Table of Contents

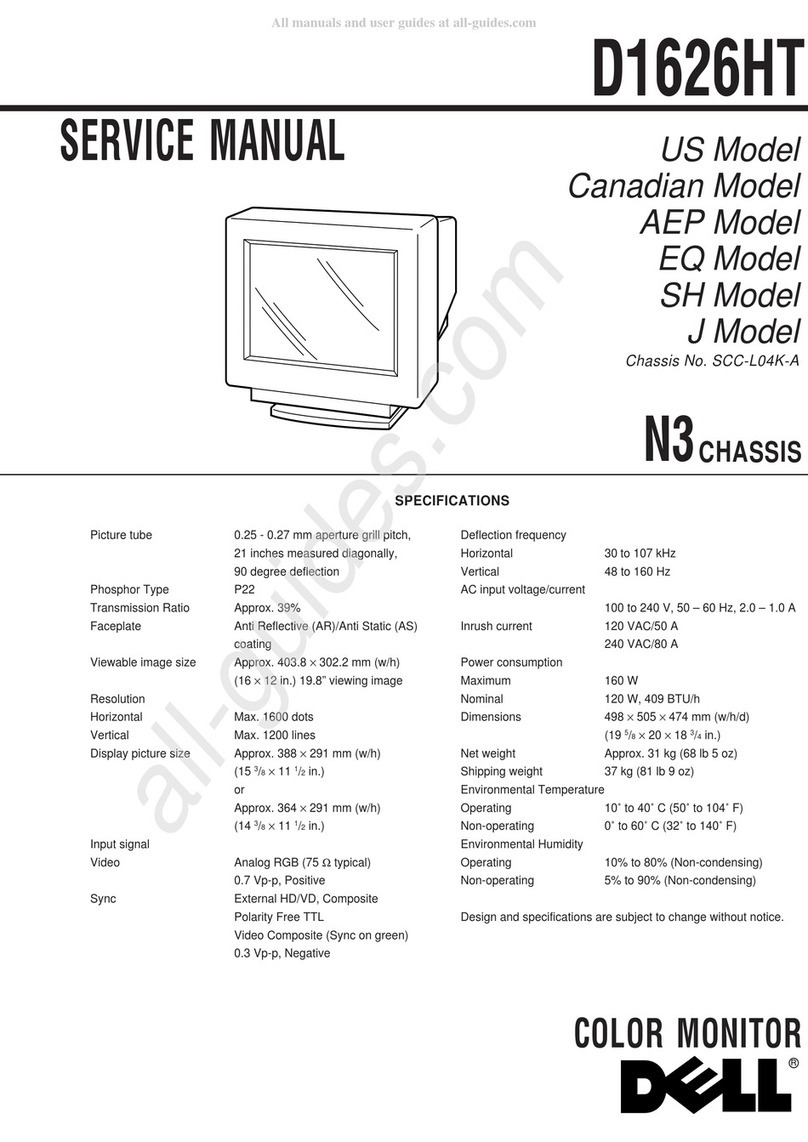

CHAPTER 1- PRECAUTIONS & SAFETY NOTICES ...................................................................................................................... 3

1. SAFETY PRECAUTIONS ...................................................................................................................................................... 3

2. PRODUCT SAFETY NOTICE ............................................................................................................................................... 3

3. SERVICE NOTES ................................................................................................................................................................... 3

CHAPTER 2- SERVICE TOOLS & EQUIPMENT REQUIRED....................................................................................................... 4

CHAPTER 3- CIRCUIT THEORY ........................................................................................................................................................ 5

1. BLOCK DIAGRAM ..................................................................................................................................................................... 5

2. ELECTRONIC CIRCUIT THEORY ................................................................................................................................................ 7

3. FACTORY PRESET TIMING TABLE ................................................................................................................................. 13

4. POWER ON/OFF SEQUENCY ................................................................................................................................................... 13

5. D-SUB CONNECTOR PIN ASSIGNMENT .................................................................................................................................. 14

6. AC OUTLET PIN ASSIGNMENT ............................................................................................................................................... 14

7. INNER CONNECTOR PIN ASSIGNMENT .................................................................................................................................... 14

8. KEY PARTS PIN ASSIGNMENTS ............................................................................................................................................... 16

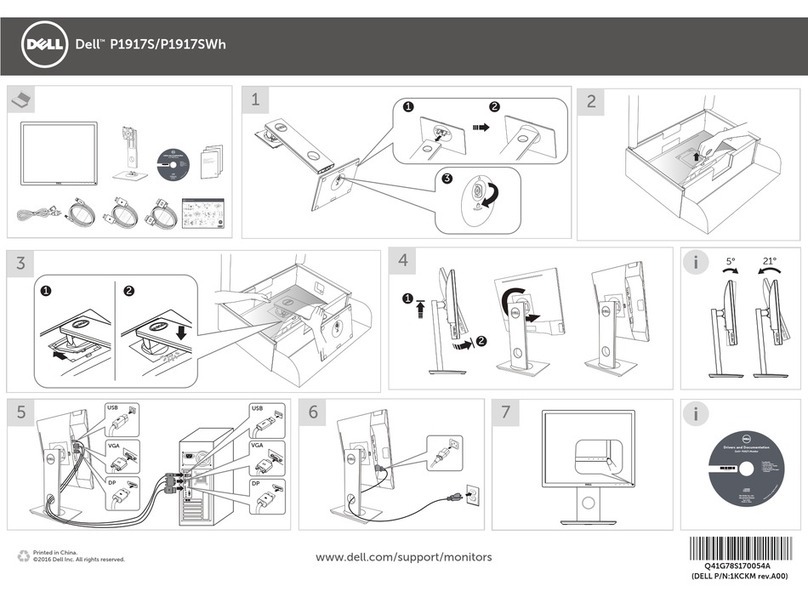

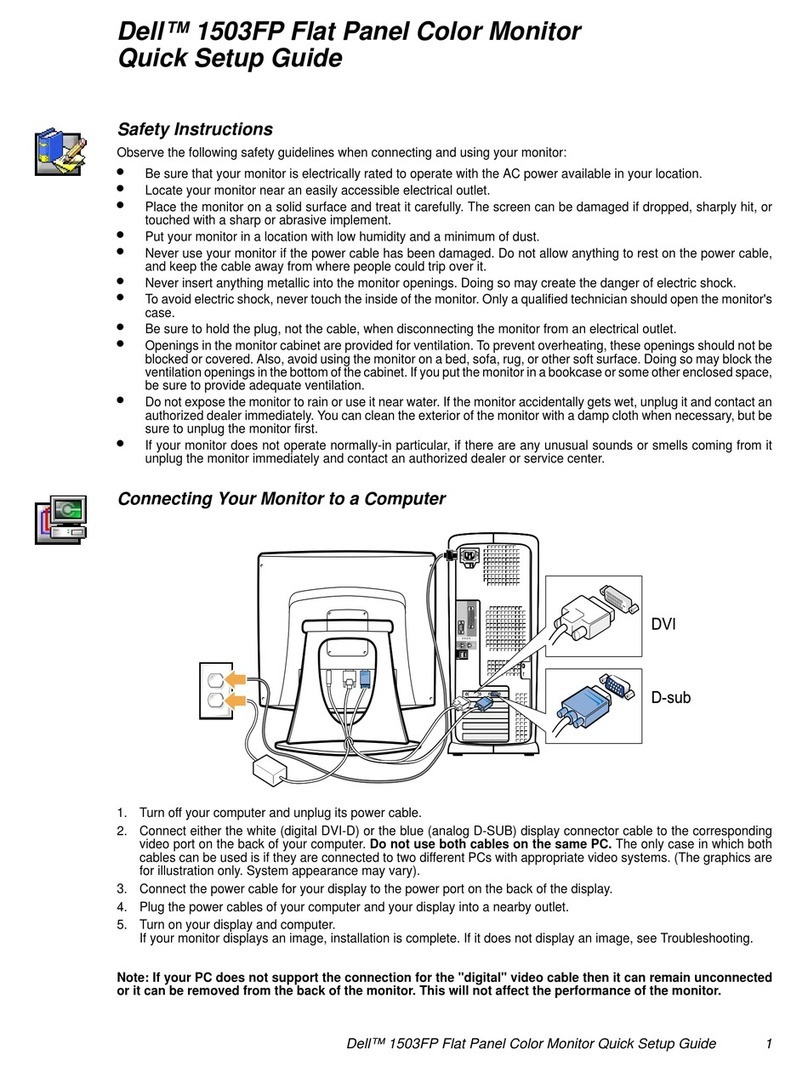

CHAPTER 4- DISASSEMBLY & ASSEMBLY .................................................................................................................................. 21

1. EXPLODED DIAGRAM ............................................................................................................................................................. 21

2. 2208WFP DISASSEMBLY BLOCK............................................................................................................................................ 22

3. ASSEMBLY BLOCK.................................................................................................................................................................. 23

CHAPTER 5- TEST AND ADJUSTMENT ......................................................................................................................................... 24

1. FUNCTION KEY DEFINITIONS .................................................................................................................................................. 24

2. OSD CONTROL....................................................................................................................................................................... 24

3. FACTORY MODE INTRODUCTION ............................................................................................................................................ 26

4. BURN-IN PATTERN .................................................................................................................................................................. 27

5. AUTO COLOR BALANCE (AUTOMATICALLY CALIBRATE CHIP ADC PARAMETER BY USING CHIP INTERNAL DAC.) ................ 27

6. UPLOAD FIRMWARE TO MCU VIA VGA CABLE...................................................................................................................... 32

7. AFTER REPAIR,TO ENSURE THE QUALITY YOU SHOULD DO THE FOLLOWING TEST AND ADJUSTMENT. ................................... 27

CHAPTER 6- TROUBLE SHOOTING ............................................................................................................................................... 30

1. COMMON ACKNOWLEDGE...................................................................................................................................................... 30

2. NO POWER LED OFF.............................................................................................................................................................. 30

3. POWER NORMAL LED AMBER................................................................................................................................................ 31

4. BACKLIGHT CAN’T BE TURNED ON ......................................................................................................................................... 38

5. NO PICTURE BACKLIGHT ON ................................................................................................................................................ 39

6. AT 32-GRAY SCALE PATTERN,COLOR LOST IN SOME SCALE .................................................................................................... 40

CHAPTER 7- RECOMMENDED PART LIST................................................................................................................................... 35

ATTACHMENT 1- BILL OF MATERIAL .......................................................................................................................................... 37

ATTACHMENT 2- SCHEMATIC ........................................................................................................................................................ 47

ATTACHMENT 3- PCB LAYOUT....................................................................................................................................................... 60