Delachaux Conductix-Wampfler 1900 Series User manual

1

IOM 1900 / 2400 DUAL HOSE REEL MANUAL

P/N 962101 2008.10.24 Rev. 2

Dual Hose Reel

Series 1900 / 2400

2IOM 1900 / 2400 DUAL HOSE REEL MANUAL P/N 962101 2008.10.24 Rev. 2

The technical data and images which appear in this manual are for informational purposes only. NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE CREATED BY THE DESCRIPTIONS AND DEPICTIONS OF THE

PRODUCTS SHOWN IN THIS MANUAL. Conductix makes no warranty (and assumes no liability) as to function of equipment or operation of systems

built according to customer design or of the ability of any of its products to interface, operate or function with any portions of customer systems not

provided by Conductix.

Seller agrees to repair or exchange the goods sold hereunder necessitated by reason of defective workmanship and material discovered and reported to

Seller within one year after shipment of such goods to Buyer.

Except where the nature of the defect is such that it is appropriate, in Seller’s judgment, to effect repairs on site, Seller’s obligation hereunder to remedy

defects shall be limited to repairing or replacing (at Seller’s option) FOB point of original shipment by Seller, any part returned to Seller at the risk and cost

of Buyer. Defective parts replaced by Seller shall become the property of Seller.

Seller shall only be obligated to make such repair or replacement if the goods have been used by Buyer only in service recommended by Seller and

altered only as authorized by Seller. Seller is not responsible for defects which arise from improper installation, neglect, or improper use or from normal

wear and tear.

Additionally, Seller’s obligation shall be limited by the manufacturer’s warranty (and is not further warranted by Seller) for all parts procured from others

according to published data, specifications or performance information not designed by or for Seller.

Seller further agrees to replace or at Seller’s option to provide a refund of the sales price of any goods that do not conform to applicable specifications or

which differ from that agreed to be supplied which non-conformity is discovered and forthwith reported to Seller within thirty (30) days after shipment to

the Buyer. Seller’s obligation to replace or refund the purchase price for non-conforming goods shall arise once Buyer returns such goods FOB point of

original shipment by Seller at the risk and cost of Buyer. Goods replaced by Seller shall become the property of Seller.

There is no guarantee or warranty as to anything made or sold by Seller, or any services performed, except as to title and freedom from encumbrances

and, except as herein expressly stated and particularly, and without limiting the foregoing, there is no guarantee or warranty, express or implied, of

merchantability or of fitness for any particular purpose or against claim of infringement or the like.

Seller makes no warranty (and assumes no liability) as to function of equipment or operation of systems built to Buyer’s design or of the ability of any

goods to interface, operate or function with any portions of Buyer’s system not provided by Seller.

Seller’s liability on any claim, whether in contract, tort (including negligence), or otherwise, for any loss or damage arising out of, connected with, or

resulting from the manufacture, sale, delivery, resale, repair, replacement or use of any products or services shall in no case exceed the price paid

for the product or services or any part thereof which give rise to the claim. In no event shall Seller be liable for consequential, special, incidental or

other damages, nor shall Seller be liable in respect of personal injury or damage to property not the subject matter hereof unless attributable to gross

misconduct of Seller, which shall mean an act or omission by Seller demonstrating reckless disregard of the foreseeable consequences thereof.

Seller is not responsible for incorrect choice of models or where products are used in excess of their rated and recommended capacities and design

functions or under abnormal conditions. Seller assumes no liability for loss of time, damage or injuries to property or persons resulting from the use of

Seller’s products. Buyer shall hold Seller harmless from all liability, claims, suits and expenses in connection with loss or damage resulting from operation

of products or utilization of services, respectively, of Seller and shall defend any suit or action which might arise there from in Buyer’s name - provided

that Seller shall have the right to elect to defend any such suit or action for the account of Buyer. The foregoing shall be the exclusive remedies of the

Buyer and all persons and entitles claiming through the Buyer.

Conductix Incorporated

3

IOM 1900 / 2400 DUAL HOSE REEL MANUAL

P/N 962101 2008.10.24 Rev. 2

1.0 Safety Instructions

1.1 Pressure Warnings

1.2 Operational Warnings

1.3 Maintenance Warnings

1.4 Specifications and Listings

1.5 Pressure and Temperature Rating

1.6 Labels and Markings

2.0 Installation

2.1 Application Types

2.2 Mounting

2.3 Guide Rails

2.4 Roller Guides

2.5 Ratchet

2.6 Hose Installation and Replacement

2.7 Spring Tension Adjustment

3.0 Operation

4.0 Maintenance

4.1 Maintenance Warnings

4.2 Lubrication

4.3 Inspections

4.4 Swivel Joint Assembly Replacement

4.5 Spring Motor Replacement

5.0 Troubleshooting

6.0 Replacement Parts

INDEX

4IOM 1900 / 2400 DUAL HOSE REEL MANUAL P/N 962101 2008.10.24 Rev. 2

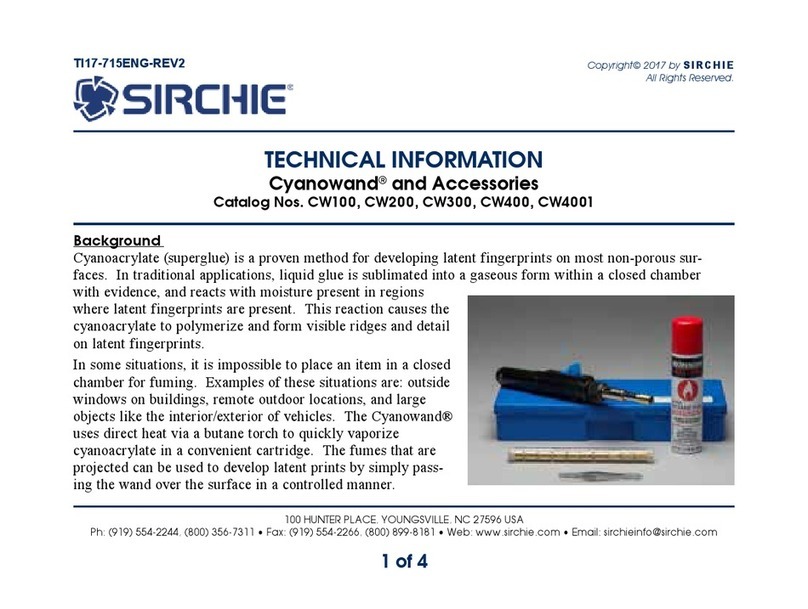

Basic Component Identification

Swivel

Reducer Spring

Motor

Frame

Spool

Shaft

Roller

Guide

Spool

Assembly

Reducer

Swivel

5

IOM 1900 / 2400 DUAL HOSE REEL MANUAL

P/N 962101 2008.10.24 Rev. 2

1.0 Safety

1.1 Pressure Warnings

1.1.1 This equipment should be properly installed before use in accordance with local codes and ordinances.

1.1.2 The pressure to the hose reel should be disconnected from the hose reel before any service functions are performed.

1.1.3 This hose reel must not be used for pressure greater than the rating listed on the label. See section 1.5 for Pressure and Temperature ratings.

1.2 Operational Warnings

1.2.1 Exercise care when handling the hose reel during normal operation. This hose reel has a rotating spool powered by springs under tension.

1.2.2 Do not use hose different from that for which the reel is intended. Changes in diameter, weight per foot, length of hose or flexibility will affect the

operation of the reel.

1.2.3 Mounting hardware and fasteners should be installed to maintain tightness under vibration and checked periodically to ensure tightness.

1.2.4 Overhead installation mountings should be such that the reel is not supported by bolts in tension. A safety chain or cable is strongly recommended

to minimize damage and/or possible injury in the event of mounting failure.

1.3 Maintenance Warnings

1.3.1 WARNING: Modification of this equipment may cause excessive wear and will void the warranty. Contact the manufacturer regarding changes or

modifications of equipment which could affect reliability or safety.

1.3.2 DO NOT DISASSEMBLE THE SPRING MOTOR FOR ANY REASON. Serious personal injury could result. This hose reel is equipped with springs

under tension. Contact the factory for assistance.

US: 1-800-521-4888

Canada: 1-800-667-2487

1.4 Specifications & Listings

1.4.1 1900 / 2400 Series Hose Reel products are not certified or listed by any independent certifying or regulatory body.

1.4.2 The following specifications apply to all 1900 / 2400 Series Hose Reels:

1.4.2.1 1900 / 2400 Series Hose Reels are intended for industrial use and are provided with permanent mounting means.

1.4.2.2 1900 / 2400 Series Hose Reel Spring Motors are weather-tight and self-contained.

1.5 Pressure & Temperature Rating

1.5.1 All Insul-8 1900 / 2400 Series Hose Reels without hose installed are rated at 5000 P.S.I. Reels should not be used at pressures greater than

the rating of the hose.

1.5.2 Installed hose is suitable for delivery of specified fluids only.

1.5.3 The operational rating of a reel not equipped with hose is determined by the capacity of the installed hose. The pressure rating of the reel

without hose must not be greater than 5000 P.S.I. Variations in the OD of higher rated hose will affect the operational capacity of the reel.

1.6 Labels & Marking

1.6.1 Hose reels with and without hose

1.6.1.1 The marking of the hose reel provided with or without hose includes the following:

1.6.1.1.1 The label on the frame includes the Conductix-Wampfler name and logo, the product catalog number, PSI rating, description of the reel

and what type and length of hose intended for use on the reel.

1.6.1.1.2 The maximum pressure rating for every hose reel supplied without hose is marked on the Conductix-Wampfler Identification Label.

Actual rating is determined by the installed hose and is not to exceed the indicated maximum rating. The pressure rating of the hose

installed on reels provided without hose must be marked on the label upon installation.

6IOM 1900 / 2400 DUAL HOSE REEL MANUAL P/N 962101 2008.10.24 Rev. 2

2.0 Installation

2.1 Application Types

2.1.1 Stretch Applications

2.1.1.1 The hose is suspended without any intermediate support.

Stretch reels generally require a line pull equal to two times the

weight of the hose with fluid, which allows approximately 10%

sag at full extension. On long applications where sag cannot be

tolerated, it is sometimes desirable to put supports at intervals

of 5 to 10 feet.

2.1.2 Lift Applications

2.1.2.1 The hose is lifted vertically in lift

applications. The reel is normally designed

to handle only the total weight of the hose

with fluid. Some lift applications may

require ball stops to control the length of

hose to be retracted.

2.1.3 Drag Applications

2.1.3.1 The reel is mounted on a stationary object and is required

to drag the hose over the surface to the reel. The hose is

supported by the ground or some type of hose tray.

2.1.4 Retrieve Applications

2.1.4.1 The reel is mounted on the moving object and winds up or pays

out the hose as the machine approaches or moves away from

the fixed end. Retrieve applications can be elevated 4 feet from

the hose support surface.

SUSPENDED SUPPORTED

4’ MAX

MOBILE

FIXED

7

IOM 1900 / 2400 DUAL HOSE REEL MANUAL

P/N 962101 2008.10.24 Rev. 2

2.0 Installation

2.2.1 Standard Mounting

2.2.1.1 The reel is mounted by bolting the base to any flat surface which is structurally sound enough

to support it and the forces of winding and unwinding the hose.

2.2.1.2 The spool drum must rotate on a horizontal axis. Use a level to confirm this.

2.2.1.3 The reel should be oriented so that the hose extends perpendicular to the rotation of

the spool. The total hose deflection should not exceed 15Oto either side of the guide.

Installations without a roller guide have no tolerance for deflection.

2.2.1.4 If deflection is constant to either side of the reel and operation is impaired, re-mount the

reel.

2.2.1.5 A Pivot Base should be used if the angle of deflection is not constant and exceeds 15Oto

either side. Otherwise, excessive hose wear and unreliable operation will result.

2.2.1.6 A safety chain should be used for all overhead installations.

2.2.2 Pivot Base Mounting

2.2.2.1 All 1900 & 2400 Series Dual Hose Reels can be furnished

with an optional pivot base to allow the reel to rotate and

keep the extended hose perpendicular to the application.

See table below for appropriate selection.

2.2.2.2 Pivot bases rotate up to 345O.

2.2.2.3 A Pivot base is required in carousel or loop-track

applications.

2.2.2.4 When a pivot base is used, the reel must be mounted

horizontally (“ceiling” or “floor” mounted).

2.2.2.5 The roller guide should be mounted to require the hose to

travel perpendicular to the axis of pivot base rotation. This

will guard against hose twisting and ensure effective swivel

action from the pivot base.

Spool Width

5.0

8.0

Pivot Base

40274A

40274C

Hose Deflection with Guide.

30O

2.2 Mounting

8IOM 1900 / 2400 DUAL HOSE REEL MANUAL P/N 962101 2008.10.24 Rev. 2

2.0 Installation

2.3 Guide Rails

2.3.1 The optional guide rails can be installed on any of the 1900 & 2400

Series Dual Hose Reels.

2.3.2 Guide Rails provide a barrier between the hose and rotating spool

flange rim. They also act as a safety barrier for installations where

human contact with the rotating spool flange is likely to occur.

2.3.3 Guide Rails provide additional assurance that the hose will wrap

efficiently on the spool for applications involving rigorous motion.

2.3.4 Guide Rails can act as a substitute for the roller guide in applications

that require a two-way pay-out.

2.3.5 Guide Rail Installation

2.3.5.1 Guide Rails are mounted to the base using the holes on the

side edges of the base.

2.4 Roller Guides

2.4.1 All 1900 / 2400 Dual Hose Reel units are equipped with a roller guide.

The guide’s function is to center the hose on the spool and to help the

reel wrap the hose more evenly.

2.4.2 The guide must be located and secured prior to making any hose

connections.

2.4.3 The hose should not bear against either of the spool flanges during

winding as this will tend to inhibit level winding of the hose.

2.4.4 The guide should be secured at the best of two possible positions so

that a minimum change of direction occurs at the guide; otherwise,

hose life will be reduced and reel operation will be impaired.

2.4.4.1 Mount the guide to the reel between the inside edge of the

frame and the spool. Using the two longer motor mount bolts in the

required holes, place the guide arm in position so the cable pays

horizontally off the top of the spool or vertically towards the top of the

spool.

9

IOM 1900 / 2400 DUAL HOSE REEL MANUAL

P/N 962101 2008.10.24 Rev. 2

2.0 Installation

2.5 Ratchet

2.5.1 The ratchet option allows the extended hose to be pulled out and held from retraction by spring tension; generally appropriate for operator

attended applications.

2.5.2 The ratchet for the 1900 & 2400 Series Hose Reels is spring loaded. It is designed to function in all acceptable mounting configurations.

2.5.3 The ratchet option can be installed at the time of purchased or later added to reels that have already been introduced to service.

2.5.4 Ratchet Option Installation

2.5.4.1 WARNING: Fluid Pressure should be disconnected from the reel before beginning any service or maintenance functions. Follow lock-

out/ tag-out procedures appropriate to the facility.

2.5.4.2 Ratchet Pawl Installation

2.5.4.2.1 The ratchet pawl assembly is attached to the reel frame as

a unit. The holes provided for the attachment of the ratchet

pawl assembly are located in the lower middle of the frame.

2.5.4.2.2 Insert the (2) 3/8 -16x1” bolts (provided) in the frame.

2.5.4.2.3 Position the ratchet pawl assembly over the protruding bolt

shafts.

2.5.4.2.4 Secure using the (2) sets of 3/8-16 hex nuts & lockwashers

provided.

2.5.4.3 Ratchet Plate Installation

2.5.4.3.1 Loosen the (2) 1/4-20 setscrews on the spool hub with a

1/8” allen wrench and adjust spool so that the ratchet pawl

pin clears the spool by 0.030” to 0.125”.

2.5.4.3.2 Locate the four (4) bolt holes in the inside spool flange for

the ratchet teeth. These will be arranged in two sets of

two, 180 degrees from each other.

2.5.4.3.3 Mount the ratchet teeth in one of these sets of holes

oriented as in the figure below. Be sure to install the

provided bolts from inside the spool so that the nuts are on

the outside of the spool and will not rub on the hose.

2.5.4.3.4 A second set of ratchet teeth can be added to the second

set of holes if desired to provide more frequent locking

positions.

10 IOM 1900 / 2400 DUAL HOSE REEL MANUAL P/N 962101 2008.10.24 Rev. 2

2.0 Installation

2.6 Hose Installation Warnings

2.6.1 Hose Installation Warnings

2.6.1.1 If an existing hose is being replaced, remove the old hose. Replacement hose should be the same size and length and pressure rating

as the existing hose. Any variations to existing hose specifications should be pre-approved by the factory.

2.6.1.2 Variations in inner and outer hose diameters will significantly impact reel performance. Factory specifications should be matched as

closely as possible. Contact Conductix-Wampfler Sales for further information.

2.6.1.3 Shut-off and relieve the fluid or air pressure to the reel before attempting to disconnect the hose. Disconnect all pressure as per Lock-

out/Tag-out procedures outlined in OSHA section 1910.147.

2.6.2 Hose Removal

2.6.2.1 Disconnect supply pressure from the reel and carefully drain pressure from hoses.

2.6.2.2 Remove ball stop and all the spring tension on the reel. Make sure that the hose ends are through the roller guide arm and back on the

hose drum.

2.6.2.3 Remove the roller guide head from the guide arm.

2.6.2.4 Remove the hoses from the drum by looping the hoses over the flange without turning the spool.

2.6.2.5 Remove the swivel on the outer side of the spool from the reel shaft.

2.6.2.6 Remove the two (2) clamps that hold the hoses to the drum.

2.6.2.7 Remove the five (5) 1/4-20 nuts from the outer flange and slide the flange off the edge of the shaft.

2.6.2.8 Slide the drum off the remaining drum bolts.

2.6.2.9 Unscrew hose fittings from shaft assemblies. If hoses were not supplied with swivel ends, it will be necessary to cut banding from hoses

to allow hose to rotate independent from each other.

2.6.3 Hose Installation

2.6.3.1 Prepare the hose to be loaded onto the reel. Support the hose, or lay the full length of hose out in the direction of travel. Make sure the

hose will lay flat by removing any twist from the hose.

2.6.3.2 Apply pipe joint compound to all NPT connections and connect the hose to the shaft or elbow assemblies as required to avoid kinking

the hose when wound on the shaft.

2.6.3.3 Slide the cable drum onto the five (5) drum bolts guiding the two on either side of the drum entrance through the tubing.

2.6.3.4 Slide the outer flange on the shaft and insert the drum bolts into the bolt holes.

2.6.3.5 Install the (5) 1/4-20 nuts on the drum bolts and tighten.

2.6.3.6 Install cable clamps on cable by bolting through the two holes in the drum. Make sure the clamps are the right size to hold tightly

around the hose.

2.6.3.7 Band the two hoses together by an acceptable method for your hose type and application. Bands should not be placed more than two

feet (2’) apart. This step is not required for bonded dual hoses such as oxygen/acetylene hose.

2.6.3.8 Wind the hose onto the reel by turning the spool manually in a counter clockwise direction when viewed from the spool side. (Custom

left hand reels are reversed.)

2.6.3.9 Reinstall the roller guide and outer swivel and adjust set-up turns as required.

2.6.4 Hose Pressurization

2.6.4.1 Verify all connections before pressurizing the hose reel.

2.6.4.2 Fully extend the hose before pressurizing the line. The hose will tend to expand and may become wedged between the flanges.

2.6.4.3 Inspect both the reel and the hose for leaks (using soap & water for all gas applications) at the joints after initial pressurization.

11

IOM 1900 / 2400 DUAL HOSE REEL MANUAL

P/N 962101 2008.10.24 Rev. 2

2.0 Installation

2.7 Spring Tension Adjustment

2.7.1 Spring Tension Warnings

2.7.1.1 The adjustment may require mechanical assistance in more demanding applications and installations.

2.7.1.2 WARNING: Do not allow hose to retract without restraining the retraction speed. Walk the hose back to the reel during the spring tension

adjustment process.

2.7.2 Spring Pre-Tensioning

2.7.2.1 The proper pre-tensioning required for effective operation varies by hose diameter and hose weight. Trial and error is the most effective

means of setting the proper spring pre-tension. Pre-tensioning is achieved by pre-loading the spring with setup turns (reel revolutions).

2.7.2.2 Relieve the reel of all spring tension before putting on setup turns. Grasp the end of the hose and the spool and rotate both spool and

hose together in the payout direction until you feel the spring catch engage and the spring tension starts.

2.7.2.3 Initially start with (2) set-up turns, Adjust according to section 2.7.3

2.7.2.4 Feed the end of the hose through the roller guide (if present) and test the Spring Tension. Pull the hose out the required distance and

allow it to rewind.

2.7.3 Adjusting Spring Tension

2.7.3.1 Additional setup turns may be added. One setup turn can be removed if the torque tension is too high.

2.7.3.2 Do not add or remove setup turns on the reel after the hose has been terminated. The resulting twist may kink the hose and shorten

hose life.

2.7.3.3 Disconnect the terminated end of the hose and/or remove the ball stop if applicable.

2.7.3.4 Add one wrap of hose to the spool by pulling the end of the hose through the roller guide and winding the hose around the spool. The

hose should then be fed back through the roller guide.

2.7.3.5 Relocate the ball stop if applicable.

2.7.4 Spring Cycling

2.7.4.1 The spring should be cycled after mounting but before terminating the free end. This will verify the tension adjustment and assure that

the hose will retract properly.

2.7.4.2 Spring cycling is accomplished by pulling the hose out the required distance and walking it back to the retracted position while counting

the number of complete rotations made by the reel. The number of rotations should not exceed the maximum number for the given

spring as indicated in the following table. This procedure should be performed five to ten (5-10) times.

Maximum Spring Turns

Spring Motor Number of Turns

E, EP, F, FP 15

L, LP 22

ES, ES 30

LS 44

12 IOM 1900 / 2400 DUAL HOSE REEL MANUAL P/N 962101 2008.10.24 Rev. 2

3.0 Operation

3.1 Do not exceed the pressure or temperature rating of the hose. Do not exceed the pressure or temperature rating of the reel. Pressure and

temperature above the rated capacity could cause damage to equipment and personal injury could result.

3.2 Operate the reel within the hose size, length and spring tension limits for which it was intended.

3.2.1 Note: Two wraps of hose should remain on the reel at maximum extension to avoid excessive tension on the hose clamps.

3.2.2 The spring should not be wound to the last two turns at maximum payout to avoid over-stressing the spring, thus reducing spring life or

damaging the reel.

3.3 Keep the reel and hose clean to avoid excessive wear and damage.

3.4 Arrange for maintenance service if damage is found on the hose or reel.

3.5 Hose should be fully retracted when not in service to maximize spring life.

4.0 Maintenance

4.1 Maintenance Warnings

4.1.1 Be sure all pressure is off for maintenance.

4.1.2 Follow lock-out/tag-out procedures as outlined in OSHA section 1910.147 where appropriate.

4.2 Lubrication

4.2.1 All springs and bearings are lubricated for life at the factory. Additional lubrication should not be required.

4.2.2 Do not apply any lubricants or solvent cleaning agents to the swivel joint.

4.3 Inspections

4.3.1 Periodically check the reel for any loose or missing fasteners. Tighten or replace as necessary.

4.3.2 The swivel joint assembly should be checked periodically for leakage.

4.3.3 Inspect hose for damage or wear which would make it unsafe to use.

4.4 Swivel Joint Assembly Replacement

4.4.1 The swivel joint should be replaced, not rebuilt, if it becomes damaged.

4.4.2 Turn off supply pressure and carefully drain hoses of all pressure.

4.4.3 Unscrew supply lines from swivel to be replaced.

4.4.4 Unscrew swivel from end of reel shaft and dispose of the damaged swivel.

4.4.5 Apply pipe joint compound to threads of new swivel.

4.4.6 Screw new swivel into end of reel shaft and tighten.

4.4.7 Apply pipe joint compound to threads of supply hose and screw into swivel

13

IOM 1900 / 2400 DUAL HOSE REEL MANUAL

P/N 962101 2008.10.24 Rev. 2

4.0 Maintenance

4.5 Spring Motor Replacement

4.5.1 Spring Motor Warnings

4.5.1.1 CAUTION: Do not open the spring motor or personal injury may result.

4.5.1.2 The spring replacement process is determined by the spring configuration and cannot be performed in the field. The entire spring motor

must be replaced as a unit.

4.5.1.3 For further instructions, consult the factory.

In the USA call: 1-800-521-4888

In Canada call: 1-800-667-2487

4.5.2 Spring Motor Life

4.5.2.1 Spring life is determined by duty cycle and application requirements. Spring life can vary depending on operating environment,

application range, and duty cycle. Actual performance and maintenance scheduling can only be determined by individual factors in the

application.

4.5.3 Spring Motor Removal & Replacement

4.5.3.1 Turn off pressure supply to reel and carefully drain pressure from hoses.

4.5.3.2 Unhook hose ends from external equipment and allow reel to fully retract using care not to let the reel retract in an uncontrolled manner.

4.5.3.3 Unscrew swivel fittings from both ends of the shaft.

4.5.3.4 Unwind hoses off of spool without pulling against spring tension or winding spring.

4.5.3.5 Remove hose clamps from spool drum.

4.5.3.6 Remove the five (5) 1/4-20 nuts from the outer flange and slide flange off the end of the shaft.

4.5.3.7 Slide the spool drum off the bolts.

4.5.3.8 Unscrew hose and fittings from shaft.

4.5.3.9 Remove the two (2) setscrews from aluminum drive hub on inner flange.

4.5.3.10 Slide inner flange off the shaft.

4.5.3.11 Unscrew spool shaft section from motor shaft section.

4.5.3.12 Remove REEL-SAFE sprocket from motor shaft sprocket if so equipped.

4.5.3.13 Remove snap ring from shaft near frame.

4.5.3.14 Remove five (5) 1/4-20 nuts and bolts from around the motor flange. Note: dual spring motors have spacers between motor flange and

frame.

4.5.3.15 Slide motor out of frame bearing.

4.5.3.16 Install new motor in reverse order.

14 IOM 1900 / 2400 DUAL HOSE REEL MANUAL P/N 962101 2008.10.24 Rev. 2

5.0 Troubleshooting

Problem Possible Cause Solution

Reel will not retract hose but has some tension

1) Improper pretension. 1) See tension adjustment Section 2.7

2) Incorrect reel for application (lift vs. stretch). 2) Quantify application vs. reel selection.

3) Improper hose or hose length installed. 3) Install hose for which reel is intended.

4) Roller “hose” guide adjustment. 4) Check guide alignment

5) Ratchet is installed in constant tension

application. 5) Remove Ratchet

Reel does not have spring tension 1) Broken spring (Quantify application to

prevent reoccurrence.) 1) Replace spring.

Reel will not engage 1) Broken ratchet pawl spring. 1) Replace pawl spring.

Reel will not disengage 1) Over-extension of reel.

1) Manually rotate reel spool to disengage

ratchet. Do not overextend or adjust guide

to prevent lockup when reel is overextended.

2) Readjust ball stop if applicable.

Hose improperly wraps on reel (wraps above or

jumps flange).

1) Improper hose or hose length installed 1) Install hose for which reel was intended.

2) Hose guide adjustment 2) Check & adjust guide alignment.

Hose twisting or knotting.

1) Improperly installed hose. 1) See hose installation section of IOM)

2) Hose rubbing on or bending around fixed

object.

2) Check roller guide for function and hose pay

out path.

3) Excessive spring tension. 3) Quantify application vs. reel selection.

4) Inadequate anchoring of hose. 4) Adjust anchoring method. i.e. add strain

relief (kelloms grip).

System leaks, looses or does not transfer fluids/

gas.

1) Faulty hose or connections.

Inspect and repair or replace

2) Worn swivel joint

15

IOM 1900 / 2400 DUAL HOSE REEL MANUAL

P/N 962101 2008.10.24 Rev. 2

1900 / 2400 Dual Hose Reel Parts View

1

6F

6D

6B

6A

5

4

3 A & B

2

1

1B

1A

3

6C

6E

1B

1A

16 IOM 1900 / 2400 DUAL HOSE REEL MANUAL P/N 962101 2008.10.24 Rev. 2

6.0 Replacement Parts

P E ES H62

3

Assy

42962

42963

3A

Bearing Housing

40220

40220

3B

Bearing

E23

E23

Discriptive Digit

#2

E&F

G, H, J, K, L & M

Frame Assembly

42934

42935

E&F

G, H, J, K, L & M

Guide Arm

4

40258D

40257D

E&F

G, H, J, K, L & M

Guide Head

5

42944

42945

42946

42947

42948

42949

42950

42951

42952

L

LS

LP

E

ES

EP

F

FS

FP

Spring Motor Assembly

2Q

1

Assy

43870

43871

43872

1A

Swivel

E614-.25

E614-.375

E614-.500

1B

Reducer

05918

05906

05917

4

6

8

Swivel Kit

1/4”

3/8”

1/2”

6F

Grommet

102296

102296

102296

102296

102296

102296

102296

102296

6E

Outer Flange

42937

42937

42939

42939

42939

42939

42939

42939

6C

Drive Hub

S390-8048-TK

S390-8048-TK

S390-8048-TK

S390-8048-TK

S390-8048-TK

S390-8048-TK

S390-8048-TK

S390-8048-TK

6

Assy

42953

42954

42955

C/F

C/F

42956

C/F

C/F

6A

Shaft

42933

42933 + 42961

42933

42933

42933

42933 + 42961

42933 + 42961

42933 + 42961

6B

Inner Flange

42936

42936

42938

42938

42938

42938

42938

42938

Discriptive

Digit #2

E

F

G

H

J

K

L

M

Spool

6D

Drum

42940

42941

42940

C/F

C/F

42941

C/F

C/F

40212A

40212AA

40212B

40212BB

E

F

G, H & J

K, L &M

Guide Rails (Option)

40274A

40274C

E, G, H & J

F, K, L & M

Pivot Base (option)

40251A

Ratchet (Option)

40260A

Spool Lock

(Option)

(Q) Recommended Spare Part

Swivel Kit

Catalog # Description # Part #

1-3 4 43874

1-3 6 43875

1-3 8 43876

4 (Oxy/Ace) 6 43873

5 #F C/F

17

IOM 1900 / 2400 DUAL HOSE REEL MANUAL

P/N 962101 2008.10.24 Rev. 2

Notes

18 IOM 1900 / 2400 DUAL HOSE REEL MANUAL P/N 962101 2008.10.24 Rev. 2

Notes

19

IOM 1900 / 2400 DUAL HOSE REEL MANUAL

P/N 962101 2008.10.24 Rev. 2

Notes

20 MANUAL NAME P/N 962101 2008.10.24 Rev. 2

www.conductix.com

Conductix-Wampfler

10102 F Street

Omaha, NE 68127

USA

Customer Support

Phone: 800 521 4888

Fax: 800 780 8329

Phone: 402 339 9300

Fax: 402 339 9627

www.conductix.com

This manual suits for next models

1

Table of contents

Other Delachaux Tools manuals