Deimic One Master User manual

ONE

Master

Installation guide

smart home for everyone

WARNINGS ...................................................................................................................................... 1

1. DEiMiC ONE MASTER DEVICE SPECIFICATION ......................................................................... 3

1.1. DESCRIPTION............................................................................................................................3

1.2. TECHNICAL DATA .....................................................................................................................4

1.3. THE DEVICE PINOUT DESCRIPTION ...........................................................................................5

1.4. APPLICATIONS..........................................................................................................................6

2. ASSEMBLY ................................................................................................................................... 7

2.1. PREPARATION TO ASSEMBLY....................................................................................................7

2.2. GUIDELINES..............................................................................................................................8

2.2.1. WIRES................................................................................................................................8

2.2.2. ELECTRICAL SWITCHGEAR................................................................................................10

2.2.3. CONNECTIONS INSIDE ELECTRICAL SWITCHGEAR.............................................................11

2.2.4. MARKING ........................................................................................................................12

2.2.5. GOOD ADVICES................................................................................................................13

3. EXAMPLES OF WIRING DIAGRAMS......................................................................................... 15

3.1. POWER SUPPLY CONNECTION................................................................................................15

3.2. NETWORK CONNECTION ........................................................................................................16

3.3. OUTPUTS CONNECTION - LIGHTS............................................................................................17

3.4. OUTPUTS CONNECTION –SHUTTERS......................................................................................18

3.5. OUTPUTS CONNECTIONS –GATES, GATEWAYS.......................................................................19

3.6. OUTPUS CONNECTIONS –LED LIGHTS ....................................................................................20

3.7. OUTPUTS CONNECTION –CONTACTORS ................................................................................22

3.8. INPUTS CONNETION –SWITCHES AND BUTTONS....................................................................23

3.9. MOTION SENSORS CONNECTION............................................................................................24

3.10. EXTENSIONS MODULES CONNECTION ..................................................................................25

4. FIRST START .............................................................................................................................. 26

4.1. TEST BUTTON.........................................................................................................................26

4.2. DEiMiC ONE MOBILE APPLICATION.........................................................................................26

4.3. FIRST START OF DEiMiC ONE APPLICATION.............................................................................27

5. GUIDELINES ............................................................................................................................... 28

5.1. ROLLER BLINDS, SHUTTERS AND MARQUISE...........................................................................28

5.2. GATE DRIVES..........................................................................................................................30

5.3. CENTRAL HEATING .................................................................................................................31

6. REVISION HISTORY ................................................................................................................... 33

CONTENS

1Installation guide DEiMiC ONE MASTER v1.8

WARNINGS

This instruction is a part of the product and shall be kept for future reference. Before

installation you should read product documentation, which contains important information

on the device settings and operation.

The module is comply with EU directives, including EMC 2004/108/EC, LVD2006/95/

EC. Declaration of Conformity is available on www.deimic.one.

The producer takes no responsibility for damages caused by inappropriate usage of the

device, inappropriate assembly or not obeying assembly instructions.

The installation must be performed in accordance with every safety standards for electrical

installations and electrical regulations .

The device should be installed by qualified electrician.

Every installation work should be done with power off.

Every repairs must be performed be authorized service only. Device modifications or repairs

done by anyone who is not authorized by the producer are forbidden and means lose of the

warranty.

To avoid risk of electrical shock never open the device and do not touch any

inside components of the device with your hands.

For safety reasons it's necessary to obey all the instructions in this document. Failure to

follow these instructions may result in death or serious injury.

DEiMiC company products are not intended for use in medicine, avionics and industry.

DEiMiC company devices should be installed inside rooms, in places available for a fitter and

conservator.

Remember to ensure proper ventilation for the device and do not expose it to the effects

of weather conditions.

Because of continuing products development, the producer reserves the right to change and

modify the device and its documentation without notice.

2Installation guide DEiMiC ONE MASTER v1.8

RoHS

WARNINGS (continued)

Utilization of waste electrical and electronic equipment is regulated by the EU directive

2002/96/EC. The Directive prohibits disposal of waste electrical and electronic equipment

with other garbage under penalty of a fine.

According to the law, worn out devices must be separately collected and sorted. Customers

should contact their local authorities or the seller to get information about disposal of a

waste electrical and electronic equipment.

3Installation guide DEiMiC ONE MASTER v1.8

1.

DEiMiC ONE MASTER

DEVICE SPECIFICATION

1.1. DESCRIPTION

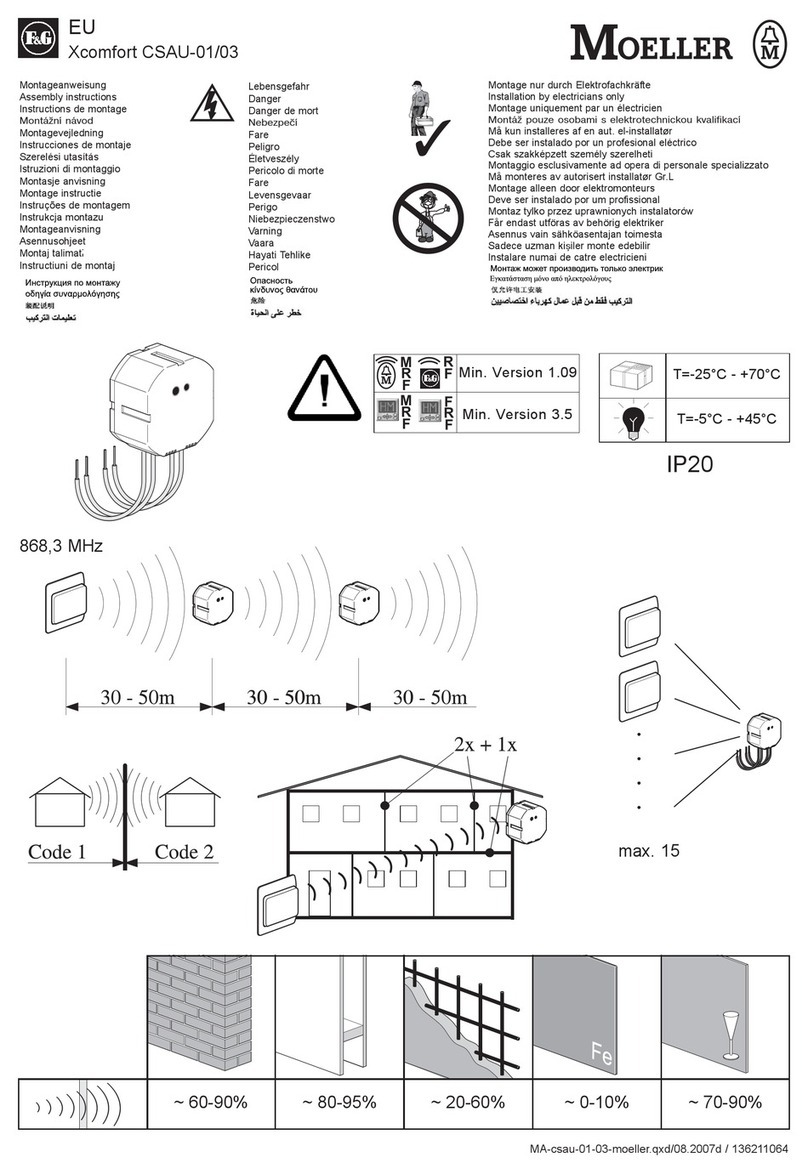

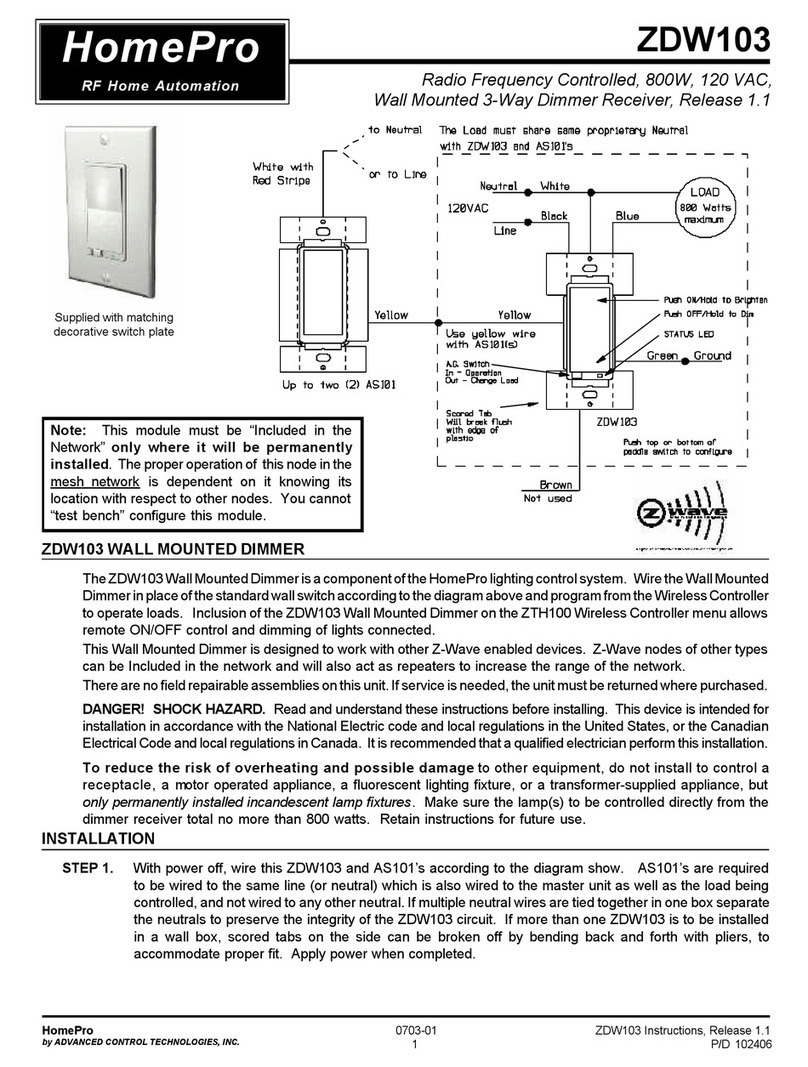

Figure 1.

DEiMiC ONE MASTER

device

DEiMiC ONE MASTER

device is a base of intelligent building control system. The

device contains 55 inputs (e.g. for switches connections), 36 relay outputs, 4 outputs

dedicated to gates control and 4 dimmable LED outputs. Six of the inputs are dedicated to

motion sensors connections. The device also have two RJ-45 sockets - one for LAN

connection, second for connecting extension modules (

DEiMiC ONE EXPANDER

and

DEiMiC ONE COMFORT

).

DEiMiC ONE COMFORT

module extends the system capabilities by adding

temperature control functionality and increasing number of the system inputs and outputs.

The module includes 22 relay outputs, 8 dimmable LED outputs, 2 relays dedicated to

LEDs power suppliers switching, 32 discrete inputs and 10-channel temperature

controller, which contains a output for a recuperator control and a relay for central heating

furnace switching. Each temperature controller channel includes an analog input for a

temperature sensor connection and a relay output for a heater control.

DEiMiC ONE

EXPANDER module extends system capabilities by increasing number of

the system inputs and outputs. The module includes 64 inputs, 32 relay outputs and 8

dimmable LED outputs. Six of the inputs are dedicated to motion sensors connections.

4 Installation guide DEiMiC ONE MASTER v1.8

1.2. TECHNICAL DATA

Tab. 1. DEiMiC ONE MASTER device parameters

Parameter Value

Number of high-current relay outputs 36

Number of low-current relay outputs (1 A, 250 V AC) 4

Number of dimmable LED outputs (12 V or 24 V) 4

Number of all discrete inputs 55

Number of discrete inputs for motion

sensors connection 6

Number of Ethernet ports 1

Number of USB ports 2

Number of extensions headers 1

Power supply 12 V DC, min. 20 W

Dimensions (length/width/height) 321x109x54 mm

Used space in electric switchgear 18 modules

Installation place Electrical switchgear

Tab. 2. High-current relays maximum load

Load type Max. power

Resistive 2000 W

Fluorescent tube 500 W

Inductive 200 W

5 Installation guide DEiMiC ONE MASTER v1.8

1.3. THE DEVICE PINOUT DESCRIPTION

Figure 2.

DEiMiC ONE MASTER

pinout description

POWER

SUPPLY

LEDS LOW-

CURRENT

OUTPUTS

HIGH-

CURRENT

OUTPUTS

HIGH-

CURRENT

OUTPUTS

INPUTS FOR

MOTION

SENSORS

INPUTS

DISCRETE

INPUTS

6 Installation guide DEiMiC ONE MASTER v1.8

1.4. APPLICATIONS

DEiMiC smart home system provides control of all electrical devices inside

a building such as lights, shutters, car gates and garage gates, heating

devices, alarms, irrigation devices, ventilation and sound systems. The

device is cooperating with motion sensors, temperature sensors and switches.

Thanks to LAN network connection, the

DEiMiC

system can be controlled

via tablet or smartphone, providing the user all information about the

system state from almost every place in the world.

Figure 3. Smart home system with

DEiMiC ONE MASTER

7 Installation guide DEiMiC ONE MASTER v1.8

2. ASSEMBLY

2.1. PREPARATION TO ASSEMBLY

During assembly the following tools may be useful:

phillips screwdriver,

slotted screwdriver,

precision pliers,

flat pliers,

driller,

drill-driver,

nippers for cable cutting,

digital multimeter,

connectors crimper,

cable stripper, soldering

tool.

EVERY INSTALLATION WORK SHOLUD BE

DONE WITH POWER OFF

BEFORE ASSEMBLY, IT IS NECESSARY TO READ THE

INSTRUCTION, ESPECIALLY THE WARNINGS ON PAGE 1

Before assembly it is recommended to prepare a object plane.

Preparation of the object plane and putting there all system devices,

switches and sensors will make easier future work.

8 Installation guide DEiMiC ONE MASTER v1.8

2.2. GUIDELINES

2.2.1. WIRES

1. All standard light sections should be routed from an electrical switchgear

with a 3x1,5mm2 wire or other according to the lamp

producer recommendations.

2. Every roller blinder, marquise, shutter should be routed directly to an

electrical switchgear with 4x1mm2 wire or other according to the

driver producer recommendations.

3. Gate driver should be routed from an electrical switchgear according

to producer specification + UTP cat. 5 cable to the controller.

4. Every motion sensor should be connected with another UTP cat. 5 cable

directly from an electrical switchgear.

5. One UTP cat. 5 cable should be placed between Ethernet router and an

electrical switchgear.

During wires installation it is recommended to ensure appropriate

space between low-voltage wires and mains electricity wires. It is

recommended to avoid situations where signals wires are placed

parallel to the mains electricity wires.

9 Installation guide DEiMiC ONE MASTER v1.8

6. A 1 mm2 multi-conductor cable should be lead to heating distributors

(number of the cable conductors = quantity of valves + 2).

7. A UTP cat. 5 cable should be placed in the all switch boxes directly from

an electrical switchgear (if any localization have more than 6 buttons, it

necessary to add one more UTP cat. 5).

8. A UTP cat. 5 cable should be lead to the temperature sensors directly from

an electrical switchgear.

9. Chosen switchable electric socket should be connected directly do an

electrical switchgear.

10. LED and RGB lighting circuits – Power suppliers should placed in an

electrical switchgear; connection: 2 or 4 multi-conductor cable with cable

cross-section adjusted to cables length and lighting power.

11. Gelled wires only should be placed inside ground and outside the object.

12. A 2x1 mm2 wire form an electrical switchgear should be lead to a

gate electro connector.

Do not use shielded cables to the switches, especially high-class cables.

You should use good quality cables only. Choose UTP cat. 5 cables which

are made from copper.

10 Installation guide DEiMiC ONE MASTER v1.8

2.2.2. ELECTRICAL SWITCHGEAR

1. Dimensions of an electrical switchgear should be adjusted to quantity of

installation modules and protections. One

DEiMiC

module uses space of

18 modules.

2. Electrical equipment, protective and residual-current devices should be

chosen and installed by a electrician only.

3. One protection should be done for every 6 lighting circuits.

4. One protection should be done for every 6 shutters.

5.

DEiMiC

system needs one B6 circuit breaker.

6. Whole electrical switchgear must be described in details and sent to a

investor.

Every wire connection which differs from above rules

must be consulted with the system installer.

The control cabinet should be protected against unauthorized access.

11 Installation guide DEiMiC ONE MASTER v1.8

2.2.3. CONNECTIONS INSIDE ELECTRICAL SWITCHGEAR

1. Every building outgoing wire, which are not controlled by the

DEiMiC

system

(electric sockets, furnace, alarm, fridge power supplies etc.) should be

connected to circuits breakers like in traditional installations.

2. Circuits controlled by

DEiMiC

system should be connected according to

following rules:

a) Neutral wires connected on terminal strips comply with residual-current

devices.

b) Ground wires connected to grounded strips.

c) Lighting hot wires led out at single terminal.

d) Shutters hot wires led out at two single terminal, where first one sets

the direction up (apply the same rule for roof windows and other mechanisms

where direction is controlled by wire connection sequence), second one – the

direction down.

e) Switchable electric sockets hot wires led out at single terminal.

f) Switches UTP cables led to an electrical switchgear with description

andenough free space to allow access for every place in the switchgear.

g) Sensors UTP cables led to an electrical switchgear with description and

enough free space to allow access for every place in the switchgear.

h) Temperature sensors cables led to an electrical switchgear with description

and enough free space to allow access for every place in the switchgear.

12 Installation guide DEiMiC ONE MASTER v1.8

2.2.3. CONNECTIONS INSIDE ELECTRICAL SWITCHGEAR (continued)

i) Heating distributors outgoing wires should be connected with valves, inside

hermetic boxes, led out with terminal form an electrical switchgear side and

described according to documentation delivered by central heating installer

(room names assigned to the valves).

j) All terminals leading out to devices which are power supplied by voltage

lower than 230 V should be marked and different terminal colors should be

used.

2.2.4. MARKING

1. All wires should be permanently marked at both sides with a proper

distance, which ensure description visibility after removing wire isolation.

2. Terminals and fuses should be numerated (marked).

3. Marks must not be duplicated.

4. Descriptions of terminals should be placed inside electrical switchgear.

5. If possible, please use marks from previous projects and figures which were

done to a building needs.

13 Installation guide DEiMiC ONE MASTER v1.8

2.2.5. GOOD ADVICES

1. Dimensions of an electrical switchgear should be properly chosen due to

possibility of a need more number of devices than expected (more space also

makes installation work more comfortable).

2. A twisted-pair cable and a coaxial cable should be routed from an electrical

box to a control cabinet (it will make easier future phone/network/TV

connection).

To make installation easy and painless we strongly requests for perform

installation in accordance with following rules:

1. After finishing wiring please check quantity of circuits in terms of included

figures.

2. A readable description should be prepared in electronic version.

3. All doubtful situations should be consulted with the installer.

4. All changes introduced by a investor should be immediately reported.

5. During start-up all lighting circuits should be ended by a bulb and a holder.

6. All circuits led out by terminals should be power supplied before

installation end in purpose of elimination of possible short circuit (damaged

wire).

We recommend separate electrical sockets circuits with separate

protections in electrical switchgear for every room.

14 Installation guide DEiMiC ONE MASTER v1.8

2.2.5. GOOD ADVICES (continued)

7. Check shutters and other drives connections in terms of properly work

and terminals direction sequence.

8. Temporary installation, used by workers, should be connected to the

switchgear after finishing a connection.

15 Installation guide DEiMiC ONE MASTER v1.8

3. EXAMPLES OF WIRING DIAGRAMS

3.1. POWER SUPPLY CONNECTION

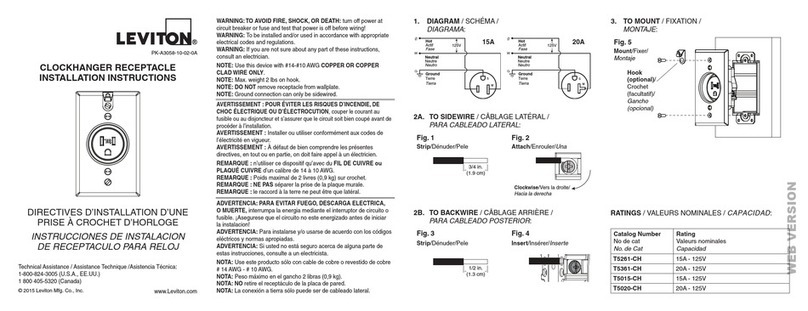

Figure 4. Power supply connection diagram

16 Installation guide DEiMiC ONE MASTER v1.8

3.2. NETWORK CONNECTION

Default IP: 192.168.1.99

Figure 5. Network connection

diagram

17 Installation guide DEiMiC ONE MASTER v1.8

3.3. OUTPUTS CONNECTION - LIGHTS

Figure 6. Lights connection diagram

18 Installation guide DEiMiC ONE MASTER v1.8

3.4. OUTPUTS CONNECTION – SHUTTERS

Figure 7. Shutters connection diagram

Other manuals for One Master

1

Table of contents

Other Deimic Home Automation manuals

Popular Home Automation manuals by other brands

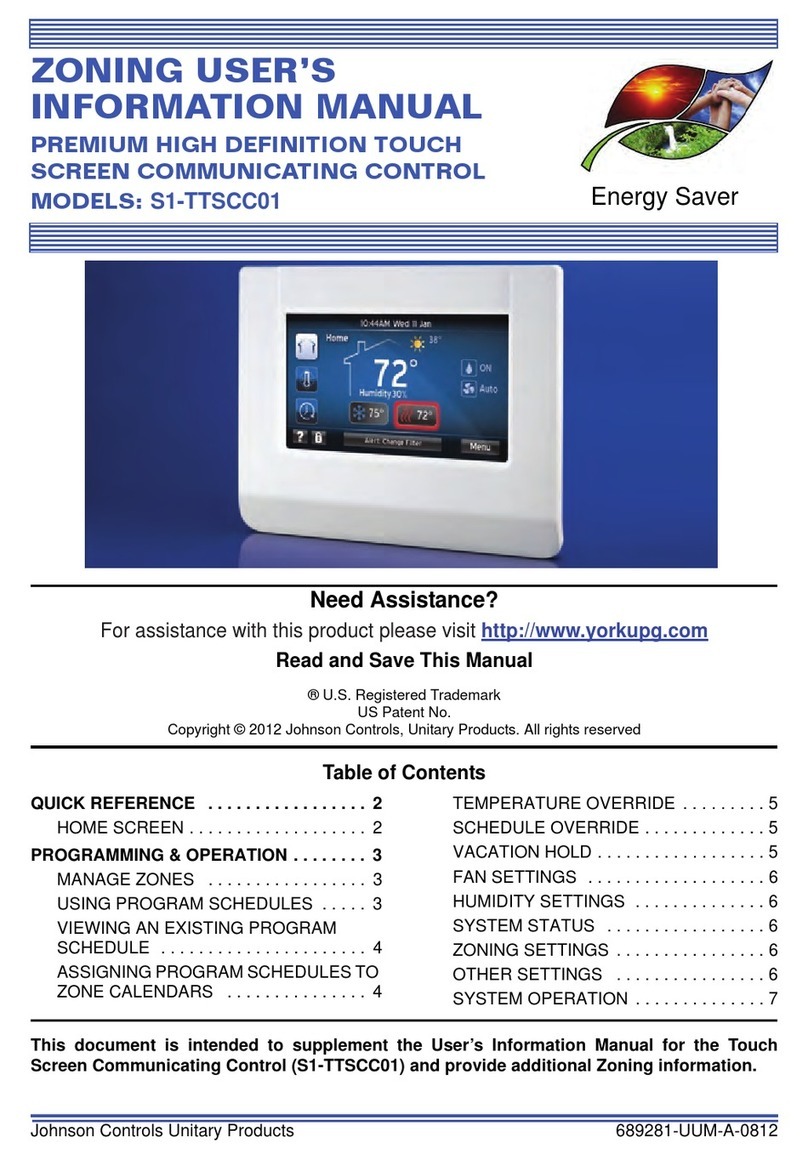

Johnson Controls Unitary Products

Johnson Controls Unitary Products S1-TTSCC01 Zoning User's Information Manual

INSTEON

INSTEON LampLinc 2456D3 manual

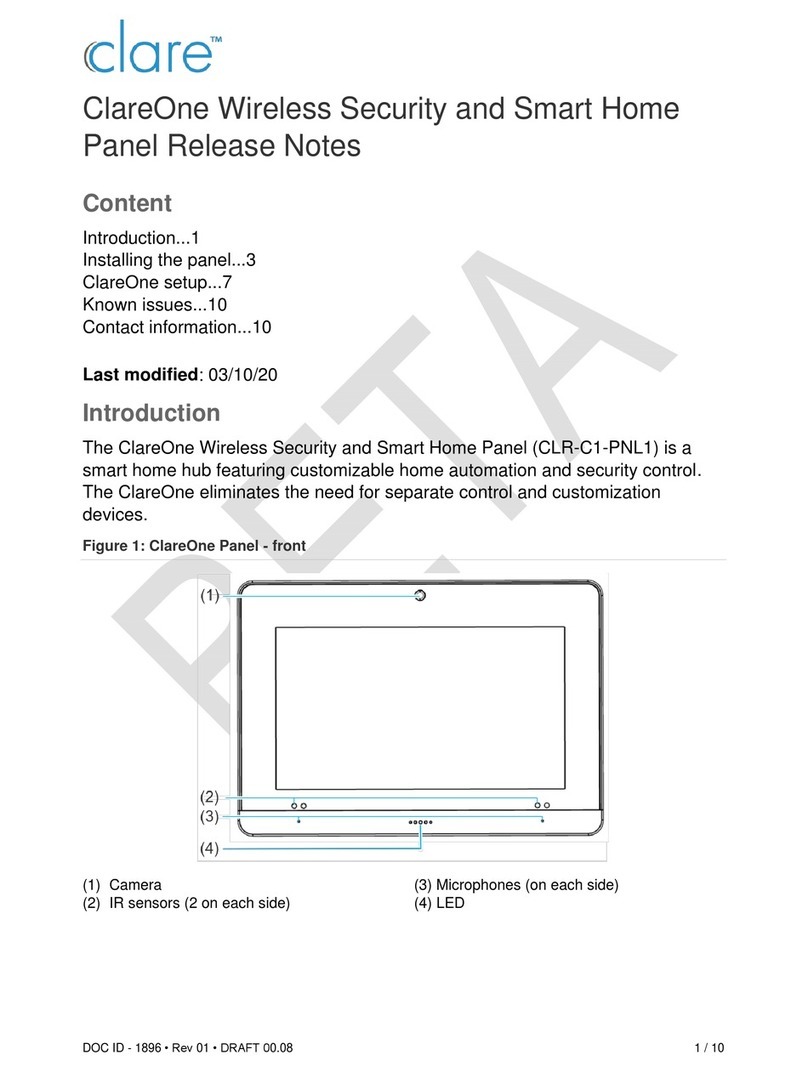

Clare Controls

Clare Controls ClareOne CLR-C1-PNL1 Release notes

Housegard

Housegard NOTE quick guide

EcoFlow

EcoFlow EFM100-LD-HV user manual

S&C

S&C TripSaver II manual