Deliverance MJH-A1 User manual

1

MJH‐A1ManualFeb26,2021

Operator’sManual:DeliveranceMiniJackHammerModelMJH‐A1 106273

Seepages11and12

2

TableofContents

SafetyInformation……………………………………………………..…………..Page3

ProductSpecifications…………………………………………………..……..…Page4

OperatingInstructions…………………………………………………..………..Pages5&6

Maintenance&Troubleshooting…………………………………………..…Page7,8&9

ExplodedView,QuickChangeHammerHeads&PartsList……….Pages10,11&12

MJH‐A1ManualFeb26,2021

3

TO AVOID SEVERE PERSONAL INJURY OR PROPERTY DAMAGE

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD READ AND STUDY THIS MANUALTOUNDERSTANDAND

FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS. FAILURE TO FOLLOW WARNINGS COULD RESULT IN DEATH OR

SERIOUS INJURY. KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

SAFETY INSTRUCTIONS:

EYE PROTECTION which conforms to ANSI/ CE specifications and provides protection against flying particles both from the

FRONT and SIDE should ALWAYS be worn by the operator and others in the work area when connecting to air supply,

loading, operating or servicing this tool. Eye protection is required to guard against flying fasteners and debris, which

could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment must conform to

the requirements of the ANSI Z87.1 and 89/686/EEC, and provide both frontal and side protection. NOTE: Non‐side

shielded spectacles and face shields alone do not provide adequate protection.

CAUTION: Additional Safety Protection will be required in some environments. For example, the working area may include

exposure to noise level which can lead to hearing damage. The employer and user must ensure that any necessary hearing

protectionisprovidedandusedbytheoperatorandothersintheworkarea.Some environments will require the use of head

protection equipment. When required, the employer and user must ensure that head protection conforming to ANSI Z89.1/ CE is

used.

AIR SUPPLY AND CONNECTIONS

Do not use oxygen, combustible gases, or bottled gases as a power source for this tool as tool may explode possibly

causing injury.

Do not use supply sources which can potentially exceed 200 PSI (14 kg/cm2) as tool may burst, possibly causing injury.

SAFETY INSTRUCTIONS

Alwayswearbreathingprotectionduetoparticlesthatcouldbecomesuspendedintotheair.

Alwaysoperatethetoolinasafemannerandbecarefulforthesafetyofothersintheworkareaaroundyou.

Alwayskeepthetoolproperlymaintained.

Alwayskeephandsawayfrommovingparts.

Alwaysholdthetoolawayfromclothingandhairtoavoidthepossibilityofbecomingentangled.

Alwayskeeptoolawayfromanyelectricalsourcetoavoidelectricshockbeingtransmittedthroughthetool’saluminum

housingoranyotherportionofthetoolorit’sattachments.

Neverleavethetoolconnectedtotheaircompressorwhennotinuse.

Neveroperatethetoolnearflammablesubstances.

OnlyuseRepairPartsandAttachmentsrecommendedbythemanufacturerofthistool.

MJH‐A1ManualFeb26,2021

44

209.77mm(8.26”)

173.43mm(6.83”)

51.00mm(2.00”) Length:209.77mm(8.26”)

Height:173.43mm(6.83”)

Width:51.00mm(2.00”)

Weight:4.30lbs

ChiselShankDiameter:.401”

ToolBitRetention:QuickConnect

BoreSize:20.68mm(.814”)

StrokeLength:44.00mm(1.73”)

BlowsperSecond:37

AdjustableSpeedControl

AirInletThread:1/4‐18NPT

SwivelAirConnector

AirHose:3/8”

WorkingPressure:90PSI(atthetool’sInlet)

PRODUCTSPECIFICATIONS

MJH‐A1ManualFeb26,2021

5

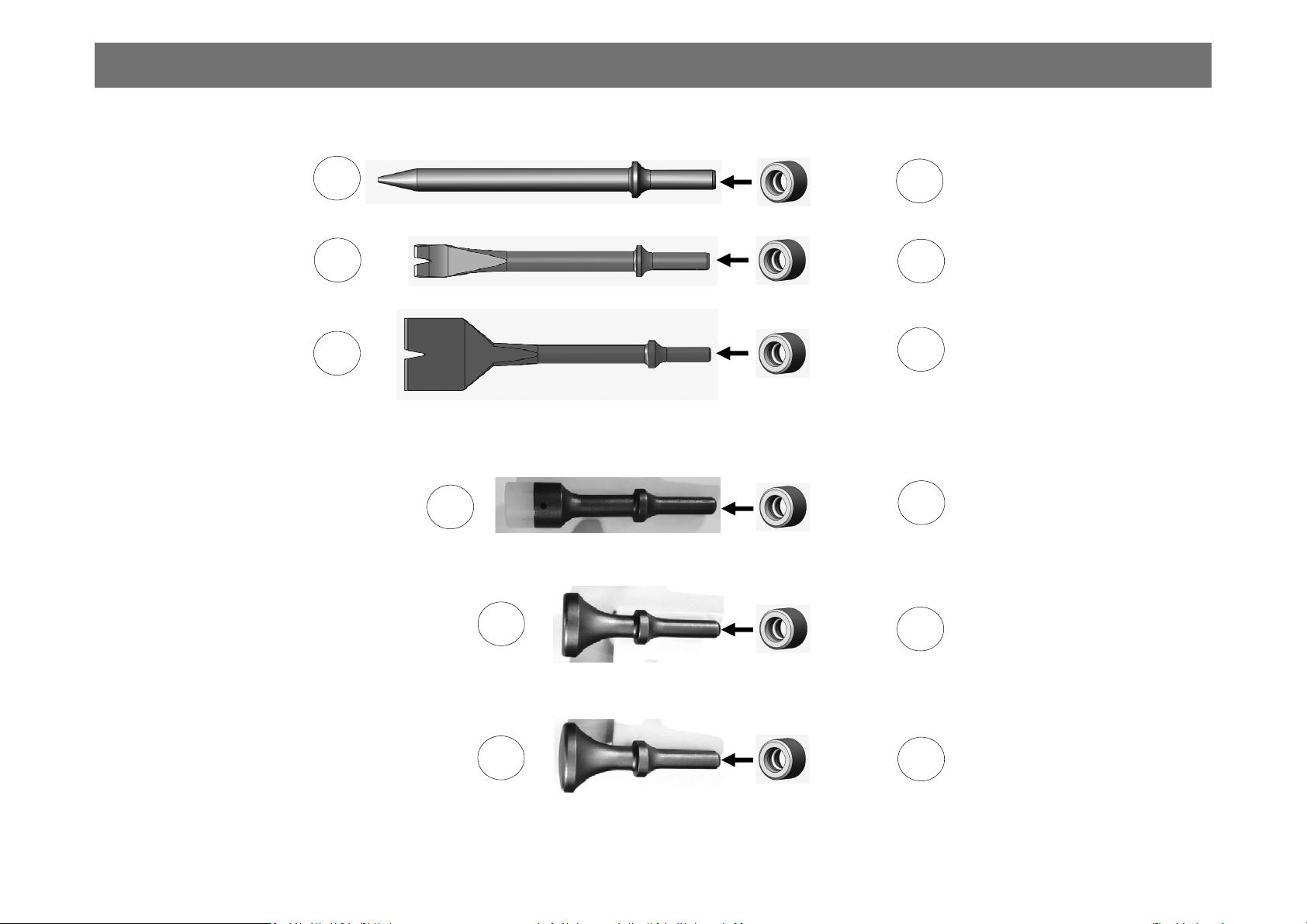

NailGuide

Instructions:HowToLoadaQuickChangeHammerHeadintotheTool

ProcessingToolwithadapterfor

Chiseling/Scraping/Hammering

FencingStapleGuide

ForstandardProcessingTools,insertadapterontoshank

beforeinsertingtheQuickChangeHammerHead Adapter

PullbackSpring

LoadedCollar

1

2

InsertQuick

Change

Hammer

Head

ReleaseSpring

LoadedCollar

3

MJH‐A1ManualFeb26,2021

6

Instructions:HowtoOperatetheToolwithQuickChangeHammerHeads

Setthecompressoroutputregulatortoapressurethatwillcreate90PSIattheendofthehosethatthetoolwillbeconnected to.

Pleasereadalloftheinstructionsandwarningscarefullybeforeoperatingthetool.

3

worksurface

4

Pullthetrigger

5Pushtooltoward

worksurface

Positionthe

toolsothat

theFastener

pointortipof

Processing

Toolisagainst

thework

surface

2

ForNail&Staple

Guides,Muzzle

LoadFastenerinto

Guide.For

ProcessingTools,

skipthisstep

Fastener

Guide

Fastener

1

MJH‐A1ManualFeb26,2021

7

Maintenance,TroubleShooting

Care&Maintenance

1) Alwaysremovethetoolfromtheairsupply

beforeperforminganymaintenanceonthe

tool.

2) Tokeepthetoolproperlylubricated,addtwo

orthreedropsofAir‐ToolOildailyintotheair

inletfitting.Iftoolisusedheavily,addmore

dropsperday.

3) Ifthetoolistobestoredforanextended

periodoftime,lightlylubricatethetooland

brieflyoperatethetooltoinsurethattheoil

hasbeendistributedthroughoutthetool.

Storethetoolinaclean,drylocation,outof

thereachofchildren.

IfToolRunsSlowlyorwillnotoperate

1) Ifthereisgritorguminthetool,flushthetoolwithair‐tool

oilorgumsolvent.

2) Ifthereisnooilinthetool,addtwoorthreedropsofair‐

tooloilintotheairinletfittingandthenbrieflyoperatethe

tooltodistributetheoilthroughoutthetool.

3) Ifairleaksfromtheinletfitting,disconnectthetoolfromthe

airsupply,removeinletfitting,addthreadsealanttapeonto

thethreadsofthefittingandthenre‐installinletfitting.

4) Ifmoistureisobservedsprayingfromtheairtoolexhaust,

waterislikelyinsidetheaircompressortank.Disconnectair

toolfromhose.Unplugcompressorfromelectricalsupply.

Releaseairpressurefromthecompressortankanddrain

waterfromtheaircompressortank.

5) Sinceairpressuredropsthroughthehose,useapressure

gageatthetoolendofthehoseandsetthecompressor

outletregulatortoapressuresettingthatwillproduce90PSI

atthetoolendofthehose.

Addtwoorthreedropsof

OilDailyintoAirFittingInlet

MJH‐A1ManualFeb26,2021

8

QuickConnect

Coupler

Procedure to re-align the Quick Connect Coupler on the MJH-A1 Tool

IftheNailGuidesand/orotherQuickChangeHammerHeadsbecomedifficulttoinsertandremove

fromthetool,theQuickConnectCouplermayneedtobere‐alignedasdescribedbelow.

Step 1: Remove the three set screws from the Quick Connect Coupler.

Step 2: Slightly loosen the Quick Connect Coupler by unscrewing it slightly.

Step 3: Install a Universal Nail Guide into the coupler to insure a proper alignment of the

Coupler versus the cylinder bore.

Step 4: Re-tighten the Coupler by hand just snug, not too tight.

Step 5: Add medium strength Loctite #243 onto all three set screws.

Step 6: Install all three set screws to almost tight, then backed off slightly to avoid

causing a misalignment of the coupler versus the cylinder.

Step 7: Tighten all three set screws evenly.

ThreeSetScrews

UniversalNailGuideDPSH‐2010

MJH‐A1ManualFeb26,2021

9

Ifthemagnetsneedtobereplaced,followthisprocedure

TofurthersecuretheMagnetsinplace,addalayer

ofepoxyallaroundontopofthemagnetsalso

AddEpoxyallaround

circumferenceofthe

holes,thenInsert

DPSH‐1387Magnets SlightlyliftupontheendoftheHeatShrink

Tubingtohelpliftitoutoftherecessed

diameter,thenSlidetheHeatShrinkTubingto

exposethemagnetholes

1

2

Note:IfneedtoreplacetheHeatShrink

Tubing,seechartbelowshowingreplacement

partnumbersforeachofthefourNailGuides

3

4

SlidetheHeatShrinkTubingbackoverthemagnetholes

MJH‐A1ManualFeb26,2021

10

PartsExplodedView&PartsList

18

19

20

9

810 11 12 13 14 10

15

16

17

Shownon

Page11

Shownon

Page12

Note:Item34DPSH‐1930

Adapterisasub‐assembly

containingAdapterDPSH‐1867

andInternalO‐ringDPSH‐1869

MJH‐A1ManualFeb26,2021

11

DPSH‐2000SpikeNailGuide

DPSH‐20601‐1/2”NailGuidefor7/16”NailHeads

DPSH‐2030FenceStapleGuide

(.500”OutsideCrownx.131”StraightLeg)

DPSH‐2050FenceStapleGuide

(.700”OutsideCrownx.164”StraightLeg)

DPSH‐2010Universal(2‐1/2”)NailGuide

DPSH‐20201‐1/2”JoistHangerNailGuide

DPSH‐1720De‐Nailer

DPSH‐1725FlooringDe‐Stapler

DPSH‐1735FencingDe‐Stapler

24

22

23

21

25

26

27

28

29

MJH‐A1ManualFeb26,2021

NailGuidesandHammerHeads

12

DPSH‐1930

DPSH‐1900PoundingHammerwith

35mmDiameterFlatSteelFace

Adapter

Adapter

DPSH‐1930

DPSH‐17363/4”WideUn‐Nailer Chisel

DPSH‐1593ConicalChipper

DPSH‐19282”WideUn‐Nailer Scraper

DPSH‐1930

Adapter

DPSH‐1905PoundingHammerwith

35mmDiameterConvexSteelFace

DPSH‐2015PoundingHammerwith25mm

DiameterReplaceablePolyurethaneFace

DPSH‐2015

DPSH‐1905

DPSH‐1900

DPSH‐1930

Adapter

Adapter

DPSH‐1930

DPSH‐1930

Adapter

33

31

32

30

34

35

36

36

36

36

36

36

MJH‐A1ManualFeb26,2021

Table of contents

Popular Tools manuals by other brands

Klein Tools

Klein Tools STP100 instructions

AHB

AHB SUGINO Barriquan BC10-20 instruction manual

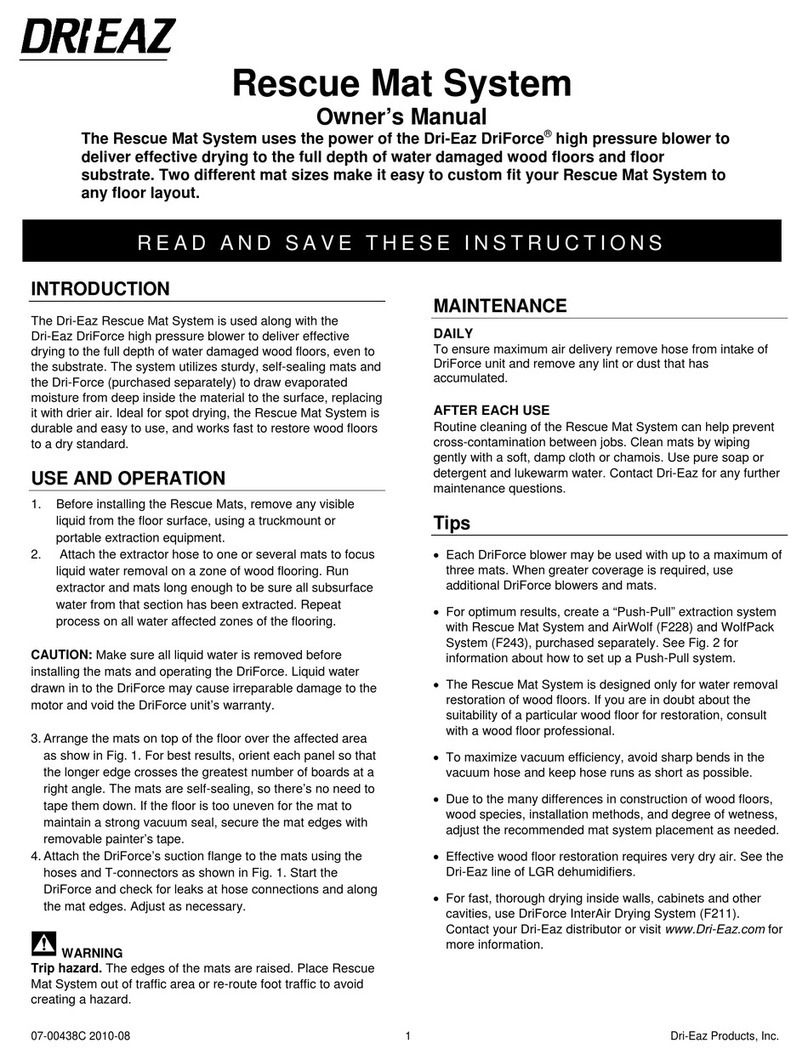

Drieaz

Drieaz Rescue Mat F286 owner's manual

Central Pneumatic

Central Pneumatic 61244 Owner's manual & safety instructions

FLORABEST

FLORABEST FSG 85 D1 Translation of the original instructions

ICON

ICON A5 2021 Service bulletin

Traditional Tool Repair

Traditional Tool Repair DSA-116 Operation, parts and safety manual

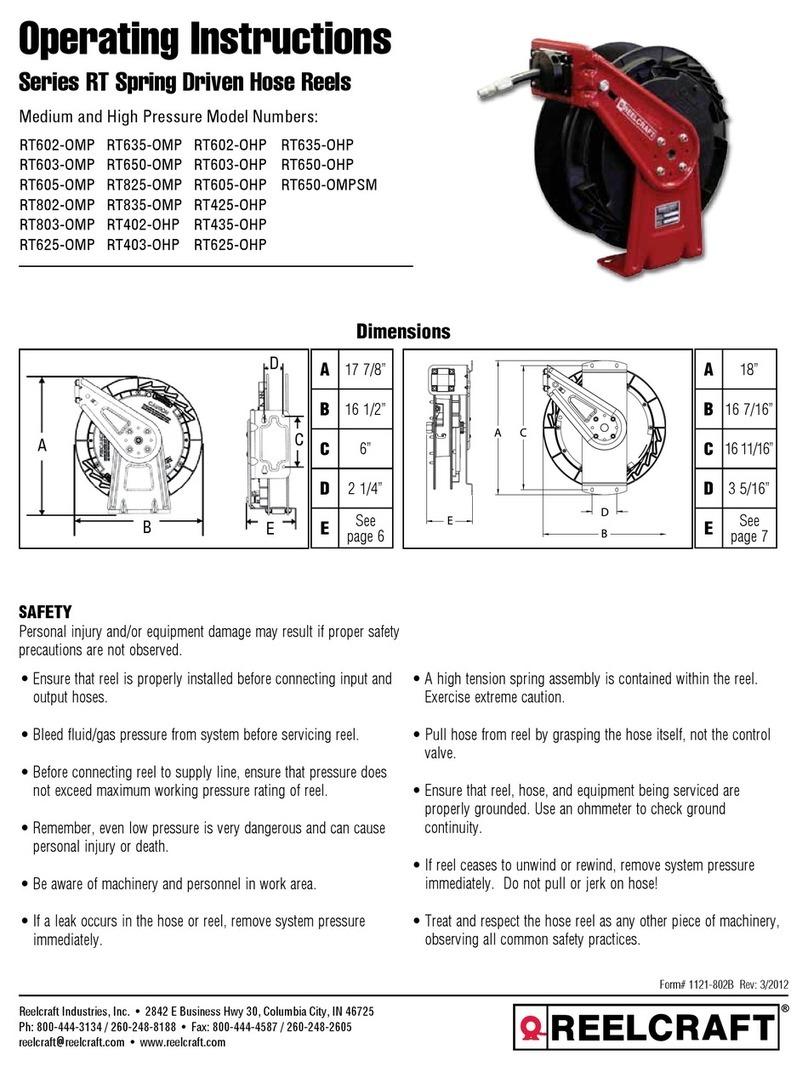

Reelcraft Industries, Inc.

Reelcraft Industries, Inc. RT635-OMP operating instructions

Equalizer

Equalizer FA4TM Operator's instruction manual

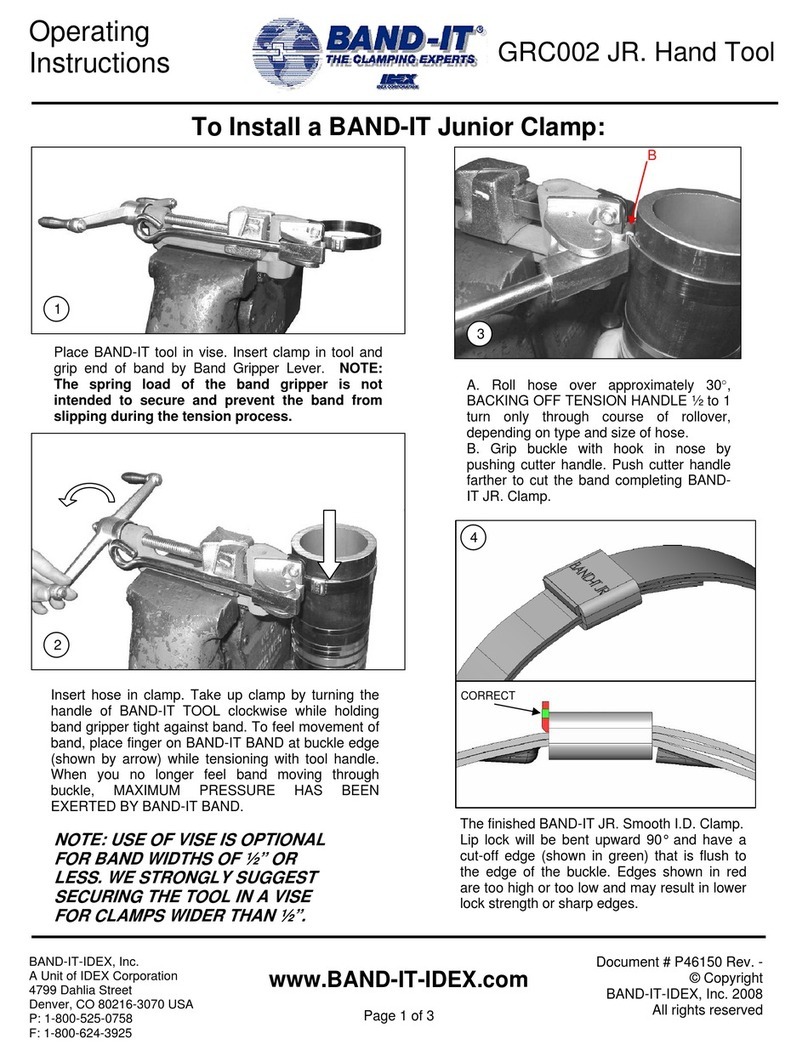

Band-it

Band-it GRC002 operating instructions

Delta

Delta 36-850 instruction manual

sunjoe

sunjoe 24V-AGR100 manual