Delfin Bisky 400 User manual

Bisky

Instruction manual

pag.ii

Bisky_firsth_page_en.fm

Bisky

This page has been intentionally left blank

pag.1

Bisky_en_03TOC.fm

Bisky

Chapter 1 General Information............................................................................................ 2

1.1 List of documents.................................................................................................. 2

1.2 This instruction manual......................................................................................... 2

1.3 Property................................................................................................................. 3

1.4 Conventions.......................................................................................................... 4

1.5 Manufacturer's identification detail........................................................................ 4

1.6 Machine identification data.................................................................................... 5

1.7 EC conformity declaration..................................................................................... 5

1.8 Warranty................................................................................................................ 6

1.9 Technical assistance............................................................................................. 7

1.10 Use of the manual................................................................................................. 7

1.11 Machine description.............................................................................................. 8

Chapter 2 Information on the safety features.................................................................... 9

2.1 Safety criteria........................................................................................................ 9

2.2 Personnel qualifications...................................................................................... 10

2.3 Safety rules......................................................................................................... 11

2.4 Protections.......................................................................................................... 12

2.5 Interlocking devices............................................................................................. 13

2.6 Safety devices..................................................................................................... 14

2.7 Signs illustrating the dangers on the machine .................................................... 15

2.8 Dangerous zones and residual risks................................................................... 17

2.9 Noise emission.................................................................................................... 19

Chapter 3 Machine Characteristics................................................................................... 21

3.1 Machine specifications........................................................................................ 21

3.2 Qualified operator................................................................................................ 22

3.3 Transport............................................................................................................. 23

3.4 Preliminary operations ........................................................................................ 25

3.5 Storing of the machine ........................................................................................ 26

3.6 Allocation............................................................................................................. 27

3.7 Installation of the machine .................................................................................. 28

3.8 Machine testing................................................................................................... 28

Chapter 4 Operator interface............................................................................................. 31

4.1 Main control panel............................................................................................... 31

Chapter 5 Machine programming...................................................................................... 33

5.1 Tooling, adjustments and setting up of the machine ........................................... 33

5.2 Recipes............................................................................................................... 34

Chapter 6 Use ..................................................................................................................... 61

6.1 Dangerous areas and residual risks during the use............................................ 61

pag.2

Bisky_en_03TOC.fm

Bisky

6.2 Operators qualification........................................................................................ 61

6.3 Working area ...................................................................................................... 61

6.4 Functioning methods .......................................................................................... 62

6.5 Starting of the machine....................................................................................... 62

6.6 Starting of the machine....................................................................................... 63

6.7 Emergency stop.................................................................................................. 63

6.8 The re-starting of the machine after an emergency has been activated............. 63

6.9 Description of the procedures............................................................................. 64

6.10 Recipe management pages................................................................................ 68

6.11 Switching off the machine................................................................................... 72

6.12 Introduction of the tray........................................................................................ 72

6.13 Introduction of the rotary, fixed or wire cut plates............................................... 73

6.14 Wire cut optional................................................................................................. 74

6.15 Dismantling the hopper....................................................................................... 77

Chapter 7 Maintenance...................................................................................................... 81

7.1 Hygienic regulations to respect during the machine cleaning and washing of the

machine. 81

7.2 Standard maintenance........................................................................................ 81

7.3 Cleaning method................................................................................................. 86

7.4 Programmed maintenance ................................................................................. 87

7.5 Dismantling of the conveyor belts....................................................................... 89

7.6 Scrapping and disposing of the machine............................................................ 90

Chapter 8 Adjusting the height of the dough extrusion table....................................... 93

8.1 Height adjustment............................................................................................... 93

Chapter 20 Attached list of documents.............................................................................. 95

pag.1

01_info_gen_en.fm

Bisky

Dear Customer,

Thank you for having chosen our machine. We take the pleasure to

supply you with this instruction manual, with the objective to help

you operate our machine efficiently and safely.

We invite you to read the contents with utmost care and make sure

that all the personnel that operate, maintain, repair and eventually

dismantle the machine fully understand the contents.

We are at your disposal for any further information that you may

require on the machine or on any idea to improve the machine

functions, safety and manual.

We remind you that we have at your disposal our technical

assistance office for any questions you may have for repairs and

maintenance, this to ensure the maximum security to the personnel

and to ensure a long machine life.

Kind regards

The Manufacturer

pag.2

01_info_gen_en.fm

General Information

Bisky

Chapter 1 General Information

1.1 List of documents

• Instruction manual (this instruction manual).

1.2 This instruction manual

Manual's datas

Instruction manual:

Bisky

•Edition:2.0

• Year and month it was printed : August 2009

Addressees

• Transport of the machine.

• Installation.

• Operator.

• Maintenance.

pag.3

01_info_gen_en.fm

General Information

Bisky

1.3 Property

The information in this manual is reserved property, all rights are reserved.

This manual cannot be reproduced or photocopied in any of its parts without

having requested written permission to the Manufacturer.

This instruction manual is addressed to the owner, user of the machine, to managers or

employees with appointed responsibility, to personnel in charge of handling, installing,

operating, watching, maintaining, dismantling ect. the machine.

The Manufacturer declares that the information contained in this manual are relative to the

technical specifications and safety devices of this machine.

The Manufacturer is not responsible for direct or indirectinjury to persons, things or domestic

animals

subsequent to the incorrect use of the machine or due to conditions other than

recommended in this manual.

The Manufacturer reserves the right to update this manual and the machines of the same

model but

with different serial numbers without any prior notice.

The information contained in this manual refer to the machine specified

Machine identification data

on page 5.

pag.4

01_info_gen_en.fm

General Information

Bisky

1.4 Conventions

Meanings and symbols

• Left, right : refers to the operators position when standing in front of the operating

panel.

• Qualified personnel : people with experience, and specific training, in depth

knowledge of the safety regulations and all the relative instructions of how to avoid injury

to people, or any other danger.

Typogrphical conventions

Writings with big characters and dark black characters : Indicates the title of a chapter or a

paragraph of a chapter, or a table or a drawing identification

DPI: Individual Protection Device.

Represents a number, for example , indicates the start button on the control

panel.

represents a letter, for example indicates a part on the machine.

NOTE The notes contain very important information, evidenced in a separate

paragraph and in dark letters.

BEWARE Are important information that help avoid damage to the machine or other

equipment connected to the machine.

DANGER Are important information the can avoid injury to the personnel responsible

for the machine in all its life span..

1.5 Manufacturer's identification detail

Delfin Srl

Plant: Via Keplero, 18

36034 Malo (VI) ITALY

Tel. 039/0445/580688

Fax. 039/0445/587112

E-mail: [email protected]

Internet: http://www.delfin.it

pag.5

01_info_gen_en.fm

General Information

Bisky

1.6 Machine identification data

Type:

Model: Bisky

Serial number:

Year of construction:

Fig. 1.1 Identification plate

Machine type____________________________ Volt____________

Model__________________________________ Hz_____________

Serial number________________________________ Kw_____________

Year of construction_______________________Phase____________

Certificate of origin______________________ Weight___________

1.7 EC conformity declaration

Vedere

Attached list of documents

Document 1 EC Conformity declaration

on page 95.

pag.6

01_info_gen_en.fm

General Information

Bisky

1.8 Warranty

General conditions

1. The warranty is 12 months from the effective delivery date of the machine. Any

defects are to be notified in writing to the manufacturer within 8 days from there

being.

2. If during this period structural defects or faults on material appear, the defected parts

will be replaced or repaired free of charge.

3. We do not acknowledge damages due to overloads, improper use, wear or tear due

to climatic conditions.

4. All transport charges, costs and custom taxes due to the replacement of defected

parts are at the buyers expense.

5. Replacement and repairs are subject to the execution of the payment terms by the

buyer. In no case we accept responsibility for paid out salaries, wages, decrease in

profit, loss of time and claims by third parties.

6. Our warranty does not include worn out parts, replacement or repairs due to

improper use, bad maintenance or lack of expertise. We will in no way be considered

responsible for direct or indirect damages.

7. For parts assembled on this machine, but not manufactured by us, such as electrical/

electronic equipment ext. are not included in the warranty. The warranty does not

cover parts subject to wear and tear.

8. Any returns of goods must be previously authorized by us in writing. The goods must

be perfectly packed and returned CIF to our company.

NOTE Should the machine be repaired in the same place where it was fitted, the

warranty coupon must be shown to the technician in charge of assistance.

Be careful because the warranty will be effective only it the coupon has

been completely filled in.

BEWARE Any particular warranty terms are to be specifically expressed in writing in

the buyers/sellers contract

The following conditions will cause the warranty to be invalid.

• • Unforeseen use of the machine.

• • Use of tools other than those specified in

Chapter 7 Maintenance

.

• • Assembly of the machine in conditions other than those specified in

Chapter 7

Maintenance

.

• • Electrical and pneumatic connections other than those specified in

Chapter 7

Maintenance

.

• • Use of non original spare parts.

pag.7

01_info_gen_en.fm

General Information

Bisky

Request for spare parts or maintenance under warranty

Modalità

Request for spare parts, or request for maintenance for machine under warranty must be

made in writing to the Manufacturer or the nearest authorized agent, immediately after the

defect or problem has come to being. General conditions a page 5. When requesting

spare parts always inform the manufacturer or agent the machine serial number and

model, this data is written on the identification plate fixed to the machine.

NOTE The in observance of the information in this manual will exclude the

Manufacturer from any responsibility in case of accidents to persons and or

property or malfunctioning of the machine.

1.9 Technical assistance

This manual must be considered an integral part of the machine, however it can never

replace the proper training and work experience of the user, who should read this manual

before starting to work on the machine.

Requests for service visits

Technical assistance service

You can contact our technical assistance office by contacting us at the following address:

DELFIN S.R.L.

Plant: Via G. Keplero n° 18

36034 Malo (VI) ITALY

Tel. 039/0445/580688

Fax. 039/0445/587112

E-mail: [email protected]

Internet: http://www.delfin.it

When requesting assistance or spare parts, you must specify the machine model and serial

number.

Requests for spare parts

When requesting spare parts, please state the following information:

• • Type of machine.

• • No. of production order marked on the relevant label.

• • Year of construction.

1.10 Use of the manual

Read the manual carefully,

Chapter 1 General Information

,

Chapter 2 Information on the safety

features

,

Chapter 3 Machine Characteristics

,

Chapter 4 Operator interface

,

Chapter 5 Machine

programming

.

For any information regarding the installation, use, maintenance and demolition of the

machine, consult the relative chapters.

pag.8

01_info_gen_en.fm

General Information

Bisky

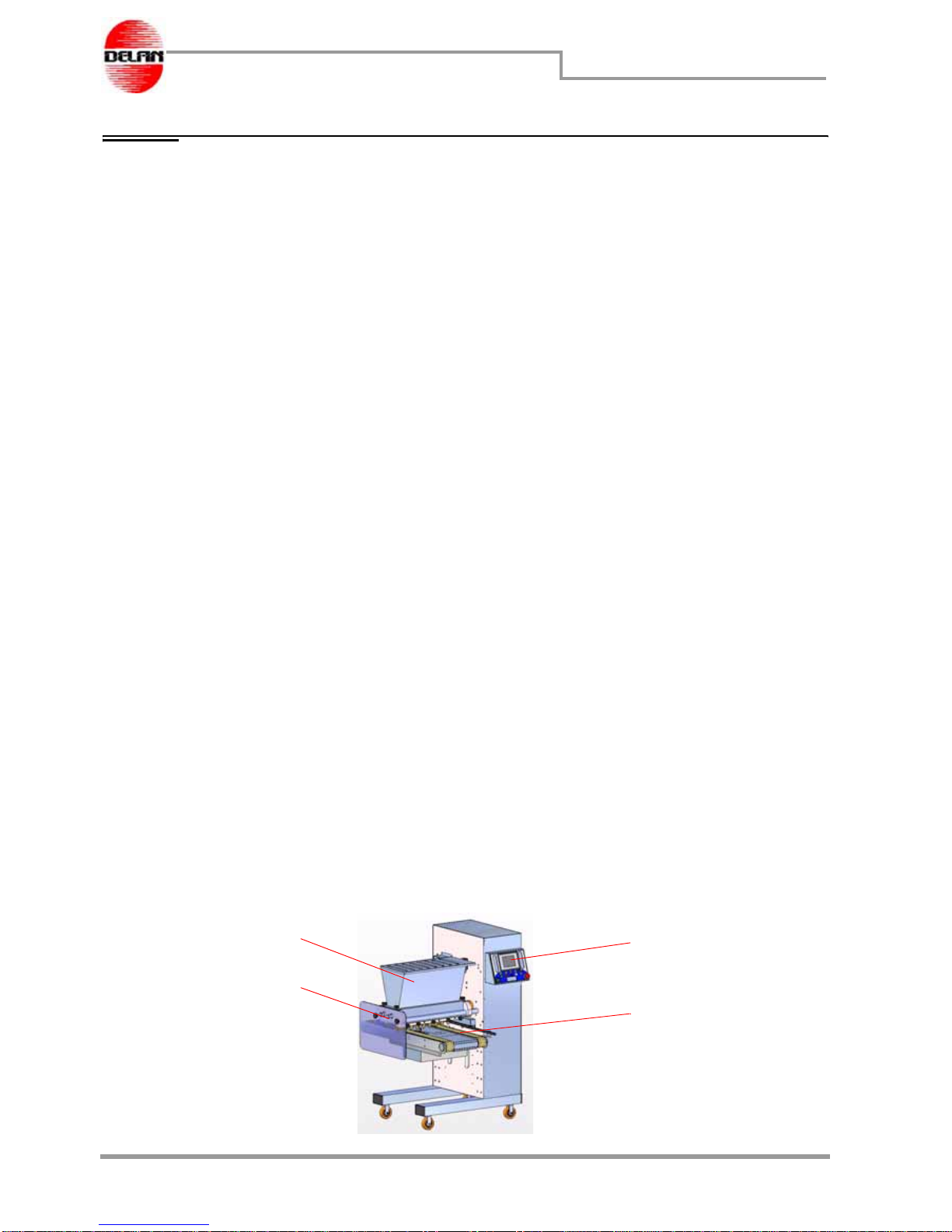

1.11 Machine description

Foreseen uses

Foreseen operation:

The machine is intended for the production of biscuits/cookies of different shapes and sizes.

Dough used on the machine:

Semi-hard and soft dough used for the production of biscuits.

Working place

The machine was designed and constructed for use in an indoor ambient, repaired from

atmospheric agents.

Power supply nature foreseen

The machine is powered by external electrical supply that converts into mechanical

movement, necessary for the machine functioning.

The machine is not to be used in the following conditions :

All uses not explicitly specified in the list on page 6 are considered unforeseen uses, and in

particular:

• Use of the machine in an area with explosives.

• Use of the machine in a flammable area.

• Washing of the machine zone where the control apparatus are fitted with water jets;

• Use of dough other than those foreseen.

• Handling of material to be extruded with weight higher than that specified in

Envisaged uses on page 6.

Machine composition

In this section the main parts of the machine and theIr functions withinthe production cycle

are described .

Main parts of the machine

The machine is composed of the following main parts :

a. Stainless steel hopper in which the dough is introduced

b. Control panel with screen in order to program the machine

c. Conveyor belt that transports the tray in which the dough is deposited

d.

Extruding head that contains the extruding rollers and on which the moulds and

nozzles are assembled

Fig. 1.2 Main parts of the machine

ab

c

d

page 9

02_safety_en.fm

Information on the safety features

Bisky

Chapter 2 Information on the safety features

2.1 Safety criteria

In the design and construction of this machine standards and suitable precautionary

measures were adopted to satisfy the essential safety requirements of Machine Directive

2006/42/EC, Low Voltage Directive 2006/95/EC and Electromagnetic Compatibility

Directive 2004/108/CE and its successive amendments.

The accurate analysis of the risks carried out by the manufacturer has eliminated the main

obvious risks connected to the correct operation of the machine. The complete

documentation of the standards applied to the machine to ensure its safety are contained

in a technical manual of the machine deposited by the Manufacturer.

The Manufacturer recommends the final user to carefully follow the instructions, procedures

and recommendations contained in the manual, and to observe the safety features,

hygienic, and ambient regulations and laws in the working area of the machine. The

protective mechanisms foreseen are to be integral for the entire technical life of the

machine.

DANGER Do not wear large clothes, ties, neck laces, watches which might get

entangled in the moving parts of the machine.

NOTE The Manufacturer is not responsible for injury caused to people, domestic

animals or property, due to negligence, or for disregarding the contents on

the safety features and recommendations in this manual.

page 10

02_safety_en.fm

Information on the safety features

Bisky

2.2 Personnel qualifications

NOTE The Manufacturer is not responsible for injury caused to people, domestic

animals or property, due to negligence, or for disregarding the contents on

the safety features and recommendations in this manual.

Stage of machine

technical life Qualifications of the responsible personnel

Transport The personnel transporting the machine must have read,

understood and applied the contents in:

Chapter 2 Information

on the safety features

,

2.3 Safety rules

a pag. 11 of this manual.

Installation An experienced and qualified electrician or technician that

have understood and applied the contents in:

Chapter 2

Information on the safety features

,

Chapter 3 Machine

Characteristics

,

Chapter 5 Machine programming

,

Chapter 7

Maintenance

.

Testing and fine tuning Qualified technical personnel thoroughly trained on this

specific machine, that have understood and applied the

contents in:

Chapter 2 Information on the safety features

,

Chapter 3

Machine Characteristics

,

Chapter 5 Machine programming

,

Chapter 7

Maintenance

Use Operator trained for the daily use of the machine must have

understood and applied the contents in:

Chapter 2 Information

on the safety features

,

Chapter 3 Machine Characteristics

,

Chapter 5

Machine programming

,

Chapter 7 Maintenance

.

Maintenance There are three type of maintenance personnel that can

carry out repairs on the machine:

• Mechanical maintenance personnel : Qualified

mechanical technician that is capable of carrying out

maintenance with the guards open and in normal working

conditions, capable of intervening on mechanical parts that

need adjustment, maintenance and repair. It is forbidden to

intervene electrically whilst the machine is under electrical

tension.

•Electrical maintenance personnel : Qualified electrical

technician that is capable of carrying out electrical

maintenance withthe guards open and in normal conditions,

capable of intervening on electrical parts that need

adjustment in the electrical panel even when the machine is

under tension.

• Construction technician : Qualified technician put at

disposal by the Manufacturer to carry out repairs and

maintenance of complicated nature and in particular

situations, in accordance with the owner of the machine.

Demolition Qualified mechanical technician that have understood and

applied the contents in:

Chapter 2 Information on the safety

features

.

page 11

02_safety_en.fm

Information on the safety features

Bisky

2.3 Safety rules

The following safety information specifically refers to the use of a dropping machine model

Bisky.

Before starting up the machine, the operator must be fully aware of the location and

functioning of all the commands to operate and adjust the machine.

The operator must know how to carry out the adjustments described in this manual. Make

sure that the following safety rules are read and understood. They must be observed every

day, even during maintenance operations to the machine in order to avoid injuries to the

personnel and damage to the machine. The keys for the keylock switch (Fig. 2.1 Keylock

switch) for safety guards deactivation and machine start-up enabling must never be left on

the machine. They must be kept by the person in charge of the machine maintenance

operations or by the shop superintendent.

NOTE The Manufacturer cannot be held responsible for possible injuries to the

personnel in charge of machine and/or production line operation arising

from the non-observance of these safety rules and/or the tampering with the

machine and/or the production line safety devices.

Fig. 2.1 Keylock switch

page 12

02_safety_en.fm

Information on the safety features

Bisky

2.4 Protections

DEFINITION

Safety guards are all those safety measures adopted which involve the application of

specific technical mechanisms (guards, safety devices) to protect people from dangers

which cannot be neutralized completely through design.

Fixed guards

• All the fixed parts are fixed by means of bolts, screws ext. and must be unscrewed

with a tool in order to be removed

• Steel guard (A) protects against the mechanisms, the electrical/electronic

components.

Fig. 2.2 Fixed guards

NOTE The manufacturer will not be liable for injuries to persons or animals or for

damages to properties caused by the tampering with the machine safety

devices.

A

page 13

02_safety_en.fm

Information on the safety features

Bisky

2.5 Interlocking devices

DEFINITION

Emergency blocks, are switches that cause the machine to stop immediately when

activated, and do not allow the machine to start again until the emergency has been re-

activated, and the re-set button (on control panel) is pressed.

For instance, end of stroke micro-switches are considered interlocking devices because

they are used to detect when any mobile safety guard is opened. The photocells are also

considered interlocking devices. On the machine the following end of stroke micro-

switches are found and are used to stop the machine:

• a micro-switch “a” stops the machine when the steel grill (3) that cover the stainless

steel hopper is opened. The micro-switch is activated by a cam attached to the shaft on

which the grill pivots and is under the machine body;

• a micro-switch "B" stops the machine in case a tray is not found in the deposit position

above the conveyor-belts;

• a micro-switch "C" stops the machine in case the plate is extracted from its working

position;

• a photocell "D" is located at the tray infeed to stop the motion in case its reading area

was interrupted;

• two photocells "E" have been fitted at the tray outfeed to stop the motion in case their

reading is interrupted.

NOTE A side Plexiglas protection "F" has been fitted to the deposit zone and

equipped with two fastening knobs to immediately stop the machine

operation.

Fig. 2.3 End of stroke micro-switch

bd e a

cf

page 14

02_safety_en.fm

Information on the safety features

Bisky

2.6 Safety devices

DEFINITION

Active emergency systems are emergency stops assembled on the machine to prevent or

reduce the danger and injury, and are activated purposely by the operator.

1. The machine was designed with safety guards which render all its moving parts safe

and enable the operator to work under safe conditions. The Manufacturer declines

any responsibility arising from the tampering with these safety devices.

Fig. 2.4 Emergency mushroom-head button located on the control panel.

2. Some special safety systems have been installed on the machine with the purpose of

immediately stopping the machine in case of an emergency condition (

Fig. 2.4

Emergency mushroom-head button located on the control panel.

).

3. The moving guards (which can be opened through a handle) have been installed so

that when they are opened the machine stops immediately.

4. The fixed safety guards (which cannot be opened without a tool or removing some

screws) must be removed only after cutting out the electric power supply.

5. Immediately advise your superiors about any deficiency in the safety system and

guards and of any dangerous condition which occurs.

6. Under no circumstance should the safety devices be removed or tampered with.

page 15

02_safety_en.fm

Information on the safety features

Bisky

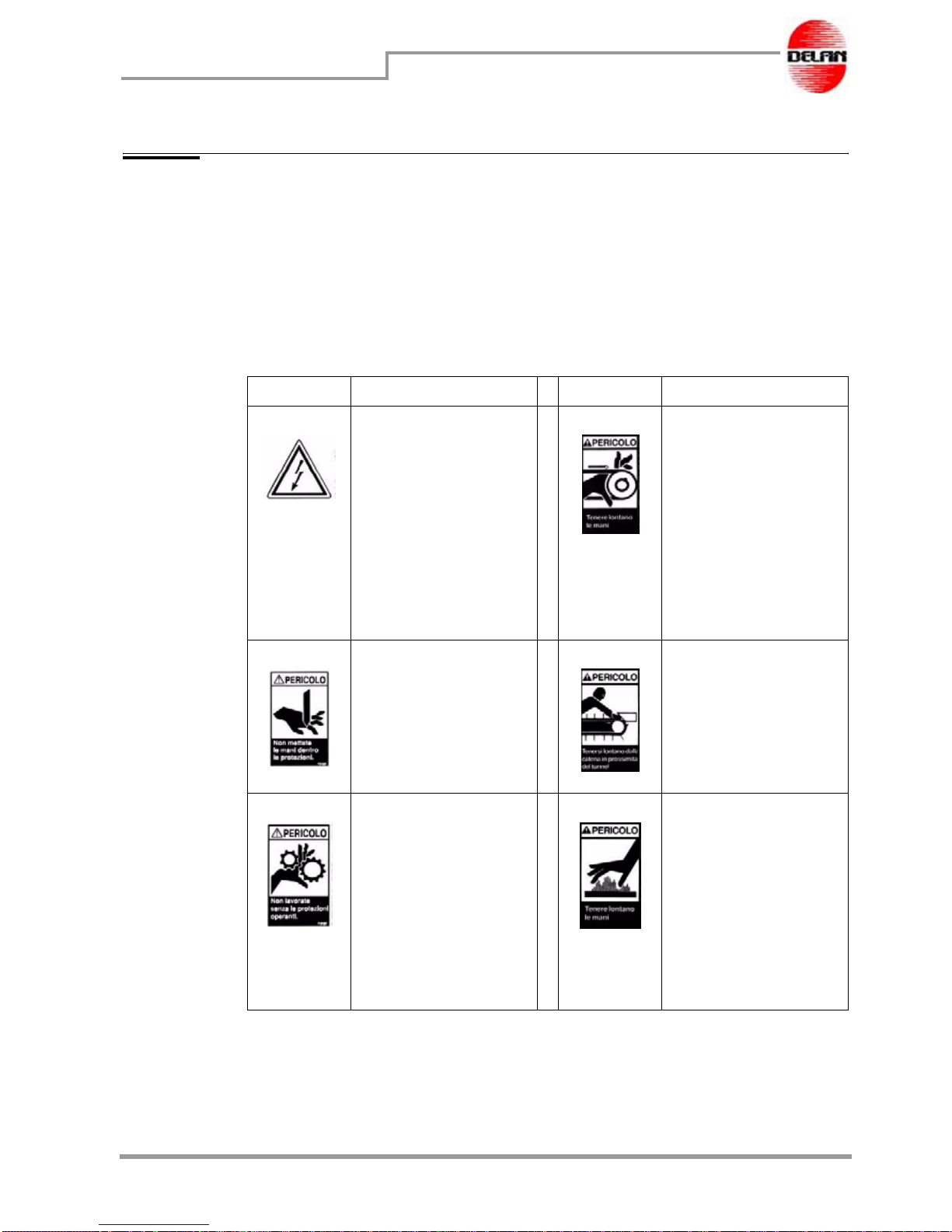

2.7 Signs illustrating the dangers on the machine

Safety labels

Safety labels are affixed in all areas where the operator - if not reminded- could be in

danger The labels are not to embellish the machine but are there to ensure the necessary

safety conditions for the operator to work in and must be understood before he operates

the machine.

LABEL MEANING LABEL MEANING

Located on the rear

guard to warn against

the presence of high

voltage inside. Be care-

ful and do not open the

safety guards without

having disconnected

the current supply

beforehand.

Located on the rear

casing to warn the

operator about the

presence inside of

driving chains, likely to

be dangerous, and

therefore it is necessary

to disconnect the

electric supply and wait

until the machine has

completely halted

before operating.

Located on the mobile

safety guard to warn

the operator that when

this guard is open, he

must keep his hands off

the moving parts

before starting operat-

ing.

Pay particular care

when the machine is

running because the

chain and the pushers

could injure your hands!

Located on the rear

casing to warn the

operator not to open

thedoorwithouthaving

cut the current supply

off and to wait until the

machine has com-

pletely stopped. This

precaution is important

in order to avoid inju-

ries to the operator's

hands.

Located on the

Plexiglassafetyguard,it

signals that the zone is

hot when the machine

is in function. Do not

touch this zone and use

gloves if operating in

this area for a long

time.

page 16

02_safety_en.fm

Information on the safety features

Bisky

Located on the rear

casing to signal that

inside the door some

dangerous electrical

connections are pres-

ent and therefore the

current supply must be

disconnected before

starting any operation.

Located next to all the

electric connector

blocks to remind the

operator to disconnect

the machine before

removing these covers.

Located on the guards

that cover any moving

parts. Before removing

these safety guards the

machine must be

turned off.

Located next to all the

safety devices which

can be removed only

with the use of tools. It

reminds the operator to

work with all the safety

guards in place and

thatbeforecarryingout

any intervention to the

machine, it must be

completely stopped.

LABEL MEANING LABEL MEANING

D_rimoz.eps

This manual suits for next models

2

Table of contents