heat-timer MPC Platinum User manual

MPC Platinum Installation and Operation Manual 1

HT# 059085-00 F

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

MSI CONNECTION

ON BACK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

C O R P O R A T I O N

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Installation and Operation Manual

Steam Outdoor Reset Boiler /Motorized

Valve Cycling Heating Control

MPC

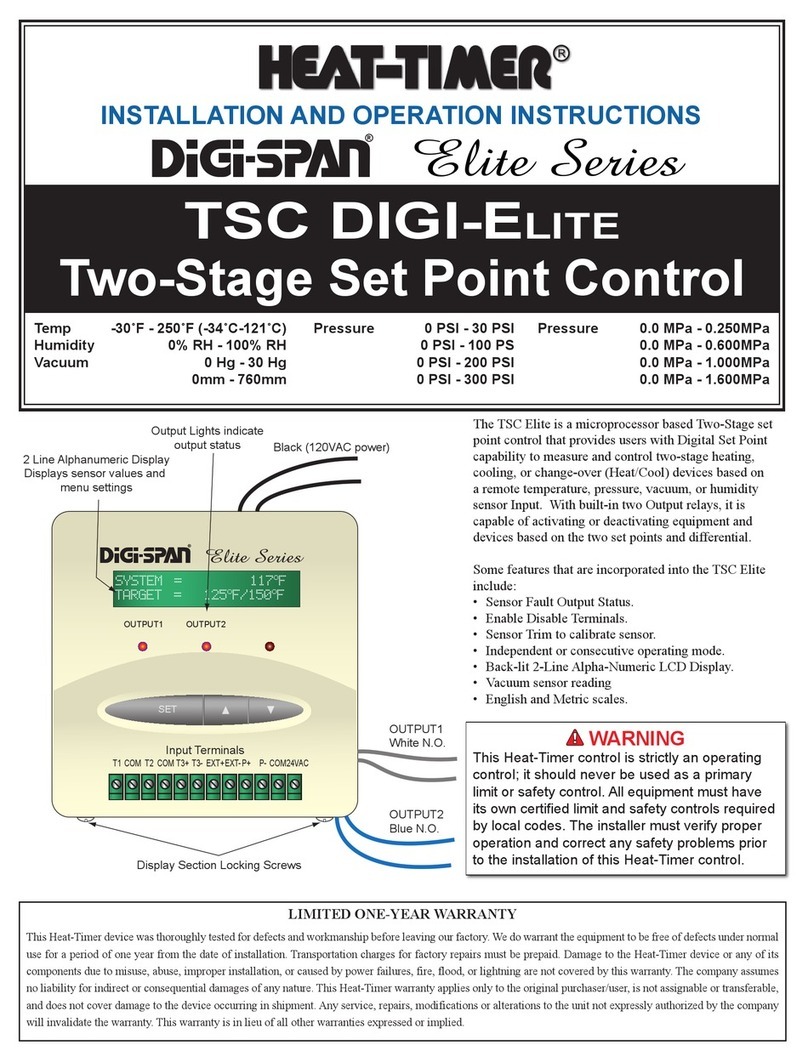

WARNING

This Heat-Timer control is strictly an operating control; it should

never be used as a primary limit or safety control. All equipment

must have its own certified limit and safety controls required by local

codes. The installer must verify proper operation and correct any

safety problems prior to the installation of this Heat-Timer control.

Platinum

2MPC Platinum Installation and Operation Manual

HT# 059085-00 F

MPC Platinum Function Chart . . . . . . . . . . . 3

Understanding the Cycle Concept. . . . . . . . .4

Sequence of operation . . . . . . . . . . . . . . . . 5

Cycle Timeline . . . . . . . . . . . . . . . . . . . . .5

. . . . . . . . . . 6

Initial Program. . . . . . . . . . . . . . . . . . . . .6

Selecting the System Features . . . . . . . . . . . .6

Making Sure You Have the Right Control . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . .8

Mounting the enclosure . . . . . . . . . . . . . . . .8

Rear of Control. . . . . . . . . . . . . . . . . . . . .8

Sensor Installation. . . . . . . . . . . . . . . . . . .9

Outdoor Sensor Installation . . . . . . . . . . . . . .9

Heating System Sensor (HSS) Installation . . . . . . 9

Wiring the power. . . . . . . . . . . . . . . . . . . 10

Output Wiring . . . . . . . . . . . . . . . . . . . . 10

Wiring To a motorized valve . . . . . . . . . . . . . 10

Wiring To a Boiler . . . . . . . . . . . . . . . . . . 10

Wiring To System Output. . . . . . . . . . . . . . . 11

Wiring to Auxiliary Clock . . . . . . . . . . . . . . . 11

Wiring to Option Outputs . . . . . . . . . . . . . . . 11

Input Wiring . . . . . . . . . . . . . . . . . . . . . 12

Wiring System Sensor . . . . . . . . . . . . . . . . 12

Wiring the Outdoor Sensor. . . . . . . . . . . . . . 12

Wiring the Shutdown . . . . . . . . . . . . . . . . . 12

Wiring The Prove. . . . . . . . . . . . . . . . . . . 12

Network and Aux Temp . . . . . . . . . . . . . . . 12

Testing the Sensors . . . . . . . . . . . . . . . . . 13

Aux Input . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring Network Sensors . . . . . . . . . . . . . . . 13

Connecting Wireless Sensor System . . . . . . . . 13

Remote Communication Wiring . . . . . . . . . . 14

BACnet Wiring . . . . . . . . . . . . . . . . . . . . 14

BACnet IP Wiring . . . . . . . . . . . . . . . . . . 14

BACnet MS/TP Wiring . . . . . . . . . . . . . . . . 14

MODBUS RTU Wiring . . . . . . . . . . . . . . . . 15

Internet Wiring . . . . . . . . . . . . . . . . . . . . 15

Ethernet Connection to Modem . . . . . . . . . . . 15

Ethernet Connection to Platinum Control . . . . . . 15

DHW Energy Saver Wiring . . . . . . . . . . . . . 15

AUTO/BYPASS Switch. . . . . . . . . . . . . . . . 16

Setting the Control . . . . . . . . . . . . . . . . . 16

Display and Changing Settings. . . . . . . . . . . 16

menu Types . . . . . . . . . . . . . . . . . . . . . 16

Display Messages . . . . . . . . . . . . . . . . . . 17

Menu Settings . . . . . . . . . . . . . . . . . . . . 18

Startup Settings . . . . . . . . . . . . . . . . . . . 20

Sensor Type . . . . . . . . . . . . . . . . . . . . . 20

Operation Mode . . . . . . . . . . . . . . . . . . . 20

Cycle Length . . . . . . . . . . . . . . . . . . . . . 20

Sensor Fault . . . . . . . . . . . . . . . . . . . . . 20

Day light saving mode . . . . . . . . . . . . . . . . 21

Option Outputs Modes . . . . . . . . . . . . . . . 21

Option relay 1 mode . . . . . . . . . . . . . . . . . 21

Option 2 Relay Mode . . . . . . . . . . . . . . . . 21

Option 3 relay mode . . . . . . . . . . . . . . . . . 21

DHW Supply and return Defaults . . . . . . . . . . 22

Setting the Date and Time . . . . . . . . . . . . . . 22

Operation. . . . . . . . . . . . . . . . . . . . . . . 23

System Settings . . . . . . . . . . . . . . . . . . . 23

Season . . . . . . . . . . . . . . . . . . . . . . . . 23

Day and Night Heat Adjustment . . . . . . . . . . . 23

Cycle Length Table. . . . . . . . . . . . . . . . . . 24

Boost Mode . . . . . . . . . . . . . . . . . . . . . 26

Vari Boost Curves . . . . . . . . . . . . . . . . . . 26

Early Shutdown Curves . . . . . . . . . . . . . . . 27

Warm-up Enable and Learn . . . . . . . . . . . . . 27

System Run-On . . . . . . . . . . . . . . . . . . . 28

Thermal Lockout . . . . . . . . . . . . . . . . . . . 28

Space Lockout . . . . . . . . . . . . . . . . . . . . 28

Day and Night Space Targets . . . . . . . . . . . . 28

Schedules . . . . . . . . . . . . . . . . . . . . . . 29

Setting the DAY/NIGHT Schedule . . . . . . . . . . 29

Copy Schedule. . . . . . . . . . . . . . . . . . . . 30

Vacation Schedule Setting . . . . . . . . . . . . . . 30

Aux Relay Schedule . . . . . . . . . . . . . . . . . 30

Maintenance . . . . . . . . . . . . . . . . . . . . . 31

System and Outdoor Sensor Trim . . . . . . . . . 31

Fast Cycle . . . . . . . . . . . . . . . . . . . . . . 31

Password and Local Security. . . . . . . . . . . . 31

DHW Settings . . . . . . . . . . . . . . . . . . . . 32

Using the Supply/Return Sensor . . . . . . . . . . . 32

Supply/Return Set Point . . . . . . . . . . . . . . . 32

Supply/Return Peak/Light Differential . . . . . . . . 32

DHW Demand Schedule . . . . . . . . . . . . . . . 33

DHW Copy Schedule . . . . . . . . . . . . . . . . 33

Shift . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Communication Options. . . . . . . . . . . . . . 34

Internet Communication Features . . . . . . . . . 34

Internet Communication. . . . . . . . . . . . . . . 35

Internet ID . . . . . . . . . . . . . . . . . . . . . . 35

Internet Port forwarding Table . . . . . . . . . . . . 35

BACnet Communication Features . . . . . . . . . 37

BACnet Communication. . . . . . . . . . . . . . . 37

Selecting BACnet IP or BACnet MSTP . . . . . . . 37

. . . . . . . . . . . . . . 37

BACnet Device ID . . . . . . . . . . . . . . . . . . 37

IP and Mask Addresses . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . 37

BACnet Device ID . . . . . . . . . . . . . . . . . . 37

MS/TP Address/ MAC Address . . . . . . . . . . . 38

MSTP Baud rate . . . . . . . . . . . . . . . . . . . 38

MPC Platinum BACnet Variable List . . . . . . . . . 38

BACnet PICS Statement . . . . . . . . . . . . . . . 40

MODBUS Communication Features . . . . . . . . 41

. . . 41

MODBUS Communication Options . . . . . . . . . 41

MAC Address . . . . . . . . . . . . . . . . . . . . 41

MODBUS Baud . . . . . . . . . . . . . . . . . . . 41

MPC Platinum MODBUS Variable List. . . . . . 41

Troubleshooting. . . . . . . . . . . . . . . . . . . 43

Diagrams . . . . . . . . . . . . . . . . . . . . . . . 45

Warranty . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . 56

Content

MPC Platinum Installation and Operation Manual 3

HT# 059085-00 F

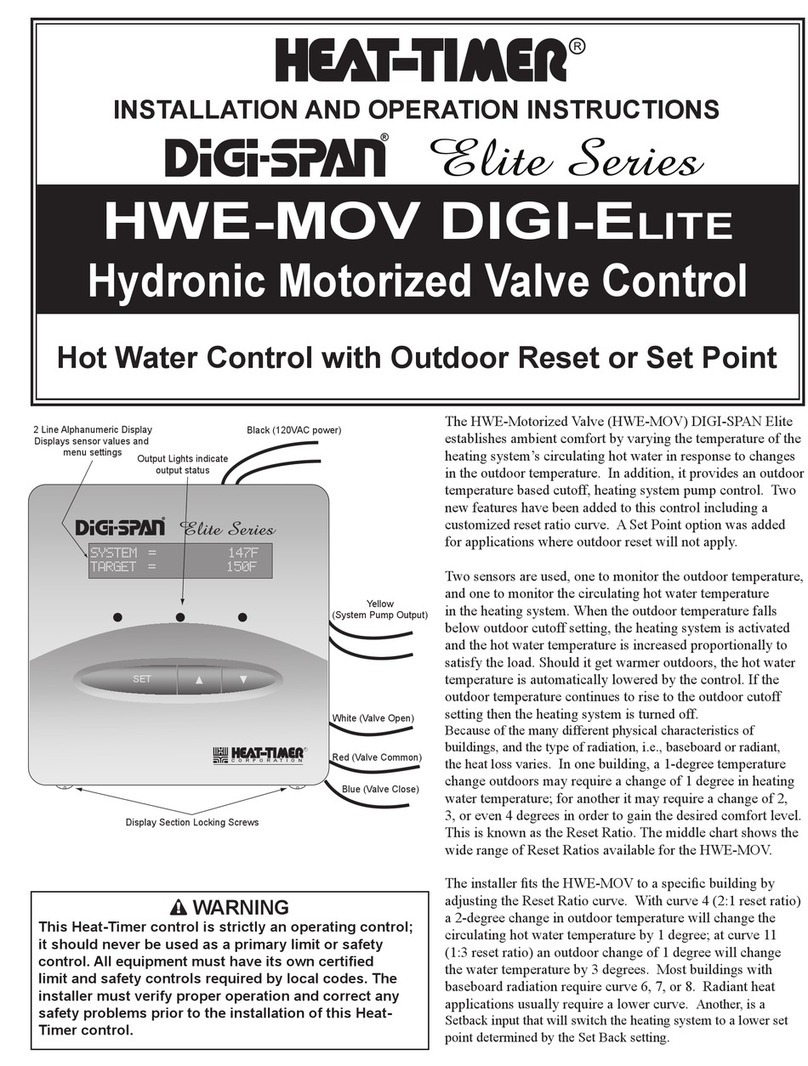

MPC PLATINUM FUNCTION CHART

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

C O R P O R A T I O N

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

From heating system sensor

When closed, outputs

are turned off*

From Heat-Timer network

sensors**

Checks status of system

components*

From outdoor sensor

mounted in the shade

Red lights indicate when the

associated stage relay

is activated

Remote Communication

Option**

* DRY CONTACT ONLY

** Only available with the Remote Communications package

Depress the knob to move

forward through the menus and to

accept changes. To change a

setting's value, rotate the knob.

Depress the button to go back

through the menus

Digital display shows the cycle status,

outdoor cutoff, outdoor, and system temperatures.

To view and adjust settings, press the

Adjust/Select button.

From DHW Control*

Green Earth

Ground screw

120VAC

Power

BYPASS position runs

the output.

Valve and Burner

Outputs are active

when MPC requires

steam

Operates additional equipment based

on a separate Aux Schedule

OPTION outputs can be programmed

to operate additional equipment or

Internet Modem.

NETWORK

MSI CONNECTION

ON BACK

4MPC Platinum Installation and Operation Manual

HT# 059085-00 F

UNDERSTANDING THE CYCLE CONCEPT

The Heat-Timer MPC Platinum is a microprocessor-based control designed to manage a low-pressure steam heating system. It

operates a steam boiler or a two-way steam valve to provide the desired amount of heat to the building.

The MPC Platinum operates based on the CYCLE principle. Heat-Timer created this principal specically for steam heating

systems to overcome the inabilities of standard thermostatic controls to cope with the unique challenges of low-pressure steam

heating. Unlike water and air systems, steam systems take time to build up a "head of steam". Moreover, once the system starts

heating up, it has momentum that takes time to dissipate. This makes it difcult to control its temperature.

Cycle-On

21 Minutes

Cycle-Off

39 Minutes

Establish

Heat

Cycle-On

21 Minutes

Establish

Heat

Cycle delayed until

System Temperature drops

below System Set Point-Diff

1 2 3 4 1

60 Minute Cycle

(Cycle-On=21 + Cycle-O=39)

Cycle length based on outdoor temperature

By monitoring the outside temperature, the MPC Platinum is able to anticipate the building heating needs. Each CYCLE period

(usually 60 minutes long, but adjustable depending on the type of radiation units) consist of a Cycle-ON segment and a Cycle-OFF

segment. The length of the Cycle-ON segment will vary with the outside temperature. The colder it is outside, the longer the

Cycle-ON part.

MPC

Platinum

PREV.

(DEL)

OUT

TEMP

AUX

INPUT0

AUX

TEMP0

AUX

TEMP1

MENUFUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selectsnextday

PREV./NEXT stepsthroughoutput status

LINE

NEUTRAL

DAY

HELP NEXT

PRESSTO

SELECT

BACK

MON 12/28/04 10:43Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP2

DONOT APPLYANY VOLTAGE

TOSENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

MSI CONNECTION

ON BACK

PROVE

SHUTDOWN

SYSTEM

TEMP

AUTO

BYPASS

ALLSENSORS MUST BE

GOLDSERIES SENSORS

INPUTS

ROUTESENSOR AND AUXILIARY WIRES

THROUGHTHIS KNOCKOUT ONLY

SYS

AUX

CLOCK

OPTION

1

OPTION

2

T

T

T

Cycle On

Cut= 55oF Day

OD= 31oF SYS= 148oF

OUTPUT

BBURNER

MOTORIZED

VALVE

SYSTEM OPTION

1

OPTION

2

OPTION

3

AUX

CLOCK

T

T

C O R P O R A T I O N

R

2 3 4 5 6 7 8 9 11 12 13 14 15 16 17

OPTION

3

10 18

R W

Outdoor

Sensor

MPC Platinum

Zone A

Boiler Water Line

Boiler

Zone B

Zone C

Condensate

Receiver

System Sensor

Installed on Dry

Return Above

Water Line

Optional Location:

System Sensor

At Furthest Radiator

Burner

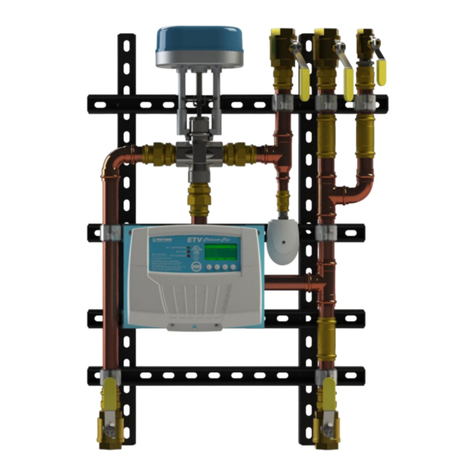

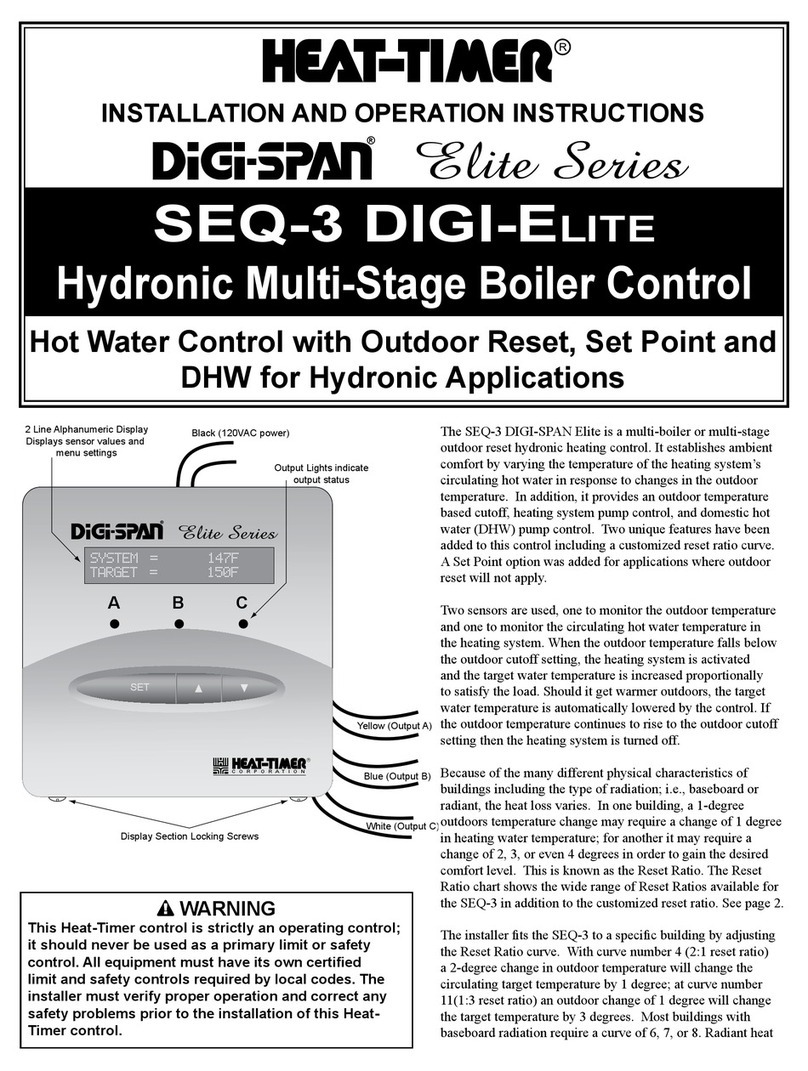

The MPC Platinum constantly checks the outside temperature by means of a solid-state sensor located on the exterior of the

building. At the same time, it monitors the heating system of the building by means of a heating system sensor. This heating system

sensor is located where it will show that heat has reached the furthest location in the building (or the hardest to heat area). Based on

this combined data, the MPC Platinum sends instructions to the heating plant to control the heat level in the building.

In addition to adjusting the length of the Cycle-ON segment, the outdoor temperature acts as a system cutoff. When the outdoor

temperature rises above one of the adjustable cutoff temperatures (Two outdoor cutoffs are available. One is for the day and the

other is for the night), the MPC Platinum will not call for any heat. When the outdoor temperature drops below the cutoff, the

MPC Platinum will automatically begin controlling the heating cycle. Once the heating system is active, the heating system sensor

will register when heat has reached throughout the building. The combined effect of these two sensors is to provide an even,

comfortable level of heat throughout the building.

MPC Platinum Installation and Operation Manual 5

HT# 059085-00 F

Sample Mild Weather Cycle

Sample Cold Weather Cycle

Cycle Length 60 minutes

Heat On Heat Off

Cycle-On

8 Minutes

Cycle-Off

52 Minutes

Establish

Heat

Cycle-On

21 Minutes

Cycle-Off

39 Minutes

Establish

Heat

The MPC Platinum is able to maintain two different heat levels. The Day heat level is the higher level of heat. It provides

comfortable temperatures when the building tenants are active. The Night heat level provides lower heat and conserves energy when

the building is empty or when tenants are asleep. Both heat levels rely on the identical cycle concept, but the lower Night settings

provide less heat given the same outdoor temperature.

SEQUENCE OF OPERATION

• The MPC Platinum activates the steam source when the outside temperature falls below the outdoor sensor cutoff (factory set at

55°F for Day and 40°F for Night, but fully adjustable).

• The MPC Platinum will continue to call for heat, keeping the steam source active, until the heating system sensor reaches its

adjustable Set Point. This indicates that steam has gotten entirely through the system, or that "heat is established".

• Once "heat is established", the Cycle-ON segment of the cycle will begin.

• During the Cycle-ON period, the MPC Platinum will keep the steam source activated. The length of the ON part of the cycle

is dependent on the outdoor temperature, the Day/Night setting, and several user selectable adjustments that can be tuned to the

specic heat loss characteristics of the building.

• Once the Cycle-ON part has ended, the Cycle-OFF part of the cycle will begin. The MPC Platinum will turn off the boiler or

close the steam valve for the remainder of this cycle.

• When the Cycle-OFF part is over, the MPC Platinum will once again activate the steam source unless either the outside

temperature has risen above the cuttoff, or the thermal lockout is active.

• With the thermal lockout, the heating system sensor temperature must fall below the Set Point through an adjustable differential

before the heating source can be reactivated. This allows residual heat in the pipes to continue to heat the building. Once the

pipes have cooled sufciently, a new cycle can begin.

• However, if the MPC Platinum is an Internet capable control and space sensors are installed, the control checks for Space Lockout

before staring another cycle.

CYCLE TIMELINE

Internet Control Cycle Timeline view

6MPC Platinum Installation and Operation Manual

HT# 059085-00 F

• During a heating cycle, the control switches between the different cycle states. The states are divided into groups.

• During any of the operational states, the control has the output relays energized. And during the energy saving states, the control

has the output relays de-energized.

• An Internet control Cycle Timeline is viewable on the History tab of the ICMS site. They are part of the Stock History.

• State Groups are divided into either Boiler-On or Boiler-Off. The Boiler-On groups are represented by the reddish background.

They are graphed on the upper portion of the Cycle-Timeline Internet history graph. The Boiler-Off groups are graphed on the

bottom portion of the graph and has a bluish background.

• These Internet graphs help troubleshoot and ne tune the control operation.

TYPICAL STEAM HEAT CONFIGURATION

The MPC Platinum works with virtually any non-vacuum steam heated system. The MPC Platinum can control a boiler directly to

create steam. For systems where a central plant provides steam, the MPC Platinum opens or closes a motorized valve to allow or

prevent steam from entering the heating system. The MPC Platinum also works with one or two-pipe steam systems.

However, based upon the specic layout of the steam heating system there are several differences in locating the heating system

sensor and in the output wiring to the boiler or motorized valve that the user need to observe. It is important to carefully check the

piping diagrams at the end of this manual to determine which of the following four layouts matches your heating system:

• One Pipe Steam - Motorized Valve

• Two Pipe Steam - Motorized Valve

• One Pipe Steam - Direct Burner Operation

• Two Pipe Steam - Direct Burner Operation

For subatmospheric vacuum type steam systems, see Heat-Timer SRC Platinum Control on the Heat-Timer web site

(http://www.heat-timer.com).

INITIAL PROGRAM

Setting an Initial Program ease's the conguration of the MPC Platinum while giving the opportunity to utilize many of the energy

saving and comfort features. The program should consist of the following:

• Select the features your system can utilize,

• Make sure you have the right control and accessories,

• Install the Control,

• Set the System Startup,

• Set the System Settings,

• Set the Schedules

• Adjust the Day and Night Heat Adjustments and the Set Point

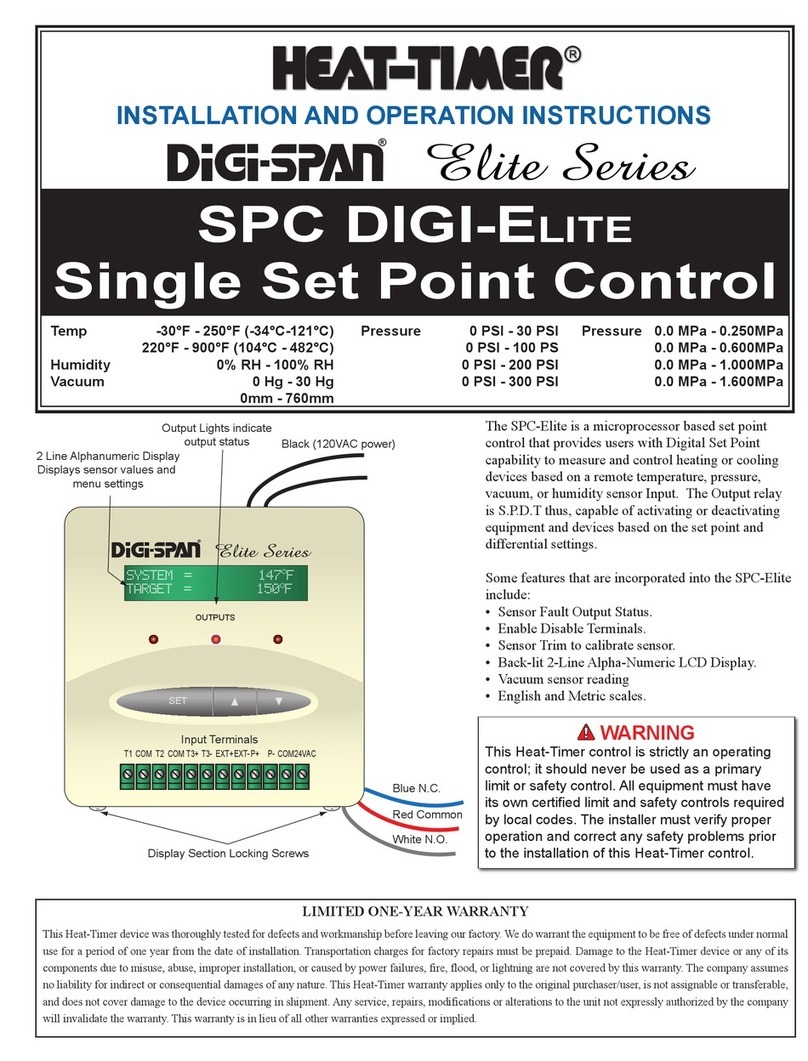

SELECTING THE SYSTEM FEATURES

Heat-Timer designed the MPC Platinum with low-pressure steam building heating as the primary purpose. With this in mind, the

user can use many of the control features to ease, enhance, and improve the system performance. Below is a list of its major features.

Steam Outdoor Reset

• The MPC Platinum regulates the amount of steam sent to the building based on the outdoor temperature. It uses the Cycle concept

based on the Day and Night Heat Adjustment and outdoor cutoffs to regulate the heat. The colder it gets, the longer the Cycle-On

runs. See "AUTO/BYPASS Switch" on page 16.

Night Setback

• Whenever the outdoor temperature falls below the Outdoor Cutoff, the MPC Platinum adjusts the Cycle-ON and Cycle-OFF ratio

to hold a constant Day or Night heat level. The Night heat level is for when the building is unoccupied or tenants are sleeping.

Day and Night Schedules

• The MPC Platinum has 4 Day and 4 Night settings for each day of the week. By setting a Schedule, Day and Night Heat

Adjustments, and Outdoor Cutoffs, you can save energy while providing comfortable heat to the building. The settings allow

the MPC Platinum to reduce the length of the steam Cycle-ON portion during the night or when building is unoccupied. See

"Schedules" on page 29.

MPC Platinum Installation and Operation Manual 7

HT# 059085-00 F

Vacation Schedule (Available with Internet Control Only)

• This feature gives the user the ability to provide a lower-than-night space target between two specied date-time combinations.

This provides additional savings for schools and ofce buildings to use in long holiday periods. See "Vacation Schedule Setting"

on page 30.

Space Sensor Feedback (Available with Internet Control Only)

• For better control and much more energy saving capabilities you can add wireless or wired space sensors to the MPC Platinum to

ne tune its operation and increase the system's overall efciency. When you add space sensors to the space average, the MPC

Platinum checks the space average before the beginning of each cycle to determine if the building is sufciently heated. See

"Space Lockout" on page 28.

System Output

• The system output relay connects to and operates a combustion air-damper or other boiler room equipment and it will energize

whenever there is a call for the boiler. In addition, if you connect the combustion air-damper's end-switch to the Prove input

terminals, it will stop the boiler from ring if the damper is not fully open. See "Installation" on page 8.

Boost and Early Shutdown

• The boost returns the building to its Day (Normal) heat level after Night (Setback) heat level. It does it by running the burner

or valve output for a period of time that depends on the outside temperature. It offers an adjustable curve parameter to tune its

operation to the specic building. See "Boost Mode" on page 26.

• The Early Shutdown feature shifts the Day schedule to Night Setback before the last Night Time setting for that day. The Early

Shutdown varies based on Outdoor temperature (OD). The warmer the Outdoor temperature the earlier the MPC Platinum shifts to

Night Setback. See "Early Shutdown Curves" on page 27.

Remote Communication

• The MPC Platinum is upgradable to Internet, BACnet IP, BACnet MSTP, or MODBUS communication to allow monitoring and

controlling of all of its functions from a remote location. Only the Internet communication package allows the MPC Platinum to

accept a variety of additional sensor inputs to monitor their status and provide web, E-Mail, or text message alarms under specied

adjustable conditions.

MAKING SURE YOU HAVE THE RIGHT CONTROL

If you need the MPC Platinum to do additional tasks that either are not listed or you do not know how to congure them,

contact Heat-Timer Corp. Sales Department either by Phone (973)575-4004, Fax (973) 575-4052, or over the web (visit

http://www.heat-timer.com).

8MPC Platinum Installation and Operation Manual

HT# 059085-00 F

INSTALLATION

MOUNTING THE ENCLOSURE

•Select a location near the equipment to be controlled.

•

the MPC Platinum.

•Keep the MPC Platinum control away from extreme heat, cold, or

humidity. Ambient operating temperature is from 20 to 120°F.

•Remove the control from the metal enclosure by removing the top

center screw and loosening the two bottom screws. Then, lift the

control out of the enclosure.

•Screw the enclosure to the surface through its back mounting holes.

•Return the control to the enclosure, replace the top screw, and

tighten the bottom two screws.

WARNING

Use only the provided Enclosure Knockouts. DO

NOT DRILL HOLES THROUGH THE ENCLOSURE

AS IT WILL VOID CONTROL WARRANTY.

Mounting Holes

Communication

Knockout

Wiring

Knockouts

Enclosure

Lock

REAR OF CONTROL

Activate the Battery

•Turn the MPC Platinum control over to reveal the piggyback

circuit board (CPU board).

•Remove the plastic strap that covers the battery. The contacts

should be touching the battery.

•The control has a coin Lithium battery (CR2032)

(HT# 020002-00) that is used to maintain the control's date and

time during power outages. This battery can maintain the clock

for up to a total of 100 days.

ALERT

Do not install the battery unless you plan to keep the

control continuously powered. If the control has no power,

the battery will lose its charge in 100 days.

Motherboard

CPU Board

RS485 (B)

Communication

Board

Battery

Connect to BACnet IP Network

or the Internet

CAT5 Cable RJ45

Socket

Connect to BACnet MSTP Network

or MODBUS RTU Network

RS485 Cable

Internet Communication Board (-RINet),

BACnet Communication Board (-BAC),

or MODBUS Communication Board (-BUS)

Control Communication Upgrade

•All non-communication MPC Platinum controls are upgradable to any of the available communication options. This, requires the

•The Upgrade Kit consist of two boards, a CPU Board and a Communication Board. The CPU Board has the control operating

software.

•All communication boards have an Ethernet socket that is used for the BACnet IP or Internet communication and a RS485 socket

that is used for BACnet MS/TP or MODBUS communication.

•Both boards are mounted on the back of the Platinum control's motherboard. Thus, to install both boards you need to remove the

control from the enclosure by removing 3 facing screws. Then, turn the control over to reveal its back.

•Each of the boards is mounted on a group of standoffs that must be replaced during the upgrade. See "Remote Communication

Wiring" on page 14.

•Connect the communication cable from the side Knockout.

•Reinstall the Panel in the enclosure using 3 screws.

A(+)

G

B(-)

A(+)

G

B(-)

MSI

Use Only

MPC Platinum Installation and Operation Manual 9

HT# 059085-00 F

SENSOR INSTALLATION

OUTDOOR SENSOR INSTALLATION

Only use the Heat-Timer sensor included with the unit (HT# 904220-00).

• Locate the sensor in the shade on the north side of the building. The sensor

should never be in direct sunlight.

• Be sure the location is away from doors, windows, exhaust fans, vents, or other

possible heat or cool sources.

• The sensor should be mounted approximately 10’ feet above ground level.

• Adhere the Outdoor Label provided to the back of the sensor base.

• Use the Enclosure Base bottom knockout for the conduit. Use the locknut to hold

the conduit and enclosure base together. Screw the cover to the base.

• Make sure to seal around the sensor enclosure and wall except from the bottom.

• The sensor wires can be extended up to 500’ using shielded 2-conductor cable

(HT# 703001-01) (#18/2). Do not connect the shield at the sensor. However,

connect it at the control using the terminal marked with an “O”.

• Do not run sensor wires in conduit with line voltage wiring.

ALERT

Determining the proper location for the Outdoor Sensor is very important. The MPC Platinum will

base the heat on the outdoor temperature information it receives from this location. If the sensor is in

the sun, or covered with ice, its reading will be different from the actual Outdoor temperature (OD).

Outdoor Sensor

snap-in location

Shield

not connected

Conduit

Outdoor Label

on back of Sensor

Outdoor Sensor

Mounting

screws

location

Seal around

sensor and wall

Outdoor

drip-hole

Conduit

Well

Sensor

in well

HEATING SYSTEM SENSOR (HSS) INSTALLATION

• Install the sensor at one of the following locations:

The ideal location for the HSS is on the furthest radiator in the system. This

radiator is usually the hardest to heat.

The sensor may be located on the furthest return riser. However, the sensor

MUST be above the boiler water line (on a dry return).

• Only use the sensor provided with the control. If you are replacing an earlier

Gold model Heat-Timer, it is NOT necessary to upgrade the sensor.

• Strap the HSS to the pipe using the tie-wraps provided with the outdoor sensor.

Then wrap insulation around the sensor and pipe to achieve the highest accuracy.

• The sensor wires can be extended up to 500' using a shielded 2-conductor cable

(HT# 703001-01) (#18/2).

• Do not connect the shield at the sensor. However, connect it at the control using

the terminal marked with an “O”.

• Do not run sensor wires in conduit or trough with line voltage wiring.

ALERT

If the HSS cannot sense the system is full of steam, the MPC Platinum

will not provide comfortable heat levels. Be sure the HSS is located on

a properly vented pipe that cannot easily be isolated from the system.

ALERT

NEVER Install the HSS between the

condensate receiver and the boiler.

Shield

Immersion Well

3/8" ID 1/2" NPT

Immersion Heating System Sensor

Common Supply Pipe

Heating System

Sensor Sensor Probe

Common Supply Pipe

Strap-On Heating System Sensor

Pipe Insulation

Sensor Probe

Shield

Connect

To control

Using a Pressutrol instead of the HSS

• Heat-Timer MPC Platinum control requires the use of a HSS. However, if a

good location for the HSS is not possible, it is acceptable to install a Pressuretrol

Adaptor Kit (HT# 900043-00) that connects to the boiler operating pressuretrol.

In this case, the system may not be as efcient as when using the HSS and the

Thermal Lockout feature will not be available..

ALERT

The use of the Pressuretrol Adaptor Kit

(HT# 900043-00) may reduce the system

operating efciency.

10 MPC Platinum Installation and Operation Manual

HT# 059085-00 F

WIRING THE POWER

• If possible, provide a dedicated circuit breaker for the MPC Platinum. DO NOT connect

the MPC Platinum to a circuit breaker connected to high inductance devices such as

relays, pumps, fans, or motors.

• Bring the 120VAC 60Hz power wires through a bottom knockout (KO) of the enclosure.

• Class 1 voltages must enter the enclosure through a different knockout from any Class 2

voltage wiring.

• Connect the hot line to terminal marked LINE.

• Connect the neutral line to the terminal marked NEUT. DO NOT share neutrals. The

neutral line MUST come directly from the circuit breaker.

• Connect the green ground screw to earth ground. DO NOT use the neutral line as a

ground.

• Heat-Timer recommends the installation of a Surge Suppressor and a Power Switch

before the Power Line connection for safety and ease of service.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM

AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11

12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Earth

Ground

L

N

120 VAC

OUTPUT WIRING

• All of the MPC Platinum's outputs DO NOT SOURCE any power. If power is needed at

a specic output, a separate power source must be wired in series with the output.

• Each of the output relays can switch a 6A resistive at 120VAC load or a 1A inductive

load.

WIRING TO A MOTORIZED VALVE

• The MPC Platinum is capable of operating a boiler, a oating motorized valve, or both.

• The MPC Platinum output terminal R(5) is the Common. Wire it to the 24 VAC power

source (transformer).

• Connect the transformer's second wire to the actuator Common terminal.

• The MPC Platinum output terminal B(4)is the Normally Open (N.O.). Wire it to the

actuator Open terminal.

• The MPC Platinum output terminal W (6) is the Normally Closed (N.O.). Wire it to the

actuator Close terminal.

• The N.O. and N.C. contacts are dry contacts only. They do not source any power. The

transformer is the actuator power source.

WARNING

Switching to BYPASS during power

outages activates the Output and System.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15

16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Common

Close

Open

Floating

Valve Actuator

Transformer

120 VAC

24 VAC

WIRING TO A BOILER

• The MPC Platinum s designed to operate a boiler, a oating motorized valve, or both.

• The BURNER output terminals are 7and 8. They do not source any power. Wire the

burner output in series with the boiler limit circuit.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15

16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Boiler

MPC Platinum Installation and Operation Manual 11

HT# 059085-00 F

WIRING TO SYSTEM OUTPUT

• The MPC Platinum is equipped with a System output to operate additional equipment.

The most common use for this output is operating a combustion air-damper.

• The SYSTEM output terminals are 9and 10. These terminals do not source any power.

Wire these terminals directly to the combustion air-damper activation terminals.

• The contacts can switch a 6A resistive at 120VAC load.

• A good practice is to use the MPC Platinum's Prove input terminals to connect to the

combustion air-damper End Switch. This prevents the MPC Platinum from activating

the boiler before fully opening the damper. See "Wiring The Prove" on page 12.

• The System relay energizes whenever the Output relay energizes. When the Output relay

de-energizes, the System relay remains energized for the System Run-On period before

de-energizing.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Combustion

Air Damper

WIRING TO AUXILIARY CLOCK

• The MPC Platinum is equipped with an AUX CLOCK output (terminals 11 and 12). Use

the output to operate additional equipment based on the Aux Schedule. A common use is

to turn on and off a set of lights based on a schedule. See "Aux Relay Schedule" on page

30.

• The AUX CLOCK output terminals do not source any power. Wire the AUX CLOCK

terminals directly to the equipment activation terminals if the equipment does not require

any power.

• If the equipment controlled require powering, make sure that its power consumption does

not exceed the output relay rating. Otherwise, use an isolation relay.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4

56 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B

R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Auxilary

Schedule

Activated

Device

WIRING TO OPTION OUTPUTS

• The MPC Platinum is equipped with three optional relay outputs (OPTION1 terminals 13

and 14,OPTION2 terminals 15 and 16, and OPTION3 terminals 17 and 18). Use these

outputs to operate additional equipment based on the control logic. Each of the Option

output relays has different logic operating choices. Select the desired choice from the

Startup Menu. See "Option Outputs Modes" on page 21.

• If the control is an Internet capable control, the OPTION3 output relay will function as a

relay to manage a cable or DSL modem's power.

WARNING

On Internet capable controls, you MUST use Option 3 output to

manage the power to Cable and DSL modems. However, DO NOT

use Option 3 Output to manage the power to Cellular Modems.

• The OPTION output terminals do not source any power. Wire the OPTION terminals

directly to the equipment activation terminals if the equipment does not require any

power.

• If the equipment controlled require powering, make sure that its power consumption does

not exceed the output relay rating. Otherwise, use an isolation relay. In this case, use the

OPTION terminal to break the hot power wire. going to the equipment. Then, connect

the neutral wire directly the equipment second terminal.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7

8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT

SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Option1

Option2

12 MPC Platinum Installation and Operation Manual

HT# 059085-00 F

INPUT WIRING

WIRING SYSTEM SENSOR

• Only use the Heat-Timer Outdoor sensor included with the MPC Platinum (#904250-00).

• You can extend the sensor wires up to 500’ by splicing it with 18 gauge shielded wire

(Belden #8760 or equivalent).

• DO NOT run sensor wire in conduit or trough with line voltage.

• Heat-Timer temperature sensors have no polarity. Connect the sensor wires to the MPC

Platinum terminals marked SYSTEM TEMP (terminals A1 and A2).

• Connect the shield to the circled terminal SYSTEM TEMP-A2 with one of the sensor

wires and cut shield off at sensor end.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Sensor Shield

System Sensor

WIRING THE OUTDOOR SENSOR

• You can extend the sensor wires up to 500’ by splicing it with 18 gauge shielded wire

(Belden #8760 or equivalent).

• DO NOT run sensor wire in conduit or trough with line voltage.

• Heat-Timer temperature sensors have no polarity. Connect the sensor wires to the MPC

Platinum terminals marked OUT TEMP (terminals A11 and A12).

• Connect the shield to the circled terminal OUT TEMP-A12 with one of the sensor wires

and cut shield off at sensor end.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Sensor Shield

Outdoor Sensor

WIRING THE SHUTDOWN

• You can use this feature whenever it is desirable to deactivate the MPC Platinum from a

remote location or another controller like a Building Management System (BMS).

• The Shutdown feature de-energizes the BURNER and MOTORIZED VALVE output

relays, turning off the boiler or closing the motorized valve. However, the SYSTEM relay

will remain energized for the period of the System Run-On. See "System Run-On" on

page 28.

• The Shutdown signal must be a dry contact only. DO NOT place voltage across the

SHUTDOWN terminals.

• Bring the two wires from the dry contact to the terminals marked SHUTDOWN- A3, A4.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Shutdown

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Shutdown

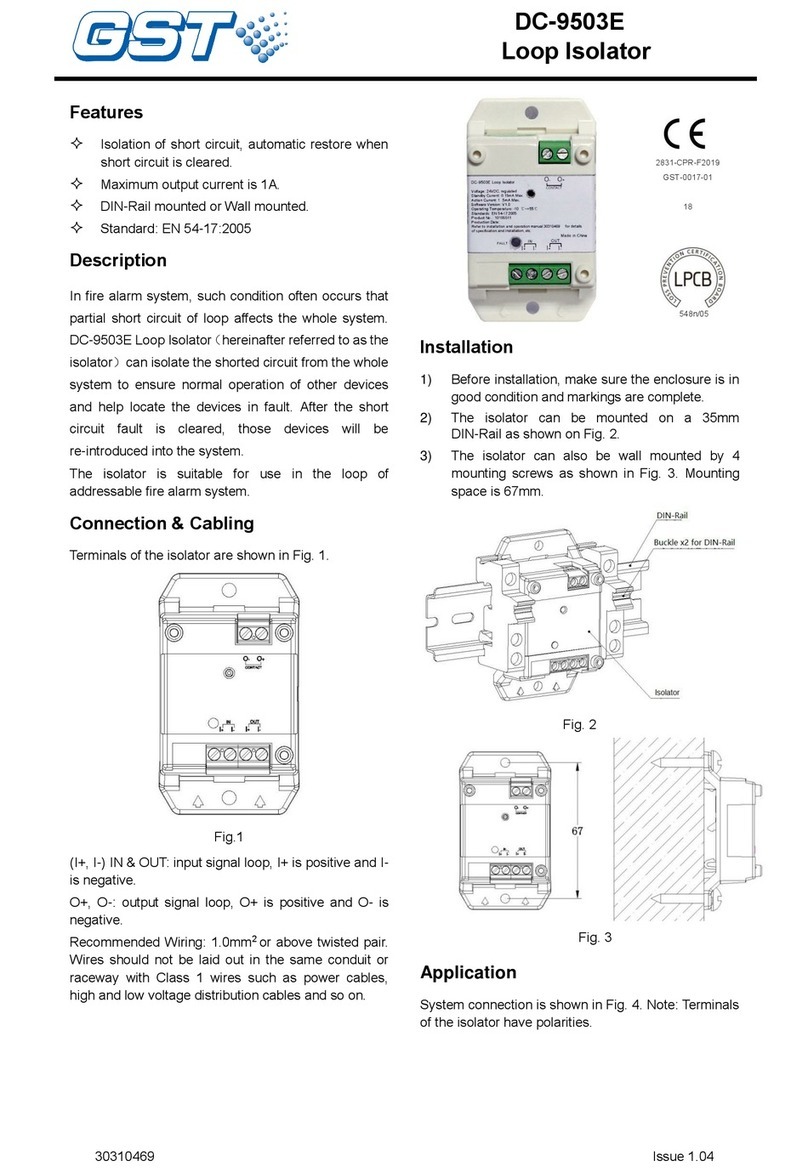

WIRING THE PROVE

• The MPC Platinum uses the Prove input to check system operation before activating the

outputs. A good practice is to use the MPC Platinum's Prove input terminals to connect

to the combustion air-damper End Switch. This prevents the MPC Platinum from

activating the boiler before fully opening the damper. See "Installation" on page 8.

• If the PROVE input terminals are open, the MPC Platinum will enable only the System

relay. The Burner and Motorized valve (OUTPUT) relays will be de-energized when the

PROVE input is open.

• The Prove signal must be a dry contact only. No voltage can be placed across the

PROVE terminals.

• Bring the two wires from the dry contact to the terminals marked A5 and A6.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Prove

ALERT

The PROVE input terminals must

be shorted for MPC Platinum to

provide heat. DO NOT remove the

factory installed PROVE jumper

unless replacing it with a Prove

signal.

NETWORK AND AUX TEMP

• The only way to congure all Network sensors and

switches is through the Internet using the ICMS web site

(http://www.htcontrols.com).

• Heat-Timer offers a large variety of network sensors. Visit

our web site (http://www.heat-timer.com) for a list of available

Network Sensors.

• The Aux Temp inputs are capable of accepting a temperature or

a switch sensor. The user can access their values by pressing

the BACK button while in the default screen.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

Sensor Shield

Temp. Sensor

Sensor Shield

Space Sensor

Switch Input

MPC Platinum Installation and Operation Manual 13

HT# 059085-00 F

TESTING THE SENSORS

•On a power up, the Platinum control goes through a countdown followed by the default screen.

•The default screen displays (SYS) to show the Heating System Sensor (HSS) temperature and (OD) to show the Outdoor

Sensor temperature.

•If either of the two temperatures reads OPEN, SHORT, or an incorrect temperature. See "Troubleshooting" on page 44.

•You can only view Network sensor readings on the Internet.

AUX INPUT

•If the boiler is activated by another control, i.e. domestic hot water aquastat, the Aux

Input will allow a Heat-Timer communication package to chart a time line for boiler

status.

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

External Boiler Call

MPC

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

AUX

INPUT 0

AUX

TEMP 0

AUX

TEMP 1

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

DAY selects next day

PREV./NEXT steps through output status

DAY

HELP NEXT

PRESS TO

SELECT

BACK

MON 12/01/2010 10:01Am

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

AUX

TEMP 2

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

SYSTEM

TEMP

BYPASS

ALL SENSORS MUST BE

GOLD SERIES SENSORS

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

T

T

T

Cycle On 13/15

Cutoff = 55oF Day

OD = 31oF SYS = 138oF

AUTO

T

T

CORPORATION

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

SYSTEM AUX

CLOCK

OPTION

1

OPTION

2

OPTION

3

BURNER

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

LINE

NEUTRAL

B R W

MOTORIZED

VALVE

OUTPUT SYS

OPTION

3

OPTION

2

OPTION

1

AUX

CLOCK

External Boiler Call

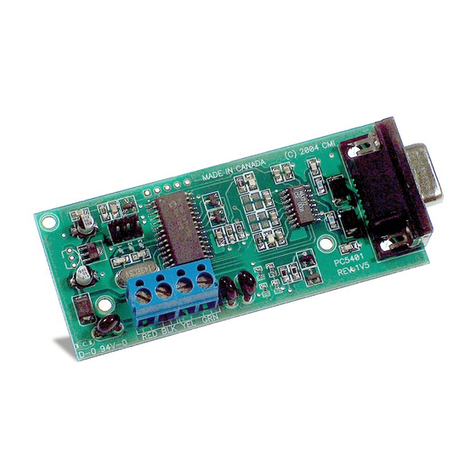

WIRING NETWORK SENSORS

(Requires Internet Communication Package Upgrade)

•

the ICMS website (http://www.htcontrols.com).

•The MPC Platinum Network terminals can connect up to 64 or 128 network sensors,

depending on the control hardware.

•Use the Mini-MIG to handle up to 16 temperature, switch, or count sensors. Multiple

Mini-MIG’s can connect to an MPC Platinum.

•A variety of network sensors is available for the MPC Platinum:

◦Stack Sensor (measures the stack temperature),

◦Water Meter Count/Pulse sensor (measures water consumption),

◦Oil Tank Monitor (measure the amount of oil in a tank),

◦Pressure, vacuum, and humidity transducers,

◦Multiple Input Gateway (Mini-MIG) that gives the capability of connecting the

control to multiple temperature or switch sensors and a single count sensors.

◦Conductivity sensors (to measure boiler chemical requirement).

Platinum

Wireless

Network

Manager

MIG

Network

Network

Sensors

AUX

TEMP 0

AUX

TEMP 1

A10

A12

AUX

TEMP 2

A13

A14

A15

A16

A17

A18

NETWORK

PROVE

SHUTDOWN

OUT

TEMP

T

T

T

T

PRESS

4-20 mA

S

+

S

RS485

Mini-MIG

Multiple Input Gateway

Power

Comm

PWR

L N

1 2

Network

N1

3 4

Input1

7

Input2

9

Input3

11

Input4

13

Input5

15 17

Input7

19

Input8

21

Input

6

10 12 14 16 18 20 22

Input9

23

Input10

25

Input11

27

Input12

29

Input13

31 33

Input15

35

Pulse

Input16

37

Input

14

24 26 28 30 32 34 36 38

T1 T2 T3 T4

125 72 73 75

RESET VIEW

8

0056789

Water

Meter

Stack

Sensor

Oil Level

Wireless

Sensor

CONNECTING WIRELESS SENSOR SYSTEM

(Requires Internet Communication Package Upgrade)

•

Internet (http://www.htcontrols.com).

•The MPC Platinum can connect to up to 64 or 128 network

sensors, depending on the control hardware. These numbers

include wireless sensors, wireless Transceivers, and the

wireless Network Manager.

•Use Wireless Transceivers to extend the range of the wireless

network and reduce building sensor wiring.

•The wireless Network Manager connects directly to the

communication board's RS485.

•The balance of the wireless system communicates its

information to the wireless Network Manager.

1 2 3 4

ON

Wireless Network Manager

Motherboard

CPU Board

RS485

Connect to

Wireless NM

Platinum Control

NM RS485

Cable (Provided)

Send Packet

Button

A(+)

G

B(-)

A(+)

G

B(-)

14 MPC Platinum Installation and Operation Manual

HT# 059085-00 F

REMOTE COMMUNICATION WIRING

•All standard Platinum controls come with a Motherboard and a CPU board.

•If the Platinum control part number ends with RINET, BAC, or BUS; then it also comes with a communication board. If a

A new CPU board and the

respective communication board will be included in any of the Upgrade Kits.

ALERT

Always bring your communication cable through one of the side

knockouts. DO NOT use the bottom knockouts for communication cabling.

BACNET WIRING

BACNET IP WIRING

•The Ethernet cable should use the Platinum control's enclosure closest

side knockout.

•Connect the CAT-5E BACnet IP cable to the RS45 communication

socket on the back of the control's Communication Board.

•For reliable communication, do not run CAT-5E cables more than

150 Ft. CAT-6 cables can have a maximum run of 300 Ft.

•

Manual".

ALERT

A BACnet capable Platinum control displays

-- NETWORK PANEL --

Motherboard

CPU Board

Communication Board

PLATINUM PANEL CONNECTED

TO BACnet IP Network

Connect to Ethernet

Connection on BACnet Network

CAT5/Ethernet Cable

Ethernet socket

connect to Cat-5 cable

BACNET MS/TP WIRING

•The RS485 cable should use the Platinum control's enclosure closest

side knockout.

•Connect the BACnet MS/TP cable to the RS485 connector

communication socket on the back of the control's Communication

Board. The Communication Board terminals are labeled 'A (+)', G

(Ground), and 'B (-)'.

•Use 18# AWG Twisted Pair cable. The cable length must not exceed

3500 feet.

•The ground RS485 terminal (G) MUST be connected to the BMS

RS485 Ground.

•

Manual".

Motherboard

CPU Board

Communication Board

PLATINUM PANEL CONNECTED

TO BACnet MS/TP Network

Connect to BACnet MS/TP Network

RS485 Cable

Black RS485 socket

connect to BACnet MS/TP

A(+)

G

B(-)

A(+)

G

B(-)

A(+)

G

B(-)

A(+)

G

B(-)

MPC Platinum Installation and Operation Manual 15

HT# 059085-00 F

MODBUS RTU WIRING

•A MODBUS communication board and a CPU board with the

MODBUS software is required for proper MODBUS communication.

•Heat-Timer Platinum control MODBUS communication uses a

RS485 connection.

•Connect the MODBUS RS485 cable to the Communication Board's

RS485 socket. The Communication Board's RS485 socket has ‘A

(+)’, G (Ground), and ‘B (-)’ terminals. Polarity is observed,

•The cable length must not exceed 3500 feet.

•Must Connect the ground RS485 terminal (G) to the BMS RS485

Ground.

•

R

ALERT

DO NOT USE the RS485 Connector on the Motherboard

for MODBUS communication. Use the RS485 Connector

on the MODBUS Communication Board instead.

Motherboard

CPU Board

TO MODBUS NETWORK

Connect Black RS485

to MODBUS Network

MODBUS

Communication

Board

INTERNET WIRING

ETHERNET CONNECTION TO MODEM

•Connect the Ethernet cable (provided) to the modem socket marked

Ethernet/LAN. Class 2 voltage wires must use a different knockout

from Class 1 voltage wires.

•Connect the other Ethernet cable end to the Communication board,

through the side knockout.

ETHERNET CONNECTION TO PLATINUM

CONTROL

•Bring the Ethernet line through one of the Platinum Enclosure side

knockouts. Class 2 voltage wires must use a different knockout from

Class 1 voltage wires.

•Connect the Ethernet cable to the Communication Board on the back

of the Platinum control. See "Platinum Internet Setup Manual".

Motherboard

CPU Board

Communication

Board

PLATINUM PANEL CONNECTED

TO THE INTERNET

Connect to Internet

CAT5/Ethernet Cable

Ethernet socket

connect to

Cat-5 cable

DHW ENERGY SAVER WIRING

•The DHW Energy Saver communicates all of its information to the Platinum control

using RS485 (3-wire connection).

•The DHW Energy Saver RS485 terminals are wired to the Platinum main board’s

RS485 (under the PCB board).

•Follow the wiring as per the graph on the right.

ALERT

DO NOT connect the DHW Energy Saver to the RS485 on the Platinum RI board.

Instead, connect the DHW Energy Saver RS485 to the Platinum main board.

•Maximum wiring length should not exceed 100 Feet. Use 18 gauge 2-conductor

shielded wire (#18). Connect the shield to the middle terminals on both of the RS485

connections. To eliminate communication errors, DO NOT splice the communication

cable wires.

•When connecting the DHW Energy Saver and a Platinum Extension to the same

connector, make sure to splice the cables externally before bringing them to the RS485

Plug Connector on the main Platinum Board. See "DHW Energy Saver Manual".

DHW Energy Saver

COM

3 4 5

A GND B

16VAC

1 2

~ ~

Use RS485

Communication

on the back of the

Platinum main board

PCB board

Shield

DHW Energy Saver

COM

3 4 5

A GND B

16VAC

1 2

~ ~

Use RS485

Communication

on the back of the

Platinum main board

PCB board

Shield

A(+)

G

B(-)

A(+)

G

B(-)

A(+)

G

B(-)

A(+)

G

B(-)

16 MPC Platinum Installation and Operation Manual

HT# 059085-00 F

AUTO/BYPASS SWITCH