

This may cause damage to the demolition and sorting

grab and slewing ring and may also cause the excavator to

lose its stability.

◊ hit or hack.

◊ plough debris.

◊ move the excavator.

◊ lift or transport loads with attachments.

◊ work underwater.

◊ work in explosive environments.

1.5 Protective equipment

The personal protective equipment must comply with

applicable health and safety regulations.

Always wear the following personal protective equipment:

◊ safety helmet

◊ safety goggles with side shields

◊ safety gloves

◊ safety shoes

◊ warning vest

1.6 Transport, precautions

WARNING!

- FALLING SUPPORT

If the load-bearing capacity of the excavator is not sucient,

it will not be stable when using the demolition and sorting

grab. The excavator could tip over and cause injury.

Using an excavator with excessive load capacity will cause

excessive load on the demolition and sorting grab resulting

in increased wear.

ØOnly attach the demolition and sorting grab to an

excavator with suitable capacity.

ØThe excavator must always remain stable.

ØRead this manual thoroughly before attaching and using

the demolition and sorting grab.

1.7 Hydraulic equipment, precautions

WARNING!

- EXCESSIVE HYDRAULIC PRESSURE

Excessive hydraulic pressure overloads the components

of the demolition and sorting grabs. This may cause

components to break or crack resulting in serious injury.

ØInsert the discharge tube of the pressure relief valve

directly in the tank to ensure safe operation!

ØThe pressure relief valve must be set to the maximum

static pressure.

ØThe settings for the pressure relief valve must be checked

to ensure the maximum static pressure of the hydraulic

system (see Technical Specications section) is never

exceeded. Apply a lead seal to the pressure relief valve.

ØPrior to the rst use, the safety devices on the hydraulic

system must be inspected for their quality, suitability

and performance by a professional/approved inspection

agency (CE marking, etc.)

ØWhen any signicant changes are made to the hydraulic

system, an acceptance inspection must be carried out in

accordance with the relevant national safety regulations.

WARNING!

- DISCHARGE OF HOT HYDRAULIC OIL

The hydraulic system is under high pressure. Hydraulic

lines may leak or burst. Discharge of hydraulic oil can

cause serious injury.

ØWhen attaching the demolition and sorting grabs, no

hydraulic lines are to be laid through the excavator cabin

ØOnly use hydraulic lines that meet with the following

quality requirements:

-For the Open and Close functions:

§Hydraulic hoses with 4 reinforcing steel cables in

accordance with DIN EN 8566 4SH.

§Hydraulic tubes; seamless cold drawn steel

tubes in accordance with DIN EN 10305.

-For the Rotate function:

§Hydraulic hoses with two steel braids in

accordance with DIN EN 853 2SN.

§Hydraulic tubes; seamless cold drawn steel

tubes in accordance with DIN EN 10305.

1.8 Consumables, precautions

WARNING!

- HOT, HIGH PRESSUSE HYDRAULIC FLUID

A leak in the hydraulic system will cause hydraulic oil to spray

out under high pressure. The oil stream can penetrate human

skin and cause permanent injury. Hot hydraulic oil can cause

burns.

ØNever use your hands to locate leaks.

ØAlways keep your face away from a potential leak.

ØIf hydraulic oil has penetrated your skin, always consult a

physician immediately.

WARNING!

- SPILLED HYDRAULIC OIL

Spilled hydraulic oil can make the oor slippery causing

people to slip and resulting in injury. Hydraulic oil is

harmful to the environment and must not penetrate the

soil or reach the water table/ground water supplies.

ØEnsure no hydraulic oil is spilled.

ØWhen hydraulic oil has spilled, clean the oor

immediately.

ØObserve all regulations regarding safety and

environmental protection when using hydraulic oil.

WARNING!

- SKIN INFECTIONS/DISEASES CAUSED BY OIL AND GREASE

Hydraulic oil and grease can cause skin rashes (or even

eczema) if they come into contact with the skin.

ØAvoid skin contact with hydraulic oil and grease.

ØUse a suitable product to protect the skin.

ØAlways wear safety gloves when working with hydraulic

oil or grease.

ØWash contaminated skin immediately with soap and

water.

1.9 Explosions and re, precaustions

DANGER!

- EXPLOSION AND FIRE

Explosions cause serious injury or can result in death.

Explosives touched by the demolition and sorting grab could

cause an explosion.

ØNever use the demolition and sorting grab in the

immediate vicinity of explosives.

ØEnsure no explosives are hidden in the concrete.

ØIdentify the location of the gas lines on drawings of the

98 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

1. Precautions and safety instructions1. Precautions and safety instructions

entire construction zone.

DANGER!

- EXPLOSION AND FIRE

The use of the demolition and sorting grab may

cause sparking which could ignite highly ammable

gases. This may result in re or explosion.

ØNever work in an environment with highly ammable

substances.

ØEnsure there are no hidden gas sources in the work area.

ØInspect the gas line drawings for the work area.

DANGER!

- EXPLOSION AND FIRE

Dust rich air can form an explosive atmosphere which can

ignite when using the demolition and sorting grab. This can

lead to re or explosion.

ØNever use the demolition and sorting grab in an explosive

atmosphere.

ØAlways ensure adequate ventilation is provided when

working in buildings or in an enclosed area.

1.10 Elektric shock, precautions

DANGER!

- ELEKTRIC SSHOCK

Any contact between the demolition and sorting grapple

and electrical circuits or other power sources will cause an

electric shock which could result in serious injury or death. The

demolition and sorting grab is not electrically insulated.

ØNever work near electrical circuits or other power sources.

ØEnsure there are no hidden electrical circuits are in the work

zone.

ØConsult wiring diagrams.

1.11 Falling rocks, precautions

WARNING!

- AIRBORNE FRAGMENTS

Material which breaks free can be thrown and cause serious

injury. Even small objects falling from a great height can cause

serious damage.

While using the demolition and sorting grab, the danger zone is

considerably greater than during regular excavation work. The

danger zone must therefore be enlarged or secured in a suitable

manner.

ØSafeguard the danger zone.

ØStop the works immediately when someone enters the

danger zone.

ØClose the windscreen and side windows of the excavator

cabin.

1.12 Emissions, precautions

WARNING!

- LUNG DISEASES CAUSED BY DUST

Using the demolition and sorting grab may release dust. Dust

produced during the demolition/moving/sorting of rocks,

concrete and asphalt or other similar materials can lead to

silicosis (also called black lung disease) by inhalation. Silicosis

is a chronic condition that can lead to cancer and death.

ØWear suitable respiratory protection.

1.13 Operating machines, precautions

WARNING!

- NARCOTICS, ALCOHOL AND DRUGS

Narcotics, alcohol and drugs make the user less attentive and

aect the ability to concentrate. Carelessness and incorrect

assessment of a situation may result in serious injury or death.

ØNever work with the excavator and hydraulic work tool

when under the inuence of narcotics, alcohol or drugs that

aect concentration.

ØNever allow other people under the inuence of narcotics,

alcohol or drugs that aect concentration work with the

excavator and the demolition and sorting grab.

1.14 Modications or

changes, precautions

WARNING!

- MODIFICATIONS OR CHANGES

Modications to the demolition and sorting grab or

the adapter plate can lead to serious injury.

ØNever modify the demolition and sorting grab.

ØUse only original parts or accessories approved by Dehaco.

1.15 Environmental

contamination, precautions

ATTENTION

- ENVIRONMENTAL CONTAMINATION BY HYDRAULIC OIL

Hydraulic oil is harmful to the environment. When hydraulic oil is

released (e.g. by leakage) the groundwater and soil may become

contaminated causing organisms to die.

ØCollect all spilled hydraulic oil to prevent environmental

contamination. For small amounts, use absorbent material.

Ensure it does not make its way into the soil, groundwater

or water lines.

ØCollect the contaminated absorbent material in an airtight

container and seal it well.

ØContact a licensed waste disposal company.

ØRemove all contaminated materials in accordance with

current environmental regulations.

1110 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

2. Overview2. Overview

2. OVERVIEW

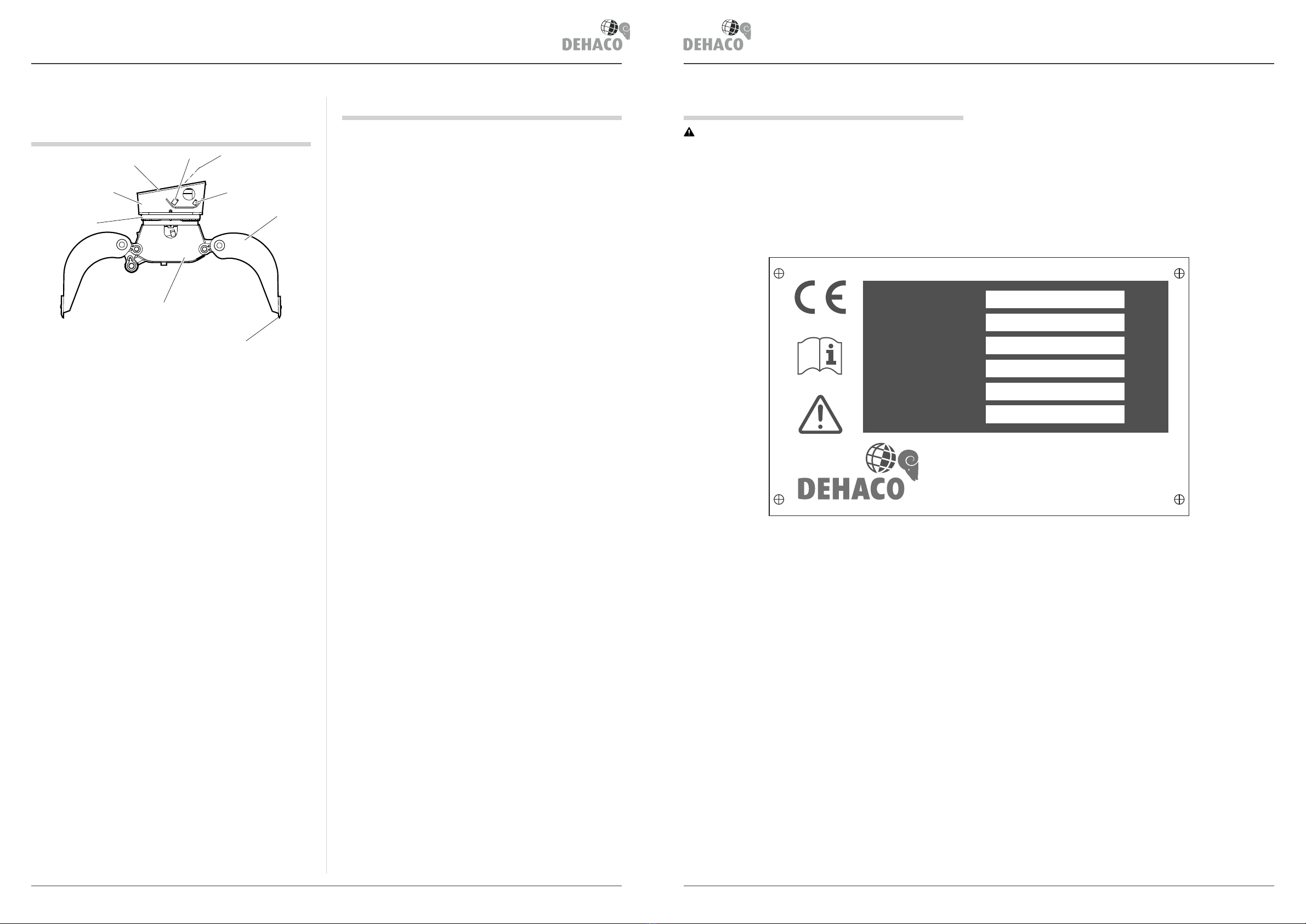

2.1 Description of the equipment

A) Port »A« function »Openen« (standard)

B) Port »B« function »Sluiten« (standard)

C) Port »R« function »Roteren«

D) Shell

E) Replaceable tooth

F) Frame

G) Slewing ring

H) Head assemblu

I) Plate with hole pattern for adapter plate

2.2 Operation

Below is a simplied explanation for operating the demolition

and sorting grab.

Close

The demolition and sorting grab is closed by operating a foot

pedal or joystick in the excavator cabin which operates line B

(function Close). The cylinders slide over the piston rod and the

shells close allowing the material to be grasped.

Open

The demolition and sorting grab is opened by operating a foot

pedal or joystick in the excavator cabin. Oil is brought to the

cylinders through line A causing the piston rod to retract and the

shells to open.

Rotate

Activate the function Rotate grab. This carries hydraulic oil to

the demolition and sorting grab motor and activates the rotation

function.

To achieve innite rotation, the demolition and sorting grab is

tted with a rotation transmission. The oil ows for the Open and

Close functions are carried through the rotation transmission.

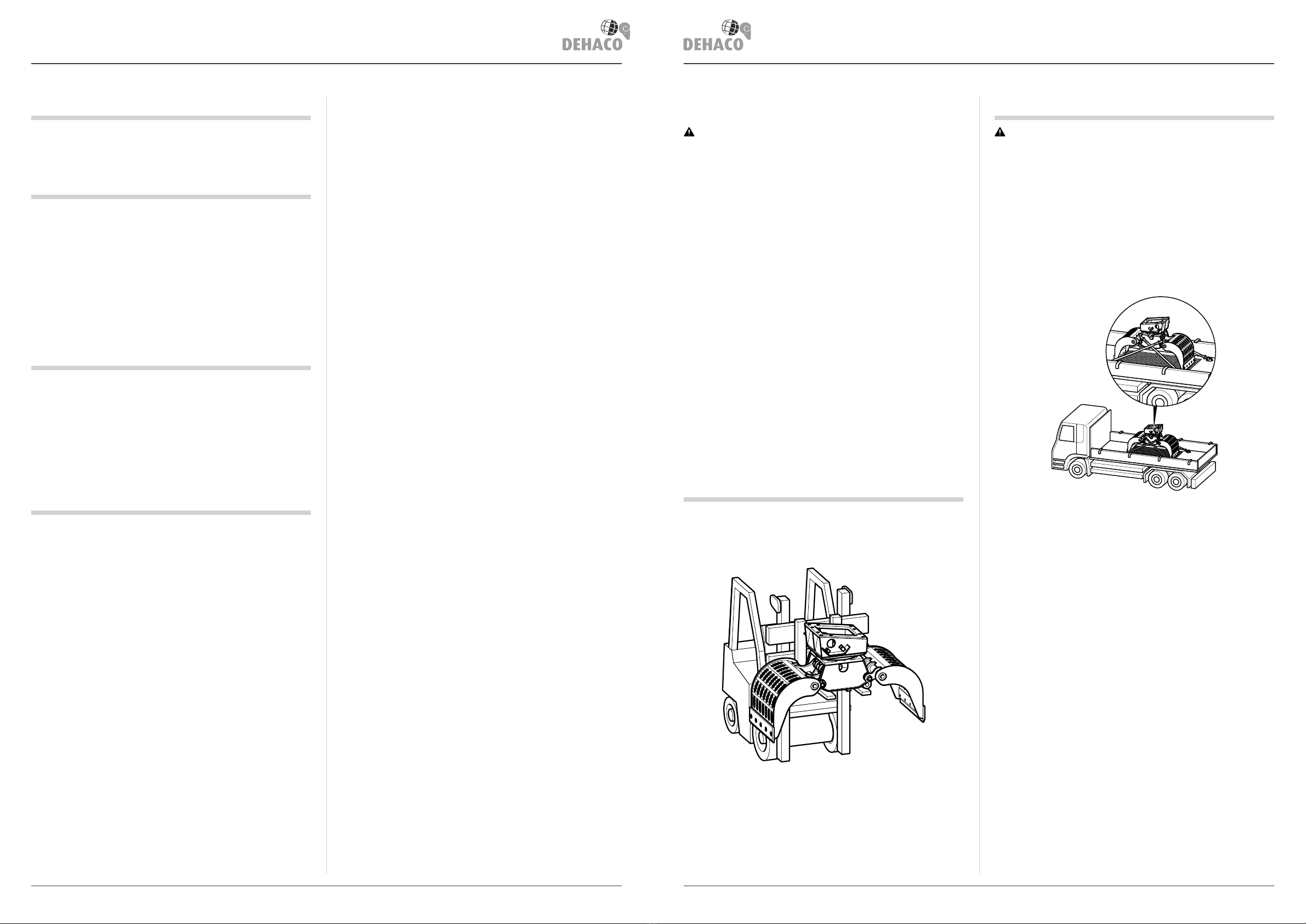

2.3 Nameplate

CAUTION!

- MISSING INFORMATION

The nameplate contains important information about the

demolition and sorting grab. A missing nameplate may lead

to misinterpretation of potential risks and may pose personal

risks. The nameplate must always be clearly legible.

ØReplace a damaged nameplate immediately.

ØUse the parts list to order a new nameplate.

DEHACO B.V.

LISSERBROEK - HOLLAND

www.dehaco.nl

AIR/OIL FLOW

WEIGHT

PRESSURE

SERIAL No.

YEAR

TYPE

Kg

l/m

bar

AB

C

D

E

F

G

H

I

1312 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

3. Transport2. Overview

2.4 Applications

General: sorting and loading work.

Demolition: masonry and timber structures.

2.5 Warranty

The following shall render the warranty void:

◊ Any use not in accordance with this manual.

◊ Maintenance which is not performed or is performed

incorrectly.

◊ Use of incorrect materials.

◊ Use of unapproved components.

◊ Damage caused by wear.

◊ Damage caused by improper storage.

◊ Changes implemented without consulting the manufacturer.

2.6 Removing the packaging

1) Remove all packaging material.

2) Dispose of the packaging material in accordance with

applicable regulations.

3) Check that the delivery is complete.

4) Inspect the delivery for any visible damage.

5) Contact Dehaco B.V. or your dealer if any defects are

identied.

2.7 Scope and content of the delivery

The demolition and sorting grab is delivered with the following:

◊ Demolition and sorting grab.

◊ Operation and maintenance manual.

◊ Parts list.

◊ EC declaration of conformity.

◊ Any ordered accessories such as hoses and couplings.

3. TRANSPORT

WARNING!

- TIPPING FORK-LIFT TRUCK AND/OR FALLING DEMOLITION AND

SORTING GRAB

A falling demolition and sorting grab and/or tipping forklift

truck can cause serious injury and property damage

ØOnly use machines with suitable capacity to transport the

demolition and sorting grab.

ØEnsure no persons are in the vicinity of the demolition and

sorting grab.

Transport the demolition and sorting grab with the shells open.

The demolition and sorting grab is more stable when being

transported with the shells open. There is also less oil in the

demolition and sorting grab when the shells are open. As a result,

less oil loss and less oil in the environment will occur should an

unexpected leak be detected.

◊ Open the shells of the demolition and sorting grab for

transport. Proceed as follows to ensure the shells remain

open:

- Seal all hose ports and connections with the supplied

plugs and cap nuts when the hydraulic hoses are

removed.

- If the hoses remain attached to the demolition and

sorting grab for transport, ensure the hoses are inserted

in the demolition and sorting grab.

3.2 Transport with a fork-lift truck

ØPlace the fork-lift truck under the housing to prevent the

demolition and sorting grab from tipping or falling.

ØLift the demolition and sorting grab slowly.

ØTransport the demolition and sorting grab to its intended

location.

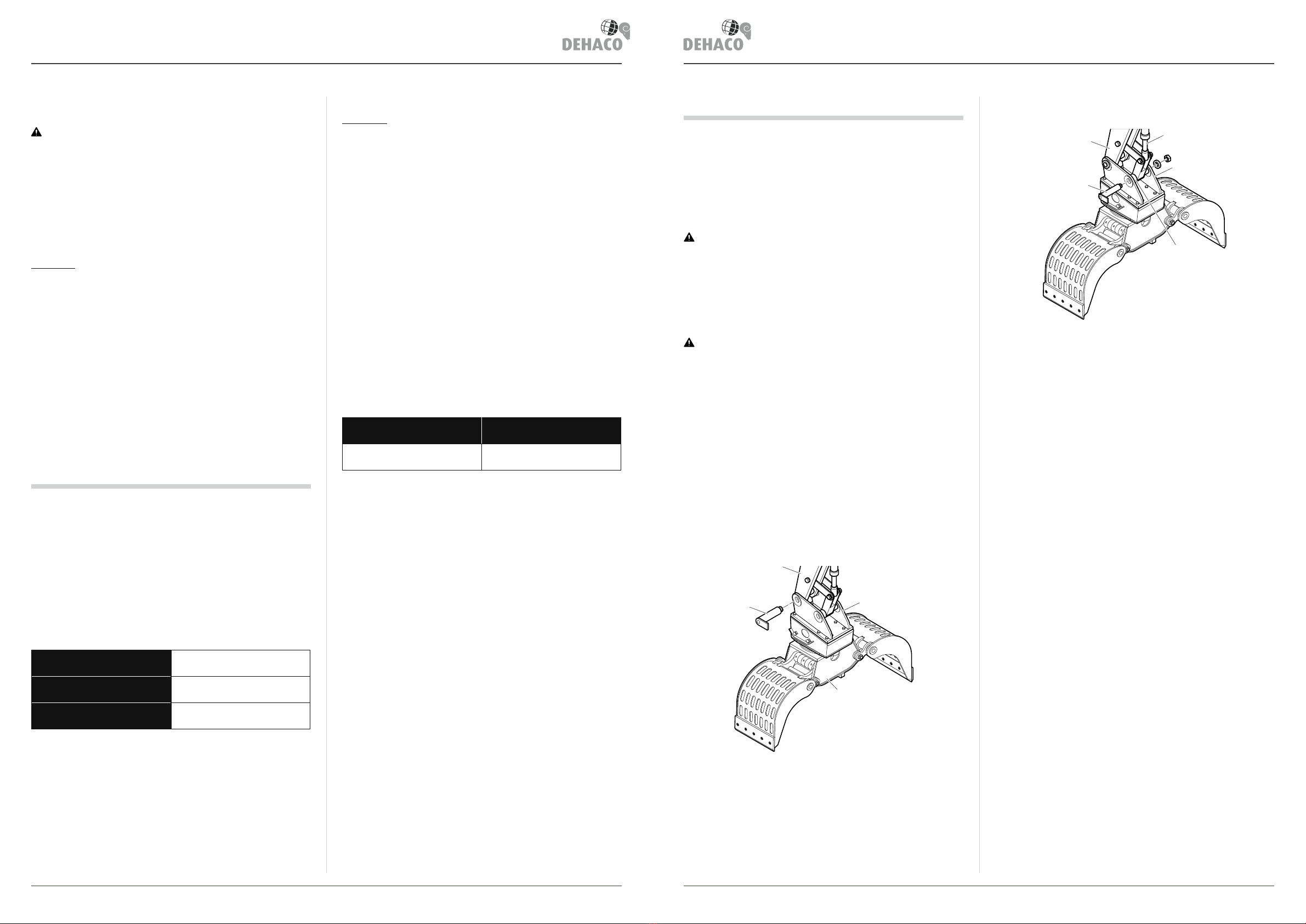

3.3 Transport by lorry

WARNING!

- DEMOLITION AND SORTING GRAB CAN SLIP OR TRIP

If the demolition and sorting grab slips or tips over and falls from

the lorry, it can cause serious injury and property damage.

ØPlace the demolition and sorting grab on an anti-slip mat.

ØSecure the demolition and sorting grab with straps or

chains.

◊ Secure the demolition and sorting grab on the loading

surface as shown in gure below.

◊ Observe all national/regional regulations regarding the

securing of loads.

1514 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

4. Installation4. Installation

4. INSTALLATION

WARNING!

- DISCHARGE OF HOT HYDRAUILC OIL

The hydraulic system is under high pressure. If the hydraulic

connections loosen or become disconnected, the hydraulic

oil will spray out under high pressure. This can lead to serious

injury.

ØEnsure the pressure in the hydraulic system is released

before connecting or disconnecting the demolition and

sortin grab.

ATTENTION

- ENVIRONMENTAL CONTAMINATION BY HYDRAULIC OIL

Hydraulic oil is harmful to the environment. When hydraulic

oil is released (e.g. by leakage) the groundwater and soil may

become contaminated causing organisms to die.

ØCollect all spilled hydraulic oil to prevent environmental

contamination. For small amounts, use absorbent

material. Ensure it does not make its way into the soil,

groundwater or water lines.

ØCollect the contaminated absorbent material in an airtight

container and seal it well.

ØContact a licensed waste disposal company.

ØRemove all contaminated materials in accordance with

current environmental regulations.

4.1 Hydraulic uids

The following uids must be used for the demolition and sorting

grab.

4.1.1 Mineral hydraulic oil

All hydraulic oils indicated by the excavator manufacturer can

also be used for the demolition and sorting grab.

◊ The oil must meet viscosity class HLP 32 or higher.

◊ In the summer and in hot climates, oils with viscosity class

HLP 68 or higher must be used.

◊ In all other cases, the specications of the excavator

manufacturer must be taken into account.

Other conditions apply when used at lower ambient

temperatures. More information is provided in the section

entitled Low ambient temperatures.

◊ Inspect the oil lter regularly!

An oil lter must be tted in the return line of the hydraulic

system. The maximum allowable mesh size is 50 microns. It must

also be tted with a magnetic separator.

4.1.2 Non-mineral hydraulic oil

ATTENTION

- MIXED HYDRAULIC OIL

Never mix mineral oil with non-mineral oil. Even small traces of

mineral oil mixed with non-mineral oil may result in damage to

both the demolition and sorting grab as well as the excavator.

Non-mineral oil loses its biodegradability.

ØUse only one type of hydraulic oil.

If non-mineral oil is used, the brand must be indicated when the

demolition and sorting grab is brought in for repair.

To protect the environment, or for technical reasons, the

hydraulic oils currently used are not classied as HLP mineral oils.

In principle, the demolition and sorting grabs from Dehaco B.V.

are designed for use with mineral oils. Contact Dehaco B.V. before

deciding to change to non-mineral hydraulic oil.

4.1.3 Grease

◊ Observe the safety regulations before working with oils and

greases.

4.2 Attaching to the excavator

A colleague’s help is required to attach the demolition and sorting

grab to the excavator.

◊ Agree on hand signals to use with your colleague to enable

them to assist in correctly positioning the excavator on the

demolition and sorting grab.

◊ Lower the arm of the excavator to position it in the adapter

plate holder.

WARNING!

- INJURY FROM SUDDEN MOVEMENTS OF THE EXCAVATOR ARM

A sudden movement by the excavator can strike your colleague

and cause serious injury.

ØMove the excavator arm carefully and in a controlled manner

when someone is in the danger zone.

ØEnsure your colleague always remains visible.

WARNING!

- CUTS OR INJURIES TO HANDS AND FINGERS

Drilled holes and surfaces may be razor sharp and cause serious

injury.

ØNever use your ngers to inspect holes or mounting surfaces.

If a pin and bushing system, follow the procedure outlined below.

If another (quick change) system is being used, we recommend

consulting the manufacturer’s manual.

◊ Follow the directions provided by a colleague to properly

align the holes in the adapter plate (B) and the excavator arm

(A).

◊ Install and secure the hinge pin (C).

◊ Raise the demolition and sorting grab.

◊ Extend the bucket cylinder (E) until the securing hole in the

coupling (F) aligns with the securing hole in the adapter plate

(B).

◊ Install and secure the coupling pin (G).

◊ Carefully move the bucket cylinder (E) to both end positions.

A

C

D

B

A

G

F

B

E

Optimum viscosity range 30 - 60 cSt

Max. initial viscosity 2000 cSt

Max. oil temperature 80ºC

Description Article number

Grease

Q8 Ruysdael CL2 9210.0007

1716 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

4. Installation

4.2.1 Making the hydraulic connections

ATTENTION

- INCORRECT HYDRAULIC SYSTEM

The excavator must have a suitable hydraulic system to operate

the demolition and sorting grab. Improperly installed piping

and incorrectly calculated dimensions may lead to excessive oil

temperatures anD damage to the demolition and sorting grab.

ØOnly use lines with the dimensions specied in the chapter

Technical Specications.

ØVerify the specied dimensions of the hydraulic lines on

existing hydraulic systems. All supply and return lines for

the hydraulic oil must have a sucient internal diameter

and wall thickness

ØEnsure the hydraulic hoses cannot be pinched.

◊ Switch the excavator o.

◊ Relieve the pressure of the hydraulic system by releasing the

pressure in the hydraulic tank.

◊ Close all valves if quick connects are not used.

ATTENTION

- DAMAGE TO HYDRAULIC COMPONENTS

Sand and dirt can enter the hydraulic lines and cause damage.

Clean all hydraulic lines and connections before

connecting the hydraulic hoses.

◊ Contaminated hydraulic pipes must be cleaned by a

specialist company.

◊ Clean contaminated hydraulic pipe connections with a

suitable universal degreaser/cleanser.

◊ Refer to information from the cleaning agent manufacturer

regarding safety and use.

4.2.2 Connecting the hydraulic hoses for the

Open and Close functions

◊ Remove the caps/blank anges from ports Aand Band store

in a safe place.

◊ Inspect for damage.

◊ Replace any damaged connections.

◊ If the two input lines from the excavator arm have the same

working pressure, connect the lines to the Open and Close

ports being careful not to cause pinching (see gure page 10).

◊ If the pressure in the two input lines dier, connect the hose

with the higher operating pressure to the Close port and the

hose with the lower pressure to the Open port being careful

not to pinch the hoses.

4.2.3 Connecting the hydraulic hoses for the

Rotate function

◊ ◊ Remove the cap nuts and plugs from the connections for

the Rotate function and store them for future use.

◊ Inspect the connections for damage.

◊ Replace damaged connections.

◊ Attach the hoses to the connector for the Rotate function.

◊ Connect both hoses for the Rotate function to the arm

carefully to prevent pinching.

WARNING!

- THRASHING HYDRAULIC HOSES

Hydraulic hoses under pressure will thrash about if a bolt

connection becomes loose or detached. This can cause serious

injury.

ØTighten the mounting screws to the correct torque.

4.3 Detaching the demolition and

sorting grab from the excavator

WARNING!

- UNEXPECTED MOVEMENTS

Sudden movements by the excavator can cause injury.

ØSecure the excavator to prevent unexpected movement.

ØFollow the instructions from the excavator manufacturer.

WARNING!

- THRASHING HYDRAULIC HOSES

Hydraulic hoses under pressure will thrash about if a bolt

connection becomes loose or detached. This can cause serious

injury.

ØRelieve the pressure in the hydraulic system before

disconnecting the hydraulic hose.

WARNING!

- HOT COMPONENTS

The hydraulic cylinder, hoses, tubes and ttings become very hot

during operation. Contact with these components can cause

burns.

ØNever touch hot components.

ØIf works need to be completed on or near hot components,

wait for them to cool down rst.

◊ Close all shut-o valves in the excavator arm system if quick

connects are not used.

◊ Disconnect the hoses to and from the demolition and sorting

grab on the side of the excavator arm.

◊ Seal all open hose ends.

4.3.1 Mechanical detachment

Note: If a pin and bushing system, follow the procedure outlined

below. If another (quick change) system is being used, we

recommend consulting the manufacturer’s manual.

◊ Request help from a colleague when detaching the

demolition and sorting grab.

◊ Agree on clear hand signals for moving the excavator arm.

WARNING!

- INJURIES CAUSED BY THE EXCAVATOR ARM OR DEMOLITION AND

SORTING GRAB

Sudden movements by the excavator can cause the excavator or

the demolition and sorting grab to strike your colleague.

ØMove the excavator arm very slow and in a controlled

manner when a colleague is in the danger zone.

ØEnsure your colleague always remains visible.

4. Installation

WARNING!

- METAL SPLINTERS

Hammering bolts out can cause splinters to y o

which can cause serious damage to the eyes.

ØWear safety goggles when hammering out bolts.

◊ Remove the bolt clips from the shank.

◊ Remove the connecting bolt with a steel pin and a hammer.

◊ Switch the excavator on.

◊ Retract the bucket cylinder.

◊ Remove the hinge pin with a steel pin and a hammer.

◊ Remove the excavator arm from the adapter plate.

4.4 Detaching the adapter plate

◊ Loosen the fastening screws for the adapter plate.

◊ Lift the adapter plate using suitable lifting equipment and

place it on wooden support blocks.

◊ Store the mounting screws and washers for future use.

1918 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

5. OperationOperation

5. OPERATION

WARNING!

- DISCHARGE OF HOT HYDRAULIC OIL

The hydraulic system is under high pressure. If the hydraulic

connections loosen, the hydraulic oil will spray out under

high pressure. This can lead to serious injury.

ØSwitch the excavator and demolition and sorting grab o

immediately if a leak is detected.

ØRelease the pressure in the hydraulic system.

ØRepair any leaks before using the demolition and sorting

grab again.

WARNING!

- HOT COMPONENTS

The hydraulic cylinder, hoses, tubes and ttings become very

hot during operation. Contact with these components can cause

burns.

ØNever touch hot components.

ØIf works need to be completed on or near hot components,

wait for them to cool down rst.

ATTENTION

- ENVIRONMENTAL CONTAMINATION BY HYDRAULIC OIL

Hydraulic oil is harmful to the environment. When hydraulic

oil is released (e.g. by leakage) the groundwater and soil may

become contaminated causing organisms to die.

ØCollect all spilled hydraulic oil to prevent environmental

contamination. For small amounts, use absorbent material.

Ensure it does not make its way into the soil, groundwater

or water lines.

ØCollect the contaminated absorbent material in an airtight

container and seal it well.

ØContact a licensed waste disposal company.

ØRemove all contaminated materials in accordance with

current environmental regulations.

ATTENTION

- EXCESSIVE HYDRAULIC OIL TEMPERATURE

The temperature of the hydraulic oil must not exceed 80 C.

Higher temperatures will damage the seals of the hydraulic

components.

ØAlways monitor the oil temperature.

ØTurn the excavator and demolition and sorting grab o

when the monitor indicates an increased oil temperature.

ØInspect the hydraulic system and the pressure relief valve.

5.1 Preparations for starting

WARNING!

- TIPPING THE EXCAVATOR OVER

An excavator that falls or tips over because it is placed on an

uneven surface can cause serious injury and property damage.

ØAlways move the excavator with the greatest caution.

ØDo not use the demolition and sorting grab before the

excavator is stable.

WARNING!

- AIRBORNE FRAGMENTS

Fragments of materials that are released when using the

demolition and sorting grab can be thrown and cause serious

injury to people if struck. Even small objects falling from a great

height can cause serious damage.

The danger zone while using the demolition and sorting grab is

signicantly larger than for excavation work.

ØSafeguard the danger zone.

ØStop working with excavator soon as someone enters the

danger zone.

ØClose the windscreen and side windows of the excavator

cabin.

◊ Precautions for starting the demolition and sorting grab:

-Ensure the demolition and sorting grab is complete.

-Inspect the demolition and sorting grab and adapter

plate for cracks.

-Ensure there are no leaks from the hydraulic lines.

The preparations required prior to starting the demolition and

sorting grab depend on the ambient temperature:

-Ambient temperatures below 0 C (see Low ambient

temperature).

-Ambient temperature higher than 30 C (see High

ambient temperature).

While working with the demolition and sorting grab, the oil

temperature must remain between 0 C and +80 C. The full

capacity of the demolition and sorting grab can be utilised at an

oil temperature of approximately +60 C.

1) Ensure no persons are in the danger zone.

2) Start the excavator according to the instructions provided by

the excavator manufacturer.

3) Allow the excavator to warm up until the specied operating

temperature is reached.

4) Place the excavator in the desired position.

5.2 Switching the demolition

and sorting grab on and o

After attaching the demolition and sorting grab to the excavator,

the grab can be operated by the excavator’s hydraulic system. All

the functions for controlling the excavator remain unchanged.

The demolition and sorting grab is switched on and o by

electrical and hydraulic signals.

◊ Switch the demolition and sorting grab on and o according

to the specied operating instructions.

◊ Leaving the excavator cabin? Switch the safety switch for the

demolition and sorting grab to “o”.

Perform the actions described above to avoid unintentional

starting of the demolition and sorting grab.

5.3 Function test

Always perform a function test before using the demolition and

sorting grab. Ensure all hydraulic lines and connections are tight

and that the demolition and sorting grab operates smoothly.

◊ Prepare the demolition and sorting grab to allow proper use

(see Preparations for starting).

◊ Raise the demolition and sorting grab using the arm of the

excavator until it hangs vertically.

◊ Close and open the shells.

◊ Rotate the demolition and sorting grab to the left and right

using the Rotate grab function.

◊ Verify the hydraulic lines of the demolition and sorting grab

work properly.

◊ Switch the demolition and sorting grab o immediately if

oil leaks from the hydraulic lines or other malfunctions are

identied.

◊ Relieve the pressure of the hydraulic system by releasing the

pressure in the hydraulic tank.

◊ Only use the demolition and sorting grab again after all leaks

and malfunctions have been corrected.

5.4 Proper use

5.4.1 Masonry demolition

Grasp the masonry with the shells of the demolition and sorting

grab and break the structure.

5.4.2 Sorting and loading

Use the shells for sorting and loading material.

5.4.3 Dust control

Keep the work area humid by continuously spraying water. This

reduces dust levels to a minimum. Dehaco B.V oers various

solutions for dust control in the form of misters and mist

sprayers. Visit www.dehaco.nl for more information.

2120 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

5. Operation

5.4.4 High ambient temperature

◊ Only use hydraulic oils with sucient viscosity.

In summer and in tropical climates, hydraulic oil type HLP 68

meets the minimum requirements.

5.4.5 Low ambient temperature

For ambient temperatures below -20 ºC

Before working with the demolition and sorting grab in ambient

temperatures below -20 ºC, ensure the excavator is suciently

warmed up.

Preferably, the excavator and the demolition and sorting grab

should be parked in a heated, covered area when not in use.

ATTENTION

- INSUFFICIENT HYDRAULIC OIL TEMPERATURE

Working with the demolition and sorting grab while the hydraulic

oil is still cold seals will damage the hydraulic component seals.

Do not use the demolition and sorting grab until

the oil temperature is at least 0 ºC.

◊ Start the excavator according to the instructions provided by

the excavator manufacturer.

◊ Allow the excavator warm up until the operating temperature

specied by the excavator manufacturer is reached.

◊ Raise the demolition and sorting grab using the arm of the

excavator until it hangs vertically.

◊ Close, open and rotate the demolition and sorting grab while

the excavator is warming up.

ATTENTION

- DAMAGE TO HYDRAULIC COMPONENTS

Hot hydraulic oil will damage a cold hydraulic demolition and

sorting grab.

Do not ll the hydraulic system with hot hydraulic oil.

The temperature of the hydraulic oil from the excavator must be

at least 0 C.

◊ Start the demolition and sorting grab when the temperature

reaches 0º C.

◊ Perform a function test and ensure all hydraulic lines and

connections are tight and that the demolition and sorting

grab operates smoothly.

◊ Allow the engine of the excavator and the pumps to remain

in operation, even during breaks.

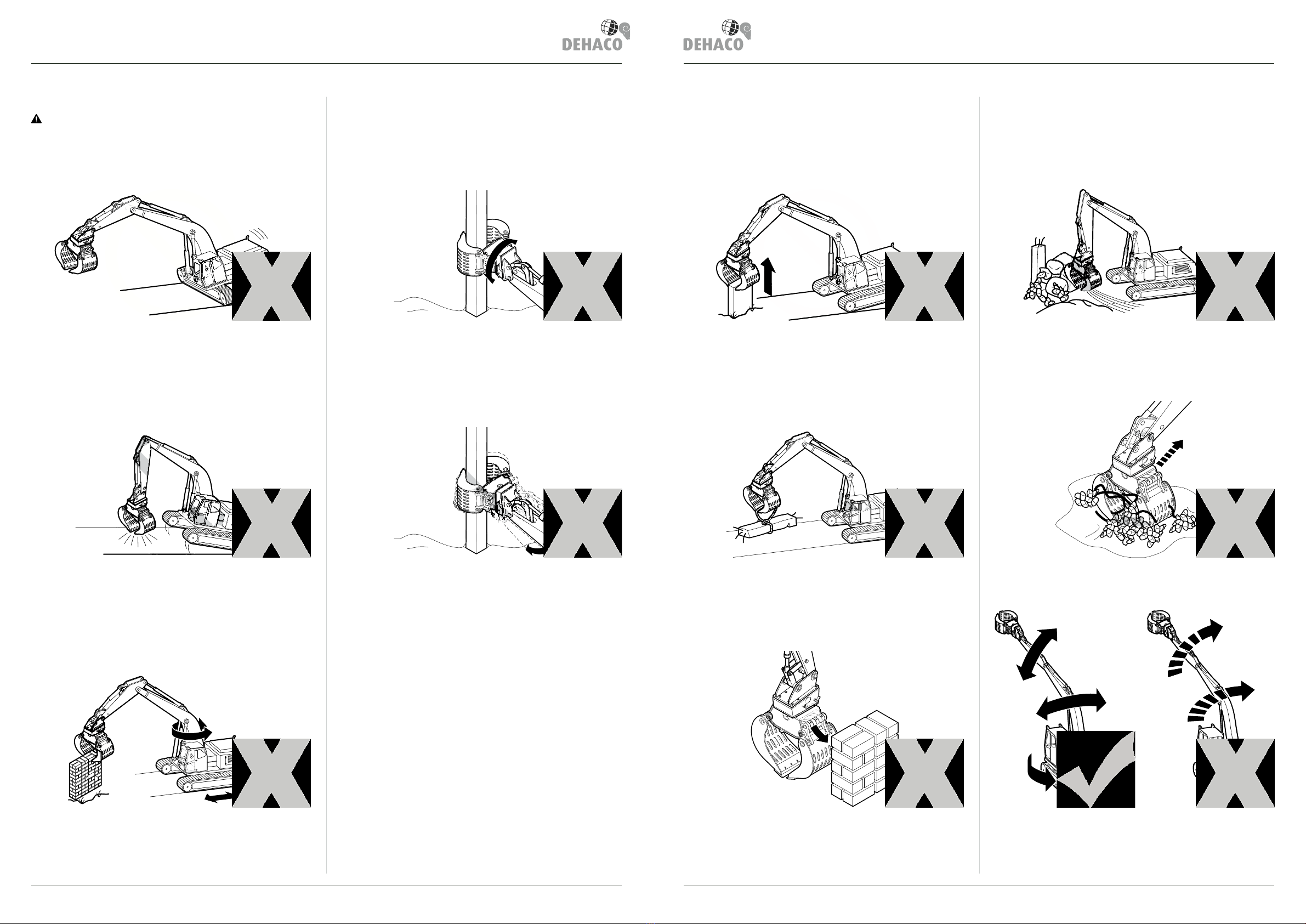

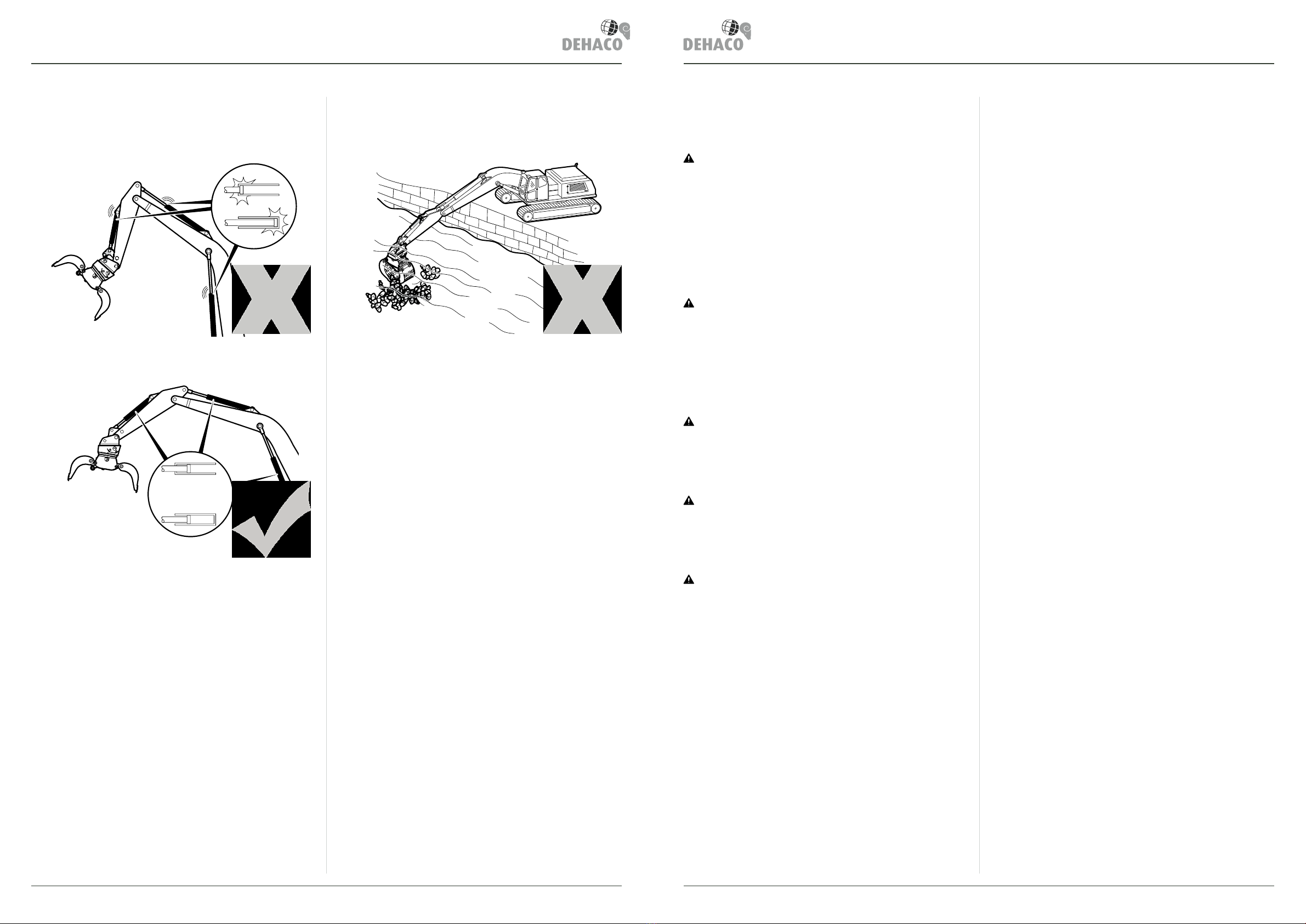

5.5 Prohibited use

5.5.1 Zwevend transport

WARNING!

- RISK OF FALLING OBJECTS

Falling objects can cause serious injury.

ØNever operate the demolition and sorting grab above the

cabin, other persons or other machines.

5.5.2 Unsafe surface

WARNING!

- RISK OF TIPPING

The excavator can tip over and cause injury and damge.

ØOnly operate the demolition and sorting grab when the

excavator is on a safe, stable surface.

5. Operation

5.5.3 Non-bearing, suspended ceilings

WARNING!

- RISK OF COLLAPSE

The excavator can crash down and cause injury and damage.

ØOnly operate the demolition and sorting grab when the

excavator is on a load-bearing ceiling.

5.5.4 Working position

WARNING!

- FALLING DEBRIS

Large pieces of falling debris can cause injury and damage.

ØNever begin demolition works from the bottom or the

middle of a structure.

2322 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

5. Operation

5.5.5 Using the chain

WARNING!

- RISK OF TIPPING

The excavator can tip over and cause injury and damage.

ØOnly operate the demolition and sorting grab when the

excavator is on a safe, stable surface.

5.5.6 Moving the excavator

Never move the excavator sideways by placing the demolition and

sorting grab on the ground to lift the excavator. This can cause

severe damage to the demolition and sorting grab.

5.5.7 Moving the arm

Never move the excavator or arm while working with the

demolition and sortin grab.

5. Operation

5.5.8 Rotating the demolition and sortin grab

Never rotate the demolition and sorting grab while operating the

grab. This can cause severe damage to the demolition and sorting

grab.

5.5.9 Extending the bucket cylinder

Never extend the cylinder while operating the grab. This action

will make the demolition and sorting grab unusable.

5.5.10 Pulling

Never use the demolition and sorting grab to pull on support

beams, supports or walls. This could result in severe damage.

Moreover, the excavator could lose stability and tip over.

5.5.11 Lifting/transporting

Never use the demolition and sorting grab to lift or transport

material. The tool is not designed for this and such use may result

in severe damage.

5.5.12 Hammering

Never use the demolition and sorting grab to hammer on or

against the structure to be demolished. This can cause severe

damage to the demolition and sorting grab.

5.5.13 Pushing debris

Never use the demolition and sorting grab to push debris.

5.5.14 Abrupt movements

Never make sudden movements with the demolition and sorting

grab in an attempt to release when stuck in a construction.

2524 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

5. Operation

5.5.15 Extreme cylinder positions

Ensure the cylinders of the excavator arm never reach their

extreme positions. If necessary, move the excavator to allow easy

operation of the demolition and sorting grab.

6. Maintenance

5.5.16 Under water use

Never use the demolition and sorting grab under water. Water

can severly damage both the demolition and sorting grab as well

as the hydraulic system of the excavator.

6. MAINTENANCE

Maintenance work must be performed by the excavator operator

regularly.

WARNING!

- DISCHARGE OF HOT HYDRAULIC OIL

The hydraulic system is under high pressure. If the hydraulic

connections loosen, the hydraulic oil will spray out under

high pressure. This can lead to serious injury.

ØSwitch the excavator and demolition and sorting grab o

immediately if a leak is detected.

ØRelease the pressure in the hydraulic system.

ØRepair any leaks before using the demolition and sorting

grab again.

WARNING!

- HOT COMPONENTS

The hydraulic cylinder, hoses, tubes and ttings become very

hot during operation. Contact with these components can cause

burns.

ØNever touch hot components.

ØIf works need to be completed on or near hot components,

wait for them to cool down rst.

WARNING!

- UNINTENTIONAL STARTING

Unintentional starting of the excavator/demolition and sorting

grab can lead to serious injury.

ØFollow the instructions to avoid unintentional starting.

WARNING!

- UNEXPECTED MOVEMENTS

Sudden movements by the excavator can cause injury

ØSecure the excavator to prevent unexpected movement.

Ø Follow the instructions from the excavator manufacturer.

WARNING!

- SERIOUS PHYSICAL INJURY

The shells of the demolition and sorting grab may close

unexpectedly and cause serious physical injury.

ØEnsure no one is present between the shells.

ATTENTION

- ENVIRONMENTAL CONTAMINATION BY HYDRAULIC OIL

Hydraulic oil is harmful to the environment. When hydraulic

oil is released (e.g. by leakage) the groundwater and soil may

become contaminated causing organisms to die.

ØCollect all spilled hydraulic oil to prevent environmental

contamination. For small amounts, use absorbent material

ØEnsure it does not make its way into the soil, groundwater

or water lines.

ØCollect the contaminated absorbent material in an airtight

container and seal it well.

ØContact a licensed waste disposal company.

ØRemove all contaminated materials in accordance with

current environmental regulations.

2726 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

1

6. Maintenance 6. Maintenance

6.1 Daily maintenance

1) For maintenance work, always place the grab in open

position on a at and stable surface and ensure the

excavator cannot move.

2) When servicing the hydraulic system, the hydraulic hoses

should be disconnected. Prior to disconnecting the hoses,

ensure no pressure remains on the hoses. See the operating

instructions of the excavator for more information.

3) The grab must be lubricated once per every 8 operating

hours using the same type of grease specied for the

excavator.

4) When the interchangeable wear blades on the grab

shells have worn away to that extent that the grab can

no longer fully close, work must be discontinued and the

interchangeable wear blades must be changed or replaced.

(NOTE The interchangeable wear blades also serve as the

end stop for the cylinders.)

6.1.1 Lubrication schedule

6.1.2 Changing/replacing wear blades

1) Ensure the nut is installed with the conical side on the inside

of the shell.

2) Bolts must be tightened to the torque indicated on the table

on page 27.

1) Lubricating pivot points

1 = 1 x per 8 operating hours

2) Lubricating pivot points

1 = 1 x per 8 operating hours

3) Lubricating slewing ring

1 = 1 x per 8 operating hours

To ensure the wear blades remain securely fastened to the

shell during shock and tearing loads, it is recommended to

tack weld the interchangeable wear blade to the xed blade.

6.1.3 Torque

The table on this page provides a summary of the torque required for the nuts and bolts on the slewing ring, blades and other components

of the DSG demolition and sorting grab.

Bolt size Torque (Nm) Torque (kg•m) Torque (ft•lb) Comments

Bout 10,9 Bout 10,9

M8 40 Nm 4 kg•m 29 ft•lb

M10 80 Nm 8 kg•m 60 ft•lb

M12 130 Nm 13 kg•m 94 ft•lb

M12 x 1,25 110 Nm 11 kg•m 80 ft•lb Caution! Fine thread!

M14 200 Nm 20 kg•m 145 ft•lb

M16 300 Nm 30 kg•m 217 ft•lb

M20 600 Nm 60 kg•m 434 ft•lb

M24 1000 Nm 100 kg•m 723 ft•lb

M27 1500 Nm 150 kg•m 110 6 f t •l b

M30 2000 Nm 200 kg•m 1475 ft•lb

M36 3600 Nm 360 kg•m 2655 ft•lb

M39 4600 Nm 460 kg•m 3393 ft•lb

2928 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

7. Troubleshooting7. Troubleshooting

7. TROUBLESHOOTING

7.1 The demolition and sorting

grab does not work

7.2 Insucient closing force

7.3 The rotate function does not work

Cause Solution By who?

Ensure the valve in the Open of Close pipe

is closed.Open the return valve. Operator

Broken connector blocking Open/Close

pipes. Replace the defective coupling components. Workshop or Dehaco/dealer service

technician

Electrical equipment in the system is faulty. Inspect the faulty electrical equipment and

repair if necessary. Workshop

The toggle switch is faulty. Inspect the toggle switch and replace if

necessary. Workshop

The magnet on the switch on valve is

damaged. Replace the magnet. Workshop

Cause Solution By who?

The pipes for Open abd Close are swapped. Connect the cables as required. Operator

The operating pressure is too low. Correct the operating pressure. Workshop or Dehaco/dealer service

technician

Cause Solution By who?

Rotary motor/gear unit/slewing ring/

rotation transmission defect.

Inspect the rotary motor/gear unit/slewing

ring/rotation transmission and replace the

defective parts.

Workshop or Dehaco/dealer service

technician

Cause Solution By who?

The oil level in the tank is too low. Check the oil level and top up if necessary. Operator or workshop

The pumping volume of the excavator is

too high; there is a constant amount of oil

spraying from the pressure reducing valve.

Check the speed of the excavator motor and

correct. Switch the pump on.

Dehaco service technician or an authorised

Dehaco dealer.

The pressure reducing valve is faulty or

there is a defect in the valve.

Fit a new pressure reducing manager or a

more accurate pressure relief valve.

Dehaco service technician or an authorised

Dehaco dealer.

7.4 The operating

temperature is too high

7.5 Oil leaks at hydraulic connections

7.6 Insucient lubrication

Cause Solution By who?

Cap nits are loose. Inspect the cap nuts and tighten. Operator

Hose connections are loose. Inspect the connections and tighten. Operator

Cause Solution By who?

Interval between lubrication is too long. Check lubrication and lubricate. Operator

3130 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

9. Storage8. Repair

8. REPAIR

WARNING!

- RISK OF PERSONAL INJURY

Improper repair of the demolition and sorting grab can cause

serious injury and damage.

ØRepairs may only be carried out by Dehaco B.V. or an

authorised Dehaco dealer.

◊ For technical support, please contact Dehaco B.V. or a

Dehaco dealer in your area.

8.1 Repair service for the

demolition and sorting grab

ATTENTION

- MIXED HYDRAULIC OIL

Never mix mineral oil with non-mineral oil. Even small traces of

mineral oil mixed with non-mineral oil may result in damage to

both the demolition and sorting grab as well as the excavator.

Non-mineral oil loses its biodegradability.

ØUse only one type of hydraulic oil.

◊ Always indicate which hydraulic oil is used when sending the

demolition and sorting grab for repair.

9. STORAGE

9.1 Demolition and sorting grab

WARNING!

- RISK OF TIPPING

If the demolition and sorting grab tips over while stored,

this can lead to serious injury and property damage.

ØPreferably, position the demolition and sorting grab on

square wooden beams or a pallet. Ensure the horizontal

surface is level.

9.1.1 Procedure for storage

1) Open the shells of the demolition and sorting grab. The

demolition and sorting grab is more stable when it is stored

with the shells open. There is also less oil in the demolition

and sorting grab when the shells are open. As a result, less

oil loss and less oil in the environment will occur should an

unexpected leak be detected.

2) Remove the demolition and sorting grab from the excavator.

3) Store the demolition and sorting grab in a dry, well ventilated

area.

4) If the only possibility for storage is in the open, the

demolition and sorting grab must be protected from the

weather. For example, by using plastic foil or protective

covers.

9.2 Grease cartridges

WARNING!

- FIRE AND HARMFUL GASES

Burning grease releases harmful gases.

ØNever store grease cartridges near ammable or self-

igniting substances.

ØDo not expose grease cartridges to direct sunlight.

◊ Store grease cartridges in a cool, well-ventilated area.

AC

B

D

3332 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

10. Disposal

10. DISPOSAL

ATTENTION

- ENVIRONMENTAL DAMAGE BY CONSUMABLES

Hydraulic oil and grease are harmful to the environment and

may not penetrate the soil, nor end up in the water table or

water supplies.

ØEnsure no oil or grease run o.

ØDispose of oil and grease according to applicable

environmental regulations.

10.1 Demolition and sorting grab

◊ Remove the demolition and sorting grab from the excavator.

◊ Remove the adapter plate.

◊ Remove the hydraulic hoses from the demolition and sorting

grab.

◊ Dispose of the demolition and sorting grab according to

applicable regulations or consult a certied specialist

company.

10.2 Hydraulic hoses

◊ Drain and collect the oil from the hydraulic hoses.

◊ Dispose of the hydraulic hoses in accordance with applicable

regulations and avoid risks to the environment.

10.3 Hydraulic oil

◊ Collect any spilled hydraulic oil.

◊ Dispose of it in accordance with environmental regulations.

10.4 Grease and grease cartridges

◊ Dispose of grease and partially empty grease cartridges in

accordance with applicable regulations.

◊ Only completely empty grease cartridges can be recycled.

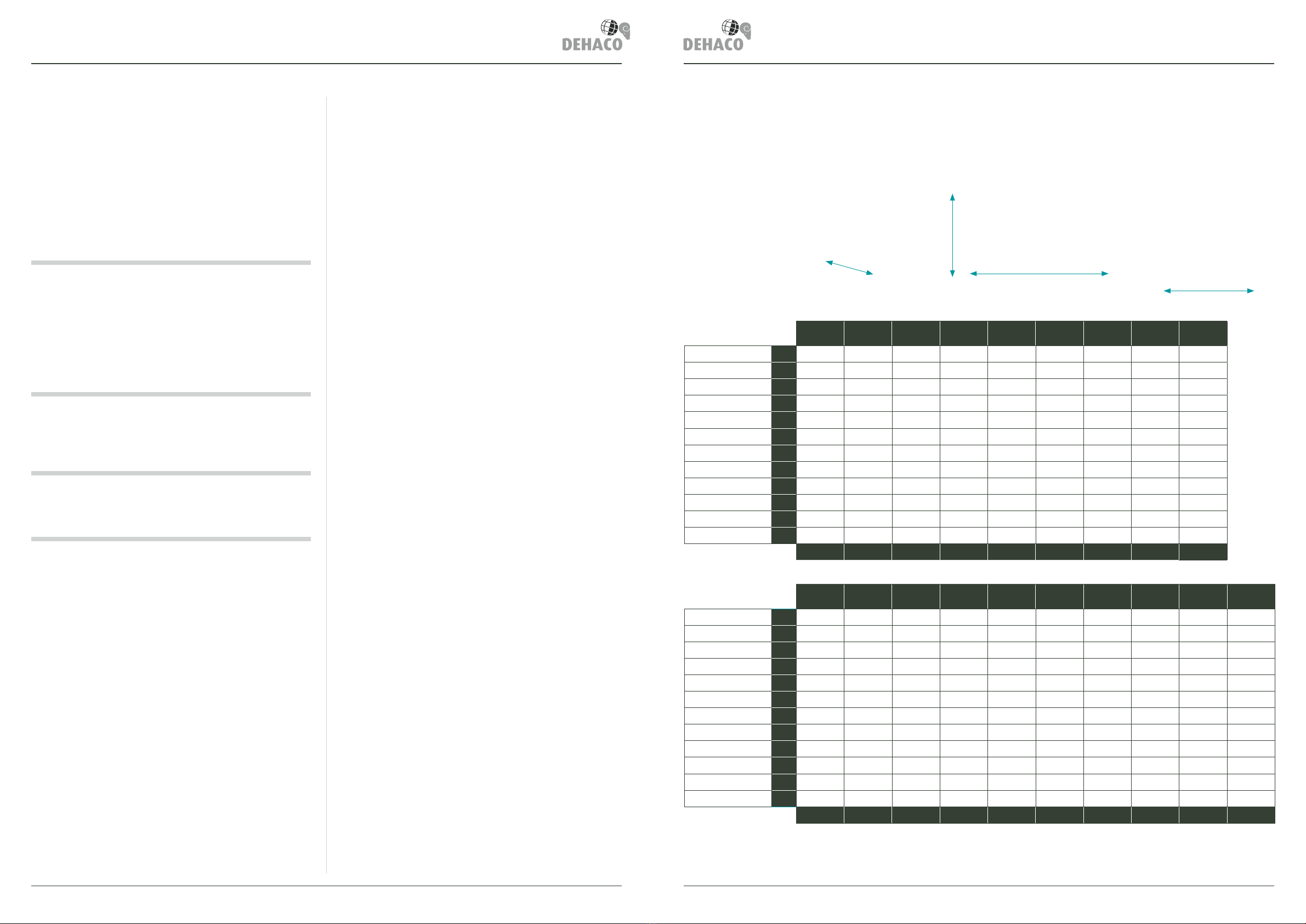

11. Technical specications F-series

11. TECHNICAL SPECIFICATIONS

Hydraulic demolition and sorting grabs

without rotation

(1) Weights only apply to standard carriers.

Each deviation must be agreed upon with Dehaco and/or manufacturer of the carrier prior to assembly.

(2) Weight excluding top bracket and hoses.

DSG70-F DSG100-F DSG150-F DSG250-F DSG400-F DSG450-F DSG452-F DSG502-F

DSG603-F

Technical specs

Excavator weight (1)

t

0,7-1,2 1-2 1,2-3 2,5-4 4-6 5-9 6-11 7-12 10-16

Weight (standard) (2)

kg

50 65 100 200 280 330 340 500 600

Cylinders 1 1 1 1 1 1 1 1 1

Operating pressure

bar

300 300 300 300 300 300 300 350 350

Oil flow

l/min

15 20 25 35 40 50 50 90 100

Shell width A

mm

300 350 450 500 600 700 700 600 800

Height opened B

mm

420 450 550 650 800 820 820 745 950

Width opened C

mm

600 770 800 1.160 1.400 1.500 1.500 1.700 1.750

Height closed D

mm

600 540 540 695 840 875 875 925 955

Width closed E

mm

430 545 545 785 850 890 885 1.055 1.070

Capacity

l

30 40 70 100 150 200 200 300 400

Closing force

kN

6 7 15 20 23 24 24 30 35

Article number 1210.0038 1210.0069 1210.0063 1210.0040 1210.0015 1210.0041 1210.0070 1210.0042 1210.0071

DSG903-F DSG1003-F DSG1102-F DSG1202-F DSG1402-F DSG1802-F DSG1900-F DSG2500-F DSG2700-F DSG3000-F

Technical specs

Excavator weight (1)

t

13-20 16-20 16-25 17-28 20-28 24-35 25-38 28-40 30-50 35-50

Weight (standard) (2)

kg

785 800 1.100 1.200 1.300 1.450 1.500 1.900 2.100 2.400

Cylinders 2 2 2 2 2 2 2 2 2 2

Operating pressure

bar

350 350 350 350 350 350 350 350 350 350

Oil flow

l/min

120 120 150 160 170 170 180 200 200 200

Shell width A

mm

900 1.000 900 1.000 1.200 1.200 1.200 1.200 1.360 1.500

Height opened B

mm

1.100 1.100 1.200 1.200 1.200 1.250 1.020 1.270 1.270 1.300

Width opened C

mm

1.950 1.950 2.100 2.100 2.100 2.400 2.250 2.250 2.250 2.450

Height closed D

mm

1.105 1.105 1.240 1.230 1.230 1.260 1.270 1.380 1.380 1.485

Width closed E

mm

1.170 1.170 1.300 1.300 1.300 1.350 1.340 1.370 1.370 1.475

Capacity

l

600 700 750 800 850 950 900 1.000 1.100 1.300

Closing force

kN

46 46 55 68 68 80 80 90 90 90

Article number v 1210.0073 1210.0074 1210.0075 1210.0076 1210.0077 1210.0078 1210.0079 1210.0110 1210.0111

3534 © 2022 Dehaco B.V. • Operation and maintenance manual DSG Demolition and Sorting grabs • No. DSG.2165.0001 • 31-01-2022

Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

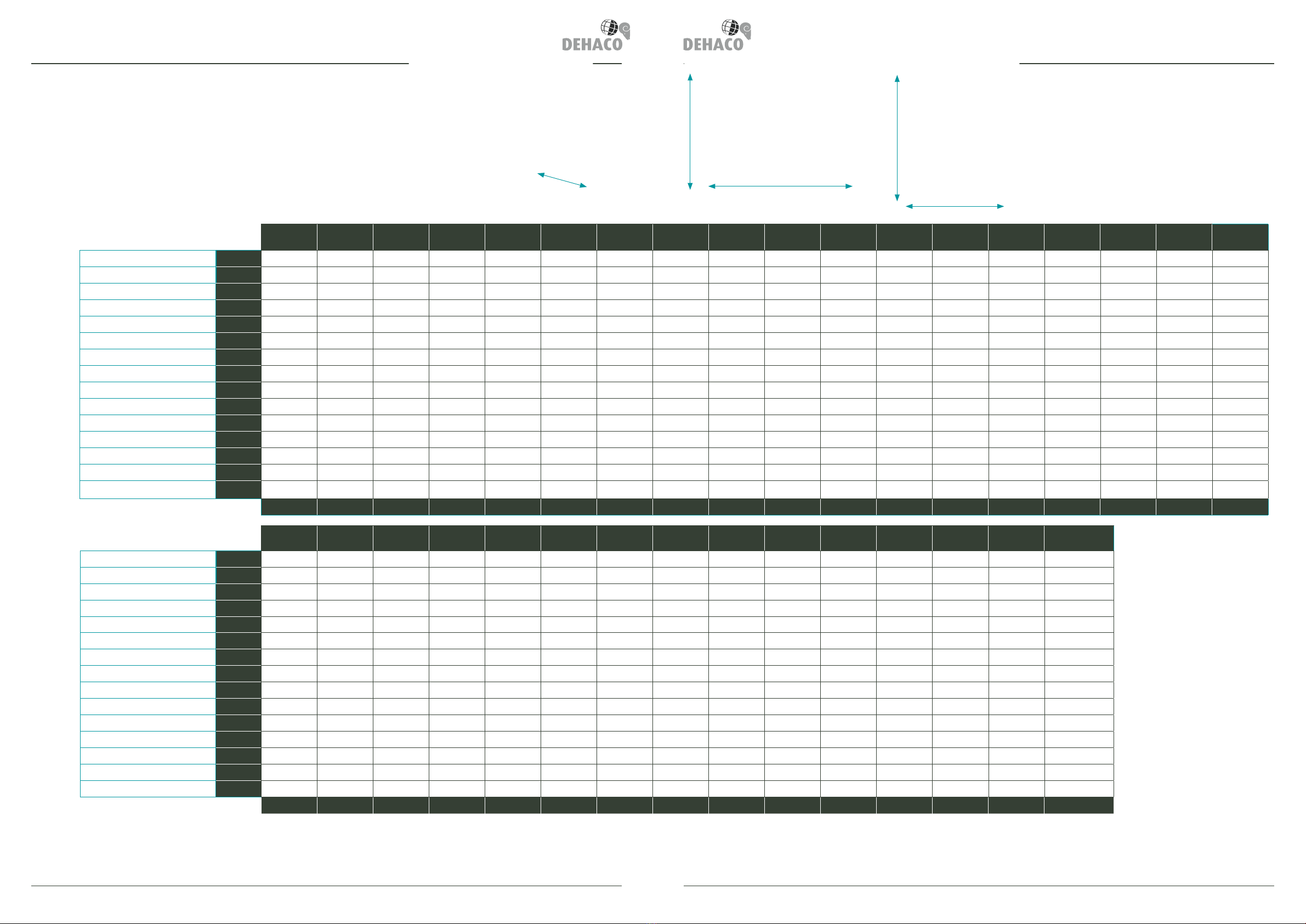

11. Technical specications R-series 11. Technical specications R-series

11. TECHNICAL SPECIFICATIONS

Hydraulic demolition and sorting grabs

with rotation

(1) Weights only apply to standard carriers.

Each deviation must be agreed upon with Dehaco and/or manufacturer of the carrier prior to assembly.

(2) Net weight including top bracket and replaceable cutting edges (approximate).

AC

D

E

DSG70-R DSG100-R DSG150-R DSG250-R DSG300-R DSG400-R DSG450-R DSG452-R DSG502-R DSG603-R DSG803-R DSG804-R DSG903-R DSG904-R

DSG1003-R DSG1004-R DSG1102-R DSG1104-R

Technische specicaties

Excavator weight (1)

t

0,7-1,2 1-2 1,5-2 2,5-5 2,5-5 4-6 5-8 6-11 7-12 10-16 12-20 12-20 13-20 13-20 16-20 16-20 16-25 16-25

Operational weight (2)

kg

75 90 140 240 280 350 400 450 600 775 935 925 985 960 995 995 1.400 1.350

Cylinders 111111111122222222

Rotationmotors 111111111222222222

Operating pressure

bar

300 300 300 300 300 300 300 320 350 350 350 350 350 350 350 350 350 350

Operating pressure rotation

bar

170-210 170-210 170-210 170-210 170-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210

Oil flow

l/min

15 20 25 35 35 40 50 70 90 100 120 120 120 120 120 120 150 150

Oil flow rotation

l/min

5 5 10 10 10 12 12 15 15 25 25 25 25 25 25 25 35 35

Shell width A

mm

300 350 450 500 500 600 700 700 600 800 800 800 900 920 1.000 1.000 900 920

Height opened B

mm

595 610 650 710 770 880 900 990 1.050 1.140 1.245 1.215 1.245 1.310 1.245 1.240 1.465 1.410

Width opened C

mm

600 770 800 1.160 1.160 1.400 1.500 1.550 1.700 1.750 1.950 1.950 1.950 1.950 1.950 1.950 2.100 2.100

Height closed D

mm

600 670 670 810 850 1.010 1.055 1.156 1.235 1.318 1.465 1.440 1.465 1.540 1.465 1.470 1.665 1.600

Width closed E

mm

430 500 545 785 780 850 890 885 1.055 1.070 1.170 1.180 1.170 1.180 1.175 1.175 1.300 1.300

Capacity

l

30 40 70 100 100 150 200 200 300 400 500 500 600 600 700 700 750 750

Closing force

kN

6 7 15 20 20 23 24 24 30 35 46 46 46 46 46 46 55 55

Article number 1210.0018 1210.0001 1210.0006 1210.0010 1210.0088 1210.0014 1210.0016 1210.0062 1210.0037 1210.0055 1210.0057 1210.0086 1210.0058 1210.0087 1210.0059 1210.0082 1210.0025 1210.0083

DSG1202-R DSG1204-R DSG1402-R DSG1404-R DSG1702-R DSG1802-R DSG1900-R DSG2500-R DSG2700-R DSG3000-R DSG4000-R DSG4500-R DSG5003-R DSG8000-R DSG13000-R

Technische specicaties

Excavator weight (1)

t

17-28 17-28 20-28 20-28 23-30 24-35 25-38 28-50 30-50 35-50 40-65 45-80 45-100 70-120 100-200

Operational weight (2)

kg

1.500 1.415 1.600 1.500 1.750 1.800 1.900 2.500 2.700 3.000 3.910 4.200 5.040 7.250 13.000

Cylinders 22222222222222 2

Rotation motors 2 2 2 2 2 2 2 2 2 2 2 2 4 4 4

Operating pressure

bar

350 350 350 350 350 350 350 350 350 350 350 350 350 350 350

Operating pressure rotation

bar

190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-210 190-250 190-250

Oil flow

l/min

160 160 160 160 170 170 180 200 200 200 250 250 250 320 320

Oil flow rotation

l/min

35 35 35 35 35 35 35 35 35 35 40 50 60 70 100

Shell width A

mm

1.000 1.000 1.200 1.200 1.200 1.200 1.200 1.200 1.360 1.500 1.500 1.500 1.500 1.800 1.800

Height opened B

mm

1.470 1.410 1.470 1.410 1.430 1.425 1.450 1.635 1.635 1.635 1.800 1.800 1.880 2.250 3.135

Width opened C

mm

2.100 2.100 2.100 2.100 2.250 2.400 2.250 2.250 2.250 2.450 2.850 2.850 3.000 3.800 4.400

Height closed D

mm

1.660 1.600 1.660 1.600 1.695 1.690 1.700 1.830 1.830 1.935 2.050 2.090 2.200 2.525 3.420

Width closed E

mm

1.300 1.300 1.300 1.300 1.340 1.350 1.340 1.370 1.370 1.475 1.755 1.755 1.890 2.400 2.700

Capacity

l

800 800 850 850 900 950 900 1.000 1.100 1.300 1.500 1.500 1.600 3.600 4.600

Closing force

kN

68 68 68 68 80 80 80 90 90 90 110 110 130 150 180

Article number 1210.0026 1210.0084 1210.0027 1210.0085 1210.0068 1210.0067 1210.0009 1210.0011 1210.0012 1210.0013 1210.0048 1210.0089 1210.0065 1210.0081 1210.0029

cmd + shift + klik

36 Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)252 - 41 79 50 • [email protected] • www.dehaco.nl

Dehaco B.V.

Headquarters

Kruisbaak 25, 2165 AJ

Lisserbroek, The Netherlands

Raamsdonksveer

Steurweg 1, 4941 VP

Raamsdonksveer, The Netherlands

T

E

www.dehaco.nl

+31 (0) 252 41 79 50

Table of contents

Other DEHACO Construction Equipment manuals

Popular Construction Equipment manuals by other brands

HEIN-WERNER AUTOMOTIVE

HEIN-WERNER AUTOMOTIVE HW93809 Operating instructions & parts manual

STEINEL PROFESSIONAL

STEINEL PROFESSIONAL HG 2120 E Translation of the original operating instructions

PFT

PFT MULTIMIX 2012 operating manual

Aichi

Aichi SV06CNL Operation Manual with Maintenance Information

DXV

DXV Percy D35105104 installation instructions

Bisonte

Bisonte BB 120 Operating/safety instructions