Delfino DRH7 User manual

Digital ORP Sensor

User Manual

Model: DRH7

Version 1.0

Daruifuno

Contents

Chapter 1 Specification......................................................................1

Chapter 2 Basic Information..............................................................2

2.1 Security Information................................................................2

2.2 Overview..................................................................................2

2.3 Dimensions.............................................................................2

Chapter 3 Installation.........................................................................3

3.1 Sensor Installation...................................................................3

3.2 Sensor Wiring............................................................................4

Ch a p te r 4 C o mm u n ic a ti o n P ro t o co l s .. . . .. . . . .. . . . .. . . .. . . .. . . . .. . . . .. . . .. .. . . . 5

4.1 Overview of Modbus RTU.........................................................9

4.2 Corresponding parameter table of communication address ..........................10

4 . 3 H o w t o u s e c o m m o n f u n c t i o n s . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2

4.3.1 Reading electrode measurements....................................................12

4.3.2 Modify electrode address....................................................12

4.3.3 Electrode calibration....................................................12

4 . 3 . 4 F a c t o r y r e s e t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 3

Chapter 5 Maintenance and Care........................................................ 14

5. 1 Ma i n te n a n c e i n te r v a l .. . . . .. . . . . . . .. . . .. . . . . .. . . . . . .. . . . . .. . . . . . . . .. . .. . . . . . . 14

5.2 Common problems and solutions ........................................................14

Basic Information

1

Measuring range

-2000 ~ +2000 mV

0.0~50.0 °C

Resolution

1 mV 0.1 °C

Accuracy

±2 mV

Calibration method

Zero calibration, slope calibration, deviation calibration

Operating temperature

0 to 50°C

Work pressure

≤2Bar

Waterproof level

IP68

Power requirements

9~36VDC

Power consumption

About 0.2W

Electrical isolation

Power and communication are isolated inside the sensor

Communication Interface

RS485 MODBUS

Shell material

ABS

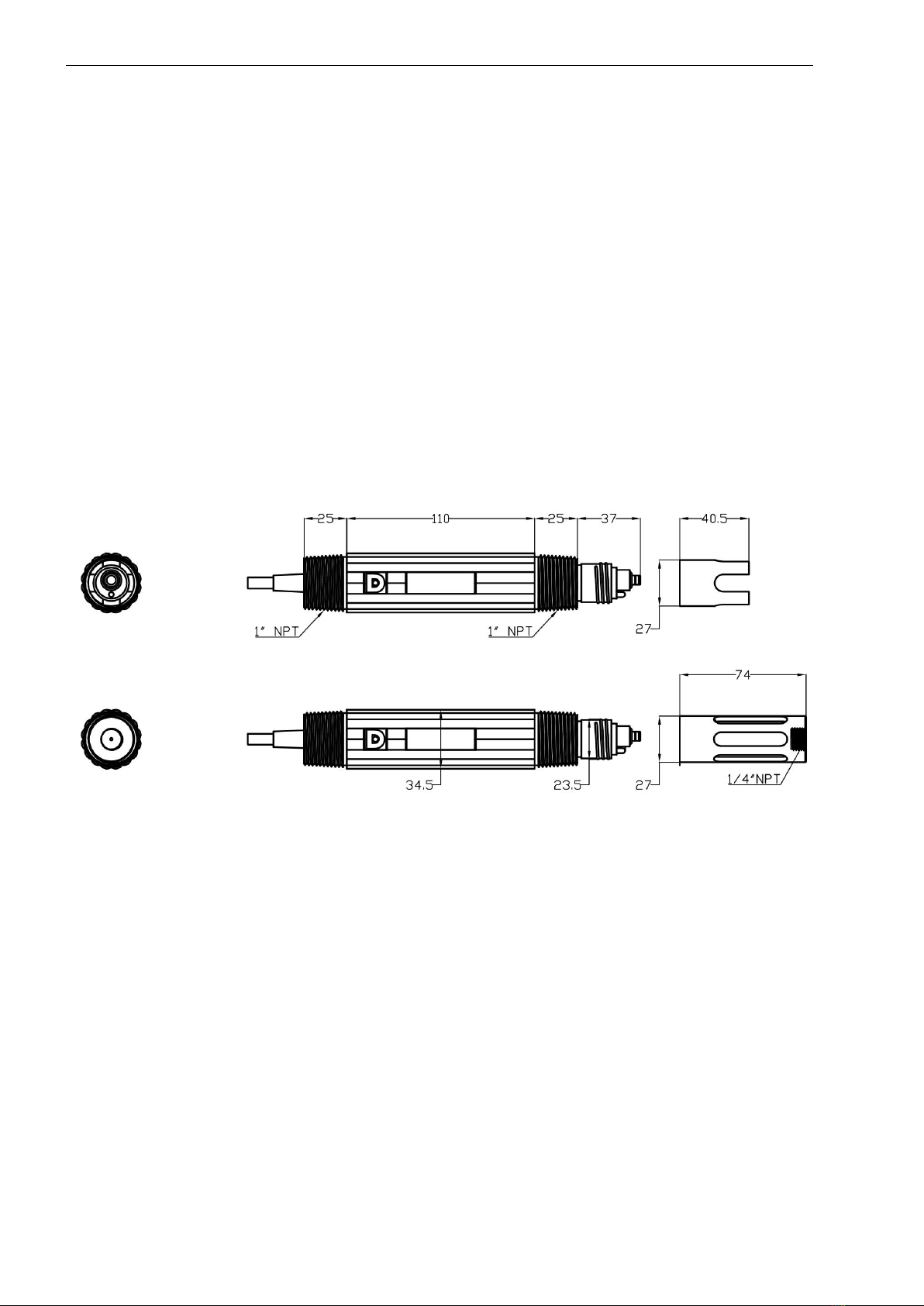

Shell size

Diameter 35mm, total length about 260mm (including

cleaning protective cover)

Installation size

One imperial 1" NPT thread on each end

Insertion depth 100mm (including cleaning connector

115mm)

weight

About 150 grams (without cable)

Cable

PUR (polyurethane) sheath, standard 10 meters, custom

lengths available

Connection method

Bare wire, M12 plug or waterproof aviation plug

Chapter 1 Specification

Product specifications are subject to change without notice.

Basic Information

2

Chapter 2 Basic Information

2.1 Security Information

Please read this manual completely before unpacking, installing and operating this

equipment. Pay special attention to all precautions. Otherwise, it may cause serious

personal injury to the operator or damage the equipment.

2.2 Overview

The digital ORP sensor adopts the classic electrochemical principle, which is reliable in

measurement and stable in performance. Widely used in environmental protection water

treatment, surface water, purified water, circulating water and other systems, as well as

electroplating, electronics, printing and dyeing, chemical, food, pharmaceutical and other

process fields. Excellent performance in sewage treatment, drinking water treatment,

surface water monitoring, pollution source monitoring, industrial process and other

applications.

2.3 Dimensions

Figure 1 Dimensions of the sensor

Installation

3

1-DN60 U-shaped card

7-M4 screw nut 8*4

2-U-shaped board

8-“8”shaped clip 25&32

3-Handle sleeve

9-M4 screw*25*2

4-DN40 U-shaped card

10-handle

5-M6 screw nut*8

11-DN32PVC Bracket

6-Rainproof elbow

12-1 inch inner wire straight pipe joint

Chapter 3 Installation

3.1 Sensor Installation

Refer to the pictures in this section to install and fix the sensor. To ensure that the sensor can

measure safely and accurately, the following conditions must be met during installation:

Choose a location that is convenient for operation and maintenance to install the sensor.

The ORP sensor needs regular maintenance;

The electrode installation angle is within ±30°, and the electrode cannot be installed

horizontally or upside down;

Do not remove the protective cap when installing the electrode on site, and then remove

the protective cap after the installation is over.

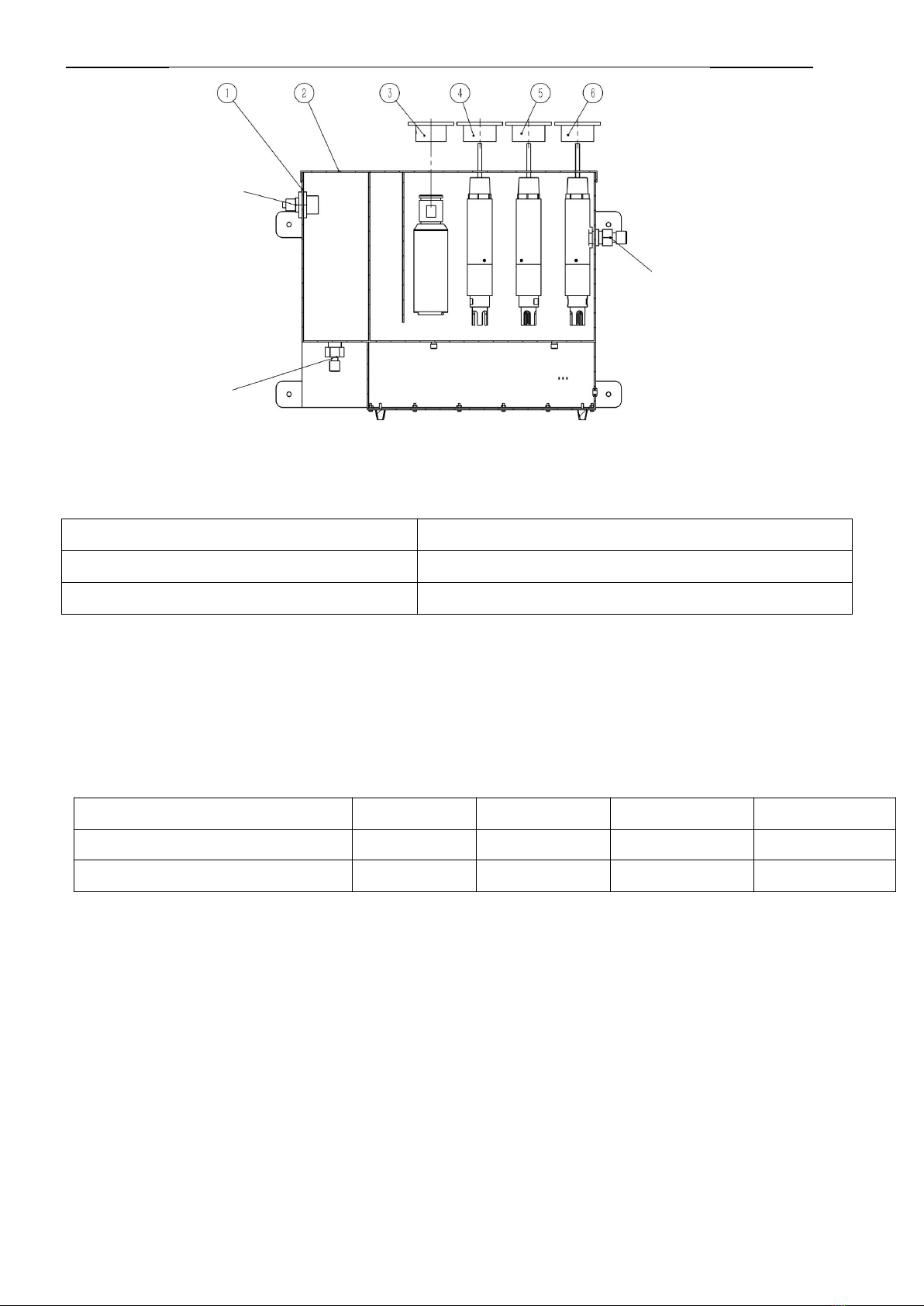

Figure 2 Schematic diagram of railing installation

Installation

4

The sensors are connected correctly as defined in the table below.

Note: Aviation plug version does not require user to connect wires.

1-Flow cell

4-pH sensor fixed connection cover

2-Flow cell cover

5-dissolved oxygen sensor fixed connection cover

3-Turbidity sensor fixed connection cover

6-conductivity sensor fixed connection cover

Wire Color

red

black

white

green

Terminal Definition

Power positive

Power negative

RS485 data A (+)

RS485 data B (-)

Instrument Terminal Symbols

V+

V-

AS

BS

Water overflow

water intake

Water outlet

Figure 3 Schematic diagram of five-parameter flow cell installation

3.2 Sensor Wiring

Protocol

5

About Modbus RTU overview:

The electrode acts as a slave on the network and supports the Modbus RTU

communication protocol.

Data communication is initiated by the host, and the first byte of the transmitted message

is the target slave address. After the first byte is received by all the slaves on the network,

each slave will decode it to determine whether the message is sent to itself.

The transmission of the RTU message frame shall start with a pause interval of at least

3.5 character time. After the transmission of the last character, a pause of at least 3.5

characters time marks the end of the message frame. A new message can start after this

pause. During transmission, the entire message frame must be transmitted in a

continuous stream. If there is a pause interval of more than 1.5 character time before the

transmission of the message frame is completed, the receiving device will flush the

incomplete message and assume that the next byte is the start of a new message.

Likewise, if a new message begins with the previous frame within less than 3.5

characters, the receiving device will consider it a continuation of the previous frame, and

this will result in an error because the final CRC The value cannot be correct.

The host can send command frames to read individual or all data results.

The data frame format is as follows (all data are in Hex format)

Host sends:

1

2

3

4

5

6

7

8

slave

address

function

code

Register start

address upper

8 bits

Register

start

address

lower 8 bits

The upper

8 bits of the

number of

registers

The lower 8

bits of the

number of

registers

CRC

lower 8

bits

CRC

high 8

bits

The slave responds:

1

2

3

4

5

5+n

5+n+1

5+n+2

5+n+3

slave

address

function

code

Data

bytes

Data 1

high 8

bits

Data 1

lower 8

bits

Data n

high 8

bits

Data n

lower 8

bits

CRC

lower 8

bits

CRC

high 8

bits

Chapter 4 Communication

4.1 About Modbus RTU Overview

Protocol

6

Example:

Send frame: [01 04 00 02 00 02 D0 0B], meaning as follows:

[01]: slave address

[04]: function code

[00 02]: The starting address of the register is 0x02

[00 02]: Read 2 registers from the starting address (ie, read 1 single-precision floating-point

data result)

[D0 0B]: CRC check data

Return frame: [01 04 04 00 00 41 C8 CA 42], meaning as follows:

[01]: slave address

[04]: function code

[04]: The number of bytes returned is 4

[00 00 41 C8]: 41 C8 00 00 (that is, the floating-point value is 25, the specific value meaning

is to find the corresponding address)

(Note: Combine two 16-bit integer registers to form a single-precision floating-point number,

pay attention to the order of the data)

4.2 Corresponding parameter table of communication address

Main measurement (read with function code 04)

Parameter

Address

Data Format

Value Range

Initial Value

Illustrate

Main measured value

2

32 Bit Float

-2000~+2000

-

Unit: mV

Temp. measurement

4

32 Bit Float

0~50

-

Unit: Celsius

Communication parameters (read with function code 03, write with function code 06)

Parameter

Address

Data Format

Value range

Initial Value

Illustrate

Address

0

Unsigned

1~254

9

-

Baud rate

1

Unsigned

0~3

1

0:4800

1:9600

2:19200

3:38400

Check Digit

2

Unsigned

0~2

0

0: no verification

1: Even parity

2: odd parity

Stop bit

3

Unsigned

1~2

1

1:1 bit

2: 2 bits

Protocol

7

System setting parameters (read with function code 03, write with function code 06)

Parameter

Address

Data Format

Value range

Initial Value

Illustrate

Sample rate

4

Unsigned

0~4

2

0: Level 2 buffering

1: Level 4 buffering

2: 8-level buffer

3: 16-level buffer

4: 32-level buffer

Temperature

mode

5

Unsigned

0~1

0

0: Automatic

1: Manual

User setting parameters (use function code 03 to read, function code 16 to write)

Parameter

Address

Data Format

Value range

Initial

Value

Illustrate

Slope calibration

point calibration

value

100

32 Bit Float

-

256

The calibration point

value can be changed,

the default is 256mV

Zero calibration

point standard

liquid value

102

32 Bit Float

-

86

The calibration point

value can be changed,

the default is 86mV

zero

106

32 Bit Float

-

0

The value is generated

according to the user

calibration, the zero value

can be changed

Slope

108

32 Bit Float

-

1

The value is generated

according to the user

calibration, the slope

value can be changed

Main measurement

offset

112

32 Bit Float

-2000~+2000

0

The main measurement

offset value can be

changed, the setting

range is between -2000

and +2000

Temperature offset

114

32 Bit Float

-100~100

0

The temperature offset

value can be changed,

the setting range is

between -100 and 100

Manual

temperature value

116

32 Bit Float

0~100

25

Manual temperature

value can be changed,

the setting range is

between 0 and 100

User calibration parameters (read with function code 03, write with function code 16)

Parameter

Address

Data Format

Value range

Initial

Value

Illustrate

Slope

calibration

200

32 Bit Float

-

-

Write the value 256 for

slope calibration

Zero calibration

206

32 Bit Float

-

-

Write the value 86 for

zero calibration

Protocol

8

Recovery (Write with function code 06)

Parameter

Address

Data Format

Value range

Initial

Value

Illustrate

Restore settings

400

Unsigned

-

-

Write the value of 99 to

restore the setting

parameters, but the

communication settings

will not be restored

Read the ORP value and temperature value measured by the electrode (assuming the

electrode address is 1)

Host sends [01 04 00 02 00 04 50 09]

[01] Indicates the electrode address, where the electrode address is 1

[04] Indicates the function code, here use the function code 04 to read the measured value

[00 02] represents the starting register address, where the starting register address is 2

[00 04] indicates the number of registers to be read, here 4 registers are read

[50 09] Indicates CRC check code

Electrode return data [01 04 08 00 00 40 E0 00 00 41 C8 9A DD]

[01] Indicates the electrode address, where the electrode address is 1

[04] Indicates the function code, here use the function code 04 to read the measured value

[08] Indicates the number of data bytes, there are 8 bytes here

[00 00 40 E0] These 4 bytes represent the ORP value, the value is represented by a

floating point number, [00 00] is the lower 16 bits, [40 E0] is the upper 16 bits, that is, the

32-bit floating point number is [40 E0 00 00 ], after converting to decimal, it is 7, and the mV

value is 7

[00 00 41 C8] These 4 bytes represent the temperature value, the value is represented by a

floating point number, [00 00] is the lower 16 bits, [41 C8] is the upper 16 bits, that is, the

32-bit floating point number is [41 C8 00 00 ], converted to decimal number is 25, the

temperature value is 25 degrees Celsius

[9A DD] means CRC check code

Modify the electrode address, change the electrode address from 1 to 2

Host sends [01 06 00 00 00 02 08 0B]

4.3 How to use common functions

4.3.1 Reading electrode measurements

4.3.2 Modify electrode address

Protocol

9

Electrode calibration (assuming the electrode address is 1)

Zero calibration:

The calibration value is the value set by the zero calibration point, the default is 86

Use function code 16 to write value 86 to register address 206 to perform calibration

Host send [01 10 00 CE 00 02 04 00 00 42 AC 4E AE]

Slope calibration:

The calibration value is the value set by the slope point, the default is 256

Use function code 16 to write value 256 to register address 200 to perform calibration

Host send [01 10 00 C8 00 02 04 00 00 43 80 CE C9]

Factory reset (communication parameters are not restored) (assuming the electrode address is 1)

Use function code 06 to write the value 99 to the register address 400 to perform recovery

Host sends [01 06 01 90 00 63 C8 32]

4.3.3 Electrode Calibration

4.3.4 Factory reset

Maintenance

10

In order to obtain the best measurement results, regular maintenance

and maintenance are required. Maintenance and maintenance include

cleaning of electrodes, checking for damage, etc.

Maintenance work

Maintenance frequency

Visual inspection

per month

Check Calibration

Monthly (depending on usage environment conditions)

Replace electrodes

Yearly (according to usage environment conditions)

Phenomenon

Approach

Electrodes cannot

communicate

1. Check whether the electrode wiring is correct

2. Check the communication setting parameters (address,

baud rate, parity bit, stop bit)

The measured

value is not normal

1. Check whether the electrode platinum ring is clean and

whether the sensor is damaged

2. Restore the electrode to the factory calibration value,

clean and re-calibrate with standard buffer

3. Check the service life of the electrode

Chapter 5 Maintenance

5.1 Maintenance Period

5.2 Common problems and solutions

Table of contents