Dehler 35 cws User guide

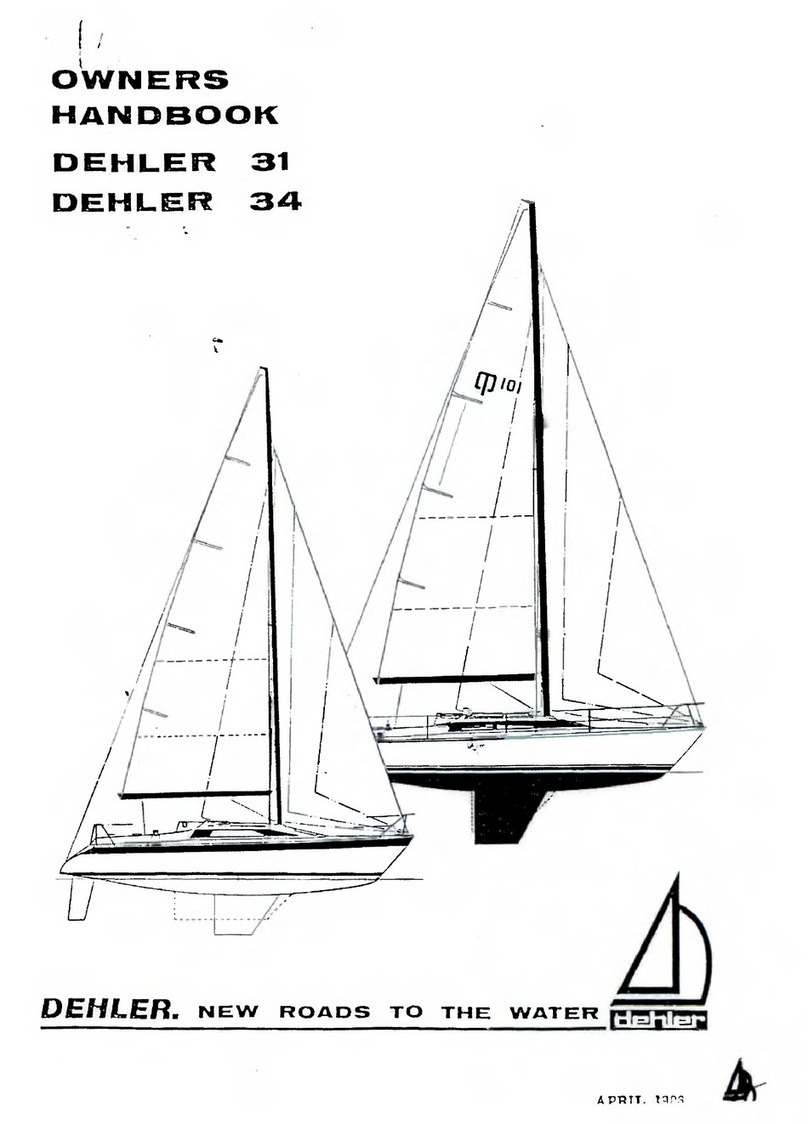

Owner’s Handbook

DEHLER 35 cws

L.O.A. 10.50 m

L.W.L 9.20 m

Beam max. 3.30 m

Superstructure Height above WL 1.70 m

Draft, upside-down keel. 1.90 m

Draft, wing keel. 1.50 m

Displacement. 5,100 kg

Ballast. 2,200 kg

Mainsail. 37 sq. m

No. 1 jib 24 sq. m

High-aspect jib 24 sq. m

Masthead Genaker 70 sq. m

Storm jib 8 sq. m

Mast Height above WL 16.20 m

Water Tank. 100 litre/ 2x 100 litre

Diesel Tank. 65 litre

Holding Tank. 50 litre

Battery 1x 90 / 110 Amp Hr.

Or 2x 115 / 135 Amp Hr.

Gas Bottle, Camping Gaz 1 x 3 kg

Yanmar inboard diesel engine

Standard specification 2 GM 18HP

Additional specification 3 GM 27HP

F= Dual circuit cooling system

Owner

A

Boat Name

L

Build Number

5

-

1

Dehler 35 cws

1

https://www.boat-manuals.com/

Contents

Preface ………………………………………………………………………………………………………… 5

Rigging ………………………………………………………………………………………………………….6

Craning …………………………………………………………………………………………………..6

Shaft Seal.………………………………………………………………………………………….…….6

Your First Task.…………………………………………………………………………………….…….6

Preparing to step the mast……………………………………………………………………………..7

Rigging the mast….……………………………………………………………………………………..8

Fitting the masthead attachments……………………………………………………………………..8

Stepping the mast……………………………………………………………………………………….9

Tuning the mast………………………………………………………………………………………...11

DEHLER Main-Drop-System………………………………………………………………….…………….12

Attaching the boom / Fitting Main-Drop canvas……..……………………………………………..13

Bending on the Mainsail…………………………………………………………………………………….14

Patches…………………………………………….…..……………………………………………….15

Inserting & tensioning the sail battens………….…..……………………………………………….15

Routing Control Lines to the Central Winches.…………………………………………………………16

Headsail………………….…………………………………………………………………………………….17

Topp-Reff roller headsail system……………….…..……………………………………………….17

Winch system………………………….………….…..……………………………………………….18

DEHLER quick-reefing System…………………………………………………………………………….19

Masthead Genoa………………………………………..……………………………………………..20

Storm Jib………..………………………………………..……………………………………………..21

Sail handling…..………………………………………..………………………………………………21

Basic Rules for trimming 7/8 rig..………………………………………………………………………….22

Headsail Trim…..………………………………………..……………………………………………..24

Mainsail Trim.…..………………………………………..……………………………………………..24

Dehler 35 cws

2

https://www.boat-manuals.com/

Rudder System………………………………………………………………………………………….…….25

Wheel Steering..………………………………………..……………………………………………...25

SOLIMAR Wheel Steering system………...………………………………………………………...25

Steering Pedestal..….…………………………………..……………………………………………..25

Compass………….….…………………………………..……………………………………………..27

Rudder Bearings…….………………………………..………………………………………………..27

Emergency Tiller……….……………………………..………………………………………………..27

Anchor……….. ……………………………………………………………………………………………….28

Bow Anchor with Electric Windlass…………………..……………………………………………...28

Stern Anchor Arrangements…………………..…………………………………………….………..29

Engine Installation..………………………………………………………………………………………….30

Servicing…………………………….…………………..……………………………………………...30

Winterizing………………………….…………………..……………………………………………...30

Engine Controls – starting the engine……………..…………………………………………….….30

Centraflex shaft coupling……………..…………………………………………….………………..31

Fuel Supply……………….……………..…………………………………………….……………….31

Warranty….……………….……………..…………………………………………….……………….31

Shaft arrangement…………..…………………………………………….…………………………..32

Folding Propeller..…………..…………………………………………….…………………………...32

Drinking Water System……..…………………………………………….…………………………...32

Skin Fittings & Stopcocks…………………………………………………………………………………..33

Electrical System……………………………………………………………………………………………..34

Battery Capacity…………..…………………………………………….……………………………..34

Instrument & Switch Panel……….…………………………………….……………………………..35

Switch Panel……….…………………………………….……………………………………………..35

Shore Power Supply Terminal………………………………….…………………………………….36

Navigation Lights/ Mast lights.………………………………….…………………………………….37

Switch Boxes for Electric Winches……….…………………….……………………………………37

Circuit Diagram…………………….……….…………………….……………………………………37

Maintenance of Electrical System.……….…………………….………………………………….…37

Circuit Diagram…………………………….…………………….…………………………………….38

Engine Circuit Diagram………………….…………………….………………………………………39

Dehler 35 cws

3

https://www.boat-manuals.com/

Switches & Fuses……….………………….…………………….……………………………………40

Main & Secondary Electrical Distribution Connectors.……….……………………………………40

Tracking Down Faults in the Electrical System……….……….……………………………………41

Servicing the Winches………………………………………………………………………………………42

Autopilot……………….………………………………………………………………………………………42

Maintenance………………………..……….…………………….……………………………………43

Central Heating System……………………………………………………………………………………..43

Operating the heating system on board….…………………….……………………………………43

Malfunctions……………………………..….…………………….……………………………………43

Interior Fittings/ Deck………………………………………………………………………………………..44

Refrigerator/Cool Box…………………..….…………………….……………………………………44

Drinking Water System……..…………………………………………….…………………………...44

Dirty Water Tank…………..…………………………………………….………………………….….44

Cockpit Shower………..…………………………………………….………………………….……..45

Hot Water…………………..…………………………………………….………………………….…45

Marine Toilet……………..…………………………………………….………………………….……45

Shower………..…………………………………………….………………………….……………….46

Bilge Pump…..…………………………………………….………………………….………………..46

Gas System……..…………………………………………….………………………….…………….47

Anti-slip Deck Covering……………………………………………………………………………….48

Dehler 35 cws

4

https://www.boat-manuals.com/

Dear Sailing Friend

Your DEHLER 35CWS has been built and fitted

out with the utmost care. We wish you many

relaxing and enjoyable hours of sailing in her.

Naturally, to get the most out of your boat,

proper handling and a little care and attention

are called for. In short, observe the age-old

principles of good seamanship, the first

requirement of which is that one should know

how to help oneself in any situation. This is a

principle with which any experienced

yachtsman will be familiar.

It is often the case with a brand-new boat that

minor finishing touches will be required.

Experience dictates that it takes a little time to

become fully acquainted with a new vessel,

and to further fit it out to one’s requirements.

We will of course be happy to offer any advice

or assistance you need in this respect. It is

generally assumed that a yachtsman of

average practical inclination will sort out minor

problems himself. It is on this basis that we

deploy our experts effectively in genuinely

serious cases.

Drawing on our accumulated expertise and

knowledge, we have come up with some tips

that you should note.

It may be that certain minor modifications

introduced during series production of these

boats cannot be immediately incorporated into

the descriptions given here. Please ask us if

something is not entirely clear to you.

One more thing: the DEHLER 35CWS is

designed and built to cover and unlimited

cruising range if it is fitted out to appropriately.

You can make long passages and withstand a

fair amount of rough weather without undue

concern, provided you have adequate sailing

experience to cope with any problems you may

encounter. If this is not the case, we advise you

to first familiarise yourself thoroughly with the

boat’s capabilities so as to avoid getting into

difficulty due to ignorance or foolhardiness As

the saying goes: “God comes to the aid of

sailors in distress, but the sailor must do the

steering himself”.

Happy sailing on your new DEHLER 35CWS –

and good luck.

Dehler 35 cws

5

https://www.boat-manuals.com/

Fig. 1 The DEHLER 35CWS is lowered into the water

Rigging Up

Make sure that

-The crane & slings have a safe lifting

capacity of at least 6 tons.

-The slings are of adequate width and

will not scratch the gelcoat.

-The slings will not push in the guardrails

(loosen the guardwires)

-The propeller, shaft and log impellor

remain clear of the slings (if necessary

retract the log impellor)

-All seacocks are closed

If necessary, use a sufficiently wide

crossframe (see illustration)

Your first task

Before the propeller turns for the first time,

the shaft seal needs to be vented. Squeeze

the seal with two fingers until a small

amount of water emerges at the front.

ATTENTION !

Venting should be repeated each time the boat

is hauled out of the water. (Venting must also

be carried out after drying out.)

Fig 2. Venting the shaft seal.

Dehler 35 cws

6

https://www.boat-manuals.com/

Preparation for Mast Stepping

If you decide to step and tune the mast

yourself, allow sufficient time. Even

professional yachtsmen, working in tandem,

need an entire day for this operation.

The mast comes supplied with fitted halyards,

lazy jacks and topping lift. Shrouds and stays

are fitted, together with their rigging screws. On

boats with fittings above the standard

specification, the masthead halyard, spinnaker

halyard, and pole topping lift are also fitted.

Lay the mast on two supports. Lay out the

shrouds, stays and halyards clearly.

If possible, choose a windless day to step the

mast.

Fig 3. Arrangement of the shrouds.

1. Upper shrouds

2. Upper spreaders

3. Middle shrouds

4. Lower spreaders

5. Lower shrouds

6. Auxiliary shrouds

TIP

Why not leave commissioning of your

new DEHLER 35CWS, including rigging

& tuning the mast, to trained experts at

one of our service centres?

TIP

The Gennaker and mainsail are

particularly at risk from chafe, caused by

prolonged contact with the spreader end

fittings. Protect this area using tape or

spreader boots

Dehler 35 cws

7

https://www.boat-manuals.com/

Fig. 4 Spreader end fitting, with stopper tubes.

Rigging the mast

Fit the spreader sections (long ones at the

bottom, short ones at the top). Self-locking nuts

are also provided.

The roller furling system, which forms part of

the cruising package, is supplied with the boat

as a complete kit with forestay. Assemble the

system and secure it to the mast mounting-

plate provided, as shown in the detailed

instructions.

Fix the upper and middle shrouds into the

spreader end-fittings, so that the stopper

ferrules pressed onto the shrouds lie below the

spreaders (see Fig. 4). The end-fittings are

fastened to the spreader sections by a screw.

Watch out for sharp edges (see Tip, Page 11).

Once the spreaders have been fitted, lay out

the lines clearly: Main Halyard & Topping Lift

aft of the mast, Jib, Spinnaker and/or masthead

Gennaker Halyards forward of the mast.

Signal Halyards (port & starboard) are attached

to the lower spreaders with a small block.

Belay the lines to cleats below on the mast.

The Main-Drop lines emerge from the mast

beneath the top pair of spreaders, and are first

led through small blocks under the spreaders,

then downwards. Lead the other lazy jack lines

through the eyes at the lower ends (see

diagram, Page 13) and secure them to the foot

of the mast for the time being.

Attaching Masthead fittings

Fit the Windex wind indicator, following the

manufacturer’s instructions on the packaging. A

threaded hole is provided in the masthead for

this purpose.

Fit the white all-round light (anchor light):

Remove the protective cap for both Tri-colour

and all-round lights (special accessory) and fit

the light onto the base.

To fit an electronic Wind Transducer:

The bracket is fitted to the masthead. Place the

arm of the wind transducer into it and tighten

the lock nut.

To fit a VHF aerial on the special brackets

already fitted on the masthead, follow the

manufacturer’s instructions.

If further cables are required for electronic

equipment, this can be drawn through with the

aid of the guide lanyard, which emerges at the

foot and head of the mast.

Dehler 35 cws

8

https://www.boat-manuals.com/

A strip of blue decorative tape is glued to the

sides of the mast, which can be used to

monitor mast trim. The tape is vulnerable to

chafing. Watch out for this when stepping the

mast, or when the boat is laid up for winter.

Fig. 5 Preparing the masthead for fitting the wind

transducer, aerial and tri-colour light

Fig. 6 Fitting the Wind Transducer

Fig. 7 Masthead with Windex fitted.

Stepping the mast

Prepare the Backstay tackle, as shown in the

diagram on Page 10.

Place a hoisting loop with two eyes around the

mast, equally spaced between the two pairs of

spreaders. Attach the two eyes to the crane hook.

The loop encircles all the lines, and should be

secured to prevent it riding up the mast, by a line

that is belayed to the foot of the mast.

TIP

Lengthen the guide lanyard by as much

again when using it. When inserting a

cable or line, the extended lanyard will

be drawn through the mast with it and is

then ready for feeding further

cables

/lines.

TIP

You will save time by having all the

rigging screws unscrewed to the same

length. Remove the lower split pins and

clevis pins from the rigging screw forks.

TIP

Use a hoisting loop long enough to drop

back down with the hook, once the mast

is stepped, so that it lies within easy

reach and can be released.

Dehler 35 cws

9

https://www.boat-manuals.com/

An experienced crewmember is now required

to take hold of the foot of the mast while it is

being raised upright by the crane, and guide it

to the leadthrough in the deck. The mast foot

and tabernacle are designed so that they seat

automatically below deck, and no further

adjustment is needed.

As soon as the mast has been stepped, it

should be secured to prevent it from falling

over. The roller furling system, shrouds and

stays can now be attached in the usual

sequence.

Fig. 8 1. Upper single blocks

2. Triple block

3. Triple block with becket

4. Lever clutch

5. Securing strop

Mast collar for deck leadthrough

Care is required when fitting the mast collar

each time the mast is stepped, as any mistake

will result in leaks around the mast. Fig. 9

illustrates the arrangement. The mast is sealed

off inside (8), and any water that penetrates the

mast drains off through the drain hole (2). A

sealing strip seals the mast between the

section and the collar.

Before the collar is fastened to the deck yoke,

a supporting rubber gasket can be inserted into

the gap and secured with a band clamp. If the

mast is not watertight, water will collect in the

inner cover (6) or run down into the boat

between the mast section and the inner mast

casing (7).

Fig 9 Mast leadthrough

1. Mast

2. Drain hole

3. Mast collar

4. Hose clip

5. Inner skin

6. Plastic cover

7. Mast casing

8. Seal inside mast

9. Sealing strip

10.Supporting rubber gasket

11. Deck

12. Deck reinforcement

13. Mast section

Dehler 35 cws

10

https://www.boat-manuals.com/

Tuning the mast

Fasten the shrouds to the eyes of the

chainplates, as shown in the diagram on

Page 7.

The forestay/roller furling system is of fixed

length and has no rigging screw. Tighten

the standing backstay tackle so that the

mast bends aft.

Tension the upper and middle shrouds

equally, so that the section flexes forward

by roughly 2 mast widths. Then draw the

mast back by one mast width using the

lower and auxiliary shrouds. To do this,

measure the distance between the threaded

rods in the rigging screws.

Now tension the remaining shrouds in pairs,

one after the other.

A glance up the mast track will reveal

whether the shrouds have been tensioned

equally: the mast track must be straight and

there should be no S-bend in the mast.

The standing backstay must always be

under tension when sailing. The limit strop

prevents the line from running out.

Fig. 10 Shrouds can be tensioned more easily with a

mole wrench & spanner.

TIP

A 21mm open-jaw spanner (or mole

grips) and a spanner of sufficient size

are suitable tools for tensioning the

shrouds.

TIP

A permanently attached and taut Main

halyard secured to the gooseneck can

be used to monitor the success of the

tuning operation

TIP

The clevis pins in the rigging screws

should run through the chainplate

eyes from outboard to inboard. Wrap

tape round the rigging screws to

prevent the sharp ends of the split

pins, used for securing, from causing

injury.

Dehler 35 cws

11

https://www.boat-manuals.com/

Fig 11. When the distance between the threaded

rods in the rigging screws is the same, then the

respective pair of shrouds is trimmed correctly.

The DEHLER Main-Drop-System

Battened Mainsail with integral canvas

sleeve and furling lines (lazy-jacks) for the

7/8th rig of the DEHLER 35 CWS.

Fully battened sails were first used

successfully on yachts many years ago,

and have now been revived thanks to the

development of new types of sailcloth.

The new cut of the battened Mainsail offers

the perfect combination of Mainsail

trimability and ultimate ease of handling.

The full-length battens maintain the efficient

shape of the Mainsail and prolong its life,

preventing the sail from flogging noisily

when it is being set, stowed or reefed, and

thereby reducing strain on the material.

The sail battens ideally complement the

main-drop system with integral canvas

boom cover and lazy-jacks. Fixed to each

side of the boom is a strip of tough, durable

Vinyl fabric, which protects the stowed

Mainsail.

Once the zip has been unfastened, the

mainsail can be set. The strips on both

sides are held up by the lazy-jacks. When

the sail is being stowed, it drops down onto

the boom into the cover, guided by the lazy-

jacks. A quick straightening of the sail, then

close the zip and the sail is stowed.

If the Mainsail is to be out of use for any

length of time, cover it at the mast with the

extra canvas cover.

When moored up, ensure that the boom

slopes downward sufficiently aft enough to

allow rainwater to drain easily.

TIP

When lowering or hoisting the Mainsail,

make sure that the boat is lying exactly

head to wind.

TIP

Spray the mainsail slides

occasionally with a lubricant. This

will make it considerably easier to

hoist the mainsail.

Dehler 35 cws

12

https://www.boat-manuals.com/

Fig. 12 Attaching the furling lines (lazy-jacks)

Attaching the boom

Fitting the main-drop sailcover

Fit the boom on the gooseneck with the aid

of a crewmember and secure it with the

bolt. The topping lift is fastened to the eye

on end of the boom by a knot and the boom

is hauled into a horizontal by tensioning the

topping lift at the mast.

The mainsheet is routed partly through the

boom, and for this reason is secured on the

boom. The diagram on Page 14 shows how

the mainsheet line is routed. The Halyard

routing diagram on Page 16 shows the

routing of the mainsheet to the starboard

coaming winch.

Fig. 13 shows how the kicking strap is

attached, and the diagram on Page 16

shows how it is routed back to the cockpit.

Fig. 13 Boom kicking strap

Insert the boom cover for the main-drop

system into the grooves on the boom, from

fore to aft. The wide end of the cover should

be at the mast end, with the zip on the

inside.

Insert the stiffening battens into the batten

pockets in the cover, from fore to aft.

Dehler 35 cws

13

https://www.boat-manuals.com/

Attach the lazy-jack lines (furling lines) to

the cover sections, as shown in Fig. 14.

Belay the lines on their mast cleats.

Make sure that the topping lift is always

under greater tension than the lazy-jack

lines, otherwise these could be torn out of

the boom cover.

Mainsheet routing

Bending on the Mainsail

Fig. 14 Before bending on the mainsail, haul up one

side of the main-drop cover.

Make sure that the deck has been washed

before unpacking the mainsail.

-Guide the foot of the mainsail into the

boom groove, from fore to aft.

-Fasten the tack of the sail to the forward

boom fitting.

-Shackle the clew outhaul to the clew.

-Lift the slide stopper clear of the mast

track, feed the mainsail slides into the

mast track then close the slide stopper.

-Insert the sail battens into their pockets,

from luff to leech (see description on

Page 15).

-Shackle Main halyard to headboard.

Make sure that the halyard shackle pin

is properly engaged.

-Shackle the guide blocks for Reef 1 &

Reef 2 pendant lines to their leech

webbing strops.

TIP

Ensure that the batten ends are

protected by tape or a thin plastic cap.

TIP

Before bending on the mainsail, haul up

one side of the main-drop cover a little

way by its lazy-jacks, and let the other

side hang down. This makes it easier to

control the sailcloth.

Dehler 35 cws

14

https://www.boat-manuals.com/

-Fasten the forward end of the reef

pendant lines to the luff webbing/rings

with bowlines or patent hook.

Patches

When a boat is running with the mainsail

eased off, the sailcloth comes into contact

with the spreaders and shrouds. This

increased mechanical load can lead to

chafe, damaging the material and seams.

A battened mainsail is particularly prone to

chafe; therefore 14 patches are supplied

with the mainsail. These should be affixed

at precisely the points where the sail and

shrouds or spreaders come into contact.

Wait until the mainsail shows the first signs

of light soiling at the points where the

patches should be stuck on.

The area to be protected from the vertical

sections of the upper shrouds can be

measured, and patches can affixed here

before the boat is taken out for the first

time. Patches are stuck to both sides of the

sail at all points.

Fig. 15 Patches protect the mainsail against chafe.

Inserting and tensioning the sail battens

The sail battens are supplied bent into a

circle, and so are under tension. Caution is

advised when unpacking them.

Ensure that the ends of the battens are

always protected by plastic caps that are

glued in place.

First lead the fabric tongue on the

tensioning sleeve back through the

tensioner.

Fig. 16a

TIP

It takes two people to bend on the heavy

sail. Make sure that the sail slides are

inserted into the mast track in the correct

order, and that they are not upside down.

TIP

Put a figure-of-eight knot in the forward

reef pendant lines before unbending the

sail, to prevent them from disappearing

into the boom.

Dehler 35 cws

15

https://www.boat-manuals.com/

Feed each batten according to length under

the metal bridge of the tensioning device,

and into its relevant batten pocket, working

from fore to aft. Some adjustment of the

batten length may be required.

Guide the webbing tongue around the

forward end of the batten and back aft

under the metal bridge.

Fig. 16b

Thread the tongue into the clamping wedge.

Fig. 16c

Press the clamping wedge forward under

the metal bridge on the tensioning sleeve,

at the same time pulling on the tongue, and

then secure it with the lock tab.

Fig. 16d

Routing control lines to the Central

Winches

All halyards and reefing lines, together with

Jib Sheet and Kicking Strap, are routed via

deck sheaves and partly-concealed

conduits, to the coachroof winches or the

two coaming winches. The diagram in Fig.

17 suggests one way of leading the

halyards and lines aft.

Fig. 17 1. Port Jib Sheet

2. Reef 2/ Pole downhaul

3. Reef 1.

4. Port Jib car adjustment

5. Spinnaker halyard

6. Pole uphaul

7. Masthead fore halyard

8. Cunningham

9. Kicking strap

10. Jib halyard

11. Starboard Jib car adjustment

12. Mainsheet

13. Main Halyard

14. Starboard Jib sheet

15. Roller Reef line

The number of lines led aft will vary

according to specification.

Dehler 35 cws

16

https://www.boat-manuals.com/

If the boat’s specification includes a

spinnaker and the pole downhaul is to be

led aft, we recommend replacing Reef 2,

which is then taken forward and belayed on

the mast.

If possible, tie control lines together into a

bundle, which is fed aft using a length of

stiff wire.

When unrigging, don’t forget to pull

messenger lines through the outer halyard

conduits.

Fig. 18

Control lines, and a stiff wire, are bound with tape side-

to-side in a flat bundle, and are pulled aft through the

conduit below deck.

Headsail

Topp Reff 2090 below-deck roller

headsail system

The Topp Reff roller furling system has

been tried and tested on many boats. When

it is combined with the cruising jib and the

Dehler quick reefing mechanism, a wide

range of wind strengths can be covered

without having to change sail. Please refer

to Page 20. The system can be fitted and

dismantled easily on the specially extended

forestay. See the instructions on fitting

included among the documents

accompanying your boat.

Fig. 19 Roller furling system

TIP

It is difficult to pull lines with frayed ends

through the narrow duct. Check the ends

at the close of each season.

Dehler 35 cws

17

https://www.boat-manuals.com/

The forestay acts as the load-bearing

element in the roller system, with the tube

section foil being used only to furl the sail

evenly and cleanly. The system is attached

to the mast using the T-terminal toggle

supplied. When stepping the rig, the

complete system is raised up with the mast

and the foot of roller system is taken

forward. The drum is guided into the anchor

locker at the same time as the mast foot is

lowered through the deck aperture.

The control line runs under the deck and is

belayed on a clutch aft in the cockpit

coaming.

-Functioning of the system is guaranteed

only if the halyard swivel/slide is at the

end of the section tube when the sail is

bent on.

-Bear in mind that the control line, due to

the right-hand twist of the forestay wire,

must be reeled in counter-clockwise, so

that when the sail is being furled the

system rotates in a clockwise direction.

-Haul in the spinnaker halyard tight when

not in use, to prevent it being rolled up in

the Furler.

-When the boat is not in use for long

periods, furl the sail tightly and secure it

with a strop at the clew, or unbend it.

-A canvas headsail cover (with a

tensioning line at the back) will protect

the sail against ultra-violet radiation and

keep it clean.

DEHLER 35 CWS winch system

This system can only be fully exploited if the

cockpit coaming winch has an electric winch

motor. The electric switches for first and

second speeds are located in four easily-

accessible positions. Pressing a switch sets the

relevant coaming winch in motion.

Stow lines that are not in use in the line bags.

Mark all clutch levers to indicate which are for

sheets and which are for halyards. Instructions

on servicing the electric winches are included

in the information supplied by Harken.

ATTENTION !

The electric winch drive is very powerful,

and the winch should be used with care.

Halyards and reefing lines under extreme

load must be hauled in on the winch before

the clutch lever is released, otherwise the

lever mechanism will be damaged. If the

clutch lever is pointing aft horizontally, the

line is free to run.

TIP

The clutch lever for the leeward jib

sheet should always be pointing aft

horizontally,

Dehler 35 cws

18

https://www.boat-manuals.com/

DEHLER quick-reefing system

The DEHLER quick-reefing system, in

conjunction with the Main-drop system

facilitates swift and easy reefing of the

mainsail from the cockpit by a single crew

member. This applies to both the first and

second reefs.

Both luff and leech are hauled down onto

the boom at the same time, using the

reefing line.

Attach the two reefing lines as shown in the

diagram in Fig. 20.

Once the mainsail halyard has been

slackened off, haul Reef 1 or Reef 2 line in

tightly, using the electric winch.

ATTENTION !

If the forward reef cringle does not fall onto

the boom parallel to the aft cringle, you

must pull the rear reefing line. Failure to do

this will result in the cloth around the reef

cringle being torn.

The sail drops onto the boom between the

Main-drop cover sections. It is not covered.

The clutch is then closed on the reefing line.

Fig. 20 Guide block at the leech reef cringle.

The luff of the reefed mainsail is then re-

tensioned with the halyard.

The mainsheet, kicking strap and standing

backstay are then re-trimmed.

TIP

Before commencing reefing, slacken off

the mainsheet, Cunningham and

kicking strap.

TIP

Mark the clutch levers by the central

winch, to show which control the main

halyard and reefing lines.

Dehler 35 cws

19

https://www.boat-manuals.com/

Masthead Genaker

In light winds, a masthead Genaker of

approximately 70 square meters can be

carried instead of the normal jib or cruising

jib. With the Genaker, the DEHLER 35CWS

quickly reaches its best speed on any

course.

The masthead Genaker is set flying

between the spinnaker pole, which is

extended as a bowsprit, and the masthead.

Pull the tack of the sail to the eye of the

spinnaker pole, using a tack line that is then

belayed on a bow deck cleat. Haul the luff

tight using the masthead Genaker halyard.

The Genaker is controlled by sheets led

through blocks attached 9with stand-up

springs) to toe rail plates, and the coaming

winch which can be operated either

manually or electrically.

Roller-furled high aspect jib

The biradial-cut sail is manufactured from

differing cloth strengths. A continuous

fibreglass sail batten running parallel to the

forestay ensures that the sail is furled

cleanly.

The leech is cut concave and has no further

battens. The sail is also equipped with

trimming lines in the foot and leech.

The headsail sliding cars are infinitely

adjustable on their own tracks, and

adjustments are made by control lines led

to clutches on the coachroof to port and

starboard.

Fig. 22 DEHLER 35 CWS with masthead

spinnaker and normal spinnaker.

TIP

Hoist the sail in its sleeve (snuffer) with

the jib still up. Then ease the snuffer

sleeve up to the masthead and belay

the endless line to a mast cleat. Only

then should the jib be furled.

TIP

To achieve optimum sail shape after

the first reef stage, the sail batten must

be rolled up fully. When the sail is re-

trimmed, the upper and lower batten

ends should no longer be visible

Dehler 35 cws

20

https://www.boat-manuals.com/

Table of contents

Other Dehler Boat manuals