Dehler 31 User guide

/

/

I

/

/

/

I

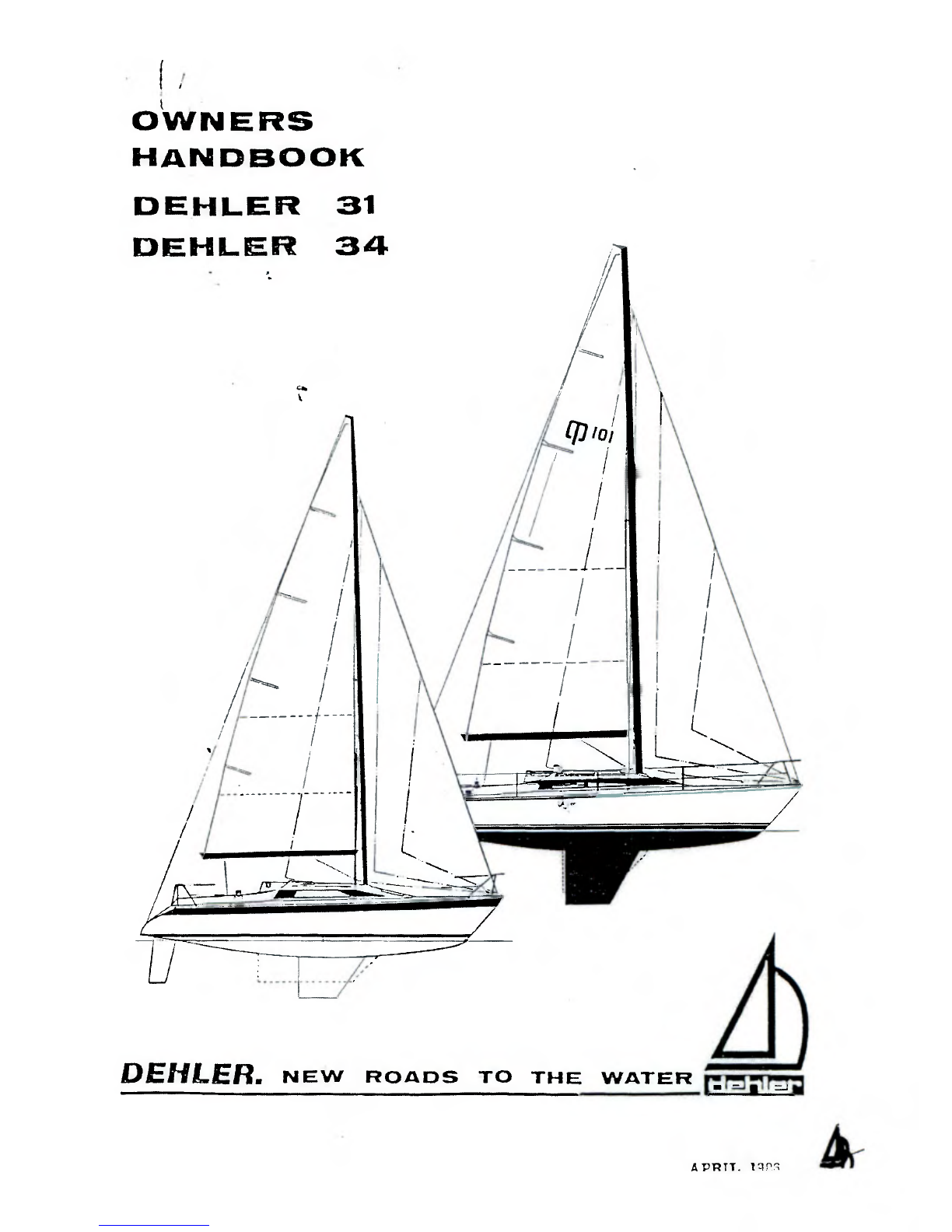

OWNERS

HANDBOOK

DEHLER 31

DEHLER 34

/

/

/

I

I

I

I

/

L

I

-,-

Li

DEHLER.

NEW ROADS TO THE WATER

r

no

Ai-

APPTT.

?P

DEHLER 31

HULL

(Approx):

SAIL AREAS

(App rox):

LO.R. RIG

(Approx):

PRINCIPLE DIMENSIONS

Length 0. A.

30.83 ft.

Length W.L.

24.27 ft.

Beam

10.17 ft.

Draft

4.75 ft.

Shallow draft (optional)

3.60 ft.

Displacement

7.

055

lbs

Ballast

2.866 lbs

Mainsail

282 sq. ft.

No.1 Genoa

296 sq. ft.

Total to windward

578 sq. ft.

No. 3Genoa

198 sq. ft.

Jib

140 sq. ft.

Storm Jib

61 sq.tt.

Trysail

81 sq. ft.

Spinnaker

678 sq. ft.

I

35.lOft.

J

-

1l.15ft.

L.P.

16.73 ft.

P

36.74 ft.

E

13.45 ft.

SL

34. 97 ft.

SMW

20. 07 ft.

9.40 m

7.40 m

3.10 m

1.45 m

1.10 m

3.2 to.ines

1.3 tonnes

26.2 sq.m

27.5 sq. m.

53.7 sq. m.

18.4 sq. m.

13.0 sq. m.

5.7 sq. in.

7.5 sq.m

63. 0 sq. m.

10.70 m

3.40 m.

5.10

M.

11.20 m.

4.10 m.

10.66 m.

6.12

In.

HULL

(Approx):

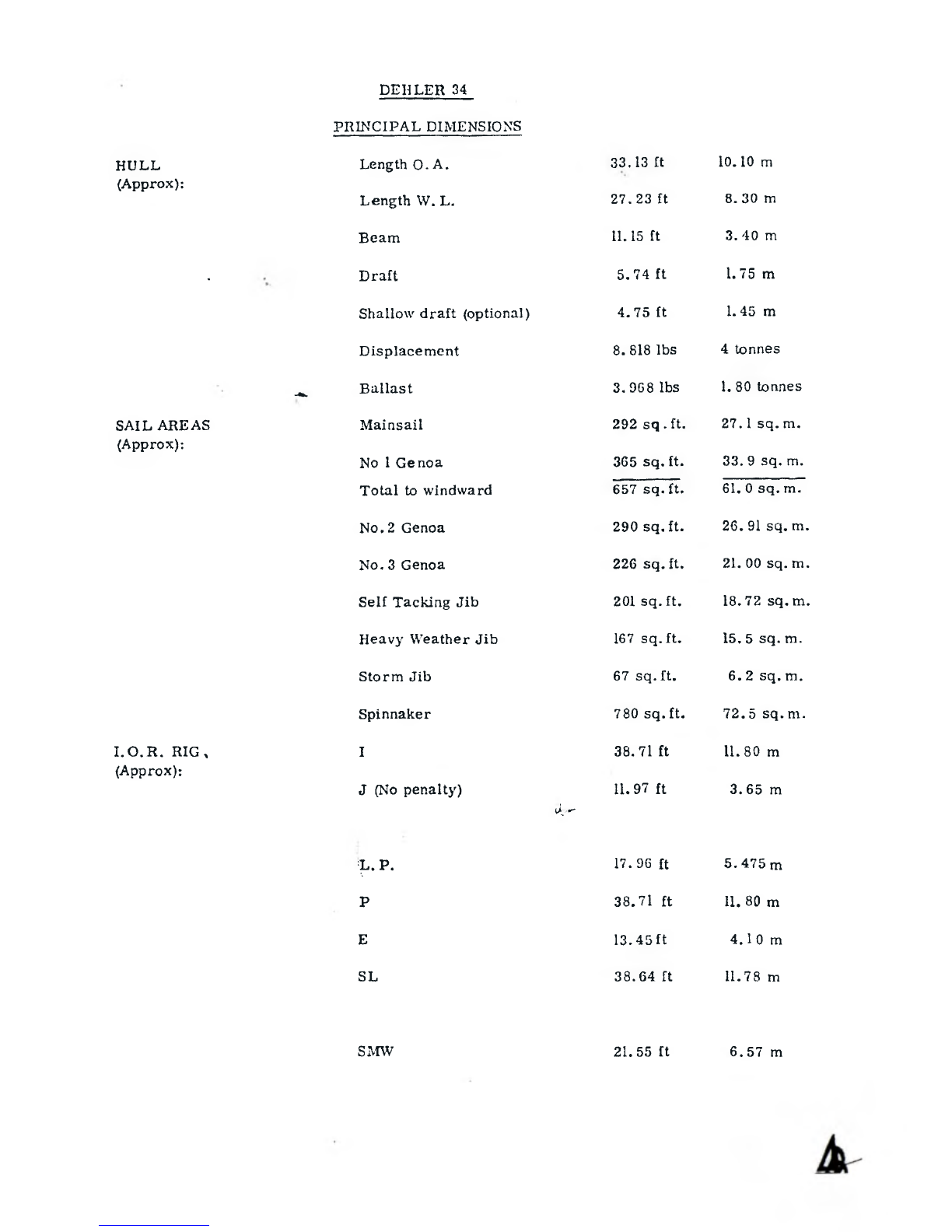

DEHLER 34

PRINCIPAL DIMENSIONS

Length 0. A.

33.13 ft

Length W. L.

27.23 ft

Beam

11. 15 ft

Draft

5.74 ft

Shallow draft (optional)

4. 75 ft

Displacement

8. 818 lbs

Ballast

3.968 lbs

Mainsail

292 sq -ft.

No 1 Genoa

365 sq. ft.

10. 10 m

8.30 rn

3.40 m

1.75 m

1.45 m

4 tonnes

1. 80 tonnes

27.1 sq. m.

33. 9 sq. m.

SAIL AREAS

(Approx):

Total to windward

657 sq. ft.

61. 0 sq. m.

No.2 Genoa

290 sq. ft.

26. 91 sq. m.

No. 3 Genoa

226 sq. ft.

21. 00 sq. rn.

Self Tacking Jib

201 sq. ft.

18.72 sq. m.

Heavy Weather Jib

167 sq. ft.

15. 5 sq. m.

Storm Jib

67

sq.

ft.

6.2 sq. m.

Spinnaker

780 sq. ft.

72.5

sq. m.

I.C.R. RIG

I

38.71 ft

11.80 m

(Approx):

J No penalty)

11. 97 ft

3.65 m

L.P.

17.96 ft

5.475 m

P

38.71 ft

11. 80 m

E

13.45 ft

4.10 m

SL

38.64 It

11.78 m

SMW

21.55 It

6.57 m

Alan BourdonYachts Ltd

42 Constitution Hill Road. Poole, Dorset BH 14 OQD

Tel Parkstone (0202) 741911

AT Reg 323645I Th

Our Ref: AJB/CEV

DEHLER 34/DEFILER 31

SAILING RECOMMENDATIONS

GENERAL OBSERVATIONS

The Dehler 34 and Dehler 31 class yachts can both be regarded as good performance

family cruiser racers. In other words they not only serve as excellent family cruising

yachts, they can be raced with success. The Dehler 34 hull form has been taken from

the same mould as our previous race winning Dehler dbl 1.0. R. Championship winning

yacht. The slightly modified current Dehler db2

S'-1,744

Z7Z is still

about 80%dbl

hull form. You will see therefore in the case of the Dehler 34 we have produced a

potentially very fast racer cruiser which will perform well under I.0.R., the new

Channel Handicap Rating System for cruiser racers, also in Club Handicap competition.

RUNNING

Due to their moderate to light displacement these yachts are capable of surfing indeed

sometimes planing downwind, which coupled to their J rig, fair sweet sections, excellent

stability and powerful semi-balanced spade rudders, will give an excellent control. Both

yachts are capable when running of carrying spinnakers in winds In excess of 40 knots

true. Under these conditions the yachts can plane in excess of 15 knots which in turn

reduces the apparent windspeed to about 25 knots. There is never any tendency for the

yachts to bury their bows or roll in heavy weather down-wind conditions, providing you

tack down-wind. Compared to a masthead rig it is even more important with a J rig

to always tack down-wind with the apparent wind on the weather quarter. When sailing

down-wind slacken off the adjustable standing backstay, ease the kicking strap slightly

to straighten the mast. This will assist in balancing the

-

helm in both reaching and

running conditions. Also ease the mainsail luff and foot tension, also the genoa luff

tension, to maximise full flowing sails.

REACHING

The Dehler 34 and Dehler 31 class yachts due to their good stability coupled to a rig

configuration can carry a full size spinnaker when reaching in quite strong winds. In

the light of experience we have found that a narrow headed heavy weather spinnaker is not

really worth the investment. When the wind becomes too strong to sensibly carry a

spinnaker on any reasonable point of sailing allowing the boat to heel too far and broach,

you will sail much faster maintaining a straight line course by flying a genoa or heavy

weather headsail. You can soon check this point by checking and assessing your speed

through the water. Naturally the broader the reach the longer you can carry a spinnaker

In a given wind strength. It follows you can, at times, when in doubt carry a spinnaker

j) sail low then reach up under genoa to the next mark. Ihis tactic can often pay, particu

Dehler Ydch

Directors:

continued/

Alan Bourdon

Julia Bourdon

Vdn I)

F)

2

larly when sailing on a long off-shore race. The chances are in long races the wind

direction invariably changes giving you the advantage of carrying a spinnaker all the

way. This is a judgement you can only make on the day of the race

)

coupled to an

assessment of the weather pattern, charts, tidal flow and E.T.A. to the next mark

on the course. Please forgive me for perhaps stating commonly known much accepted

facts and getting myself involved with racing tactics, a complex subject, well explained

by many people who are far more competent than I. The point I am attempting to

stress is the importance of complete concentration particularly under reaching con-

ditions when the crew can at times sit back and switch off. There can be no doubt

about it, when reaching (and indeed running) under really heavy weather conditions

the genoah3s very definite advantages over a spinnaker allowing you, for example

)

to steer a much steadier and straighter course to the next mark. It is deceptive, you

always appear to be travelling faster when a yacht is well heeled and making a lot of

fuss through the water. This Is not so, check your speed.

TO WINDWARD

The Van de Stadt Designed Dehier 31 and Dehier 34 class yachts enjoy a good performance

to windward, due to their excellent stability. This is where the rig configuration

with adjustable backstay pays, in that you can control the mainsail shape so effectively,

flat in strong winds and full flowing in light winds opening the leech with a good twist

away, particularly in the top third of the sail. Adjusting the kicking strap to windward

with particular reference to the way the mainsail leech can be set is most important

to get the best from any fractionally rigged yacht. Mainsail luff, foot, cunningham and

flattening reef tension is of importance to achieving the best sail shape to windward.

In wind strangths up to 25 knots (apparent) you can still just about carry an unreefed main-

sail well flattened and feathered with a well twisted open leech and the main boom set

well down the track. in this wind strength we would recommend hoisting a 110% almost

full hoist No. 3 genoa, in other words reduce the genoa overlap quickly as wind speed

increases as opposed to previous thinking, i.e. reefing the mainsail and carrying a

larger overlap genoa. Excessive genoa overlap demands the sheeting of the mainsail

well inboird due to the backwinding effect between the two sails, a situation that has

been maintained for many years, particularly with masthead rig yachts where the genoa

becomes the main driving force. In other words with J rig yachts the mainsail must be

made to work more efficiently to windward by reducing the overlap quickly and allowing

the sail to twist away, especially above the main hounds. To windward with particular

reference to J rig and the reintroduction of large mainsails, a good mainsheet man can

be regarded as just about the most Important crew member on deck, especially when

beating to windward.

BASIC POINTS TO REMEMBER

(a) Never overpress the yacht so that the vessel heels over 25 degrees continuously.

In gusting conditions, however, heeling in excess of 25 degrees for short periods is

acceptable as you must carry sufficient sail to perform efficiently in the average wind

strength prevailing. This is where the mainsheet man in careful adjustment and easing

the main boom down the mainsheet track can be regarded as just about the most important

crew member on deck.

continued

/

-~r

3

(b)

Sail flutter particularly in the leech of the main sail does not appear to slow

the boat down when sailing in hard winds or gusting conditions.

(c)

You will win more races by "flowing and going" rather than "pinching and

flinching". The only time it pays to pinch a little is when the yacht can just leebow

an adverse tide.

(d)

More races will be won by easing sheets. There is a tendancy generally among

the crew as tension mounts in close racing conditions, to over pin the mainsail and

certainly the headsail.

(e)

Keep the yacht in first class condition at all times. Delegate crew members

to being reponsihie fotmaintaining certain items of equipment. For example,

greasing winches, frequently checking for chafe in the rig and sails with particular

reference to mast sheaves, blocks, etc.

(f)

Keep the yacht light by checking and if necessary by removing all gear and

equipment not required by the racing rules on the day of the race - remember

these yachts are capable of planing.

(g)

Bottom finish is all important. For the cost of applying anti fouling and the

heavy labour costs of thereon smoothing and burnishing the anti fouling, perhaps

twice a year, you can in preference sail on a polished gelcoat finish and scrub

afloat say every 10-14 days. Alternatively "dry sail" the yacht just like the dinghy.

SAIL COMBINATIONS TO WINDWARD

1.

Full mainsail with varying degrees of mast bend, luff and foot tensions, also

cunningham and flattening reef tension with a No.1 light Mylar genoa up to 16 gusting

18 knots apparent. Note:- in the light of new experience we do not see the point in

investing in a number 1 heavy genoa as light Mylar sails appear to cope very well

throughout this wind range.

2.

Full mainsail well flattened and a No.2 Mylar (perhaps Keviar reinforced)

genoa from 16-22 knots apparent wind speed.

3.

Full mainsail sheeted down the mainsheet track, very well flattened with an

open twisting leech and a 110% No.3 Mylar/Kevlar genoa from 20-25 knots apparent

wind speed.

4.

1 or 2 reefs in a well flattened mainsail sheeted down the mainsheet track, and

a No.3 Mylar/Keviar genoa from 23-30 knots apparent wind speed.

5.

2 or 3 reefs in a well flattened mainsail set well down the mainsheet track,

and a No.4 Mylar/Kevlar genoa (heavy weather jib) from 28-40 knots apparent

wind speed.

AGAIN WE REPEAT - NEVER OVERPRESS THE YACHT ON ANY POINT OF SAILING

continued/

0

RIG CONTROL

-

PORT

RiG CONTROL

-

STARBOARD

1.

Spinnaker topping lift

5.

Main Boom Kicker

2.

Genoa Halyard

6.

Mainsail Halyard

3.

Reef 2

7.

Spinnaker Halyard

4.

Reef 1

8.

Spinnaker Downhaul

SELF TACKING .118 SYSTEM

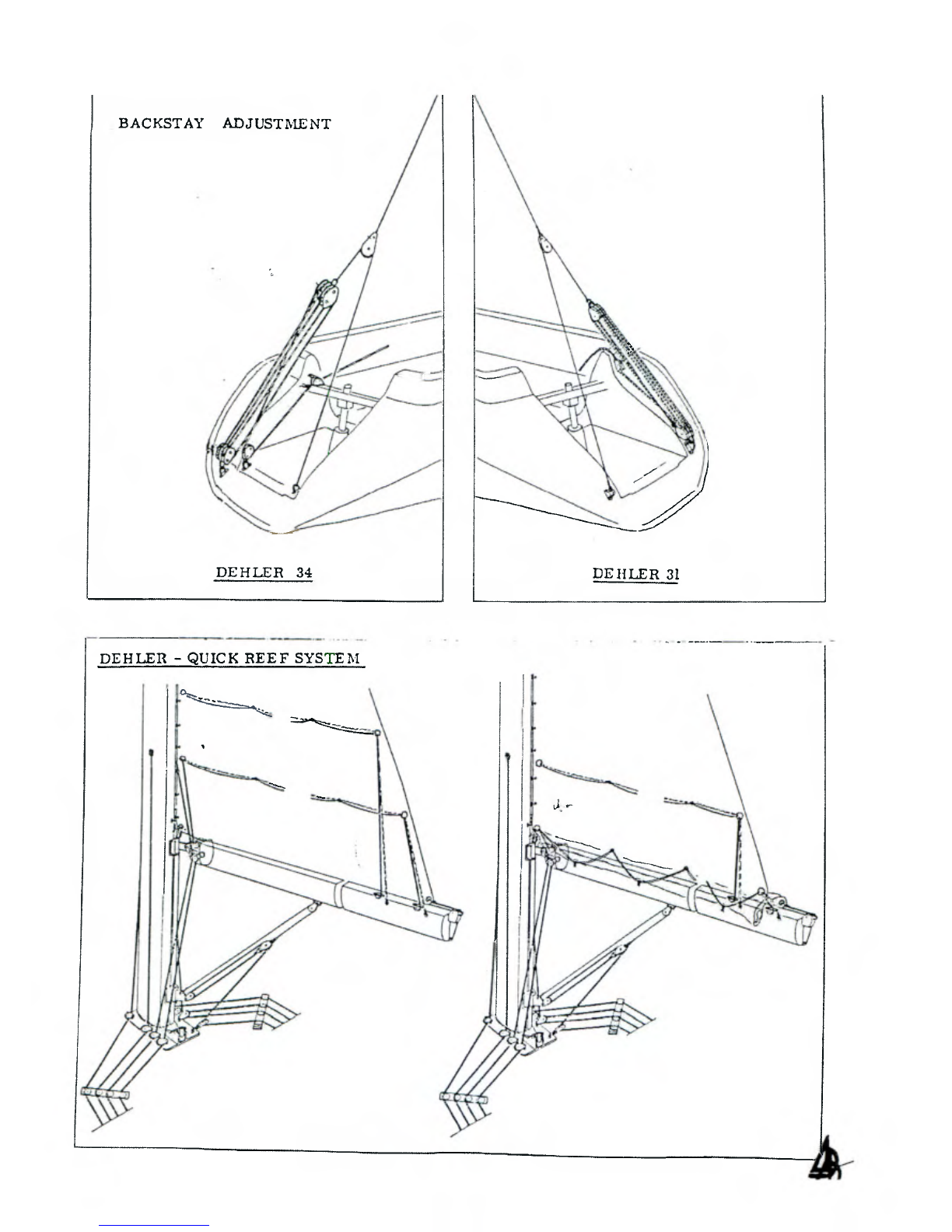

DEHLER - QUICK REEF SYSTEM

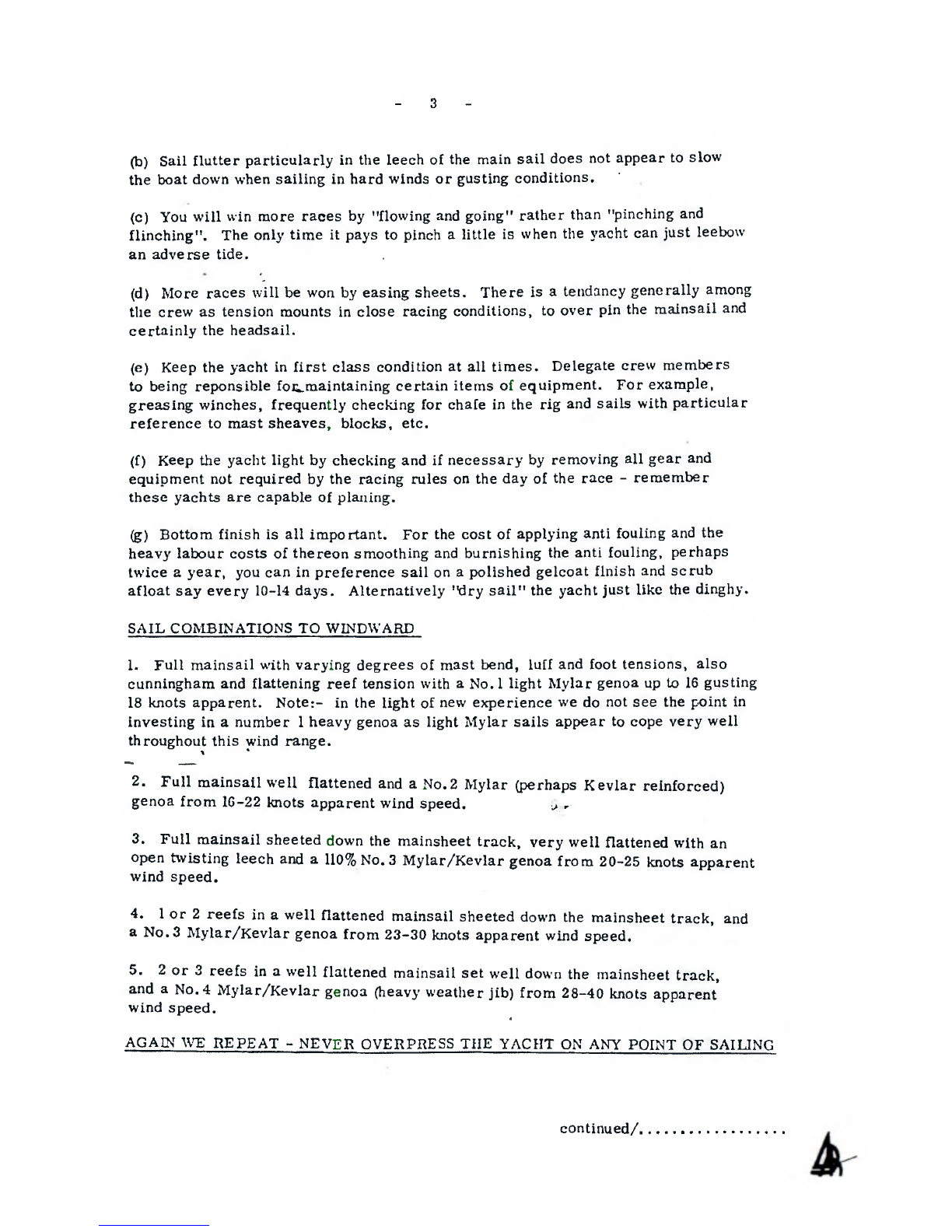

BACKSTAY ADJUSTMENT

DEHLER 34

DEHLER 31

—

T

I N

a

Wd

~

N,,Zj

cl

S

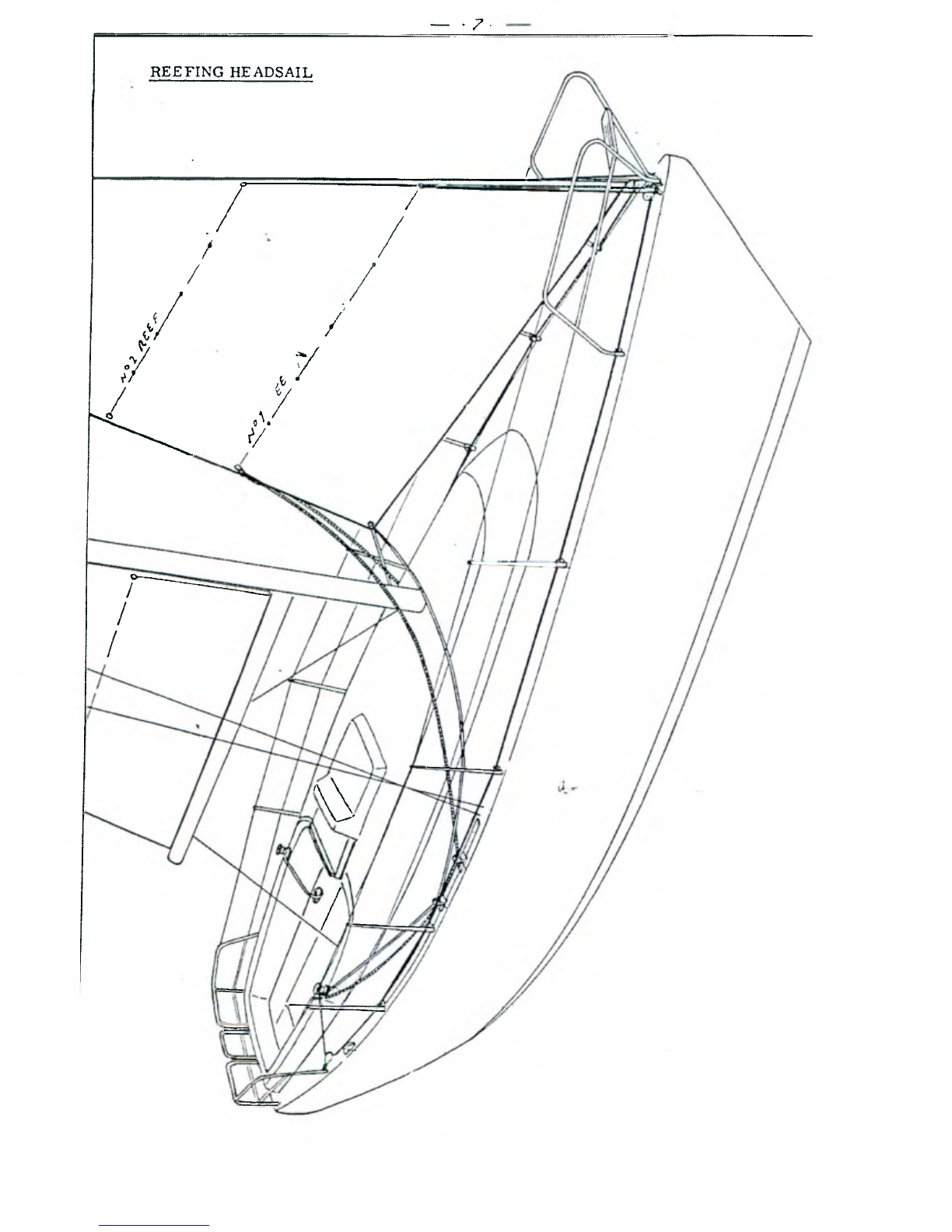

REEFING HEADSAIL

/

8

With reference to the DEHLER 31 class yacht. Bearing in mind her more moderate design

compared to the I. OR. influenced DEHTFR 34 hull form, also her very good sail area to

wetted area and displacement, it may well be, with particular reference to windward sailing,

that you nuy have to reduce the sail area more quickly compared to the DEHLER 34. As the

latest yacht within our range further experience is required before we can give precise

recommendations On sailing the yacht at her best. However, it is fair to say as a fast

family cruising yacht designed to the same formula as the DUETTA 86 G.S., also the

larger DEHLER 372, that the DEHLER 31 will perform extremely well on all points of

sailing in varying wind strengths.

THE FOREGOING INFORMATION AND WHEN TO REDUCE SAIL IN A GIVEN WIND STRENGTH

ARE BASED ON THE dbl/db2 ALSO DEHLER 34 UNDER HARD RACING CONDITIONS. WHEN

CRUISING YOU WILL WISH TO REDUCE SAIL EARLIER AS WIND SPEED INCREASES.

THE BEST HELMSMAN AND CREW WILL BE ABLE TO MAINTAIN MAXIMUM BOAT SPEED

WITH THAT LITTLE EXTRA SAIL AREA AS INDICATED. CONVERSELY THE MORE

EXPERIENCED HELMSMAN AND CREW WILL KNOW JUST WHEN TO REDUCE THE SAIL

AREA AND STILL WIN RACES.

The foregoing recommendations are given as a general guide and are based on our collective

experience sailing dbl and db2 class, also DEHLER 34 class yachts, in at times, top World

Championship race winning conditions. There will always be slight differences between yachts

and the current thinking of keen racing yachtsmen and sailmakers. I am sure these sailing

recommendations, however, will help and assist in getting the best out of your fine new

DEHLER YACHT.

Continued/

April 1986

PAGE 9

DEHLER 31/34

FAMILY CRUISERS AND CRUISER RACERS

RECOMMENDATIONS FOR CARE AND MAINTENANCE

FORWARD

We trust the following advice will assist you in maintaining your fine new DEHLER yacht

in first class condition. Much of what we say is common knowledge but we feel there is

no harm in putting it down in print.

MOULDINGS

Mouldings generally can be maintained in good condition by washing down regularly with

fresh water and in the case of stains these can be removed with mild detergents or T-Cut

polishing compounds. We believe that at least once every season the smooth area of

mouldings should be lightly polished with first a T-Cut compound and then polished with

one of the many proprietory glassfibre polishes on the market today. This will help to

maintain the rich lustre within the pigmented gelcoats and reduce bloom. Deeper scratches

and abrasions can generally be rubbed down by wet and dry sandpapers and worked up to a

high finish by the use of cutting compounds, T-Cut and finally polishing. Very deep abrasions

that cut through the gelcoat surfaces which are nominally about 20 tho' thick can be cleaned

out and filled with pigmented polyester resins prior to rubbing down and re-burnishing.

Should the yacht be severely damaged we suggest repairs should be put in the hands of an

experienced Company conversant with handling G.R. P. repairs. The yacht can also be

repaired by Dehler where it might, for example, be necessary to mould new sections of

hull and deck and, thereon graft them into the existing G.R.P. fabrication. We can supply

colour pastes and pigments to ensure the best possible colour match. It must be emphasised,

however, due to colour fade over a period of years we cannot guarantee giving you an exact

colour match. Due to the physical characteristics of G.R. P. mouldings severe damage, for

example, a hole in the hull is usually restricted to a local area and will not affect the general

structural integrity of the yacht. It is also fair to say that even if the hull is ruptured the

characteristics of G.R. P. normally mean the laminate will spring back to its original shape

confining what could be a serious leak into a very small leak of water into the hull. For

example, the writer was aboard a seriously damaged Van de Stadt designed G. R. P. yacht

some years'ago where the hull was badly holed below the water line. With careful pressure

from a seaboot the laminate sprang back into place and was then supported by the anchor

chain in a sail bag in the bilges until the yacht could be hauled ashore some hours later.

Very little water entered the yacht at this time and was eaiIy coped with by the powerful

bilge pump provided.

KEEL

Both deep and shallow draft options are constructed in cast iron and when leaving the factory

are surface coated with three coats of epoxy resin, painted and anti fouled. The keels are

fastened into the hull with stainless steel studs, nuts and plate washers. It is unusual tint

keel bolts should need to be hardened up on this form of construction as opposed to a lead

keel. The keel is initially bonded to the hull with a silicone mastic. If over a period of years

the keel shows signs of rusting particularly over the lower surfaces due perhaps to the yacht

being grounded, the areas affected can be cleaned and wire brushed and painted with a pro-

prietory brand of rust proofing paint prior to re anti fouling.

DEHLER 31/34

SPARS

Spars are painted or anodised with generally alloy or polished stainless steel fittings. It is

inevitable that spars will get scratched and rubbed over a period of time. There is no way

in which an annodised spar can be painted due to the fact that there is no adhesion to this

form of surface treatment. In other words, annodised spars will either have to be stripped

and re-anodised or stripped and painted.

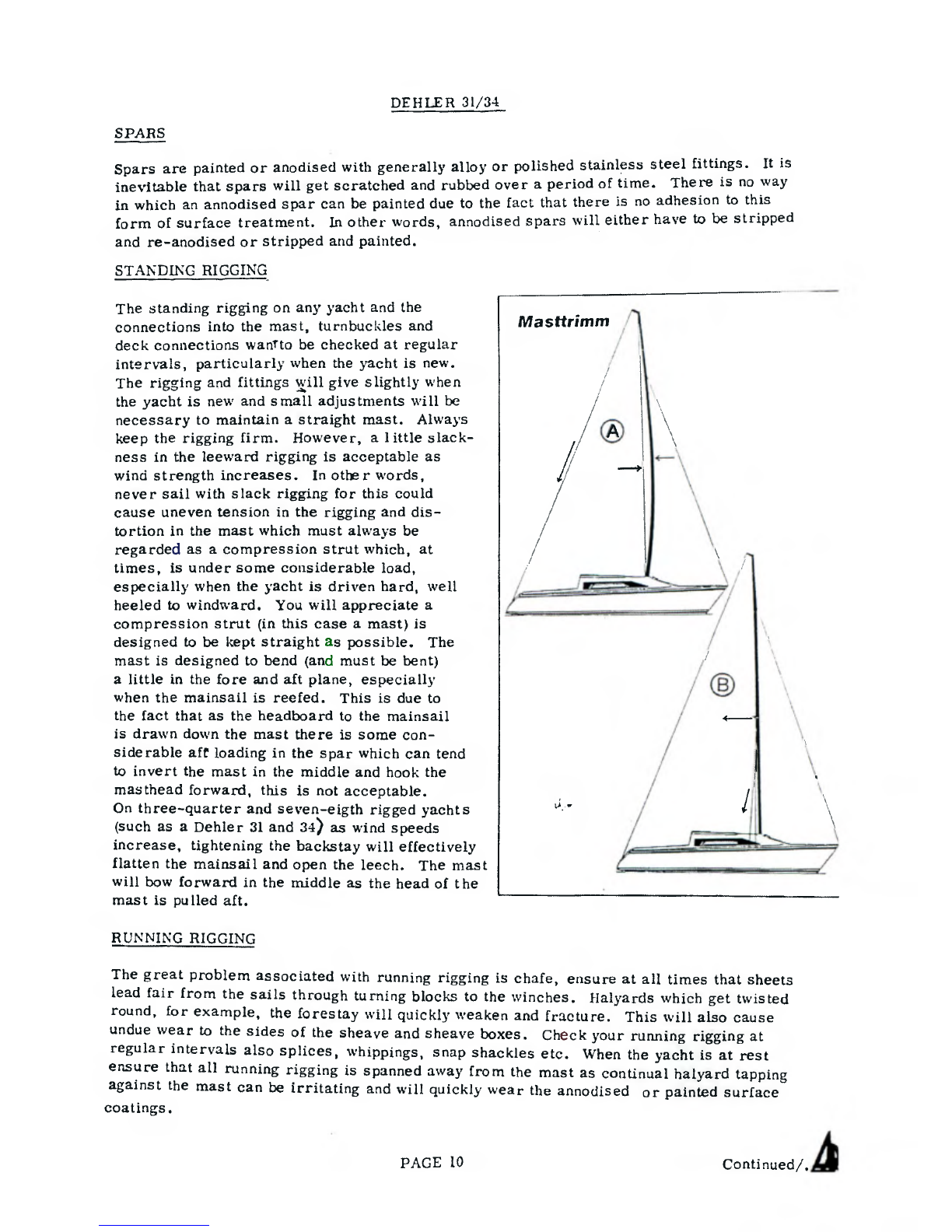

STANDING RIGGING

The standing rigging on any yacht and the

connections into the mast, turnbuckles and

deck connections wanito be checked at regular

intervals, particularly when the yacht is new.

The rigging and fittings

will

give slightly when

the yacht is new and small adjustments will be

necessary to maintain a straight mast. Always

keep the rigging firm. However, a little slack-

ness in the leeward rigging is acceptable as

wind strength increases. In otber words,

never sail with slack rigging for this could

cause uneven tension in the rigging and dis-

tortion in the mast which must always be

regarded as a compression strut which, at

times, Is under some considerable load,

especially when the yacht is driven hard, well

heeled to windward. You will appreciate a

compression strut (in this case a mast) is

designed to be kept straight as possible. The

mast is designed to bend (and must be bent)

a little in the fore and aft plane, especially

when the mainsail is reefed. This is due to

the fact that as the headboard to the mainsail

is drawn down the mast there is some con-

siderable aft loading in the spar which can tend

to invert the mast in the middle and hook the

masthead forward, this is not acceptable.

On three-quarter and seven-eigth rigged yachts

(such as a Dehler 31 and 34) as wind speeds

increase, tightening the backstay will effectively

flatten the mainsail and open the leech. The mast

will bow forward in the middle as the head of the

mast is pulled aft.

RUNNING RIGGING

The great problem associated with running rigging is chafe, ensure at all times that sheets

lead fair from the sails through turning blocks to the winches. Halyards which get twisted

round, for example, the forestay will quickly weaken and fracture. This will also cause

undue wear to the sides of the sheave and sheave boxes. Check your running rigging at

regular intervals also splices, whippings, snap shackles etc. When the yacht is at rest

ensure that all running rigging is spanned away from the mast as continual halyard tapping

against the mast can be irritating and will quickly wear the annodised or painted surface

coatings.

PAGE 10

Continued/

DEHLER 3

1

/

3

4

DECK FITTINGS AND WINCHES

Turning blocks can very often create undesirable side loads and stress into deck fittings.

Ensure that blocks always lay fair to the deck fitting and in line with loads imposed by

sheets and halyards which can, at times, be under some considerable strain.

The modern winch is a highly engineered product and most reliable in operation providing

you keep it well lubricated at very regular intervals. It is surprising how quickly salt

granules from spray wash away this lubrication. Many owners think they require bigger

winches, a situation which is generally solved by servicing their existing winches.

Check lifelines and their terminals (never tolerate slack lifelines) stanchions, pushpit

and pulpit connections at very regular intervals as they can be subjected to pretty heavy

loads at times.

RUDDER

The rudder is designed to be a semi-balanced spade configuration and is usually made from

a very hard loam plastic casting encapsulating the aluminium rudder stock. The rudder

stock has a series of web frames welded to the general structure to adequately support the

rudder blade. Rudder blades are sometimes encased within a light glass re-inforced plastics

moulding. Rudder bearings are generally constructed in water lubricated nylon. Anti-fouling

should be applied as the general underwater surfaces of the yacht.

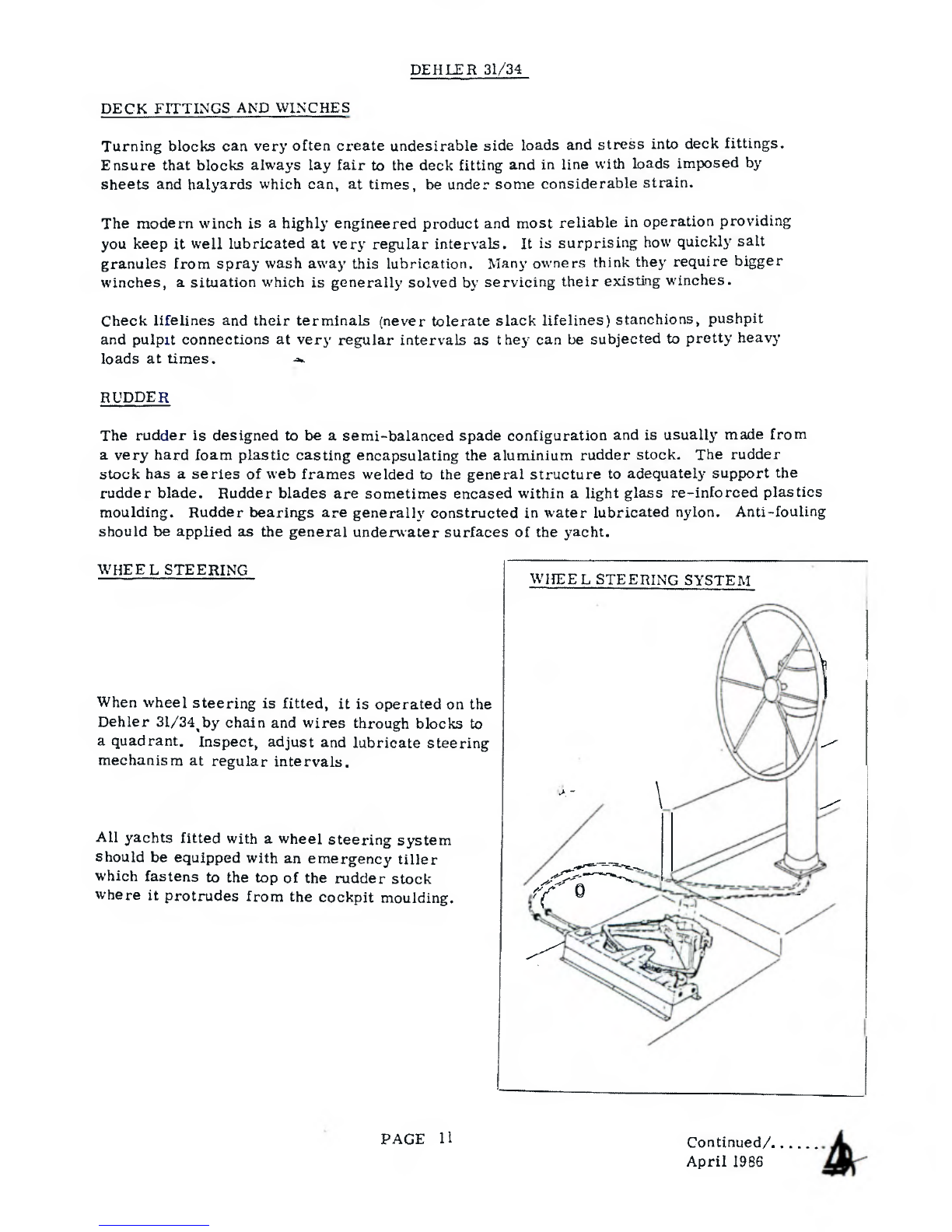

WHEEL STEERING

WHEEL STE FlUNG SYSTEM

When wheel steering is fitted, it is operated on the

Dehler 31/34,by chain and wires through blocks to

a quadrant. Inspect, adjust and lubricate steering

mechanism at regular intervals.

All yachts fitted with a wheel steering system

should be equipped with an emergency tiller

which fastens to the top of the rudder stock

where it protrudes from the cockpit moulding.

Continued/

April 1986

4—

PAGE 11

DEHLER 31/34

TILLER STEERING

When a tiller is fitted it is connected directly to the top of the rudder stock and there is

usually a friction lock device incorporated which allows you to leave the helm from time

to time when sailing short handed. On leaving the vessel, especially in tidal conditions,

always securely lash the tiller so that the rudder is fore and aft in the vessel. Never

steer the yacht with the tiller raised above the designed limit as this will distort and

strain the connection to the rudder stock.

COMPASS

The modern compass is very efficient in its operation but it is advised that when the

yacht is new a Compass Adjuster is employed to check the yacht through 360 and also

check for heeling error. Ensure that no metal objects are put close to the compass as

it can cause deviation. The addition of a handbearing compass is always worthwhile

equipment, for example, the Brookes and Gatehouse Herron D. F. equipment. If in

doubt, the main compass can be checked from time to time against a good handbearing

compass.

SAILS

Manmade fibre sails can be hard worked but remember to wash them down regularly

with fresh water and stow in a dry condition. If you have to stow when wet spread the

sails away from cushioned upholstery or make a loose stow in the sail bag provided.

Check the sails regularly for chafe on the stitching, especially around the batten pockets £

where the sail can rub against lifelines and standing rigging. Never leave the mainsail

bent on the boom for long periods without using a sail cover, sunlight affects the strength

of synthetic sail cloth, particularly nylon. All headsails not in use or being dried out

should be kept stowed in their sail bags. Always fold sails carefully before stowing in

their sail bags for this will improve general stowage below decks significantly.

ENGINE

The modern liesel engine has proved to be very reliable. An instruction manual Is

included with the ship's papers and maintenance recommendations should be observed

at all times. Regular checks should be made on the engine and gearbox oil levels

(particularly when new)and we believe it is fair to say that it will extend engine life

to change the engine oils and filters very regularly as recommended. You will note

an engine hour meter is fitted as standard and this is of great benefit when servicing

your engine to the maker's recommendations.

Check the alternator drive belt tension at regular intervals, particularly when new, due

to initial stretch. A spare fanbelt should be provided in the yacht's equipment, also

engine tools and engine spares generally, for example, a water pump impellor and drive

belt should always be carried on board. In this respect the engine, manufacturers are

ready with recommendations, help and advice.

The propellor shaft inner bearing is provided with grease cap lubrication or a sealed

bearing. A sealed bearing can be lubricated every 200 hours and/or once per year.

Ensure the shaft is well lubricated at all times and it is recommended when fitted, two

full turns of the grease cap are made every two hours the engine is running and always

when the engine is shut down. A tin of high melting grease should be provided with the

PAGE 12

Continued!

April 1986

DEHLER 31/34

ENGINE (continued)

ship's inventory for lubricating the stern gear, also for cable linkages to throttle and

gear box etc. The propellor shaft outer bearing is usually a rubber composition cutless

bearing which is water lubricated. This can be checked once a year (more frequently

in shallow mud or sandy waters) and replaced, if necessary.

When starting the engine ensure that the combined single lever throttle gear change

is in neutral and set as recommended by the engine manufacturer. As soon as the engine

has started, throttle back to a fast tick-over and ensure that a good flow of cooling water

passes through the exhaust system which can be observed from the exhaust outlet at the

transom. A noisy exhaust indicates a restriction in engine cooling water.

In general terms it is recommended that the engine runs between half and three-quarter

throttle. This will give you good boat speed and economical fuel consumption. If the

engine is allowed to labour under load this can quickly be seen by the emission of black

oily smoke from the exhaust outlet.

A folding geared propellor is usually fitted and may stick if the yacht is out of use and

afloat for some length of time. Always check that the propellor blades open freely by

checking the installation in gear prior to leaving your mooring. Scrubbing and regular

inspection will ensure reliable operation. If a non geared propellor blade is fitted and

sticks in the feathering position when the engine is put into gear a very harsh vibration

will immediately be felt. Throw the engine out of gear IMDIATELY and check the

propellor. A propellor running out of balance for any reason will quickly damage the

stern gear and most certainly fracture a "P" bracket, if fitted. A zinc waster is fitted

to the propellor shaft adjacent to the "P" bracket and this should be inspected and changed

at regular intervals depending upon where the yacht is located.

FUEL TANK

The fuel tank is vented to atmosphere and is fitted from a deck filler marked "FUEL", a

little vaseljne wiped around the threads of the fuel filler will ensure a watertight joint.

Fuel contents gauges are sometimes fitted. When laying the yacht up, especially during

the Winter months, always fill the fuel tank as this will reduce condensation.

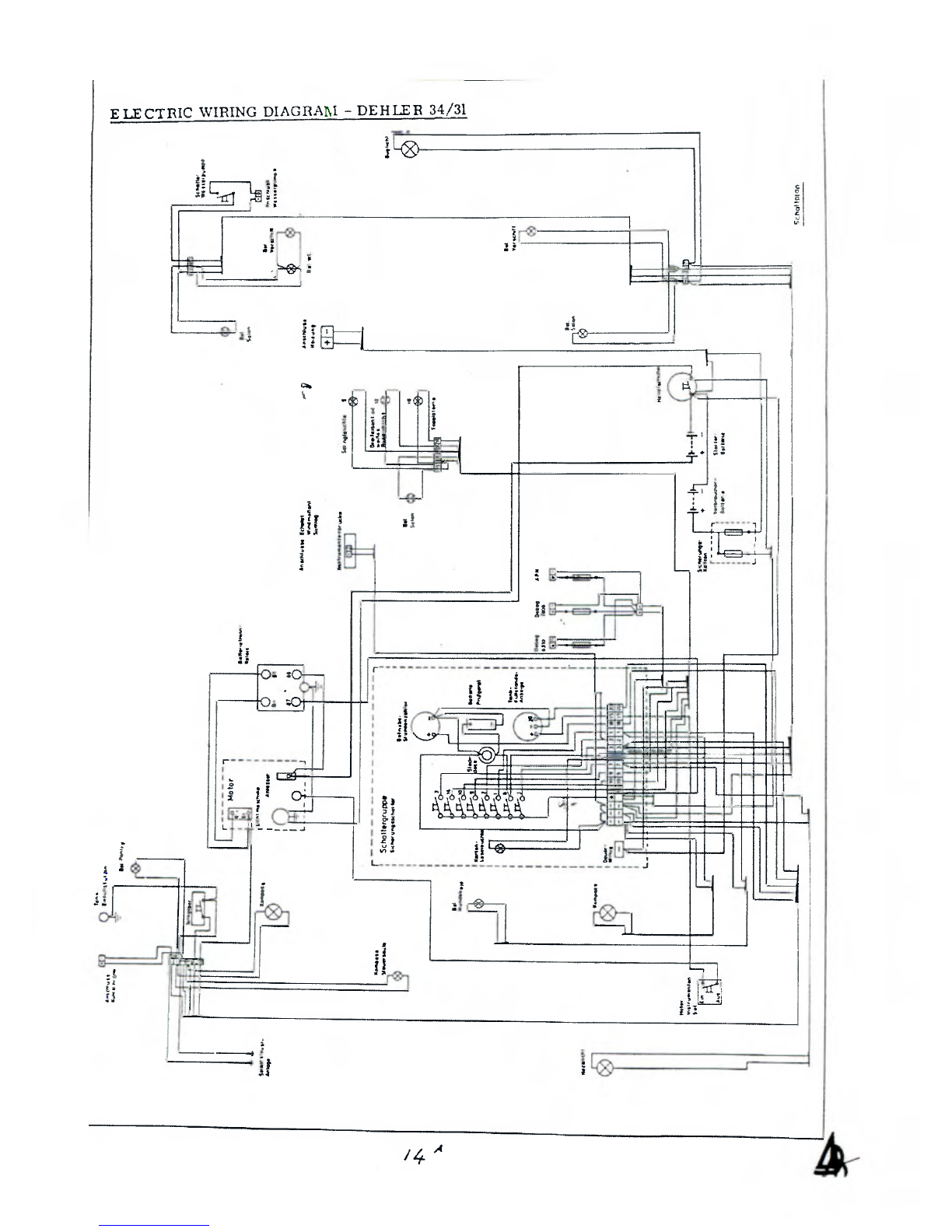

ELECTRICAL SYSTEM

A one or two battery 12 volt D. C. system is employed to service the general electrics

throughout the yacht. The second battery, when fitted, is wired for engine start only.

The battery (batteries) is charged by the engine driven alternator or through a shore

line which can be fitted as an extra. The shore line brings 220/240 volts A. C. current

converting to 12 volt D. C. for charging the batteries with the addition of an A. C. socket.

NEVER TURN OFF THE BATTERY ISOLATION SWITCH (OR ENGINE IGNITION

SWITCH) WHEN THE ENGINE IS RUNNING AS THIS WILL IMr'VIDIATELY DAMAGE

THE ALTERNATOR AND REGULATOR SYSTEMS.

'ihe battery isolation switching when turned on immediately energises the electrical

system throughout the yacht, i.e. engine start, general lighting, etc.

A

fuse box or

circuit breakers are provided for protection with Individual switching to navigation

lights, steaming light, night illumination of instruments, compasses etc,etc. A

socket is also provided into which a powerful light/signalling lamp (ship's scarer)

PAGE 14

Continued/

0: :01

0.

zQ

r

i

Ar

/4

H(

T

r

-J

I

ii

ELECTRIC WIRING DIAGRAM - DEHLIR 34/31

2L

I

I

r

000000000

1

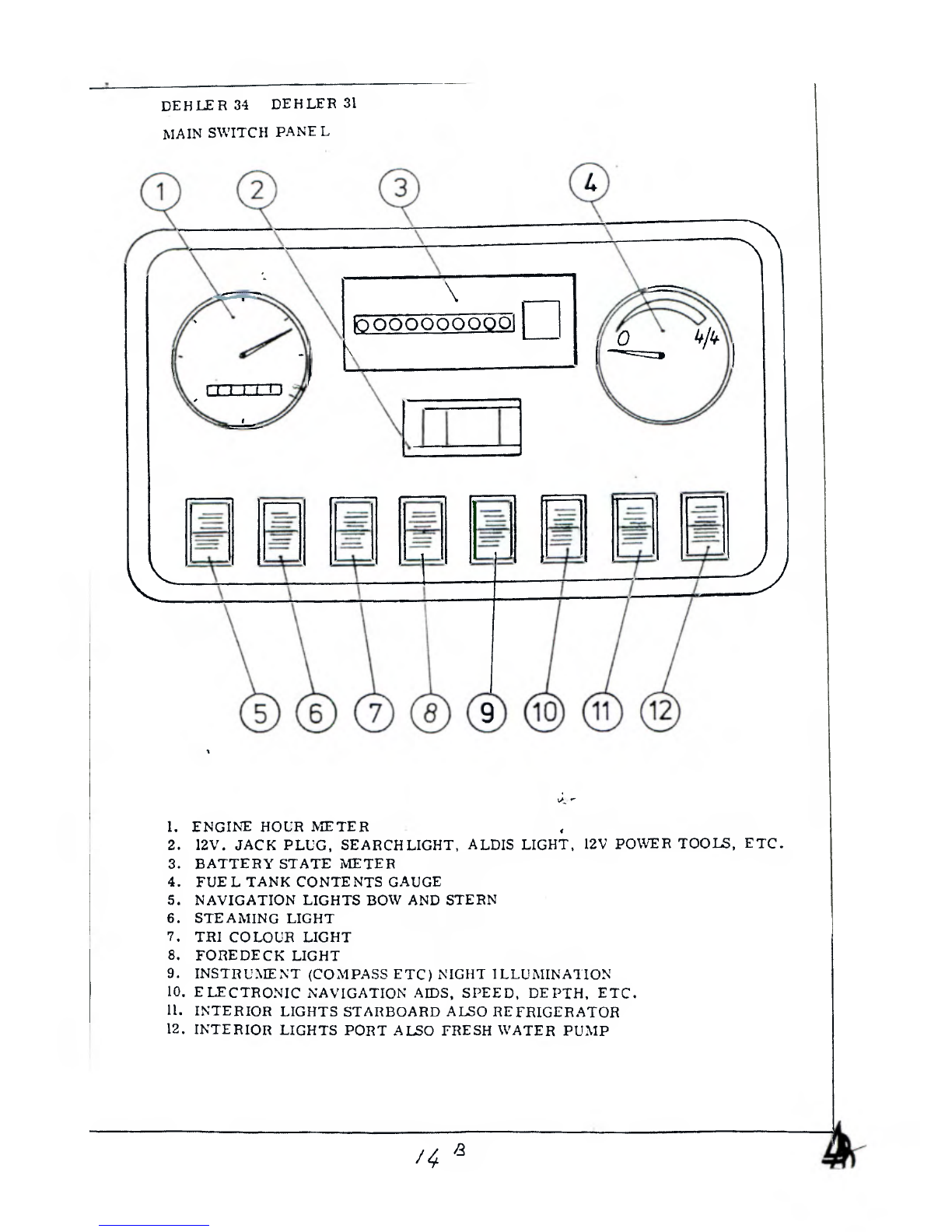

DEHLER34 DEHLER3I

NIA IN SWITCH PANEL

1.

ENGINE HOUR METER

2.

12V. JACK PLUG, SEARCHLIGHT, ALDIS LIGHT, 12V POWER TOOLS, ETC.

3.

BATTERY STATE ITER

4.

FUEL TANK CONTENTS GAUGE

5.

NAVIGATION LIGHTS BOW AND STERN

6.

STEAMING LIGHT

7.

TRI COLOUR LIGHT

8.

FOREDECK LIGHT

9.

INSTRUMENT (COMPASS ETC) NIGHT ILLUMINATION

10.

ELECTRONIC NAVIGATION ADS, SPEED, DEPTH, ETC.

11.

INTERIOR LIGHTS STARBOARD ALSO REFRIGERATOR

12.

INTERIOR LIGHTS PORT ALSO FRESH WATER PUMP

DEHLER 31/34

can be plugged. Inspect and clean electrical connections with particular reference to

on deck connections and wipe a little Vaseline around the threads of all water tight

electrical deck sockets at regular intervals. Ensure spare fuses and light bulbs,

especially navigation light bulbs, are kept on board.

Ship's batteries are located in their own individual stowages held down by webbing

straps either under the quarter berth arrangement or at the fore end of the saloon.

Check acid levels at regular intervals, especially in Summer conditions. If you

appear to be using an excessive amount of distilled water to top up batteries It could

well be the alternator regulator system is at fault by overcharging and "boiling"

the batteries. The gas emitted from a boiling battery is dangerous and a Specialist

should be called up immediately to inspect the electrical system should a fault occur.

WATER TANKS

The water tank or tanks are vented and come complete with a deck filler marked

"WATER". A changeover valve is provided on a two tank installation, one tank can

therefore be kept in reserve.

A pressure

water system is employed to the galley sink and wash-hand basins. If a shower is fitted

this also operates from the pressure water system. It Is recommended that a spare

can of "sweet "water is carried on the yacht and kept in reserve in case of contamination

to the main water supply. A little Vaseline wiped around the threads of the water filler

cap will ensure a watertight joint. For Winter lay-up or under very cold conditions

drain the water tanks and pipe lines, also water heaters if fitted.

ACCOMMODATION

The accommodation can be kept in good condition by lightly polishing or oiling all woodwork

a few times each season. Carpets, cushions and settee backrests are in an easy clean

textile material. Should they get wet, ensure that they are dried as soon as possible,

'1

wash with fresh water to remove all salt granules.

BILGES

Due to the shallow design of the yacht's bilges, a little bilge water can travel a long way.

Keep the bilges as dry as possible at all times for general comfort below. Sponge

s placed

between the keel floor frames will collect and stop the general surge of bilge water and

they can be easily squeezed into a bucket. It is of prime importance to maintain good

regular house-keeping practices below decks, particularly when sailing off-shore on

extended cruises. Keep the yacht interior dry, clean and well ventilated.

SE ACOC KS

Locate and note all seacocks and under water fittings and note their positions in the hull.

It is recommended that all seacocks are turned OFF when not in use, apart from cockpit

drains (when fitted) which are usually left open at all times. Ensure at all times that

seacocks operate smoothly and are kept well lubricated. Check pipe connections to all

through hull fi:tings regularly.

PAGE 15

Continued/

April 1986

DEHLEII 31/34

GAS INSTALLATION

The gas bottle is located in a drained container usually under one of the cockpit seats.

If the Gaz system is employed, a spare bottle can be stowed with the Gaz bottle in use

in the one container. A gas tap is fitted to the bottle and should always be turned off

when not in

use.

A second gas tap is fitted in the galley locker bulkhead and a flame

failure device fitted-to gas burners when the German legislation system is installed.

It is recommended that the gas installation be checked at regular intervals and that the

flexible pipe to the galley stove and gas bottle are changed every two years.

CHECKLIST

It is advisable to make checklist for when boarding and leaving the yacht. For example,

when leaving the yacht:-

(a)

Turn off gas and electrics.

(b)

Turn off seacocks (apart from the self-draining cockpit valves when fitted), dry

bilges, clean interior

'

'-This can affect your Insurance Policy.

(c)

Check the mooring chain, or lines and fenders when moored,

D

"i.' a Marina to

ensure security with particular reference to chafe.

(d)

Secure the sail cover, ensure halyards are secured and spanned away from the mast.

Ensure the mainsheet is well secured.

(e)

Centralise rudder, secure and lash tiller or wheel.

(f)

Check and fill or replace water, fuel and gas bottles for the following weekend.

(g)

Remove flags and ensign (penalty - drinks all round in the Club bar).

(h)

Ensure that all holdalls and clothing are accounted for, for example, young

Johnnie

Is

favourite and irreplacable toy (at that moment in time) etc.,

(j)

Check hatches are secured - who holds the yacht's keys?

(k)

Allow yourself time to check and double check for the elements can be hard and

unrelenting on a yacht and her gear.

On behalf of Van de Stadt Designs, Dehier Yachtbau GmbH, also ALAN BOURDON

YACHTS LIMITED, we wish you fine sailing and great enjoyment. We trust the

foregoing recommendations are of help in maintaining yourwessel but hasten to

add that as you become more conversant with the design and layout of your fine new

DEHLER yacht the list will, no doubt, be extended.

Please have no hesitation in contacting us at any time should a query arise which may

eventually affect the function of the yacht. Because we race and cruise the yachts we

build we are always around to offer a first class advisory and After Sales Service.

Alan Bourdon Yachts Limited,

42, Constitution Hill Road,

Parks tone,

Poole,

Dorset, BHI4 OQD

Telephone No:-. (0202) 741911.

PAGE 16

April 1986

This manual suits for next models

1

Table of contents

Other Dehler Boat manuals