3

Compact Refrigerators

Contents

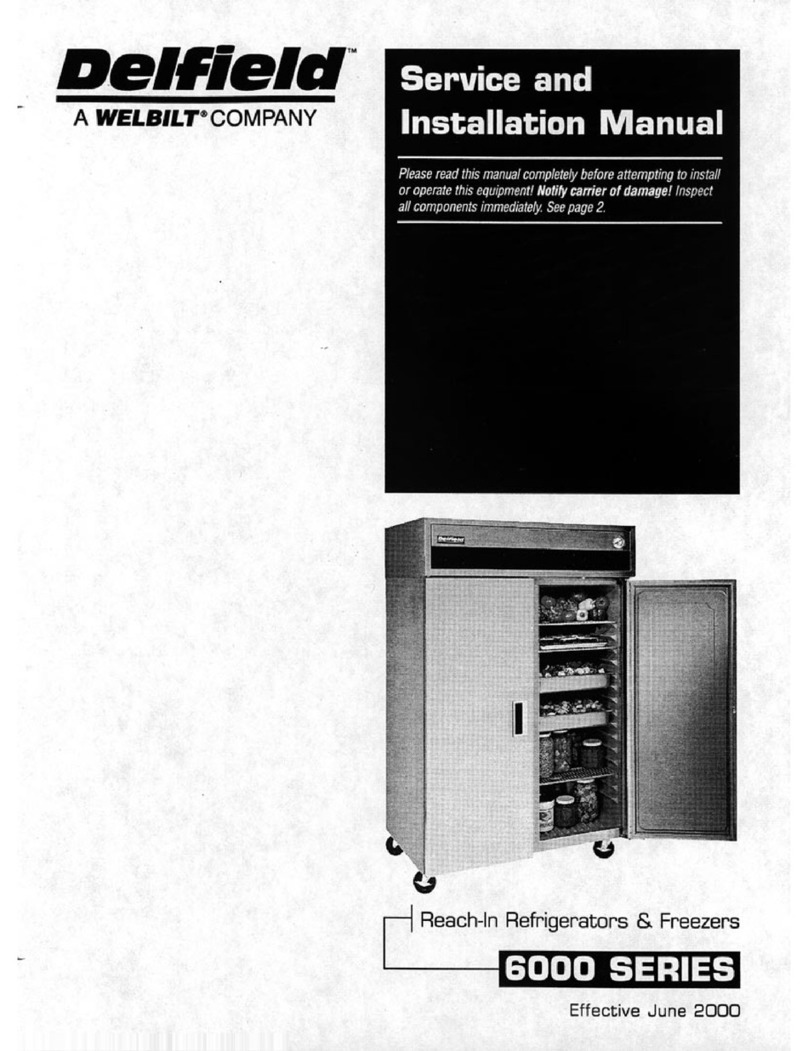

Even though most equipment is shipped crated, care should be

taken during unloading so the equipment is not damaged while

being moved into the building.

1. Visually inspect the exterior of the package an skid or

container. Any damage should be noted and reported to the

delivering carrier immediately.

2. If damaged, open and inspect the contents with the carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment notify

the carrier. Notification should be made verbally as well as

in written form.

4. Request an inspection of the concealed equipment. This

should be done within 10 days from receipt of the equipment.

5. Check the lower portion of the unit to be sure legs or casters

are not bent.

6. Also open the compressor compartment housing and

visually inspect the refrigeration package. Be sure lines are

secure and base is still intact.

7. Freight carriers can supply the necessary forms upon

request.

8. Retain all crating material until an inspection has been made

or waived.

9. Do not use forklift or pallet jack to move this equipment

once it is removed from the pallet. Doing so may cause

equipment damage and void warranty.

Uncrating the Equipment

First cut and remove the banding from around the crate. Remove

the front of the crate material, use of some tools will be required.

If the unit is on legs remove the top of the crate as well and lift

the unit off the skid. If the unit is on casters it can be "rolled" off

the skid.

Receiving And Inspecting The Equipment

Receiving And Inspecting The Equipment......................................3

Introduction ...................................................................................4

Warranty Information.....................................................................4

Regulatory Certifications ...............................................................4

Specifications............................................................................5-12

Installation ..............................................................................13-14

Location...............................................................................13

Inside Cabinet ......................................................................13

Outside Cabinet....................................................................13

Leveling ...............................................................................13

Stabilizing ............................................................................13

Plumbing .............................................................................13

Electrical Connection............................................................13

Cutting Board Bracket Mounting..........................................14

Shelf Installation Instructions ..............................................14

2-Position Pan Rails Installation Instructions ......................14

Optional Overshelf Installation .............................................15

Operation ................................................................................15-16

Refrigeration Temperature Control.......................................16

Freezer Temperature Control................................................17

Maintenance............................................................................18-19

Stainless Care And Cleaning ................................................18

Condenser Coil Cleaning ......................................................18

Gasket..................................................................................18

Doors/hinges .......................................................................19

Drain ....................................................................................19

Drawer Maintenance ............................................................19