3

English

Denitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and pay

attention to these symbols.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury.

CAUTION: Used without the safety alert symbol

indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT

THIS OR ANY D

e

WALT TOOL, CALL US TOLL FREE AT:

1-800-4-D

e

WALT (1-800-433-9258)

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or

other reproductive harm. Some example of these chemicals are:

• Leadfromlead-basedpaints

• Crystallinesilicafrombricksandcement

and other masonry products

• Arsenicandchromiumfromchemically-treatedlumber

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, always wear OSHA/MSHA/NIOSH approved,

properly fitting face mask or respirator when using such tools.

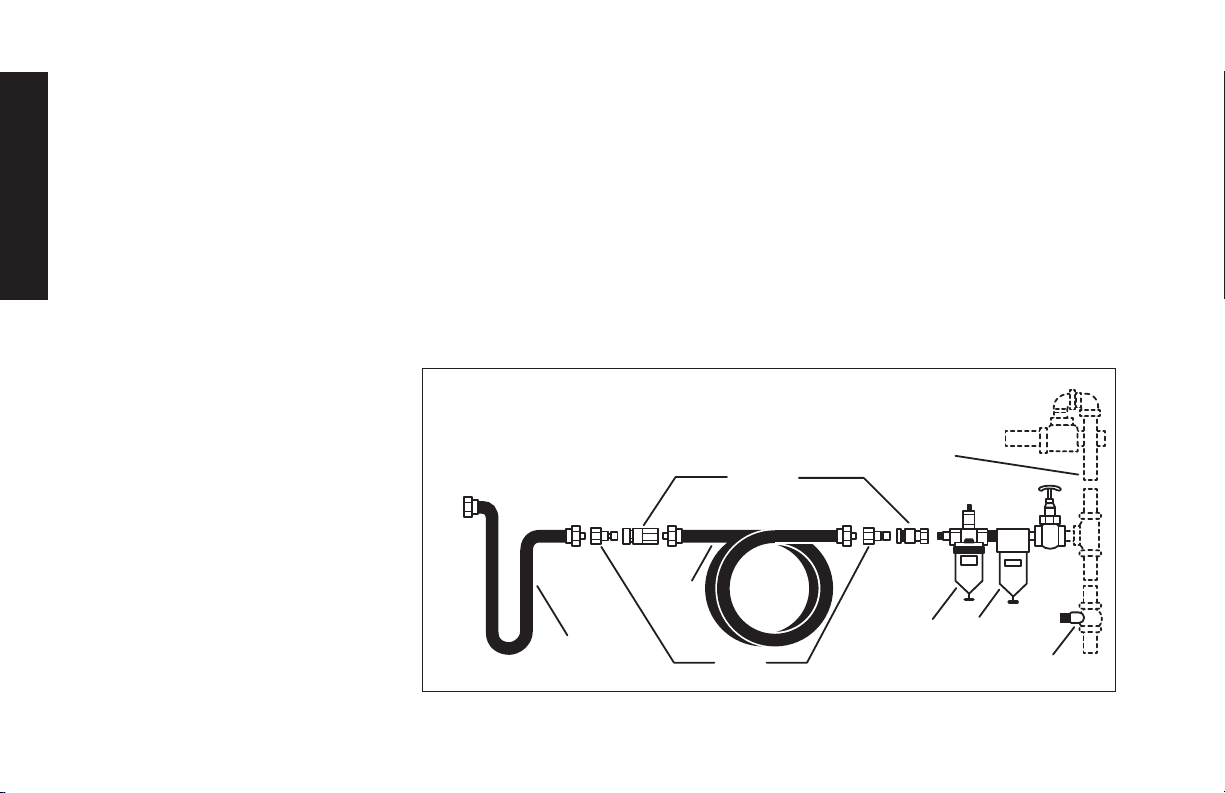

When using air tools, basic safety precautions should always be

followed to reduce the risk of personal injury.

WARNING: This product contains chemicals, known to the

State of California to cause cancer, and birth defects or other

reproductive harm. Wash hands after handling.

SAVE THESE INSTRUCTIONS

WARNING:

Improper operation or maintenance of this product

could result in serious injury and property damage.

Read and understand all warnings and operating

instructions before using this equipment. When using

air tools, basic safety precautions should always be

followed to reduce the risk of personal injury.

WARNING:

Read and understand this instruction manual and tool labels

before installing, operating or servicing this tool. Keep these

instructions in a safe accessible place.

Operators and others in work area must wear ANSI Z87.1 CAN

CSA Z94.3 approved safety glasses with side shields.

Operators and others in work area must wear ear protection.

Oil daily for optimal performance.