Epiroc Flexi ROC T20 R Instructions for use

PM No.

9852

2469

01d

Epiroc

FlexiROCT20 R

Maintenance schedules

2

SAFETY INSTRUCTIONS

Before starting, read all instructions

carefully

Special attention must be paid to

information alongside this symbol

Only use genuine Epiroc parts..

© Copyright 2016, Epiroc Stonetec S.r.l. , Italy

Any unauthorized use or copying ofthe contents or any part thereof is prohibited.

This applies in particularto trademarks, model denominations, part numbers and drawings.

Epiroc Stonetec S.r.l.

12031 Bagnolo Piemonte, Italy

3

Safety

Reference……………………………………………………………………………………………………5

4

Safety

5

Safety

Reference

Note

Always read the information in the Safety document before starting to use the rig or

starting maintenance work.

6

Safety

7

Maintenance schedules

Maintenance schedules

1. Maintenance intervals.............................................................................................................9

Foreword................................................................................................................................9

Every 4th impact hour ..........................................................................................................10

Drill-steel support - Every 4th percussion hour.................................................................10

Every 20th impact hour ........................................................................................................11

Every 100th impact hour.......................................................................................................12

Feeder - Every 100th percussion hour...............................................................................12

Dust collector (DCT) - Every 100th percussion hour.........................................................13

Every 200th impact hour.......................................................................................................14

Drill-steel support - Every 200th percussion hour .............................................................14

Every 10th engine hour.........................................................................................................15

Diesel engine/Compressor - Every 10th engine hour.........................................................15

Hydraulic system - Every 10th engine hour.......................................................................16

Fuel filter - every 10th engine hour...................................................................................17

Lubricating oil tank - Every 10th engine hour...................................................................18

Electrical system/Winch (option) - Every 10th engine hour...............................................19

Remote-control box - every 10th engine hour / daily.........................................................20

Every 50th engine hour.........................................................................................................21

Boom/Feeder - every 50th engine hour .............................................................................21

Traction gear - Every 50th engine hour.............................................................................22

Compressor components - every 50th engine hour............................................................23

Radiator - every 50th engine hour.....................................................................................24

Fuel filter - every 50th engine hour...................................................................................25

Winch (option) - Every 50th engine hour..........................................................................26

Remote-control box - every 250th engine hour .................................................................27

Every 250th engine hour.......................................................................................................28

Boom/Feeder - every 250th engine hour ...........................................................................28

Jack - Every 250th engine hour.........................................................................................29

Electrical system - every 250th engine hour......................................................................30

Dust collector (DCT) - Every 250th engine hour...............................................................31

Radiator - every 250th engine hour...................................................................................32

Diesel engine - every 250th engine hour...........................................................................33

Compressor - every 250th engine hour..............................................................................34

Every 500th engine hour.......................................................................................................35

Diesel engine - every 500th engine hour...........................................................................35

Air filter - every 500th engine hour...................................................................................36

Winch (option) - Every 500th engine hour........................................................................37

Terminal blocks - every 500th engine hour.......................................................................38

Every 1000th engine hour.....................................................................................................39

Hydraulic system - every 1000th engine hour ...................................................................39

Compressor separator- every 1000th engine hour..............................................................40

Diesel engine - every 1000th engine hour.........................................................................41

Dust collector (DCT) - Every 1000th engine hour.............................................................42

Air filter - every 1500th engine hour.................................................................................43

Every 1500th engine hour.....................................................................................................44

Traction gear - Every 1500th engine hour.........................................................................44

Winch (option) - Every 1500th engine hour......................................................................45

8

9

Maintenance schedules

1. Maintenance intervals

1. Maintenance intervals

Foreword

This instruction manual is part of the complete delivery of the hydraulic drill rig. It

provides information on the design and operation of the drill rig and contains advice

and the measures necessary to keep the rig operational. This instruction manual is no

replacement for thorough training on the drill rig. The documentation consists of the

following:

•Part 1 - Maintenance intervals Percussion hours (feeder and rock drill).

-4 th hour

-20 th hour

-100 th hour

-200 th hour

•Part 2 - Maintenance intervals Engine hours.

-Every 10th hour

-Every 50th hour

-Every 250th hour

-Every 500th hour

-Every 1000th hour

-Every 1500th hour

This instruction manual should be read in advance by all persons who are to operate

or repair the drill rig or carry out maintenance on it.

How to use these maintenance instructions

•We recommend that you make copies of all maintenance intervals and keep a

record ofeach point checked.

•The owner of the equipment is recommended to compile a filing system for each

maintenance interval.

•Carefully read all the instructions and study the drawings of the machine so that

maintenance work will be performed safely and correctly.

Genuine Epiroc spare parts

•To ensure the safety and functionality of the drill rig, always use genuine Atlas

Copco spare parts.

10

Maintenance schedules

1. Maintenance intervals

Environmental aspects

•Avoid the use of detergents and other cleaning agents containing solvents (e.g.

carbon tetrachloride). Use alternative agents that are less harmful to health and the

environment. Be sure to dispose of waste oil from the machine.

Note

The illustrations only show examples of grease nipples; check all attachments and

bearings appurtenant to relevant systems so you can find the existing grease nipples.

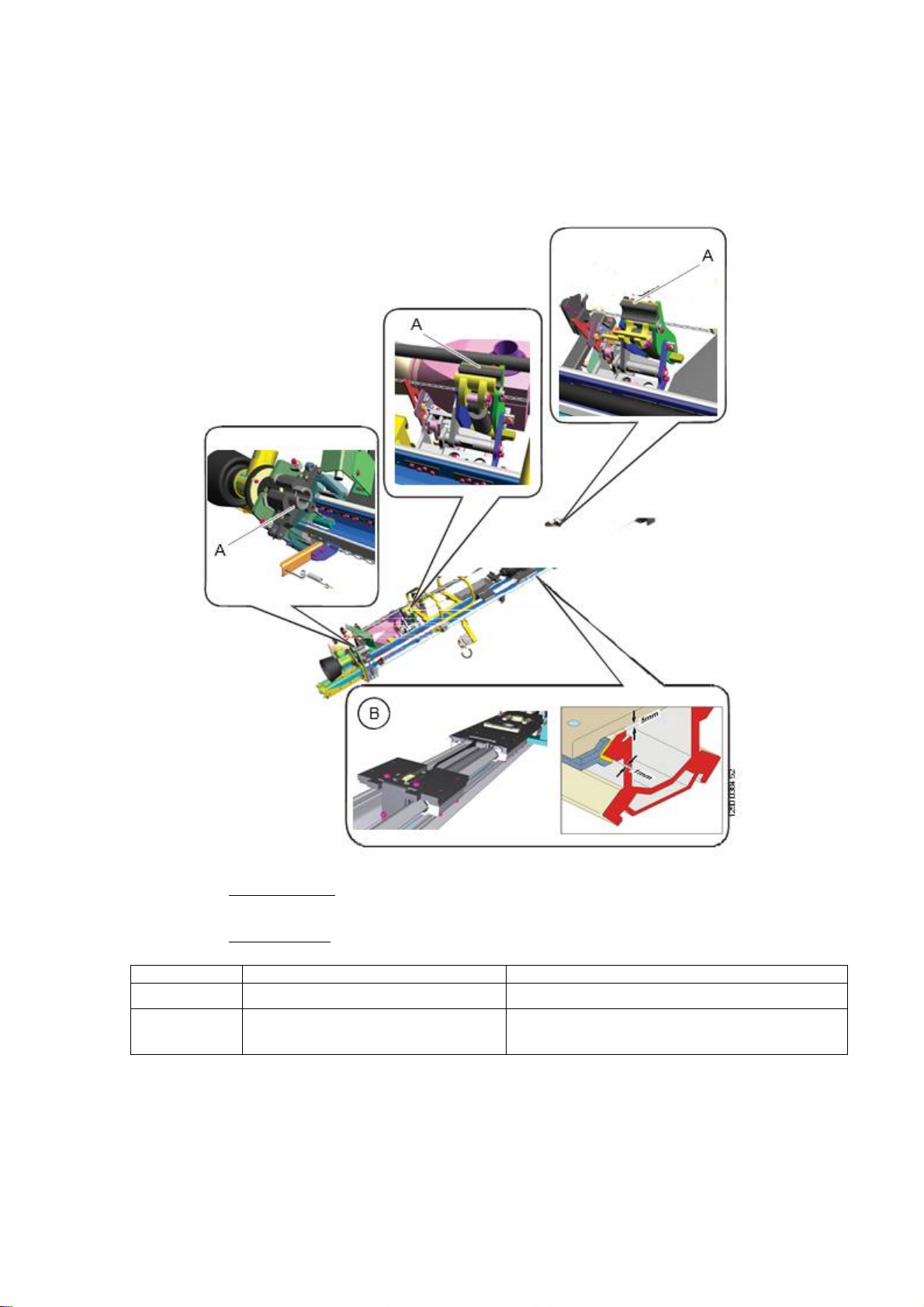

Every 4th impact hour

Drill-steel support - Every 4th percussion hour

Figure: Drill-steel support

Table: Drill-steel support

Check point

Control object

Act

ion

A Lubricating nipple Fill grease into the grease nipple

11

Maintenance schedules

1. Maintenance intervals

Every 20th impact hour

Feeder - Every 20th percussion hour

.Figure: Feeder

Table: Feeder

Check point

Control object

Action

A Feedcylinder Check for oilleakage or damage

B Spacer Check the lengthof spacer and tightening bolts.

C Rope, adjusting bolts and nuts Inspect for damage and wear

D Rockdrill

Check for wear of the pull rope and return rope.

Check tensionof the ropes. Adjust the rope tension

with bolts and nuts (C) if necessary.

E Hydraulic hoses

Check forwear

F Rock drill cradle Check mounting, play anddamage

G Drill-steel support halves Check forwear

H Boltedjoints Tightening

12

Maintenance schedules

1. Maintenance intervals

Every 100th impact hour

Feeder - Every 100th percussion hour

Figure: Feeder

Table: Feeder

Check point

Control object

Action

A Support halves/Pipe clamps Check adjustment, wear and cracks.

B Cradles/Interm/Pull

back/Slide pieces Check clearance. Check wear min

thickness 4mm.

13

Maintenance schedules

1. Maintenance intervals

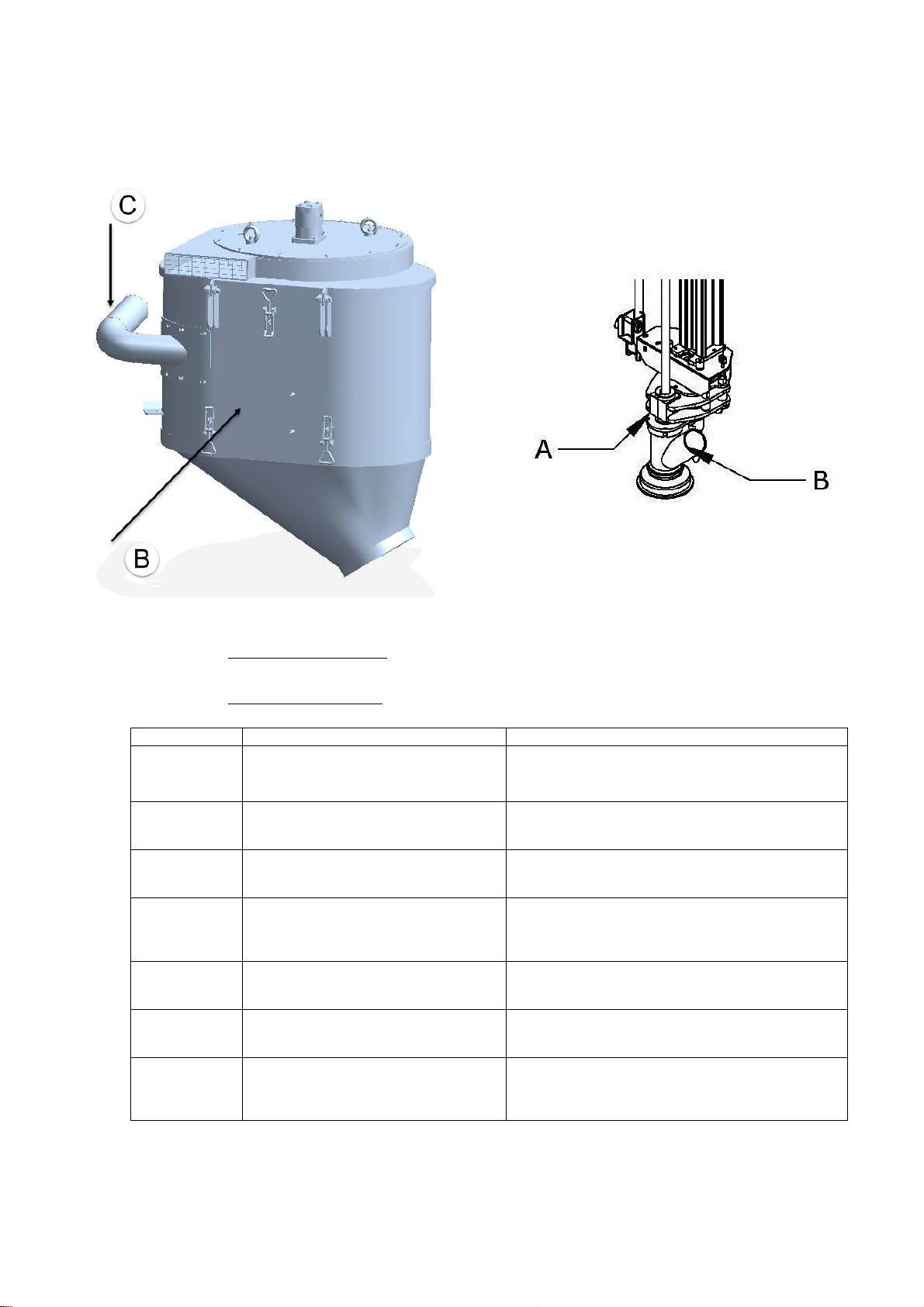

Dust collector (DCT) - Every100th percussion hour

Figure: Dust collector

Table: Dust collector

Check point

Control object

Action

- Suctionhoses

The hoses must be intact and sealed. Replace

if necessary.

A

Dust gasket

The gasket must be intact and seal around the

pipe. Replace if necessary.

B

Inlet connector pieces

The connector pieces must not be worn

through. Change if necessary.

B

Inlet and wear plate

Check with regard to wear. If the wear plate is

heavily worn, the drill cuttings will destroy the

filter. Replace the wear plate if necessary.

C

Wear protection

Wear protection must be well secured and not

be heavily worn. Replace if necessary.

C

Filter housing

Clean if drill cuttings have fastened on the wall

of the filter housing.

C

Filter

Check the filters. If clogged or damaged they

must be replaced for DCT to extract

sufficiently.

14

Maintenance schedules

1. Maintenance intervals

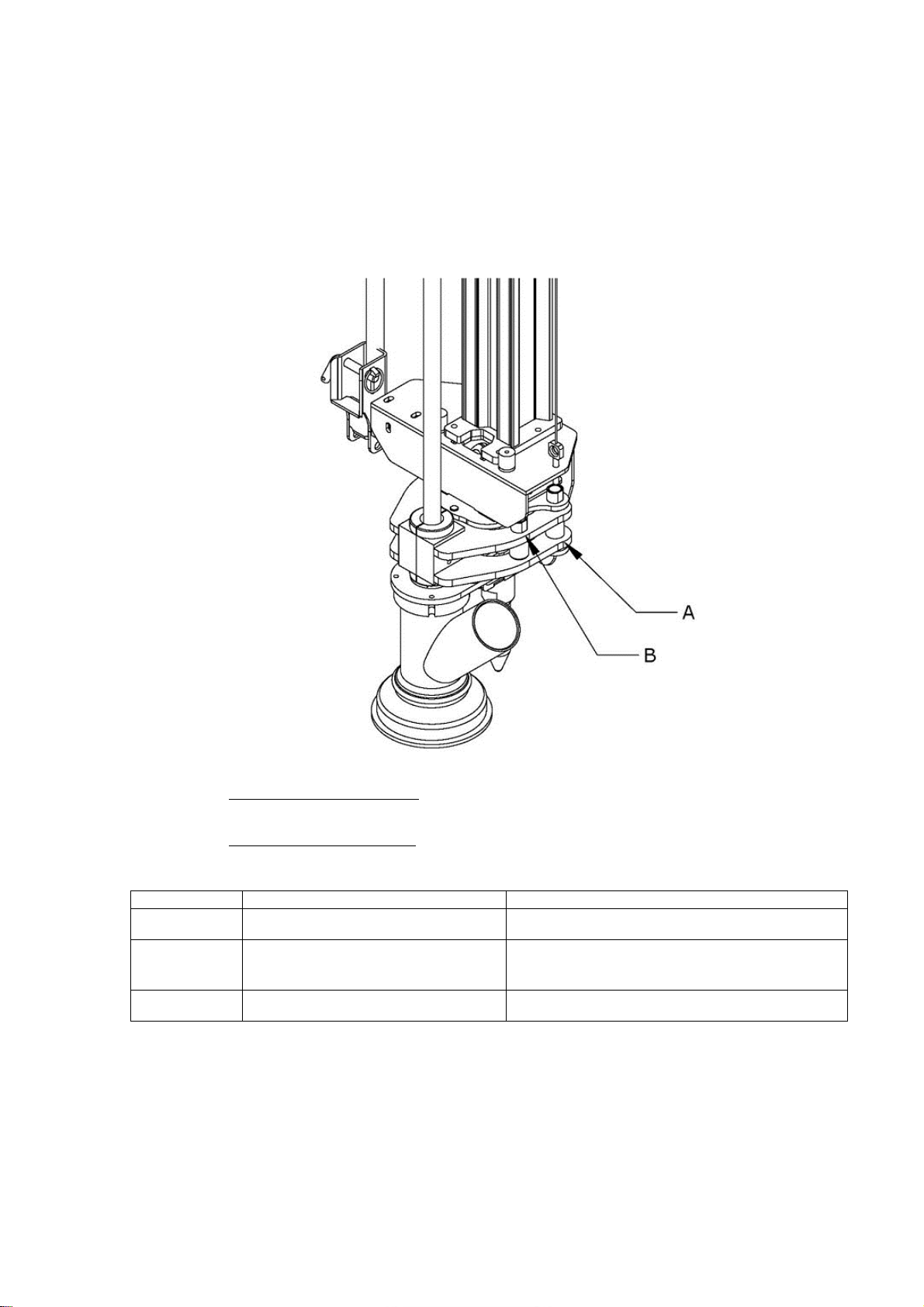

Every 200th impact hour

Drill-steel support - Every 200th percussion hour

Figure: Drill-steel support

Table: Drill-steel support

Check point

Control object

Action

A Attachment Check mounting,direction

B Boltedjoints Check adjustment; see Table Locking Torques

in the maintenance instruction manual.

- Bushings Check for wear. Replace as necessary.

15

Maintenance schedules

1. Maintenance intervals

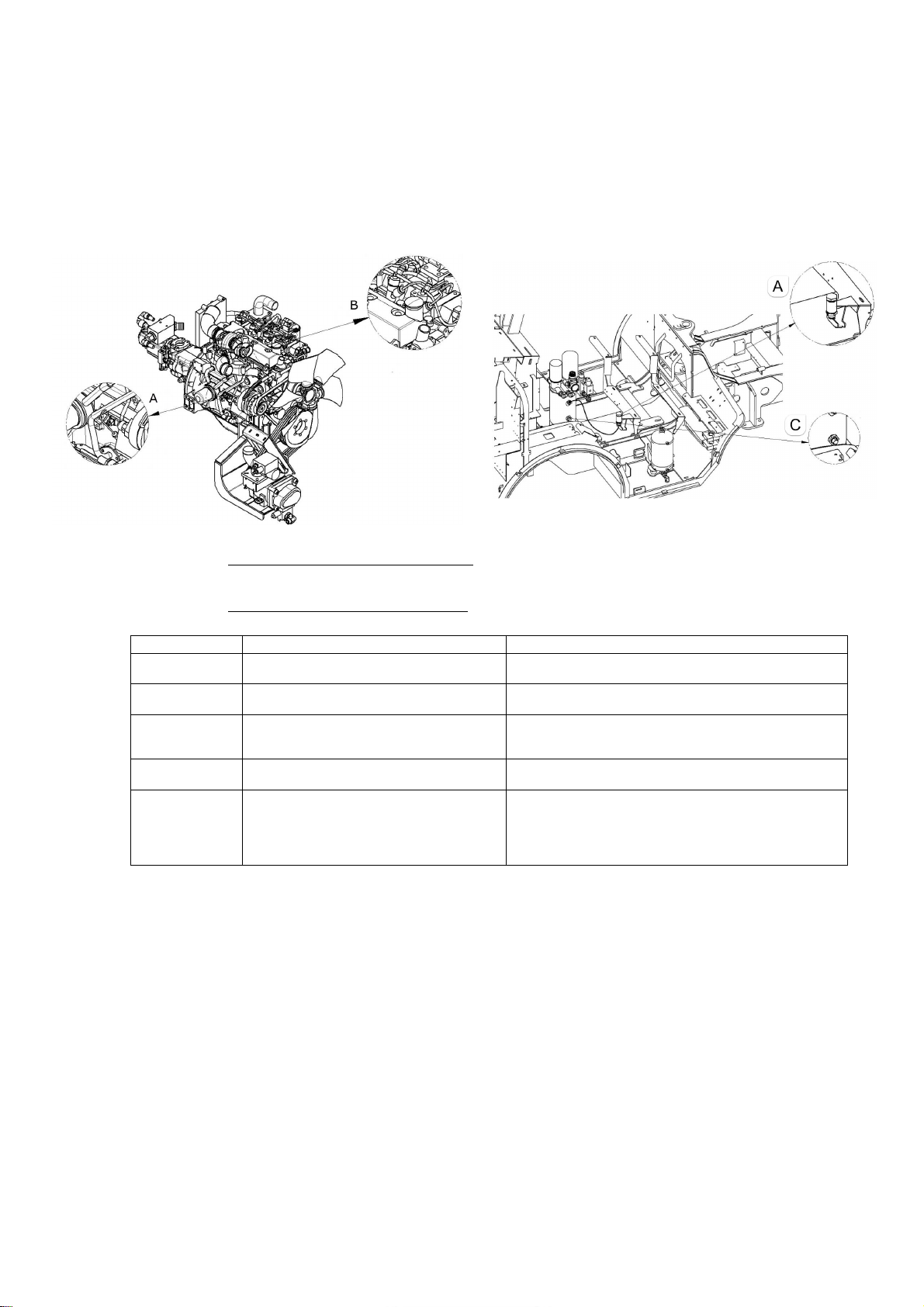

Every 10th engine hour

Diesel engine/Compressor - Every 10th engine hour

Figure: Diesel engine/compressor

Table: Diesel engine/compressor

Check point

Control object

Action

A Compressor oil level Ensure the oil is visible in the filling pipe.

B Hydraulic oil pumps Check for signs of leakage.

C Diesel engine oil level The oil must be between the two marks on the

Dipstick.

D

Diesel engine

Check for leaks.

Diesel engine Check that the engine and compressor air intake

manifolds are properly tightened and in good

conditions.

16

Maintenance schedules

1. Maintenance intervals

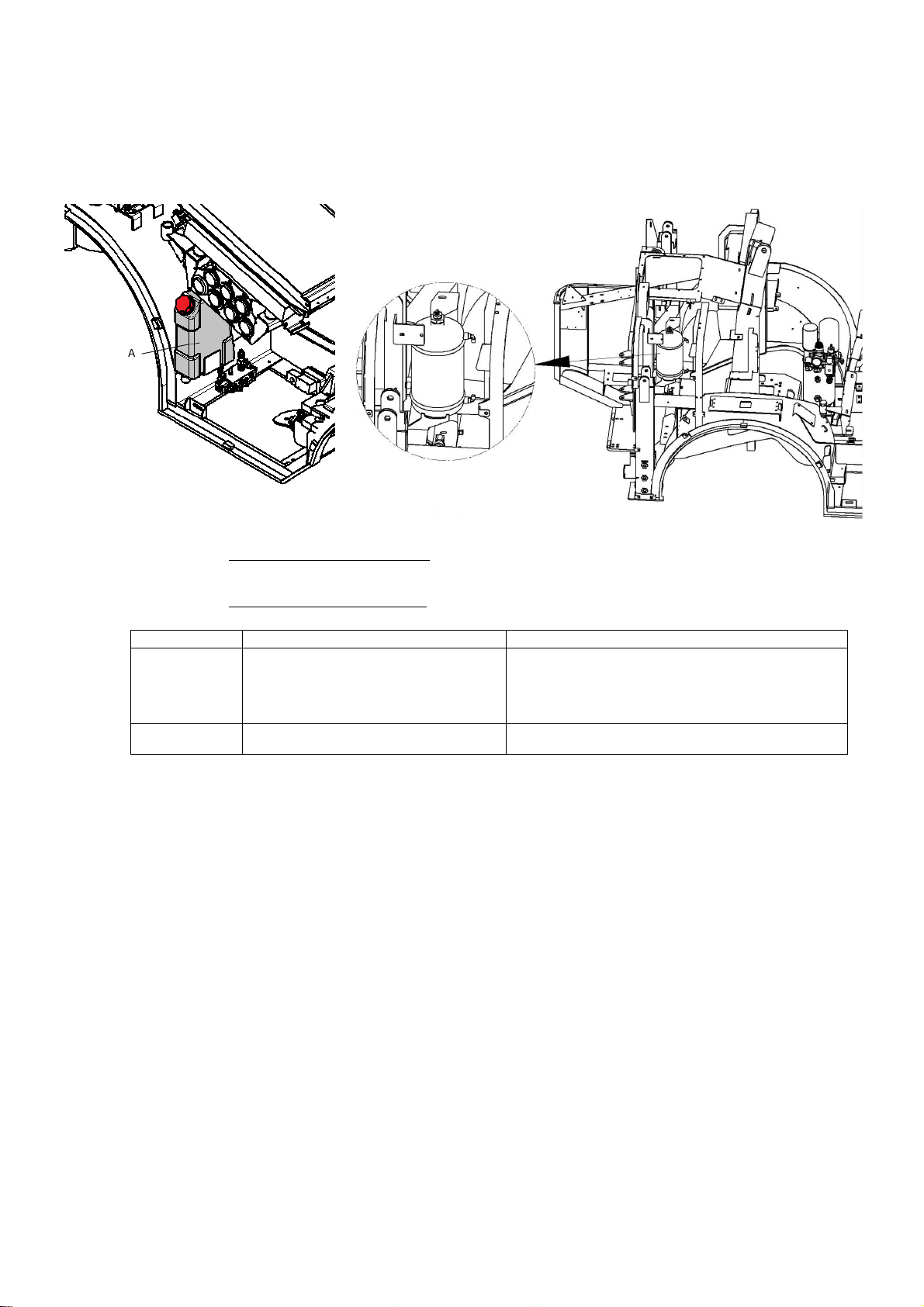

Hydraulic system - Every 10th engine hour

Figure: Hydraulic oil reservoir

Table: Hydraulic oil reservoir

Check point

Control object

Action

A Return oil filter and breather filter Replace the filters if thePMI indicates that the

filters are clogged.

B Hydraulic oiltank Connections, signs and leakage.

C Oil level

The oil level must not be in the red zone. The

rig must be positioned horizontally to give a

correct reading.

17

Maintenance schedules

1. Maintenance intervals

Fuel filter - every 10th engine hour

Figure: Fuel filter

Table: Fuel filter

Check point

Control object

Action

A Fuel filter Drain off water

18

Maintenance schedules

1. Maintenance intervals

Lubricating oil tank - Every 10th engine hour

Figure: Lubricating oil tank

Table: Lubricating oil tank

Check point

Control object

Action

A Lubricating oiltank Fill up to the highlevel mark.If all the oil in the

lubricating system has been used up, bleeding

of the system will be necessary.

Lubrication return line tank Check and if it’sempty drainit

19

Maintenance schedules

1. Maintenance intervals

Electrical system/Winch (option) - Every 10th engine hour

Figure: Electrical system/Winch

Table: Electrical system/Winch

Check point

Control object

Action

A Working lights Front and rear, check functionality

B Emergency stop buttons/wire

Attachment. Check each emergency stop

button individually. The engine must stop.

Before checking the next emergency stop

button the previous one must be reset.

C

Winch wire rope

Check for damage, unwinding, wear and

corrosion

D Hook Check damage, cracks, wear and mounting

20

Maintenance schedules

1. Maintenance intervals

Remote-control box - every 10th engine hour / daily

Figure: Remote control box

Table: Remote control box

Check point

Control object

A Rubber bellows on levers and switches: make sure none of the rubber bellows on

switches/lever is damaged

Table of contents

Other Epiroc Construction Equipment manuals

Epiroc

Epiroc HM Series Maintenance and service guide

Epiroc

Epiroc SBU 160 Maintenance and service guide

Epiroc

Epiroc DEQ171257 User manual

Epiroc

Epiroc EC Series Maintenance and service guide

Epiroc

Epiroc FlexiROC T20 R Specifications

Epiroc

Epiroc Secoroc COP 44 Specifications

Epiroc

Epiroc HC Series Maintenance and service guide

Epiroc

Epiroc SB 52 User manual

Epiroc

Epiroc SmartROC T35 User manual

Epiroc

Epiroc Secoroc COP 54 User manual