DEHAS DEMAND VALVE QualityFlow User manual

Operating Instructions

DEMAND VALVE QualityFlow

0482

Keep these instructions!

Version 3.1.

DEHAS Medical Systems GmbH

Wesloer Straße 107-109

23568 Lübeck OT Schlutup, Germany

Phone: (+49) 451 80904-0

Fax: (+49) 451 80904-111

www.DEHAS.de

1

Content

1 Preface .......................................................................................................................................... 2

2 Basic Requirement ........................................................................................................................ 2

2.1 Intended use............................................................................................................................ 2

2.2 Accessoires / Variants ............................................................................................................. 2

2.3 Applied standards.................................................................................................................... 3

3 Safety Information –Warning, caution and labeling information................................................ 3

4 Before first of use.......................................................................................................................... 5

4.1 Safety Information................................................................................................................... 5

5 Technical data ............................................................................................................................... 7

5.1 Variants.................................................................................................................................... 7

6 Commissioning, installation and service life................................................................................. 8

6.1 Commissioning ........................................................................................................................ 8

6.2 Application notes..................................................................................................................... 8

6.3 Installation............................................................................................................................... 8

6.3.1 Cylinder supply → Ventilation bag.................................................................................. 8

6.3.2 Central gas supply → Ventialtion bag ............................................................................. 8

6.4 After the use............................................................................................................................ 9

6.4.1 Cylinder supply → Ventilation bag.................................................................................. 9

6.4.2 Central gas supply → Ventilation bag ............................................................................. 9

7 Cleaning instructions..................................................................................................................... 9

7.1 Cleaning and Disinfection........................................................................................................ 9

8 Inspection & maintenance.......................................................................................................... 11

8.1 General.................................................................................................................................. 11

8.2 Maintenance and inspections ............................................................................................... 11

8.2.1 Functional test............................................................................................................... 11

8.2.2 Leak test ........................................................................................................................ 11

9 Warranty ..................................................................................................................................... 11

10 Return of goods........................................................................................................................... 12

11 Disposal....................................................................................................................................... 12

12 Manufacturer Information.......................................................................................................... 15

*Technical changes reserved!

2

1Preface

These operating instructions are intended to provide you with assistance in using the

QualityFlow demand valve. The operating instructions are divided into individual chapters.

Please note:

•Read these instructions for use carefully and completely before using the product for

the first time.

•Always act in accordance with the instructions given in the operating manual.

•Keep these operating instructions close to the product.

2Basic Requirement

Intended use:

According to Annex IX of Directive 93/42/EEC concerning medical devices, this product

belongs to Class IIb. According to this directive, only medical professionals who have been

instructed in the use of the product by an authorized person may use this product. This

product is to be used exclusively for human medical purposes.

2.1 Intended use

The demand valve is used for the application of 100 vol% oxygen during manual ventilation

with the resuscitator bag, as well as during direct non-invasive ventilation with the

resuscitator mask in spontaneously breathing patients.

2.2 Accessoires / Variants

Article No.

GTIN / UDI

Description

D-2522001

4251411701314

Adapter medium, white (24/28 mm)

D-2522002

4251411701321

Adapter large, white (26/32 mm)

D-2522003

4251411701338

Adapter small, white (15/22 mm)

D-2522004

4251411701598

Adapter Laerdal/VBM f. Demand valve

25/32 mm

D-2522005

4251411701574

Adapter Ambu, white (28/32 mm)

D-2522006

4251411702908

Adapter demand valve, white 22-23-30

mm

3

2.3 Applied standards

The product complies with the essential requirements according to Annex I of Directive

93/42/EEC (Medical Device Directive) as well as the applicable national regulations such as

the Medical Devices Act (MPDG).

Standard / Norm

Titel

DIN EN ISO 780

Packaging - Shipping packaging - Graphic symbols for handling and

storage of packages

DIN EN ISO 15223-1

Medical devices - Symbols, marking and information to be used in

the labelling of medical devices - Part 1: General requirements

DIN EN 1041

Provision of information by the manufacturer of medical devices

DIN EN ISO 5359

Anesthesia and respiratory equipment - Low-pressure hose line

systems for use with medical gases

DIN EN ISO 14971

Medical devices - Application of risk management to medical

devices

DIN EN 62366-1

Medical devices - Part 1: Application of fitness for use to medical

devices

ISO 10993-1

Biological evaluation of medical devices - Part 1: Evaluation and

testing within a risk management system

3Safety Information –Warning, caution and labeling information

Symbol

Description

The symbol indicates that the device complies with the

requirements of Regulation 93/42/EEC concerning medical devices

and all applicable international standards.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

When this symbol is used, it indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

Manufacturer

Date of manufacture

Store in a dry place / Protect from moisture / wetness

4

Unique Device Identification

Medical device

Serial number

Reference number / Article number

Product non-sterile

Temperature limit

or

Refers to the need for the user to consult the instructions for use.

Follow the instructions for use

Do not dispose of in household waste

Do not use if packaging is damaged

Moisture limitation during storage

Latex free product

Do not use oil

5

4Before first of use

Read all instructions before use!

These operating instructions provide qualified personnel with instructions for installation and

operation. It serves your safety and protects the product from damage. If you do not

understand any information or instruction in this instruction manual, do not use the product

and contact your supplier.

4.1 Safety Information

WARNINGS

•Intended use / user

•The demand valve may only be operated by medical professionals under the

direct supervision of a licensed physician.

•As with all medical products, this demand valve could cause injury to the patient if

used without precise knowledge of its operation.

•The demand valve may only be used for the purpose described in these

instructions for use.

•The configuration of the overall system and the verification of its functionality are

the overall responsibility of the medical personnel.

•Functionality and suitability of the product for the intended use must be checked

by the user before each use.

•Check the gas cylinder or the supply line accordingly before use.

•The demand valve has a gas-specific connection. The connection must not be

modified and adapted to other gases or connection systems.

•If you use a cylinder and a pressure reducer, ensure that the product is connected

to the pressure reducer and the cylinder valve is properly opened before starting

therapy.

•Ensure that the supply pressure is within the range specified in the technical data

of the demand valve.

•Maintenance / Repair

•Maintenance, repairs and periodic inspections may only be carried out by

authorized specialist personnel who have the appropriate expertise and are

familiar with the product.

•Danger: Fire and explosion hazard!

•Air, oxygen and oxygen mixtures react explosively with oils, greases and

lubricants. As a result of the compressed gas, there is a risk of fire and explosion.

The product must be kept free of oils, greases, lubricants and hand creams.

•When handling combustion-promoting gases, observe the fire protection

regulations.

•If leaks are detected in the product, contact the customer service immediately.

•When attaching accessories, check the connecting piece for tightness and secure

seating!

6

•There is a fire hazard due to escaping oxygen! DO NOT use near flames,

flammable / explosive substances, vapors or gases.

•Never smoke in an area where oxygen is administered.

•Do not exceed maximum operating pressure and maximum operating

temperature.

•Danger: Product defects!

•The use of incorrect spare parts and accessories can lead to personal injury or

functional failure. Only use original accessories and spare parts!

•Danger: Risk of injury!

•A worn or damaged product can lead to injuries. Only use the product when it is

in perfect condition!

•Do not use the product under any circumstances if it is contaminated!

•Danger: Damage to property!

•No mechanical forces may act on the product with accessories to prevent

malfunctions or damage!

•Danger: Ambient conditions!

•If the ambient temperature range is exceeded or undershot during transport

and/or storage conditions, no warranty can be given for the accuracy, function,

mechanical strength as well as the tightness of the product.

•Danger: Health hazard!

•When using oxygen, a kink in the connection hose can interrupt the oxygen

supply. The connection hose must not be kinked!

•An improperly fastened product can come loose and cause injury.

•Danger: Reduction in performance!

•Regularly check the available gas quantity at the tapping device!

•Cleaning!

•NOT suitable for sterilization.

•Never immerse the complete demand valve in liquids.

7

5Technical data

Product

QualityFlow

Classification according to Medical Device

Directive 93/42/EEC

Class IIb

Requirement

According to DIN EN ISO 5359

Connections

Connection between demand valve and hose:

M12x1

Connection between hose and supply:

M12x1 or tapping plug acc. to DIN 13260 / part

2

Operating temperature

-20 to +70°C

Required operating pressure

280 to 550 kPa (2.0 to 5.5 bar)

Maximum delivery capacity

200 l/min at -20° and 450 kPa

Set pressure

-0.5 kPa (-0.5 mbar)

Filter

25 micron

Transport / storage temperature in original

packaging

-20°C to +40°C

Marking:

Serial number, LOT, GTIN / UDI, CE marking, date of manufacture, expiration date, safety

symbols.

5.1 Variants

GTIN / UDI

Description

4251411700645

Demand valve white (without connection hose)

8

6Commissioning, installation and service life

CAUTION

•Please refer to the manufacturer's documentation for information on the

operation of the connecting devices, including the ventilation bag.

•Never open the demand valve. Otherwise, the correct function is no longer

ensured!

6.1 Commissioning

Product verification

•Before first use, the product must be subjected to wipe disinfection.

•Check that the product is in working order and does not show any contamination or

damage.

6.2 Application notes

Triggered by the negative pressure of the deploying ventilation bag, the demand valve

provides an O2 flow until the bag is filled. (Follow the instructions for use of the ventilation

bag).

•Not suitable for invasive use directly on the tube!

•Never open the demand valve! Otherwise, the correct function is no

longer ensured and the product must be returned to the manufacturer

for inspection.

6.3 Installation

6.3.1 Cylinder supply → Ventilation bag

1) Connect the demand valve with connection hose via oultlet probe to an O2 pressure

reducer of the O2 Cylinder supply bottle (characteristic value 400 to 500 kPa,

corresponding to 4-5 bar downstream pressure)

2) Insert the demand valve into the suction opening of the ventilation bag using the

corresponding adapter.

6.3.2 Central gas supply → Ventialtion bag

1) Connect the demand valve with connection hose via outlet probe to the plug in O2

coupling of central gas supply (characteristic value of the central gas supply 400 to 500

kPa, corresponding to 4-5 bar).

2) Insert the demand valve into the suction opening of the ventilation bag using the

appropriate adapter.

9

6.4 After the use

6.4.1 Cylinder supply → Ventilation bag

1) Close the valve of the O2 bottle and disconnect the connecting hose with outlet probe

from the pressure reducer of the O2 bottle.

2) Pull the demand valve out of the suction opening of the ventilation bag.

3) Prepare the demand valve according to the cleaning and care instructions.

6.4.2 Central gas supply → Ventilation bag

1) Disconnect the connecting hose with outlet probe from the the plug in O2 coupling of

central gas supply.

2) Pull the demand valve out of the suction opening of the ventilation bag.

3) Prepare the demand valve according to the cleaning and care instructions.

7Cleaning instructions

CAUTION

•Please make sure to observe the application instructions of the detergent and

disinfectant manufacturer as well as the currently applicable hygiene regulations for

the hospital.

•Use surface disinfectants based on aldehydes and quaternary ammonium

compounds; these are included in the current list of the "German Society for Hygiene

and Microbiology".

•Caution, improper cleaning and disinfection may result in property damage.

•NOT suitable for sterilization.

•Never disassemble the product.

•NEVER immerse the device in liquids.

•DO NOT use strong solvents or abrasive cleaners.

•DO NOT clean with aromatic hydrocarbons.

7.1Cleaning and Disinfection

Manufacturer:

DEHAS Medical Systems

GmbH Wesloer Str. 107-109

23568 Lübeck, OT Schlutup,

Germany

Sterilization method:

N/A

The product is not

intended for

sterilization process.

Produkt: QualityFlow

10

WARNING:

Do not use strong solvents or abrasive cleaners.

Do not clean with aromatic hydrocarbons.

Do not bring into contact with oil, grease or flammable liquids - there is an

increased risk of fire.

Do not autoclave!

Do not sterilize!

Do not immerse in liquids!

The instructions listed have been validated as SUITABLE by the medical device manufacturer for

preparing a medical device for reuse. The reprocessor is responsible for ensuring that the actual

reprocessing performed with the equipment, materials, and personnel used in the reprocessing

facility achieves the desired results.

INSTRUCTIONS

The outside of the unit must be wiped clean at regular intervals or at the latest

after each patient in accordance with the applicable hygiene standard.

Preparation for

cleaning and

disinfection:

Disconnect all gas connections and equipment before cleaning and disinfecting.

Cleaning: Manual

For this process:

1. Wipe the surfaces of the device and accessories with a lint-free cloth

soaked in water and detergent and wrung out. Do not allow any liquid to

get inside the Quality Flow demand valve.

2. Wipe again with a dry, lint-free cloth.

Disinfection: Manual

3. Wipe the outside of the Quality Flow demand valve and the adapter with

a lint-free cloth moistened with a non-oxidizing disinfectant.

4. Observe the exposure time of the disinfectant manufacturer according to

the required spectrum of activity.

Drying:

5. After the exposure time specified by the disinfectant manufacturer, wipe

dry with a dry, lint-free, low-germ cloth.

Manufacturer's

Recommendation:

The manufacturer recommends the use of the disinfectant Bacillol ® 30 Foam,

Bacillol ® 30 Tissues, Bode Chemie GmbH & Co. The current product data sheet of

the disinfectant manufacturer must be observed.

Maintenance, control

and testing:

A visual and functional check must be performed after each cleaning and

disinfection.

Packaging:

▪The device must be kept in the packaging validated by DEHAS for

transport.

Storaging:

▪Temperature: -20°C to +40°C

▪Store in a dry place.

▪Store the product in a dry, clean place free from lubricants, oil and other

contaminants.

Transport:

▪Temperature: -20°C to +40°C

Additional information:

N/A

Contact:

DEHAS Medical Systems GmbH, Wesloer Straße 107-109, 23568 Lübeck, OT

Schlutup, Germany

After each cleaning and disinfection, a visual and functional check must be carried out.

11

8Inspection & maintenance

8.1 General

Maintenance, repairs and periodic inspections may only be carried out by persons who have

the appropriate expertise and are familiar with the product.

However, the product must be cleaned regularly after use, checked for signs of damage and

its performance must be checked. Furthermore, all seals used in the product must be checked

regularly for perfect condition and correct function and replaced if necessary.

8.2 Maintenance and inspections

The demand valve and connection hose must be subjected to a visual and functional check

before each use.

The product should be subjected to a function and leak test at least once a year.

The deman valve does not have any parts that require maintenance. If the performance data

are found to be impaired during the function and leak test, please contact your dealer.

If a connection hose is supplied, the flat seal in the M12x1 screw connection must be replaced

every 2 years.

8.2.1 Functional test

Squeeze and release the resuscitation bag. With the demand valve connected, the bag should

deploy in approx. 1 second.

8.2.2 Leak test

Connect the demand valve to the pressure reducer and open the gas supply to the O2 cylinder.

No oxygen should escape audibly.

9Warranty

The warranty period for the Product is 12 months from the date of sale, subject to the

following terms and conditions:

Should any defect in the Product occur within the applicable period, Dealer, upon written

notice thereof and upon proof that the Product has been stored, installed, maintained and

operated in accordance with the instructions and in accordance with standard industry

practices, and that no alterations, substitutions or modifications have been made to the

Product, shall correct such defects by appropriate repair or replacement at its own expense.

ORAL STATEMENTS DO NOT CONSTITUTE A WARRANTY.

The dealer is not authorized to make any oral warranties about the product described in this

manual, and such statements are not binding and are not part of the sales contract. Therefore,

this second statement is the final, complete and exclusive representation of the terms of the

contract.

- Subject to technical changes!

12

10 Return of goods

Please contact your dealer in this regard. They will coordinate the return shipment for you. It

is important that you provide a description of the fault so that the return shipment can be

processed in a targeted manner. All returns must be shipped in sealed containers to prevent

damage. The dealer is not responsible for products damaged during shipping.

11 Disposal

CAUTION

•Danger of infection! The product or parts of it may be contaminated after use. Clean

and disinfect the product before disposal.

At the end of the service life:

Have the demand valve disposed of properly after consulting the relevant disposal company.

Observe the applicable legal regulations.

13

EG-Konformitätserklärung

EC Declaration of Conformity

DEHAS Medical Systems GmbH| Wesloer Str. 107-109 | 23568 Lübeck, Germany

Produkt/

Medical device:

Demandventile/ Demand valves

Artikelnummern/

Item numbers:

Siehe Anhang

See attached list

Klassifikation/

Classification:

IIb

Regel 11, Anhang IX, Medizinprodukterichtlinie 93/42/EWG

Rule 11, Annex IX of Medical Device Directive 93/42/ECC

Wir erklären hiermit in alleiniger Verantwortung, dass das oben genannte Produkt mit den

grundlegenden Anforderungen gemäß Anhang 1 der Medizinprodukterichtlinie 93/42/EWG

übereinstimmt. Alle Belegdokumente werden in den Räumlichkeiten des Herstellers und der

benannten Stelle aufbewahrt.

We hereby declare under our sole responsibility that the above product is in conformity with the basic

requirements according to Annex 1 of the Medical Device Directive 93/42/EEC. All supporting

documents are kept on the premises of the manufacturer and the notified authority.

Konformitätsbewertungsverfahren/

Conformity assessment route:

Anhang II (ohne Abschnitt 4) der

Medizinprodukterichtlinie 93/42/EWG (Vollständiges

Qualitätssicherungssystem)

Annex II (without section 4), Medical Device Directive

93/42/EEC (Full quality assurance system)

Angewandte Normen/

Applied standards:

EN 1041

EN ISO 5359

ISO 10993-1

EN ISO 14971

ISO 15223-1

Benannte Stelle/ Notified Body:

DNV Medcert GmbH, Pilatuspool 2, 20355 Hamburg,

Germany

Kenn-Nummer/ ID number:

0482

EG Zertifikats-Nr./ EC Certificate no.:

4153GB410200327

Ausstellungsdatum/ Date of issue:

2020-03-27

Ablaufdatum/ Expiry date:

2024-05-27

Lübeck, 26.08.2020

Jens Meincke, Quality Manager

DEHAS Medical Systems GmbH

14

Anhang EG-Konformitätserklärung

Attachment EC Declaration of Conformity

Produktliste / List of products

Article No.

GTIN / UDI

Description

D-DV-W-M12x1

4251411700645

Demand valve white (without connection

hose)

D-2522001

4251411701314

Adapter medium, white (24/28 mm)

D-2522002

4251411701321

Adapter large, white (26/32 mm)

D-2522003

4251411701338

Adapter small, white (15/22 mm)

D-2522004

4251411701598

Adapter Laerdal/VBM f. Demand valve

25/32 mm

D-2522005

4251411701574

Adapter Ambu, white (28/32 mm)

D-2522006

4251411702908

Adapter demand valve, white 22-23-30

mm

Ende der Liste / End of list

15

12 Manufacturer Information

Manufacturer: DEHAS Medical Systems GmbH

Wesloer Straße 107-109

23568 Lübeck

Tel: 0451/80904-0

Fax: 0451/80904-111

Homepage: www.dehas.de

Distributed by: DEHAS Medical Systems GmbH

Wesloer Straße 107-109

23568 Lübeck

Tel: 0451/80904-0

Fax: 0451/80904-111

Email: Info@dehas.de

Homepage: www.dehas.de

Rev. 3.1. Stand 07/2023

This manual suits for next models

1

Table of contents

Other DEHAS Control Unit manuals

Popular Control Unit manuals by other brands

NXP Semiconductors

NXP Semiconductors TWR-K64F120M user guide

Schnick-Schnack-Systems

Schnick-Schnack-Systems DMX-Recorder user guide

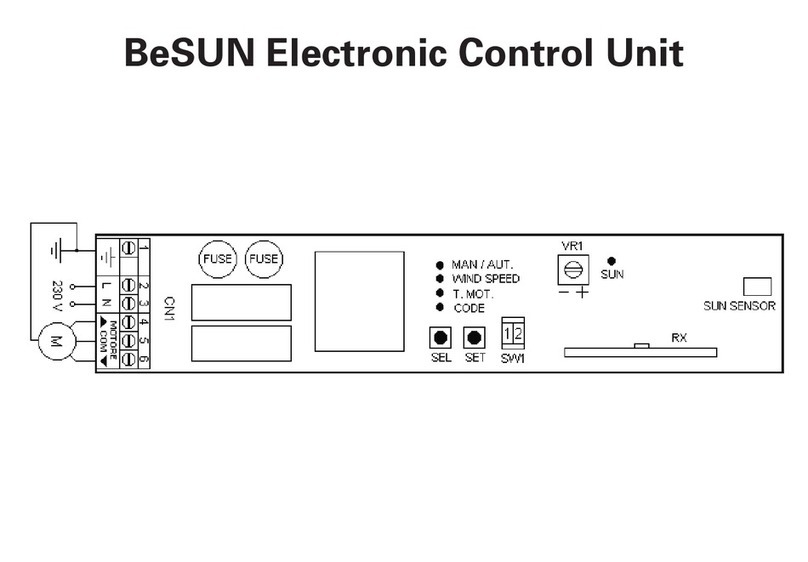

Seav

Seav BeSUN 433 manual

Honeywell

Honeywell VR400 Series operating instructions

CLA-VAL

CLA-VAL 81-01 Installation operation & maintenance

Price Pfister

Price Pfister 0X8 series installation instructions

Trenz Electronic

Trenz Electronic TE0790 manual

Vexve

Vexve TERMOVAR Series Mounting and operating instructions

Ross

Ross HDBH Series operating instructions

Roger Technology

Roger Technology H70/101AC Instructions and Recomendations for the Installer

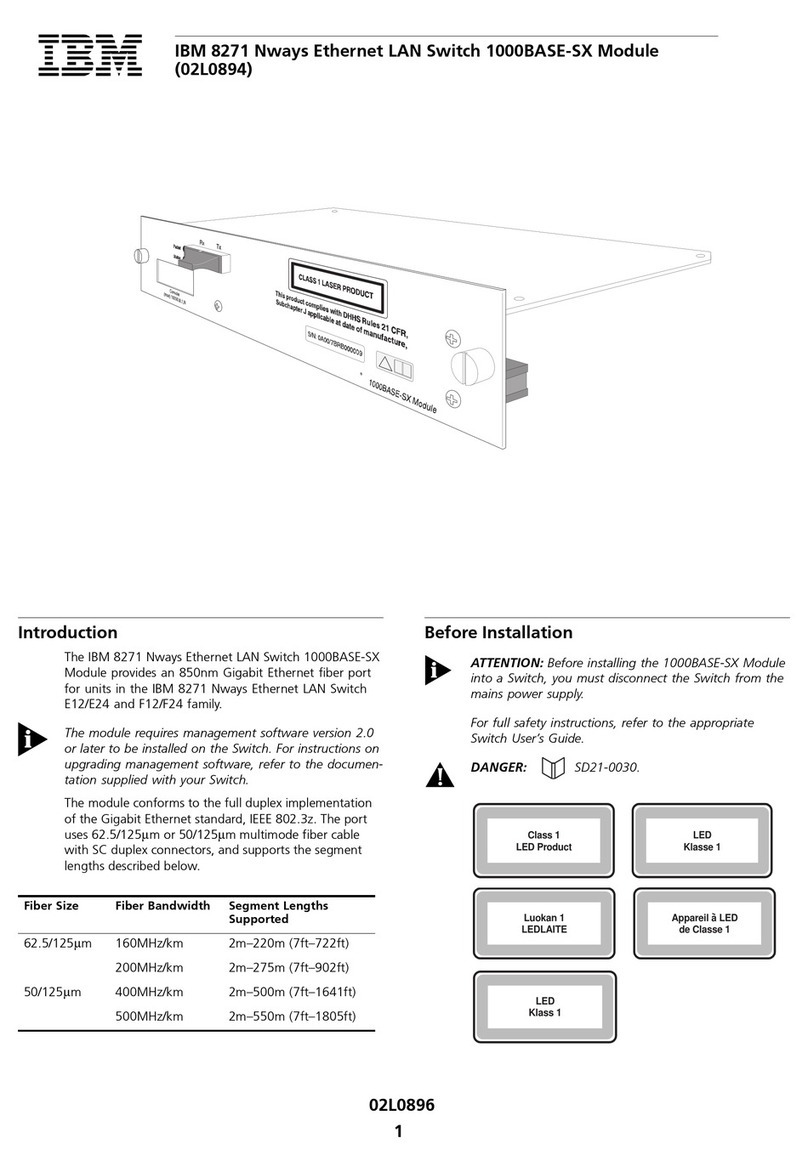

IBM

IBM 8271 Nways Ethernet LAN Switch manual

Pilz

Pilz PNOZ m EF 8DI4DO operating manual