07-00438C 2010-08 1 Dri-Eaz Products, Inc.

Rescue Mat System

Owner’s Manual

The Rescue Mat System uses the power of the Dri-Eaz DriForce®high pressure blower to

deliver effective drying to the full depth of water damaged wood floors and floor

substrate. Two different mat sizes make it easy to custom fit your Rescue Mat System to

any floor layout.

READ AND SAVE THESE INSTRUCTIONS

INTRODUCTION

The Dri-Eaz Rescue Mat System is used along with the

Dri-Eaz DriForce high pressure blower to deliver effective

drying to the full depth of water damaged wood floors, even to

the substrate. The system utilizes sturdy, self-sealing mats and

the Dri-Force (purchased separately) to draw evaporated

moisture from deep inside the material to the surface, replacing

it with drier air. Ideal for spot drying, the Rescue Mat System is

durable and easy to use, and works fast to restore wood floors

to a dry standard.

USE AND OPERATION

1. Before installing the Rescue Mats, remove any visible

liquid from the floor surface, using a truckmount or

portable extraction equipment.

2. Attach the extractor hose to one or several mats to focus

liquid water removal on a zone of wood flooring. Run

extractor and mats long enough to be sure all subsurface

water from that section has been extracted. Repeat

process on all water affected zones of the flooring.

CAUTION: Make sure all liquid water is removed before

installing the mats and operating the DriForce. Liquid water

drawn in to the DriForce may cause irreparable damage to the

motor and void the DriForce unit’s warranty.

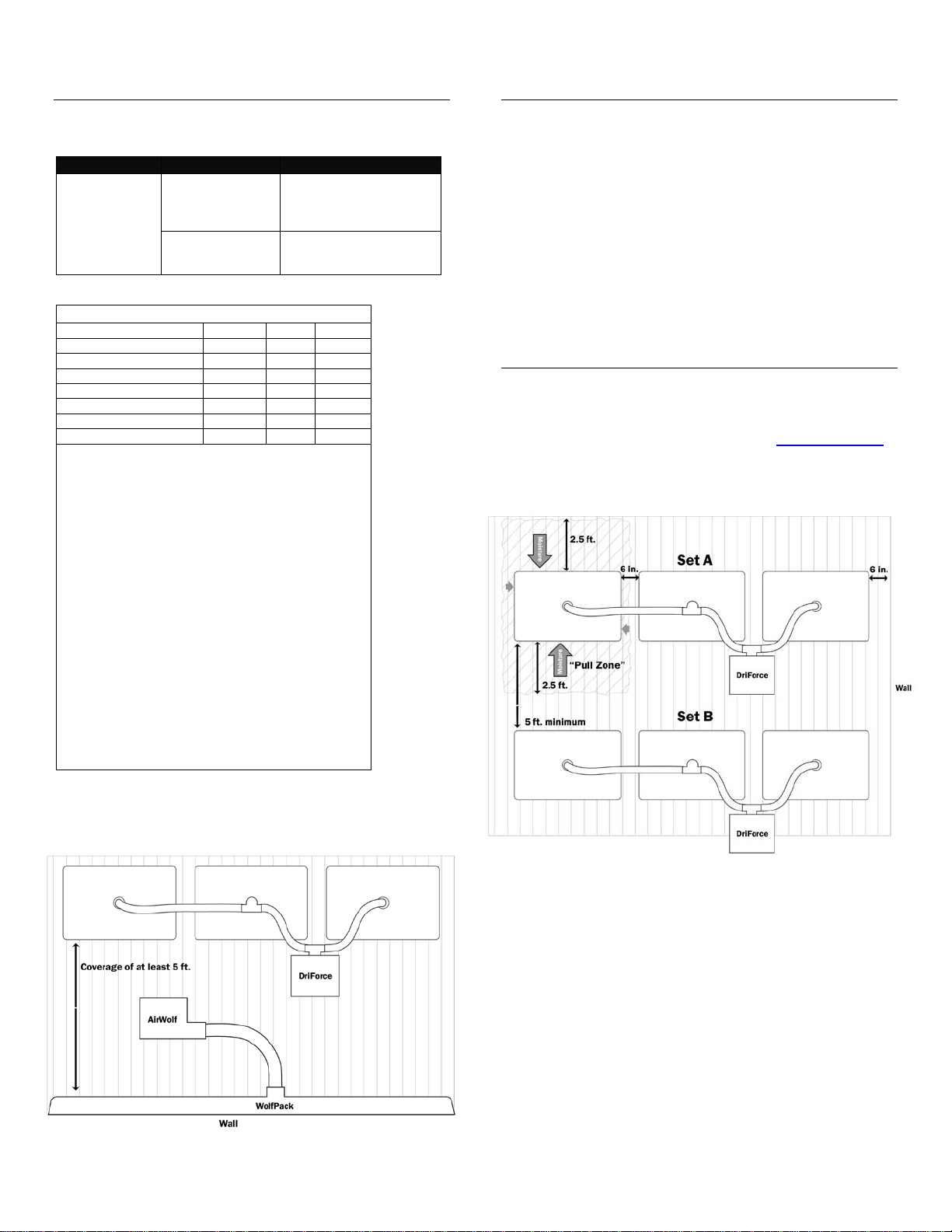

3.Arrange the mats on top of the floor over the affected area

as show in Fig. 1. For best results, orient each panel so that

the longer edge crosses the greatest number of boards at a

right angle. The mats are self-sealing, so there’s no need to

tape them down. If the floor is too uneven for the mat to

maintain a strong vacuum seal, secure the mat edges with

removable painter’s tape.

4.Attach the DriForce’s suction flange to the mats using the

hoses and T-connectors as shown in Fig. 1. Start the

DriForce and check for leaks at hose connections and along

the mat edges. Adjust as necessary.

WARNING

Trip hazard. The edges of the mats are raised. Place Rescue

Mat System out of traffic area or re-route foot traffic to avoid

creating a hazard.

MAINTENANCE

DAILY

To ensure maximum air delivery remove hose from intake of

DriForce unit and remove any lint or dust that has

accumulated.

AFTER EACH USE

Routine cleaning of the Rescue Mat System can help prevent

cross-contamination between jobs. Clean mats by wiping

gently with a soft, damp cloth or chamois. Use pure soap or

detergent and lukewarm water. Contact Dri-Eaz for any further

maintenance questions.

Tips

•Each DriForce blower may be used with up to a maximum of

three mats. When greater coverage is required, use

additional DriForce blowers and mats.

•For optimum results, create a “Push-Pull” extraction system

with Rescue Mat System and AirWolf (F228) and WolfPack

System (F243), purchased separately. See Fig. 2 for

information about how to set up a Push-Pull system.

•The Rescue Mat System is designed only for water removal

restoration of wood floors. If you are in doubt about the

suitability of a particular wood floor for restoration, consult

with a wood floor professional.

•To maximize vacuum efficiency, avoid sharp bends in the

vacuum hose and keep hose runs as short as possible.

•Due to the many differences in construction of wood floors,

wood species, installation methods, and degree of wetness,

adjust the recommended mat system placement as needed.

•Effective wood floor restoration requires very dry air. See the

Dri-Eaz line of LGR dehumidifiers.

•For fast, thorough drying inside walls, cabinets and other

cavities, use DriForce InterAir Drying System (F211).

Contact your Dri-Eaz distributor or visit www.Dri-Eaz.com for

more information.