DeLaval MM27BC Instructions for use

Preventive maintenance

Preventive maintenancePreventive maintenance

Preventive maintenance

DeLaval milk meter MM27BC

1

11

1 Task Schedule

Task ScheduleTask Schedule

Task Schedule

No 1 Replace MM27BC gasket

No 1 Replace MM27BC gasketNo 1 Replace MM27BC gasket

No 1 Replace MM27BC gasket

Replacement parts or kits:

Art No: 91470502

Required tools:

Wrench

No

NoNo

No Service task

Service taskService task

Service task Frequency

FrequencyFrequency

Frequency Max. interval

Max. intervalMax. interval

Max. interval Replacement parts

Replacement parts Replacement parts

Replacement parts

or kits

or kitsor kits

or kits

1 Replace MM27BC gasket 2000h 12 months

91470502

2 Replace fat sampler parts 2000h 12 months

85132601

3 Per od c check ng and h nts for sampl ng 2000h 12 months

91548202

89634701

4 Cal brat on 2000h 12 months

5 Change d aphragm of the RS-valve 4000h 24 months

85850901

85531630

6 Replace rubber tubes 2000h 12 months

7 Replace s l con tubes 4000h 24 months

Frequency 2000h of operat on

Max. nterval 12 months

Est mated t me: 5 m n

Serv ce type: Replace

m

x

r

_

1

0

6

1

2

4

1.

1.1.

1.

Dismount the 27BC.

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

1 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

No 2 Replace fat sampler parts

No 2 Replace fat sampler partsNo 2 Replace fat sampler parts

No 2 Replace fat sampler parts

Replacement parts or kits:

Art No: 85132601

2.

2.2.

2.

Unscrew the wing nuts and remove the

bolts.

3.

3.3.

3.

Lift off the meter inlet and change the gasket

mounted in the inlet.

4.

4.4.

4.

5.

5.5.

5.

Place the new gasket tightly into the cavity

of the inlet tube with the correct orientation

to match retangular channel. It is important

to press the inlet tube tight against the milk

meter to compress the gasket as the screws

are reinserted.

Frequency 2000h of operat on

Max. nterval 12 months

Est mated t me: 5 m n

Serv ce type: Replace

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

2 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

No 3 Periodic checking and hints for sam

No 3 Periodic checking and hints for samNo 3 Periodic checking and hints for sam

No 3 Periodic checking and hints for sam

pling

plingpling

pling

Required tools:

91548202 Test probe for 27BC.

89634701 25 / 27BC cleaning probe

1.

1.1.

1.

The fat sampler has two O-rings and a

rubber gasket or sampler plug that must be

replaced once a year.

2.

2.2.

2.

The silicon tubes and rubber bottle holder

must be replaced before they have deteri-

orated, typically 1-2 years.

Frequency 2000h of operat on

Max. nterval 12 months

Est mated t me: 30 m n

Serv ce type: Inspect

2

0

9

8

3

9

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

3 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

The testing procedure should be carried out

with meters that are cleaned properly, i.e. after

good parlour cleaning cycle.

The purpose of the periodic checking is to

determine whether the 27BC is still func-

tioning as it did at the time for the installation

and calibration. Reference values and infor-

mation shall be noted at the time for calibration

of the 27BC milk meter. The new values

at the time for the periodic check should be

noted and compared with the initial values. See

Chapter 3.1 "Periodic routine test form."

.

If one or more out of the mentioned tests fail,

the meter should be cleaned, checked again

and replaced.

Note!

Note! Note!

Note!

A test probe belongs to each installation

and should be contained on the premises, safe

from mechanical damage and dirt.

MM27BC visual inspection

MM27BC visual inspectionMM27BC visual inspection

MM27BC visual inspection

Milking parlour parameters

Milking parlour parametersMilking parlour parameters

Milking parlour parameters

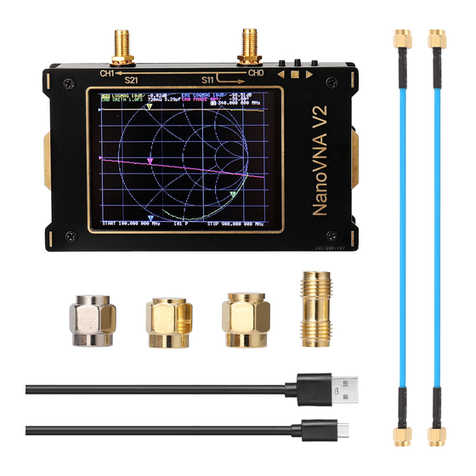

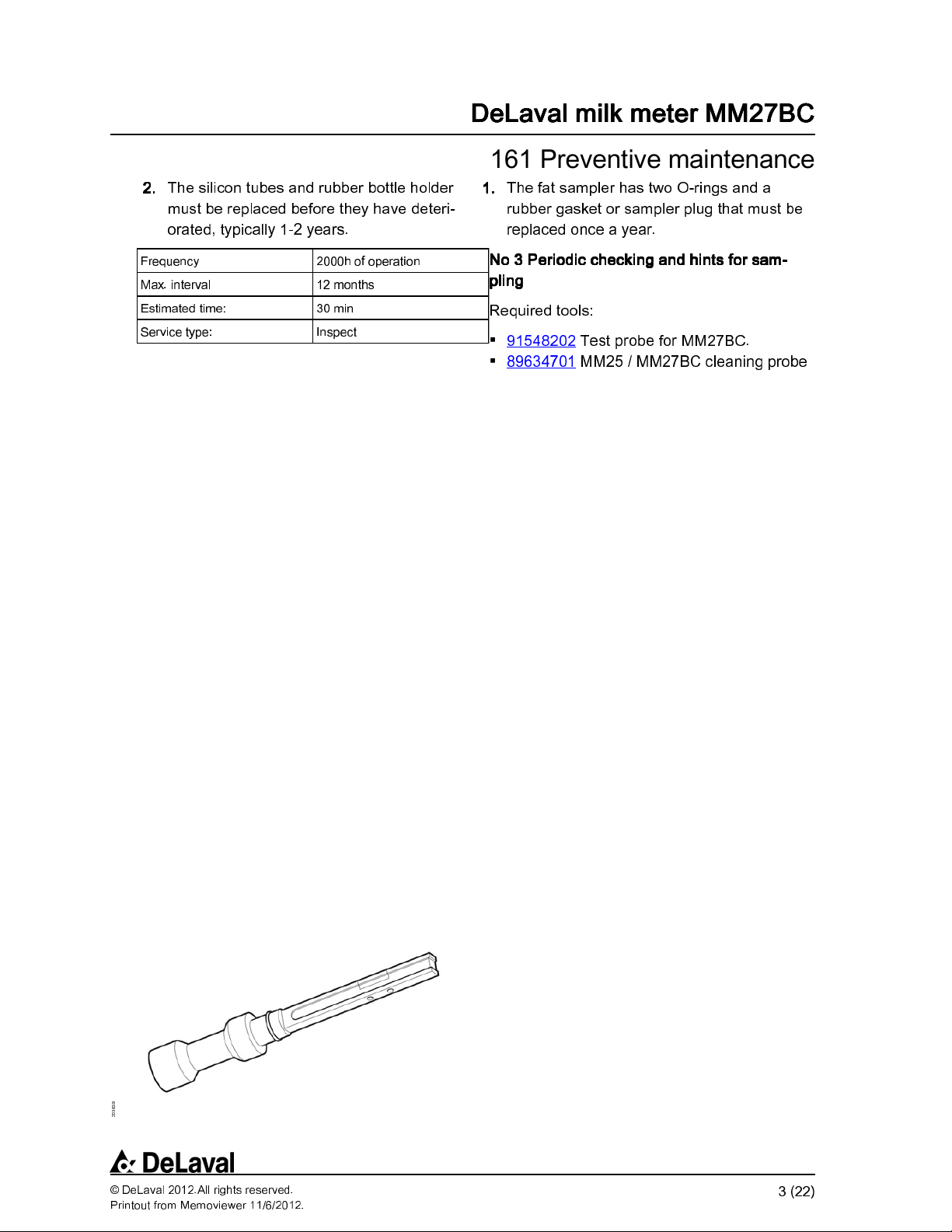

Fig. 1: Test probe with optical properties that

simulates mil . The test probe fits exactly the

interior oft the MM27BC mil channel.

v

m

x

_

1

0

7

1

5

9

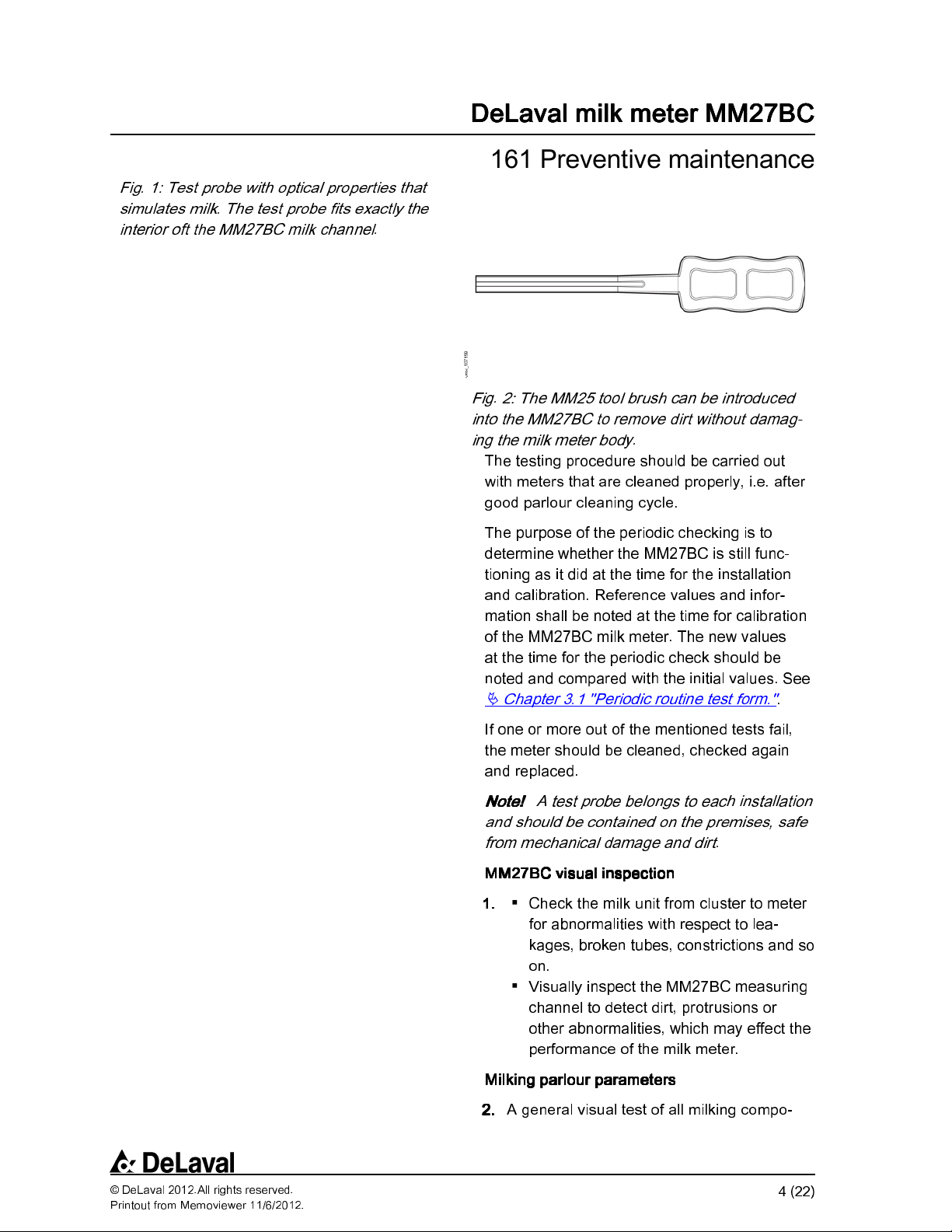

Fig. 2: The MM25 tool brush can be introduced

into the MM27BC to remove dirt without damag-

ing the mil meter body.

1.

1.1.

1.

Check the milk unit from cluster to meter

for abnormalities with respect to lea-

kages, broken tubes, constrictions and so

on.

Visually inspect the 27BC measuring

channel to detect dirt, protrusions or

other abnormalities, which may effect the

performance of the milk meter.

2.

2.2.

2.

A general visual test of all milking compo-

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

4 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

nents should be carried out to verify that

there are no big changes of equipment

installation or leakages.

The five values below represent milking

point parameters that if significantly changed

may affect the 27BC bias and therefore

the results of the milk yield measurements.

If the routine test should fail, the 27BC

meters must be recalibrated with milk.

Vacuum level:

If the vacuum level has changed by more

than 2.5 Kpa since the installation test,

the routine test fails.

Claw type:

If another significantly different claw is in-

stalled, the routine test will fail.

ilk tubes:

If the diameter of the milk tubes be-

tween milking cluster and the milk

meter has been changed, the routine

test fails.

If the length of the milk tube between

milking cluster and the milk meter has

been changed by more than +/- 10%,

the routine test fails.

If the milk tube between 27BC

meter and milk pipe line has been

changed in diameter or in length, the

routine test fails.

The height of the 27BC meter relative

to the cow platform:

If this distance has been changed by

more then 7 cm, the routine test fails.

Air inlet:

Increased air inlets or leakages will

cause deviations in the reading of the

27BC milk meter. If the air inlet has

significantly changed by more than 10%

compared with the installation test, for

example by air leakages along the cluster

to the 27BC milk meter, the routine

test fails. The air inlet can be observed

by visual inspection and by measuring

the air leakage using the VPR100.

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

5 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

Check of MM27BC internal parameters

Check of MM27BC internal parametersCheck of MM27BC internal parameters

Check of MM27BC internal parameters

3.

3.3.

3.

Each 27BC meter has the following

internal parameters:

Bias-Factor:

One value that is used to fix the meas-

ured 27BC bias.

Sub-Software:

This number represents the algorithm

used by the 27BC to compute

the yield. It is set when installing the

27BC and must remain constant.

(E.g. low line.)

Optical channel:

The milk channel and optical field must

stay the same as it was at the time for

calibration.

If by some malfunction the parameters

above have been changed, these para-

meters must be restored to the original

values. If not, the meters should be recali-

brated with milk.

Use VPR100 or PSION to read the para-

meters.

Check of internal parameters:

The meters Optical channel must be

checked. The milk channel characteristics

and optical field must stay the same as it

was at the time for calibration.

The test probe is simulating a milk flow.

The 27BC flow reading is compared

to the original reading obtained during the

installation test. If the obtained value is the

same, then the optical field and milk channel

characteristics have all stayed the same and

the 27BC measures as during the instal-

lation test.

For this test, a probe and the remote con-

trol unit (Psion/VPR100) are required. The

probe should be cleaned before usage and

as the probes are not perfectly identical; the

same probe should be used during the rou-

tine testing. The probe belongs to the milk-

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

6 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

ing parlour and should be stored under good

conditions on the farm, preventing pollution

and/or mechanical damage. Such will affect

the test results.

Principle of the test:

3.1.

3.1.3.1.

3.1.

Set all 27BC units to technician

mode using the remote control

(1:8:3:1, on the PSION remote or by

pressing technician mode tool on the

VPR100, see picture).

3.2.

3.2.3.2.

3.2.

Wash the test probe GENTLY using

any soft soap. Dry the probe after-

wards.

3.3.

3.3.3.3.

3.3.

Verify all 27BC-channels are dry

and clean.

3.4.

3.4.3.4.

3.4.

Wait 10 minutes to verify all units are

perfectly stable. If on some 27BC

units an

Hxxx

HxxxHxxx

Hxxx

message show, wait

until it disappears. The

Hxxx

HxxxHxxx

Hxxx

mes-

sage implies that the 27BC inter-

nal temperature is not stable yet.

3.5.

3.5.3.5.

3.5.

While the 27BC is in the tech-

nician mode and the 27BC chan-

nel is dry, the meter performs an inter-

nal self test. The self test status is

shown on the 27BC display as

Cxxx

CxxxCxxx

Cxxx

(a number between 85 and 100)

every 10 to 20 seconds. As long as

the meter shows the

Cxxx

CxxxCxxx

Cxxx

message

the self test is ok. If no

Cxxx

CxxxCxxx

Cxxx

mes-

sage is seen or if

SRVx

SRVxSRVx

SRVx

message ap-

pears the Self Test failed.

3.6.

3.6.3.6.

3.6.

If the Self Test failed the operator

should verify that the 27BC chan-

nel is dry and clean and wait for

the self test status again. If still the

27BC self test fails, the operator

can try to fix the problem by using

the Psion “RECAL” option. If still the

27BC self-test fails the 27BC

meter is defective and should be re-

placed.

2

0

9

8

4

0

2

0

9

8

4

1

v

m

x

_

1

0

7

1

5

9

F

i

g

.

3

:

M

M

2

5

/

M

M

2

7

B

C

c

l

e

a

n

i

n

g

p

r

o

b

e

.

Ratio min = Ref inF / Current inF

Ratio max = Ref axF / Current

axF

Write the

Ratio min

Ratio minRatio min

Ratio min

and

Ratio max

Ratio maxRatio max

Ratio max

values on the “DeLaval milk meter

27BC Periodic routine test form”.

If

Ratio min

Ratio minRatio min

Ratio min

and

Ratio max

Ratio maxRatio max

Ratio max

are be-

tween 0.98 and 1.02 the meter is

OK. Values outside the 0.98-1.02

range are too big and the meter fails

for the routine test. In case of FAIL

the 27BC channel should be

cleaned and inspected visually for

any abnormalities. Note that most of

deviation from the perfect 1.00 result

is usually because the probe test is

very sensitive. Small changes in the

probe surface and/or cleanness will

have affect on the measurement.

Failed meters

eters that failed the test should be

inspected and if necessary cleaned

internally and examined again. If a

27BC Self test fails, a RECAL

command using the Psion or VPR100

may solve the problem.

A meter that continues to fail after

F

r

e

q

u

e

n

c

y

2

0

0

0

h

o

f

o

p

e

r

a

t

o

n

M

a

x

.

n

t

e

r

v

a

l

1

2

m

o

n

t

h

s

E

s

t

m

a

t

3

0

m

n

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

7 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

No 4 Calibration

No 4 CalibrationNo 4 Calibration

No 4 Calibration

Required tools:

25-–30 litre bucket.

Bucket cover with two nipples, milk and

vacuum.

Rubber milk tube 50-–80 cm. length, de-

pending on the distance between the

27BC outlet to the nipple on the bucket.

Electronic scale, accuracy ± 5 g. (Enter

values in grams)

Calibration routine:

Note!

Note! Note!

Note!

After one wee 's use of the mil meters

or after 30 mil ed cows per mil meter, the

accuracy should be chec ed and the bias cor-

rected.

Check the air bleeds before calibration.

3.7.

3.7.3.7.

3.7.

If the

Cxxx

CxxxCxxx

Cxxx

values are lower than 80,

a RECAL of the 27BC can option-

ally be done, although NOT man-

datory. After RECAL the meter will

with display

Cxxx

CxxxCxxx

Cxxx

again but the

Cxxx

CxxxCxxx

Cxxx

values will be between 98 and 100.

3.8.

3.8.3.8.

3.8.

Insert the test probe into the 27BC

channel. After a few seconds the

meter should display a

PASS

PASSPASS

PASS

mes-

sage and two numbers. The two

values represent the flows measured

by the meter. The lower number is

the minimal flow and the higher the

maximal flow measured. The numbers

shown are 4 digits and usually be-

tween 3.000 and 4.000 kg per minute.

3.9.

3.9.3.9.

3.9.

Write the minimal and maximal flows

on the “DeLaval milk meter 27BC

Periodic routine test form” under

Cur

CurCur

Cur

rent MinF

rent MinFrent MinF

rent MinF

and

Current MaxF

Current MaxFCurrent MaxF

Current MaxF

col-

umns.

3.10.

3.10.3.10.

3.10.

During the routine test, the ratio be-

tween the

Current MinF

Current MinFCurrent MinF

Current MinF

and

MaxF

MaxFMaxF

MaxF

to the

Reference MinF

Reference MinFReference MinF

Reference MinF

and

MaxF

MaxFMaxF

MaxF

should be calculated.

additional cleaning should be re-

placed.

Reporting of the results

The results of the periodic checking

of the milk meters will be reported

to those concerned, the farmer, the

main supplier and to the national milk

recording organisation.

Cleaning tool:

Insert the tool brush into the

27BC channel to remove dirt.

e

d

t

m

e

:

S

e

r

v

c

e

t

y

p

e

:

A

d

j

u

s

t

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

8 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

Fixed air inlets should be used to obtain best

result.

The calibration must be carried out with real

milk (during milking).

Note!

Note! Note!

Note!

Collect reference values for the Periodic

testing using test probe.

Installation of the bucket for calibration:

It is important to secure the CV is installed be-

tween the bucket and the milk line to avoid re-

maining vacuum on the milk bucket.

Remove the milk tube from the 27BC and

attach on the bucket without stressing the

conductivity cable.

Add a new milk tube between the milk meter

output and the milk bucket.

No 5 Change diaphragm of the RS

No 5 Change diaphragm of the RSNo 5 Change diaphragm of the RS

No 5 Change diaphragm of the RS

valve

valvevalve

valve

Replacement parts or kits:

Art No: 85850901

Art No: 85531630

The article numbers above are kits for 1 and 10

pcs.

No 6 Replace rubber tubes

No 6 Replace rubber tubesNo 6 Replace rubber tubes

No 6 Replace rubber tubes

2

0

9

8

4

2

2

0

9

8

4

3

Frequency 4000h of operat on

Max. nterval 24 months

Est mated t me: 5 m n

Serv ce type: Replace

1.

1.1.

1.

Open by turning the cover by turning slightly

counterclockwise.

2.

2.2.

2.

Clean gently. Do not disconnect the cable.

3.

3.3.

3.

Replace the diaphragm.

Frequency 2000h of operat on

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

9 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

No 7 Replace silicon tubes

No 7 Replace silicon tubesNo 7 Replace silicon tubes

No 7 Replace silicon tubes

4.

4.4.

4.

Close the cover by turning it slightly clock-

wise.

Max. nterval 12 months

Est mated t me: 10 m n

Serv ce type: Replace

1.

1.1.

1.

2.

2.2.

2.

Replace tubes with the service items.

Frequency 4000h of operat on

Max. nterval 24 months

Est mated t me: 10 m n

Serv ce type: Replace

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

10 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

2

22

2 Calibration routine in VPR100

Calibration routine in VPR100Calibration routine in VPR100

Calibration routine in VPR100

After the first calibration it is important to take

reference values for the periodic checking of

the meters using the test probe. Please read

the instructions and recommendations from

ICAR on periodic checking of 27BC and

how to collect reference values using a test

probe.

2.1

2.12.1

2.1 Equipment

EquipmentEquipment

Equipment

VPR100 Software later than 08C

PC cable 92987001

Programmer cable 91677780

2.2

2.22.2

2.2 Test Procedure

Test ProcedureTest Procedure

Test Procedure

1.

1.1.

1.

Find kits that include silicon tube service

items in original parts.

2.

2.2.

2.

Replace tubes with the service items.

1.

1.1.

1.

Verify that the vacuum level in the milking

parlour is between 42 and 44 kPa at low

line, 48 or 50 kPa at high line.

2.

2.2.

2.

Check the milk tube connections from the

milking cluster through the 27BC up

to the milk line, Verify that there are no air

leaks.

3.

3.3.

3.

Check the condition of the milk cluster.

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

11 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

Note!

Note! Note!

Note!

The MM27BC is sensitive when it

comes to vacuum lea s, restrictions and bloc s

so it is of great importance that the installation

is according to guidelines.

When the installation is checked and approved

proceed with the actual calibration process:

Verify that it is clean, without cracks. Liners

and stubs should also be in a good condition

without cracks. Check also the air bleed on

the claw so that it is not blocked.

4.

4.4.

4.

Check and verify that there are no error

messages on the 27BC display when it

is connected to the power.

1.

1.1.

1.

Connect the IR reader to the VPR100

2

0

3

8

3

5

2.

2.2.

2.

In the VPR100 go to menu for 25W/

27BC. Choose ALCO . Use the

VPR100 to read all Alcom node number in

the parlour. ark node number on a piece

of Tape on each milkmeter. ake sure no

milkmeter has the same number. If there are

units with the same number reset them to

another nr by punching in new number on

the VPR100 and sending it to the milkmeter.

3.

3.3.

3.

Setup Buckets at milking point. ark each

bucket with node number so that it belongs

to that specific milking point.

4.

4.4.

4.

When the milking is done push calibration

on the VPR100 and read the milking points

with buckets by pointing reader to the milk-

meter. The VPR100 will automatically

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

12 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

2

0

3

8

2

9

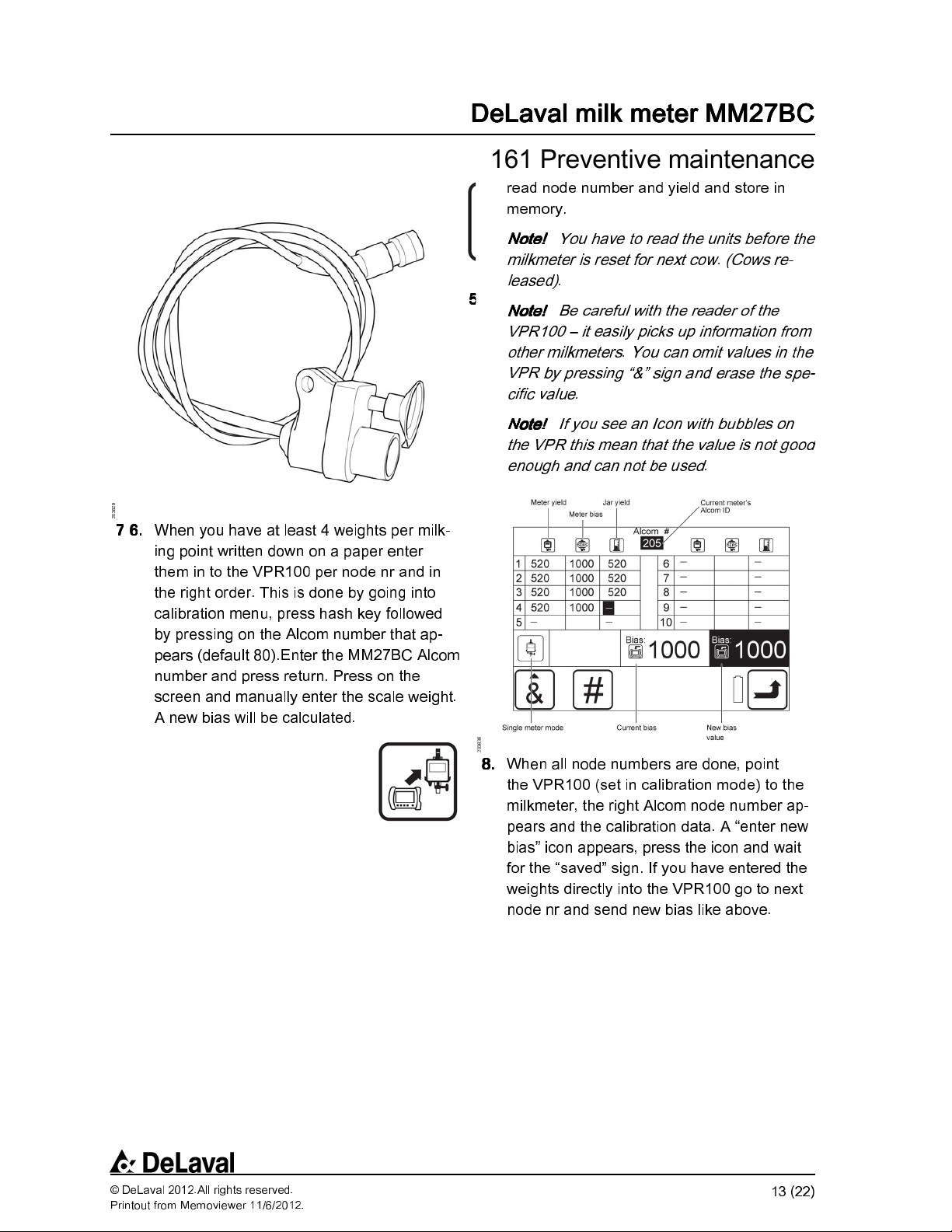

read node number and yield and store in

memory.

Note!

Note! Note!

Note!

You have to read the units before the

mil meter is reset for next cow. (Cows re-

leased).

Note!

Note! Note!

Note!

Be careful with the reader of the

VPR100 – it easily pic s up information from

other mil meters. You can omit values in the

VPR by pressing “&” sign and erase the spe-

cific value.

Note!

Note! Note!

Note!

If you see an Icon with bubbles on

the VPR this mean that the value is not good

enough and can not be used.

5.

5.5.

5.

2

0

3

8

3

6

6.

6.6.

6.

When you have at least 4 weights per milk-

ing point written down on a paper enter

them in to the VPR100 per node nr and in

the right order. This is done by going into

calibration menu, press hash key followed

by pressing on the Alcom number that ap-

pears (default 80).Enter the 27BC Alcom

number and press return. Press on the

screen and manually enter the scale weight.

A new bias will be calculated.

7.

7.7.

7.

8.

8.8.

8.

When all node numbers are done, point

the VPR100 (set in calibration mode) to the

milkmeter, the right Alcom node number ap-

pears and the calibration data. A “enter new

bias” icon appears, press the icon and wait

for the “saved” sign. If you have entered the

weights directly into the VPR100 go to next

node nr and send new bias like above.

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

13 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

14 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

15 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

16 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

17 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

18 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

3

33

3 Accuracy check

Accuracy checkAccuracy check

Accuracy check

Note!

Note! Note!

Note!

The reference values shall be recorded

at the time for the installation test just after the

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

19 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

calibration and compared to when doing the

routine test with the test probe.

Every 12 months the 27BC should be

checked so that all internal parameters and

software has stayed the same since calibration

and installation.

Note!

Note! Note!

Note!

It is very important that the same test

probe is used for reference values and for peri-

odic chec ing.

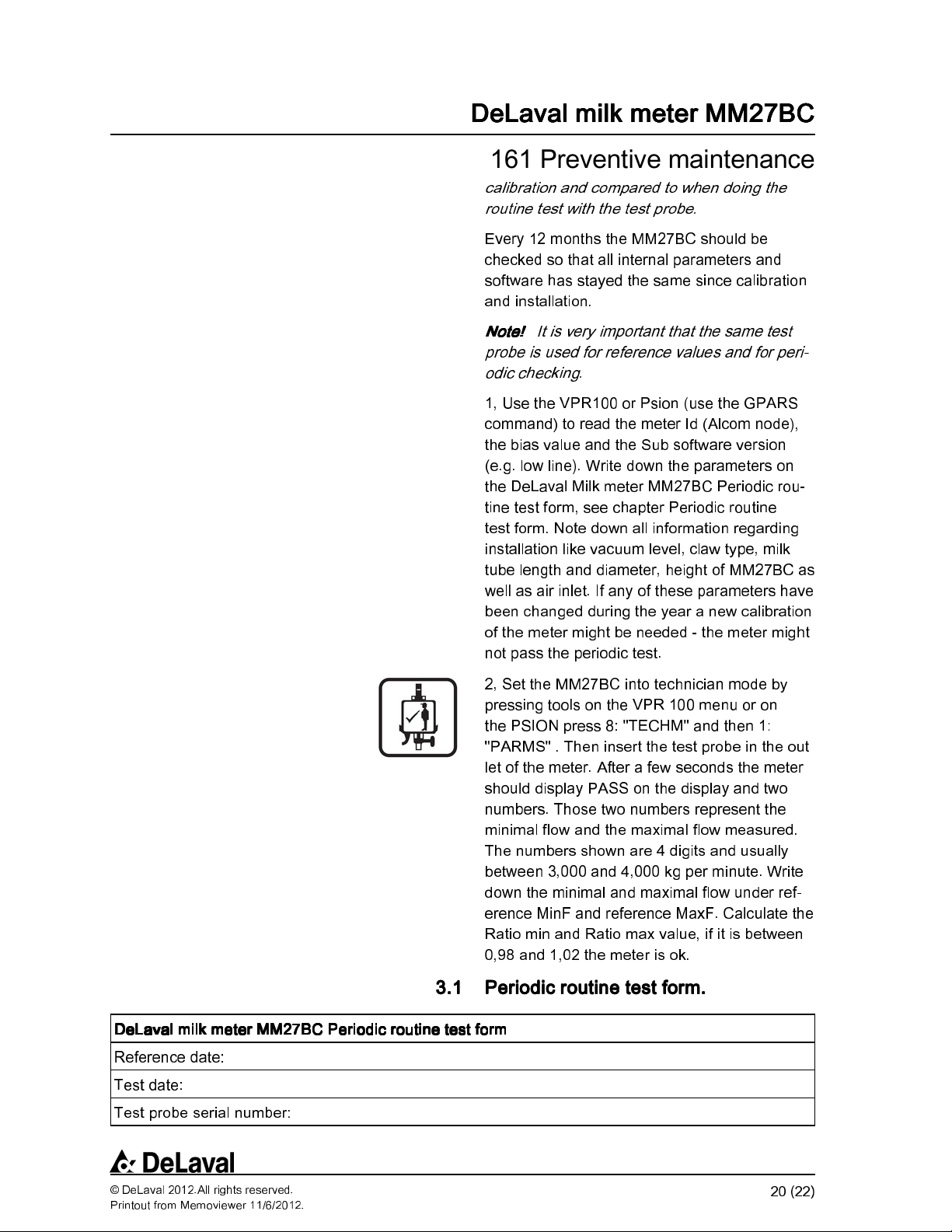

1, Use the VPR100 or Psion (use the GPARS

command) to read the meter Id (Alcom node),

the bias value and the Sub software version

(e.g. low line). Write down the parameters on

the DeLaval ilk meter 27BC Periodic rou-

tine test form, see chapter Periodic routine

test form. Note down all information regarding

installation like vacuum level, claw type, milk

tube length and diameter, height of 27BC as

well as air inlet. If any of these parameters have

been changed during the year a new calibration

of the meter might be needed - the meter might

not pass the periodic test.

2, Set the 27BC into technician mode by

pressing tools on the VPR 100 menu or on

the PSION press 8: "TECH " and then 1:

"PAR S" . Then insert the test probe in the out

let of the meter. After a few seconds the meter

should display PASS on the display and two

numbers. Those two numbers represent the

minimal flow and the maximal flow measured.

The numbers shown are 4 digits and usually

between 3,000 and 4,000 kg per minute. Write

down the minimal and maximal flow under ref-

erence inF and reference axF. Calculate the

Ratio min and Ratio max value, if it is between

0,98 and 1,02 the meter is ok.

3.1

3.13.1

3.1 Periodic routine test form.

Periodic routine test form.Periodic routine test form.

Periodic routine test form.

DeLaval milk meter MM27BC Periodic routine test form

DeLaval milk meter MM27BC Periodic routine test formDeLaval milk meter MM27BC Periodic routine test form

DeLaval milk meter MM27BC Periodic routine test form

Reference date:

Test date:

Test probe serial number:

DeLaval milk meter MM27BC

DeLaval milk meter MM27BCDeLaval milk meter MM27BC

DeLaval milk meter MM27BC

161 Preventive maintenance

20 (22)

© DeLaval 2012.All rights reserved.

Printout from Memoviewer 11/6/2012.

Other DeLaval Measuring Instrument manuals