Delixi CJX2 Series User manual

CJX2 Series AC Contactor

User Manual

Please carefully read this User Manual before installing

and operating the product, and keep this manual properly

for future reference

Safety Notice

Please carefully read this instruction before the installation, operation, run, maintenance, and inspection, and

follow the contents of the instruction to properly install and operate this product.

Danger:

⚫Do not operate the contactor with your wet hands;

⚫Do not touch the energized parts during operation;

⚫Mark sure that the product is de-energized during the maintenance and service;

Caution:

⚫The installation, maintenance and service shall be performed by the qualified professional;

⚫Please confirm that the product voltage, current, frequency and utilization category of the product

meet the operating requirements before use;

⚫Please connect the control circuit first, carry out the no-load operation test, and then connect the load if

there is no abnormality;

⚫Please tighten the terminals regularly and remove the deposited dust;

⚫Do not let foreign objects fall into the product;

⚫If you need to purchase accessories, please choose the matching accessories provided by our company;

⚫If found damage or abnormal sound when unpacking, please stop the operation immediately and contact

the supplier;

⚫When scrapping the product, please dispose the product waste properly. Thanks for your cooperation;

About CJX2-9~95 AC Contactor

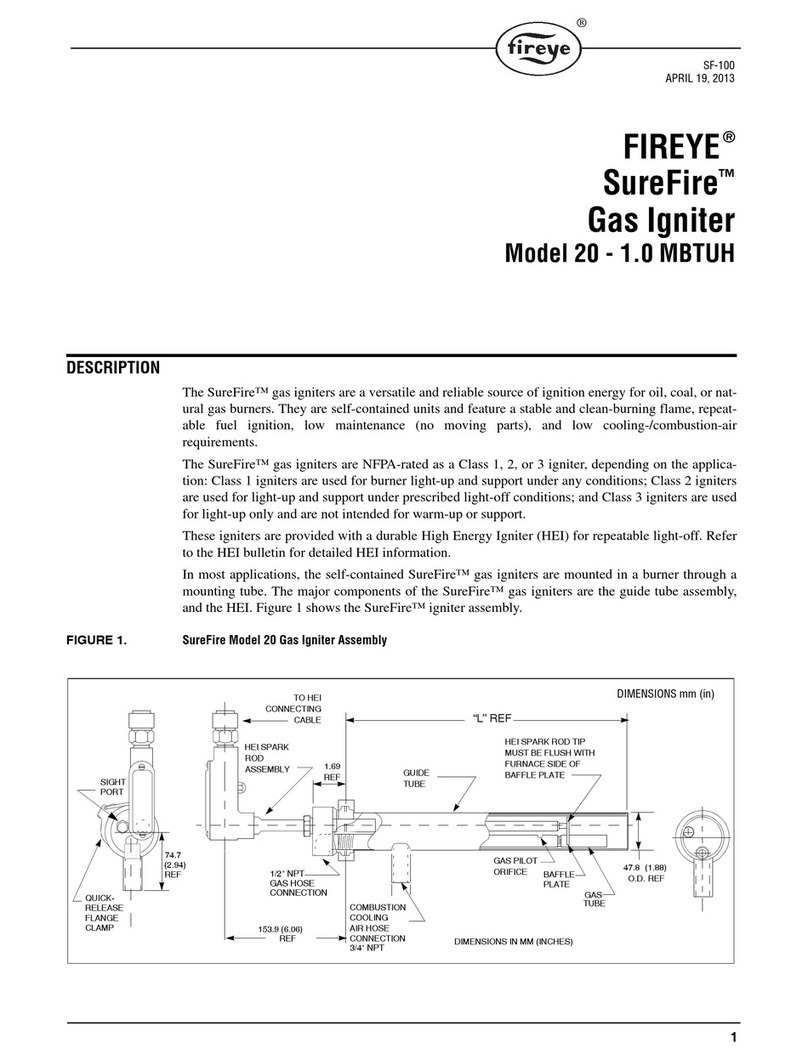

● Panel Introduction (Figure 1 Product Diagram)

Legends:

1-Main circuit outlet 2/T1, 4/T2, 6/T3

2-Product model

3-Main circuit inlet 1/L1, 3/L2, 5/L3

4-Coil inlet terminal A1

5, 10-Coil outlet terminal A2

6-NC auxiliary inlet terminal 21/NC

7-NO auxiliary inlet terminal 13/NO

8-NO auxiliary outlet terminal 14/NO

9-NC auxiliary outlet terminal 22/NC

11-Company trademark

12-Product model

13-Certification mark

14-Standard GB/T 14048.4, IEC 60947-4-1

15-Agreed free air heating current

16-Insulation voltage Ui: 690V

17-Utilization category: AC-3, mechanical interlock

N: AC4

18-Ue, Ie and Pe under use category

19-Company name

● Technical Parameters

Table l Technical Parameters

Normal Operation, Installation and Transport Conditions

●Normal Operation and Installation Conditions

(1) The ambient air temperature is not higher than +40℃, and is not below -5℃, and the average value within 24

hours does not exceed +35℃;

(2) The altitude of the installation site does not exceed 2000m;

(3) Atmospheric conditions

The relative humidity of the atmosphere does not exceed 50% when the highest ambient temperature is +40℃, and

a higher relative humidity is allowed at lower temperatures, such as 90% at 20℃. Protective measures shall be

taken for condensation occasionally occurred due to temperature changes.

(4) The installation position shall be vertical, and the inclination angle at each direction shall not exceed ±5°;

(5) Installed at a place where there is no impact, vibration, and rain or snow erosion;

(6) Pollution level: Level 3;

(7) Installation category: Class III;

(8) Rated impact withstand voltage Uimp:8000V;

(9) Rated frequency :50Hz:

(10) Protection grade: IP20:

(11) Suitable for 8h working system, intermittent cycle working system, uninterrupted working system and short-

time working system.

●Normal Storage and Transport Conditions

(1) Temperature: -25oC~+55℃, +70oC in a short time (24h);

(2) Relative humidity : ≤95%;

(3) During the transport, please handle the product gently, and do not upside it down, and prevent the product

from harsh collision;

(4) The product shall not be attacked by rain or snow during transportation and storage.

Installation Products

● The contactor has two installation methods: screw installation and rail installation. CJX2-9~32 can be installed

with 35mm standard rail, and CJX2-40~95 can be installed with 35mm or 75mm standard rail.

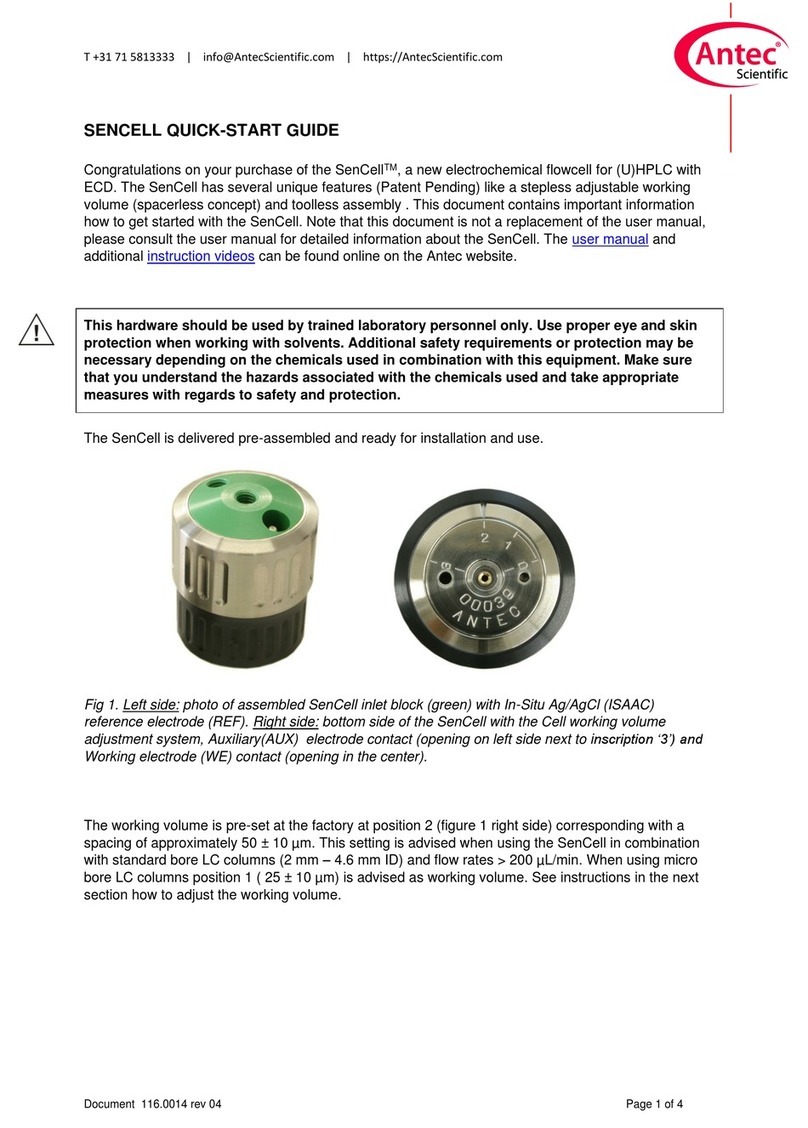

● See Figure 2, Figure 3 and Table 2 for Outline and Installation Dimensions.

Fig. 2 CJX2-9~32 Fig. 3 CJX2-40~95

Table2 CJX2-9~95 AC Contactor Outline and Installation Dimensions Unit: mm

● Outline and installation dimensions of the reversible AC contactor are shown in Figure 4, Figure 5 and Table 3

Figure 4 CJX2-9N~32N

Figure 5 CJX2-40N~95N

Table 3 CJX2-9N~95N reversible AC Contactor Outline and Installation Dimensions

Unit: mm

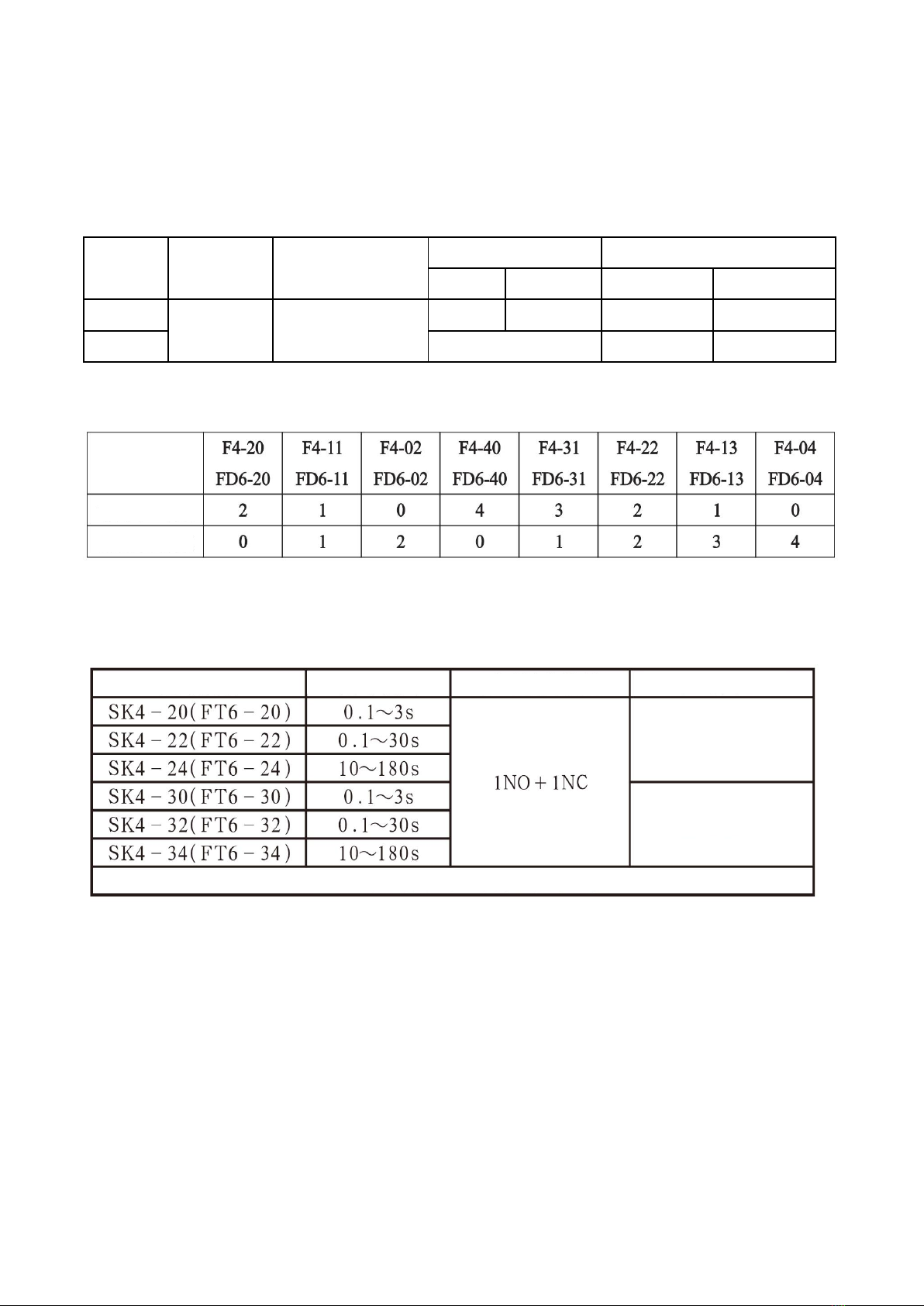

● Accessories installation

(1) Auxiliary contact

The CJX2-9~32 contactor main body has 2 NO or 2 NC auxiliary contact groups, and the CJX2-40~95

contactor main body has 2NO + 2NC auxiliary contact groups, its main parameters are shown in Table 4;

Table 4 Main parameters of auxiliary contact

Utilization

category

Rated

insulation

voltage Ui

Conventional free air

heating current Ith

Control capacity Rated operating current Ie

Make Break 220V 380V

AC-15

690V 10A

3600VA 360VA 1.6A 0.95A

DC-13 33W 0.15A -

The contactor can be equipped with an independent auxiliary contact module. Its model specification and

combination of NO and NC are shown in Table 5.

(2) Air delay head (Pneumatic timer)

The contactor can be combined with SK4 (or FT6) air delay head to form a delay contactor. The delay range

is shown in Table 6.

Table 6 Air delay head

(3) Electromagnetic starter

The contactor can be installed and combined with JRSID series thermal overload relay to form an

electromagnetic starter.

NC

NO

Model

Power-on delay

Power-off delay

Model

Time Range

Contact

Delay type

Note: The air delay head is adjusted to the minimum value when delivery.

Debugging, operation

● Check whether the technical parameters of the product meet the requirements for use;

● Connect the control circuit first, conduct a no-load operation test, and then connect the load if there is no

abnormality;

● Do not let foreign objects fall into the product;

● It is recommended to select SCPD according to type 2 coordinated protection, and its fuse type is shown in

Table 7.

Table 7 Matching fuse model

● Wiring capacity and tightening torque are shown in Table 8

Table 8 Wiring capacity and tightening torque

Maintenance

● The contactor should be tightened regularly, remove the deposited dust and other operations, otherwise there will

be a risk of fire and short circuit;

● The small metal particles splashed around the contacts of the contactor or on the arc cover should be removed,

and the contact surface should be stopped when the surface of the contact is burned to expose the base material.

Fault Analysis and Treatment

See Table 9 for common fault analysis and handling.

Table 9 Analysis and treatment of common faults

Fault Cause Analysis Treatment measures

The iron core

cannot be closed

or the suction

force is

insufficient (that

is, the contact

has been closed

but the iron core

has not been

fully attracted)

1. The power supply voltage is too low or

fluctuates too much;

2. The power supply capacity of the operating

circuit is insufficient or disconnection, wiring

errors and poor contact of the control contacts;

3. The technical parameters of the coil do not

match the conditions of use;

4. The product itself is damaged ( Such as coil

disconnection or burnout, mechanical movable

parts stuck, etc.)

1. Increase the power supply voltage;

2. Increase the power supply capacity, replace

the circuit, and repair the control contacts;

3. Replace the contactor;

4. Eliminate stuck faults and repair damaged

parts.

no release or

slow release

1. The contact is welded;

2. The movable part of the machine is stuck;

3. There is oil or dust on the pole surface of the

iron core.

1. Eliminate welding faults, repair or replace

the contactor;

2. Eliminate stuck faults;

3. Clean the pole surface of the iron core.

Coil overheating

or burning out

1. The power supply voltage is too high or too

low;

2. The technical parameters of the coil (such as

rated voltage, frequency, energization duration

and applicable working system, etc.) do not

match the actual use;

3. The moving part is stuck;

4. The pole surface of the iron core is uneven or

dust sticking.

1. Adjust the power supply voltage;

2. Replace the contactor;

3. Eliminate mechanical jamming;

4. Clear the pole surface.

Electromagnet

(AC) is noisy

1. The power supply voltage is too low;

2. The magnetic system is skewed or

mechanically stuck, so that the iron core cannot

be sucked flat;

3. The pole surface of the iron core is rusted or

foreign matter invades the pole surface of the

iron core;

4. The short-circuit ring is broken or the pole of

the iron core is broken. The surface is

excessively worn and uneven.

1. Increase the voltage of the operating circuit;

2. Adjust the magnetic system or eliminate

mechanical jamming;

3. Clean the pole surface;

4. Replace the contactor.

Contact welding

1. The operating frequency is too high or the

product is overloaded;

2. The load side is short-circuited;

1. Replace the appropriate contactor;

2. Eliminate the short circuit fault.

Certificate

DELIXI ELECTRIC LTD

Name: AC Contactor

Model: CJX2 Series

This product passes the inspection and is allowed to be

shipped.

Standard: GB/T 14048.4

Inspector: Check 06

Production date: See label on inner box

www.cn-delixi.com

The first edition of this manual was issued on Apr., 2020.

Company Commitment

Under the condition that users follow the use and storage conditions and the product are well sealed, within 18

months from the production date, our company will provide repair and replacement service free of charge for any

damage or abnormal operation due to poor manufacture quality. A paid repair will be provided if the warranty

period expires. For any damage due to one of the following situations, a paid repair will be given even if within

the warranty period:

(1) Improper operation, maintenance, or storage;

(2) Modified and improper repair without permission;

(3) Damage due to falling off or found during installation after purchase;

(4) Force majeure such as earthquakes, fires, lightning strikes, abnormal voltages, and secondary disasters; If

you have any question, please contact the dealer or our company’s customer service department.

This manual suits for next models

10

Table of contents

Other Delixi Industrial Equipment manuals