Delta Controls eZV-440 User guide

eZV-440

Application Guide

Edition 2.5

Copyright

Copyright © Delta Controls Inc. All rights reserved.

No part ofthis document may be reproduced, transmitted, transcribed, stored ina retrieval system, or translated into

any language (natural orcomputer), in any form orbyany means, without the prior written permission ofDelta

Controls Inc.

Limited permission is granted to reproduce documents released in Adobe® Portable Document Format (PDF)

electronic format inpaper format. Documents released inPDF electronic format may beprinted by end-users for

their ownuse using a printer such asaninkjet or laser device. Authorized distributors ofDelta Controls Inc. products

(Delta Partners) may print PDF documents for their owninternal use or for use by their customers. Authorized Delta

Partners may engage a printing or copying company toproduce copies ofreleased PDF documents with the prior

written permission ofDelta Controls Inc.

Information in this document issubject to change without notice and does not represent a commitment to past

versions of this document on the part ofDelta Controls Inc. Delta Controls Inc. may make improvements and/or

changes to this document /the associated software/or associated hardware at any time.

The Delta logo and enteliZONE are registered trademarks ofDelta Controls Inc.

All other trademarks are the property of their respective owners.

Document edition: 2.5

Published on February 17, 2017

Contents

About the eZV-440 ......................................................................................................................4

About This Guide ......................................................................................................................... 4

Upgrading From Older Firmware Versions................................................................................. 4

About the Configuration Graphic ................................................................................................5

Downloading the Configuration Graphic ..................................................................................... 5

Installing the Configuration Graphic........................................................................................... 5

Opening the Configuration Graphic............................................................................................. 6

Working With the Configuration Graphic .................................................................................... 7

Selecting Between Multiple Controllers ................................................................................. 7

Save to Flash, Save to PC and Load from PC .......................................................................... 7

Shortcuts ................................................................................................................................. 8

Configurable and Programmable eZV Controllers.....................................................................9

LINKnet Devices ...................................................................................................................... 9

Data Exchange......................................................................................................................... 9

Alarming .................................................................................................................................10

Trend Logs..............................................................................................................................11

Programming..........................................................................................................................12

Commissioning.........................................................................................................................15

VAV Balancing Tasks ..................................................................................................................15

1. Enable Balancing Mode ......................................................................................................15

2. Set the VAV Box Size ...........................................................................................................15

3. Set Manual Balancing Dampers .........................................................................................16

4. Set the Airflow Setpoints ....................................................................................................16

5. Check Airflow Zero Calibration...........................................................................................16

6. Calibrate the Airflow Factor ...............................................................................................17

eZV-440 Version 2.1 Application Guide

Page 2 of 67

Document Edition 2.5

7. Exit Balancing Mode ...........................................................................................................17

Check Duct Heater Airflow Safety..............................................................................................17

General Tab..............................................................................................................................18

Device Information .....................................................................................................................18

Network Settings........................................................................................................................19

Global Settings ...........................................................................................................................20

Local Inputs Tab .......................................................................................................................21

Set Up a Hardwired Temperature Sensor..............................................................................21

Set Up a Hardwired Occupancy Input.....................................................................................23

Set Up a Hardwired CO2Sensor .............................................................................................24

Set Up Damper Feedback.......................................................................................................25

Set Up Other Supporting Inputs .............................................................................................25

Set Up an Airflow Sensor........................................................................................................26

Local Outputs Tab.....................................................................................................................27

Additional Configuration Graphic Fields in Programmable Controller .................................28

Set Up an Output.....................................................................................................................28

Set Up Actuator Damper Output.............................................................................................31

LINKnet I/O Tab ........................................................................................................................32

Device Information..................................................................................................................32

Set Up a eZNS Network Sensor..............................................................................................33

Set Up a DNS-24L Network Sensor........................................................................................39

Setpoints Tab............................................................................................................................42

Space Temperature Setpoints................................................................................................42

Discharge Air Temperature Limiting Setpoints .....................................................................43

VAV / VVT Setpoints.................................................................................................................43

Setpoint Range Limiting .........................................................................................................44

Controllers Tab ........................................................................................................................45

Sequences of Operations..........................................................................................................47

Setpoint Control .........................................................................................................................47

About the eZV-440

Page 3 of 67

eZV-440 Version 2.1 Application Guide

Document Edition 2.5

Setpoint Range Limits ............................................................................................................47

Occupancy Modes ...................................................................................................................48

Occupancy Based on CO2Levels.............................................................................................50

Heating and Cooling ...............................................................................................................51

Discharge Air Temperature....................................................................................................52

Damper and Airflow Control ......................................................................................................52

Airflow Setpoints ....................................................................................................................52

Air Balancing ..........................................................................................................................54

Demand Control Ventilation.......................................................................................................54

Fan Operation.............................................................................................................................55

Single Speed Parallel Fan Sequence .....................................................................................55

Modulating Speed Parallel Fan Sequence .............................................................................56

Single Speed Series Fan Sequence........................................................................................56

Modulating Speed Series Fan Sequence................................................................................57

Appendix A: Database Configuration Objects ...........................................................................58

Input Configuration Objects .......................................................................................................58

Occupancy Configuration Objects ..............................................................................................59

Output Configuration Objects.....................................................................................................60

Setpoint Configuration Objects ..................................................................................................61

Device Instance/BACnet Address Object ...................................................................................62

Appendix B: Control Types .......................................................................................................63

Appendix C: Open Source Licensing .........................................................................................64

lwIP.............................................................................................................................................64

ST Microelectronics ...................................................................................................................65

Document Revision History ......................................................................................................66

eZV-440 Version 2.1 Application Guide

Page 4 of 67

Document Edition 2.5

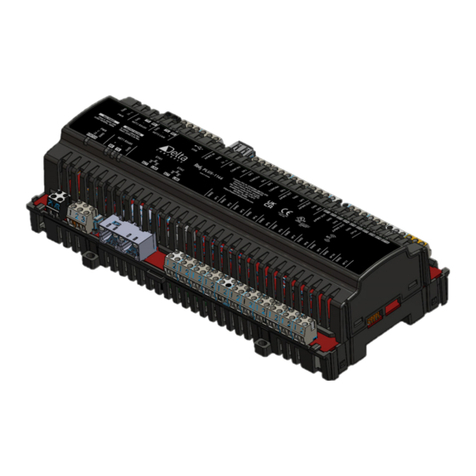

About the eZV-440

The eZV-440 and eZVP-440 controllers are native BACnet controllers with an integrated airflow

sensor and damper actuator for VAV applications, including multi-stage reheat with analog,

binary or floating control, and series or parallel fan boxes. The controller is also designed to be

compatible with Delta Controls’ eZNS and DNS-24L network sensors.

The eZV-440 controller comes pre-loaded with an algorithm which you configure to your site’s

needs using a configuration graphic. There are 2 types of eZV-440 controllers: both the

configurable (eZV) and programmable (eZVP) models use the configuration graphic for set up

but only the programmable controller allows you to create more complex control sequences

with General Control Language (GCL) programming.

About This Guide

This application guide introduces the controller and describes the differences between the

configurable and programmable models. The guide also explains how to use the configuration

graphic in ORCAview 3.40 R3 and higher to set up your eZV-440 controller. The product name

eZV-440 in this guide refers to both the configurable and programmable models unless stated

otherwise.

The configuration graphic version referenced in this guide is B-169041.1.

For help about the eZV-440 configuration page in enteliWEB 4.1 and higher, go to the online help

in enteliWEB. enteliWEB users require the applicable object permissions to change the settings

on the configuration page.

The installation guide for the eZV-440 can be found on the eZV-440

product web page on the Delta Controls Support web site

support.deltacontrols.com.

Upgrading From Older Firmware Versions

Go to the enteliZONE V340 R2.1.0 Release Notes on the Delta Controls Support web site for

more information.

About the Configuration Graphic

Page 5 of 67

eZV-440 Version 2.1 Application Guide

Document Edition 2.5

About the Configuration Graphic

The eZV-440 enteliZONE configuration graphic provides a user-friendly interface to configure

the controller’s algorithm and its corresponding objects and IO points. Each time a change is

made to a field or option, ORCAview (or enteliWEB) updates the corresponding object

references.

Appendix A

lists the fields and options, and their object references.

Downloading the Configuration Graphic

You can download the configuration graphic from the eZV-440 product web page on the Delta

Controls Support web site (support.deltacontrols.com) and install it on your operator

workstation. The version referenced in this guide is B-169041.1.

Installing the Configuration Graphic

To install the configuration graphic:

1. On your operator workstation, go to the graphic folder

C:\Users\Public\Delta Controls\3.40\Sites\<site name>\Graphics where the site name is

the name of the site that uses the eZV-440 controller.

2. Copy and paste the configuration graphic zip file into the Graphics folder.

3. Unzip the file.

There are 7 configuration (.gpc) files associated with the eZ-440 controller. Each file

corresponds to a tab on the configuration graphic.

eZV-440 Version 2.1 Application Guide

Page 6 of 67

Document Edition 2.5

Opening the Configuration Graphic

There are 2 ways to open the configuration graphic in ORCAview. Make sure the configuration

graphic is installed on your operator workstation before attempting any of these steps.

Method 1 (Recommended)

1. In the left window of the ORCAview navigator, right-click on the eZV-440 controller and

click Open.

If this is your first time using the configuration graphic, the DEV object dialog opens.

2. On the Configuration tab, click and browse to the graphics folder and select the

Main.gpc file for eZV-440 controller. Click OK.

3. In the left window of the ORCAview navigator, right-click on the eZV-440 controller

again. Click Open. Because you have set it up in step 2, the configuration graphic window

should open and will open this way each time you select Open from the right-click menu.

Right-clicking does not work if you have changed the name of the

configuration graphic file or if the Controller Graphic field in the Device

object (in the controller database) has been edited.

About the Configuration Graphic

Page 7 of 67

eZV-440 Version 2.1 Application Guide

Document Edition 2.5

Method 2

1. In the left window of the ORCAview navigator, open the Graphics folder and double-click

on one of the configuration files. A new graphic window opens. You can access all the

configuration files from this window.

2. In the numerical field at the top of the window, enter the BACnet address of the eZV-440

controller you want to configure and click

Connect

.

Working With the Configuration Graphic

This graphic is interactive and dynamic in real-time. When you select an option in a field, other

fields and options will be displayed depending on the initial option that was selected. What this

also means is that any changes made to the fields in the configuration graphic will get saved

and applied automatically as soon as they are made.

Selecting Between Multiple Controllers

If you have multiple eZV-440 controllers on the same network, instead of opening the

configuration graphic individually for each controller in the ORCAview navigator, you can switch

between controllers within the configuration graphic.

When you switch between controllers, any changes made in a previous

session will be saved automatically before you switch to the next

controller.

To select between multiple controllers:

In the numerical field at the top of the window, enter the BACnet address of the eZV-440

controller you want to configure and click

Connect

.

Save to Flash, Save to PC and Load from PC

These buttons are displayed at the top of the configuration graphic dialog. They minimize the

need to switch between the configuration graphic and the ORCAview Navigator when you are

working with multiple controllers.

The

Save to Flash

button is used to save the controller database to the controller’s flash

memory.

The

Save to PC

button is used to save the controller database .pdb file to your computer.

The

Load from PC

button is used to load a controller database .pdb file from your computer

onto the eZV-440 controller.

Both Save to PC and Load from PC allow you to save your configuration graphic settings and

copy them onto multiple eZV-440 controllers using ORCAview.

eZV-440 Version 2.1 Application Guide

Page 8 of 67

Document Edition 2.5

Shortcuts

There is a quick way to open the ORCAview object dialogs by right-clicking on the configured

input and output numbers in the configuration graphic.

In the example below, when you right-click on the number 1 and select Open SpaceTemp_AI1,

the AI1 object dialog opens onscreen.

Configurable and Programmable eZV Controllers

Page 9 of 67

eZV-440 Version 2.1 Application Guide

Document Edition 2.5

Configurable and Programmable eZV Controllers

The eZV-440 controller is designed to work predictably for typical VAV and VVT applications with

minimal setup. Using the configuration graphic, objects and setpoints are entered into the

algorithm and written to the appropriate preset objects (100-199 range, 1000+ range for

LINKnet device configuration) in the factory controller database.

In the configurable type of controllers, there are no program (PG) objects. In the programmable

controllers, even though you could still use the configuration graphic to set up your

programmable controller, local programming can be used to overwrite the algorithm by writing

to the objects in the 800-899 range.

There is a limit to the number of specific object types in these controllers. The number limits

are summarized in the table below. You cannot exceed this number by creating any new objects.

Controller Version

LINKnet objects

(LNK)

Event Objects

(EV)

Trend Logs

(TL)

Programs

(PG)

Configurable

1

0

4

0

Programmable

4

5

8

3

For a complete list of eZONE supported object types and number of instances allowed for each

object, go to the eZONE overview page on the Delta Controls Support web site.

LINKnet Devices

Configurable controllers can only connect to 1 LINKnet device at a time. This LINKnet device

has to have a device address of “1” in order for it to work with the controller algorithm. Multiple

LINKnet devices (up to 4) are only supported by the programmable controllers.

LCD and LINKnet objects are located on the eZV-440 controller and are numbered LCDx001 and

LNKx001 respectively where x is the network sensor’s device address.

enteliZONE controllers only support eZNS and BACstat LINKnet network sensors. Other

LINKnet devices like Delta Field Modules (DFM) are not supported.

Data Exchange

This section describes how the eZV-440 controllers accept and initiate data exchanges in the

network.

The eZV-440 controller accepts these data exchange requests:

eZV-440 Version 2.1 Application Guide

Page 10 of 67

Document Edition 2.5

•Poll. The default data exchange type set up in the Data Exchange Settings object (DES) is

Poll. The poll interval can be adjusted in the DES object, at a recommended minimum of

1 second per MS/TP device on a segment.

•Change of Value (Confirmed and Unconfirmed). The eZV-440 controller is limited to a

maximum of 12 subscriptions (Delta Exchange Local or DEL objects).

The eZV-440 controller does not support the Optimized Broadcast and Broadcast Data Exchange

request types. If a controller attempts to subscribe using any of these exchange types, the

exchange types will fail and revert to polling.

The programmable eZVP-440 controllers can initiate up to 12 data exchange

polling

requests

(Delta Exchange Remote or DER objects). Other types of Data Exchange initiating request types

are not supported.

The Description tab on the DES object for the eZV-440 controller lists the number of DER and

DEL requests that are in use.

The eZV-440 controller supports Bulk Data Exchange (BDE) but is limited to 2 BDE objects. Each

BDE object can hold up to 12 tag and object entries on the object’s Transmit Entries tab.

For more information about Data Exchange types, go to the Delta Controls Technical Support

web site knowledge base article KBA 1813.

Alarming

The programmable controller supports up to 5 EV objects as well as intrinsic alarming on up to

5 input and output points (see below for more information about intrinsic alarming). The

eZV-440 EV objects support these alarm types:

Alarm Type

Description

Change of State

Used to monitor and alarm a binary value.

Command

Failure

Used when you have a binary value with feedback. An alarm is generated if monitored values

do not match the feedback value.

Floating Limit

Used to alarm when an analog value varies more than a set limit from a variable setpoint

value.

Out of Range

Used to alarm when an analog value varies outside of a set of fixed limits.

The enteliZONE family of controllers does not support Change of Value or Change of Bitstring

alarm types.

Configurable and Programmable eZV Controllers

Page 11 of 67

eZV-440 Version 2.1 Application Guide

Document Edition 2.5

Even though the configurable controller versions do not have EV objects, intrinsic alarming can

be enabled on input and output points, specifically analog input (AI), binary input (BI), analog

output (AO) and binary output (BO).

EV objects will send out auto-generated messages to notify users about alarms. enteliZONE

controllers do not support alarm acknowledgments. Custom alarm messages are supported by

the eZV-440 controller firmware version 2.1 for EV objects only.

For more information about how to set up an intrinsic alarm, see the

webinar Intrinsic Alarms in ORCA 3.40 on the Delta Controls support web

site.

Trend Logs

A programmable eZVP-440 controller supports up to 8 trend logs, 4 of which are user-defined.

The configurable controller version supports 4 trend log objects (TL1 to 4) which are

pre-configured in the default database to monitor specific heating and cooling objects. However,

all TLs can be modified to monitor other objects—you can change the method of data collection

(Change of Value or polling) as well as the polling interval. However, fields that display the

maximum and total sample size are read-only.

It is not recommended to use Change of Value for objects that are expected to change at a rate

faster than every 5 seconds. TL objects have a 5-second record limit. Events that occur faster

than this record limit will result in “Log Enabled” or “Log Interrupted” entries that can be hard

to interpret.

The default database TL objects are listed in the following table.

Trend Log

Monitored Object

1

SpaceTemp (AV1)

2

CurrentHeatSetpoint (AV800)

3

CurrentCoolSetpoint (AV801)

4

HeatCoolLoad (AV802)

5

User-defined

6

User-defined

7

User-defined

8

User-defined

The eZV-440 trend logs also support Historian archiving. The enteliZONE controllers don’t

support buffer full notification events so make sure the Historian update interval is frequent

enough to avoid missing samples.

eZV-440 Version 2.1 Application Guide

Page 12 of 67

Document Edition 2.5

For more information about trend logs, see the Trending chapter on the

latest version of the ORCAview Technical Reference manual on the Delta

Controls support web site.

Programming

In the programmable controller, the 3 programs that exist alongside the internal algorithm

allow you to either create your own custom algorithm or override portions of the internal

algorithm to suit your needs. The maximum size of each program is 5 KB.

The programmable controller also allows you to create new I/O, AV, BV or MV objects in the

900-999 range for use in your custom program.

Supported GCL+ Programming Functions, Statements and Operators

The Call Statement is not used in the programmable eZVP-440 controllers. Unlike other

programmable Delta Controls controllers, the 3 programs in the eZVP-440 are automatically

scanned. The eZVP-440 controller scan rate is also designed to be a constant 10 scans/second.

A list of supported and unsupported GCL+ functions and statements for the eZVP-440

programmable controllers is recorded in KBA 2137 on the Technical support web site. The

ORCAview and enteliWEB GCL editors are not aware of these limitations, so using an

unsupported function in an eZVP-440 controller will not register a syntax error in these GCL

editors.

Overwriting the Algorithm

You can overwrite the algorithm by programming specific variables numbered in the 800 range.

For example, if you want to change how the algorithm determines the occupancy state, you

could write your own GCL+ program to set the occupancy MV800 state. Your program must

write more frequently than every 5 seconds else the factory algorithm will recapture control.

The following table displays all the variables that are programmable. For an overview that

shows the entire network of unit modules and how they relate to each other, see the diagram at

the end of this table.

Algorithm

Unit Module

Unit Module’s Function

Programmable Variable

Airflow

Setpoint

Manager

Maintains the airflow setpoint in the duct.

AV830 AirflowSetpoint

Box Mode

Controls “box mode” by monitoring the room temperature and the

inlet air temperature.

MV801 VAVDuct1BoxMode

Configurable and Programmable eZV Controllers

Page 13 of 67

eZV-440 Version 2.1 Application Guide

Document Edition 2.5

Algorithm

Unit Module

Unit Module’s Function

Programmable Variable

Controller

Manager

Determines the heating and cooling load on the system.

AV802 HeatCoolLoad

Cooling

Stage

Manager

Controls the VAV/VVT cooling sequence.

AV808 AirflowDemand

AV810 Fan1

Damper

Manager

Controls the damper position.

AV832 DamperCmd

Duct Status

Manager

Determines if there is enough duct air for heating and cooling.

BV800 AirflowStatus

Flow Loop

Manager

Controls airflow through the damper

AV831 DamperDemand

Heat Stage

Manager

Controls heating sequences of operations.

AV808 AirflowDemand

AV803 Heat1

AV804 Heat2

AV805 Heat3

AV810 Fan1

Occupancy

Manager

Determines the occupancy mode in the space at any time.

MV800 OccupancyMode

Temperature

Setpoint

Manager

Controls the active heating and cooling setpoints in the space.

AV800

CurrentHeatingSetpoint

AV801

CurrentCoolingSetpoint

Demand

Control

Ventilation

Manager

Controls the CO2 levels in the space. See the Demand Control

Ventilation sequence of operation for more information.

AV813 DemandCtrlVent

eZV-440 Version 2.1 Application Guide

Page 14 of 67

Document Edition 2.5

enteliZONE VAV Algorithm Flowchart

Temp Setpoint

Manager

Occupancy

Manager

Heat/Cool

Manager

Air Flow

Setpoint

Manager

Flow Loop

Manager

VAV/VVT

Damper

Manager

Heating Staging

Manager

Duct Status

Manager

Box Mode

Manager

Demand Control

Ventilation

MV800 Occupancy

Mode

AV800 CurrentHeating

Setpoint

AV801 CurrentCooling

Setpoint

AV802 HeatCool Load

AV830 Air Flow

Setpoint

AV831 Damper

Demand

VVT

AV832 DamperCmd

AV808 Air Flow

Demand

AV803 Heat1

AV804 Heat2

AV805 Heat3

BV800 Air Flow Status

Hydronic and

Electric Duct

MV801

VAVDuct1BoxMode

Point(s) in each algorithm manager box can be used to override the

algorithm manager

Relationship between points

AV810 Fan1

AV813 DemandCtrlVent

Commissioning

Page 15 of 67

eZV-440 Version 2.1 Application Guide

Document Edition 2.5

Commissioning

This section describes how to perform air balancing and check duct heater airflow safety.

VAV Balancing Tasks

This section describes how to perform typical air balancing tasks using the configuration

graphic’s Air Balancing tab.

1. Enable Balancing Mode

Balancing mode is enabled a state in the

Balancing Mode

field by selecting a state other than

None_

. When a state other than

None_

is selected, the object OccupancyMode_ (MV800) is

automatically assigned a

Balancing_

state.

2. Set the VAV Box Size

In the

VAVBoxSize

field, select the VAV box size you’re working with. Based on the VAV box size

you select, the algorithm then enters preset values in the following fields on the AirBalancing

tab:

•FlowFactor

•CoolingMinimum (minimum cooling airflow setpoint)

•CoolingMaximum (maximum cooling airflow setpoint)

•HeatingMinimum (minimum heating airflow setpoint)

•HeatingMaximum (maximum heating airflow setpoint)

•StandbyMinimum

•Airflow controller tuning parameters( on the Controllers tab)

eZV-440 Version 2.1 Application Guide

Page 16 of 67

Document Edition 2.5

3. Set Manual Balancing Dampers

In the Balancing Mode field, select OpenCmd_. This moves the VAV damper to its fully open

position and provides minimal airflow restriction to allow you to set the manual branch

balancing dampers.

4. Set the Airflow Setpoints

Adjust the cooling and heating minimum and maximum airflow setpoints as required in the

appropriate fields.

5. Check Airflow Zero Calibration

To verify the box zero without first doing an auto-zero calibration, in the Balancing Mode field

select CloseCmd_ to close the damper. Allow time for the damper to fully close. The airflow

reading should be zero or near zero if the airflow sensor has an accurate zero.

If the airflow is not at or near zero, visually check to make sure the damper is fully closed and

the associated VAV AHU is turned off. If you are still detecting some airflow, then the airflow

sensor needs to be zero-calibrated.

For more information about how to zero-calibrate the airflow sensor, see the section below.

To auto zero-calibrate the airflow sensor:

Note: For best results the AHU fan should be turned off when zeroing the airflow sensor.

1. Click the Zero Calibrate button.

2. Check the status of the airflow zero procedure by monitoring the Calibration Status

field:

•If zero calibration has never been performed, the field will display NotComplete_.

•When you are zero-calibrating the airflow sensor, the status InProgress_ is displayed.

•When a zero-calibration has successfully completed, Complete_ is displayed.

•If the zero-calibration is unsuccessful then Failed_ is displayed. An airflow zero fails

when the airflow reading is too far away from zero to be a simple sensor error, or when

the airflow readings are not stable. Possible reasons for a failed airflow zero include

sensor problems or the inability of the damper to fully close.

Commissioning

Page 17 of 67

eZV-440 Version 2.1 Application Guide

Document Edition 2.5

6. Calibrate the Airflow Factor

To calibrate the airflow factor:

1. In the

Balancing Mode

field, select

ClgMaxFlow_

. This will cause the VAV damper to

control to the cooling maximum airflow setpoint.

2. Wait for the

Balancer Airflow

reading to read and stabilize around the cooling

maximum airflow setpoint.

3. Measure the actual airflow from the diffusers. If the airflow reading does not agree with

the measured airflow, enter the airflow value that you just measured in the

Balancer

Airflow

field and click the

FlowFactor Auto Adjust

button.

The algorithm will automatically calculate and adjust the

FlowFactor

based on this

value.

4. Wait for the

Balancer Airflow

reading to stabilize at the cooling maximum airflow

setpoint again and measure the airflow again to confirm that the airflow is now reading

correctly.

7. Exit Balancing Mode

Exit balancing mode by selecting

None_

in the

Balancing Mode

field. Balancing mode also

automatically expires after a timeout period that you set in the AV142 object. This prevents the

system from being stuck in balancing mode if you forget to exit balancing mode after balancing

is complete.

Check Duct Heater Airflow Safety

If you have an electric duct heater, it likely has a built-in airflow safety switch or high

temperature cutout. This procedure ensures the safety switch will allow the heater to run at the

minimum heating setpoint.

Set the value of the MV170 object to the minimum heating airflow setpoint. After the airflow has

reached this setpoint and is stable, turn on the duct heater by manually commanding the

associated output. Verify that the heater is turned on. If the heater doesn’t turn on, adjust the

airflow safety or raise the heating minimum setpoint so that the safety contact is made and the

duct heater is allowed to run.

eZV-440 Version 2.1 Application Guide

Page 18 of 67

Document Edition 2.5

General Tab

The General tab is divided into 3 main sections. The Device Information section contains basic

controller information such as model number and firmware version. The Network Settings

section contains the controller BACnet address, the network number as well as the network

speeds (baud rates). In the Global Settings section, the options set here are applied to the other

tabs as well. In this configuration graphic, the temperature units and the type of VAV setup you

have are set up in the Global Settings section.

Device Information

This section describes the fields found in the Device Information section.

Field name

Description

Name

Displays the name of the Device Object. This name is also displayed in the ORCAview

navigator.

You can change this name but you are limited to 36 characters.

Model Number

Displays the controller’s Delta Controls model number. This is a read-only field.

Firmware Version

Displays the controller’s firmware version. This is a read-only field.

Firmware Build

Displays the controller’s firmware build number. This is a read-only field.

Controller Graphic

Displays the configuration graphic file that opens every time you right-click on the

controller in the ORCAview navigator. You can also enter the name of a dashboard

graphic file and set it as the default graphic.

If you leave this field blank, the Device Object dialog opens instead.

Device Description

Like the Device Object in ORCAview navigator, you can enter and modify the text

description in this field up to 64 characters.

This manual suits for next models

1

Table of contents

Other Delta Controls Controllers manuals

Delta Controls

Delta Controls DLC-G1212 User guide

Delta Controls

Delta Controls DSC-1280 User manual

Delta Controls

Delta Controls Red5-PLUS/EDGE-11 Series User manual

Delta Controls

Delta Controls eZFC-424R4-24 User guide

Delta Controls

Delta Controls DLC-D312 User guide

Delta Controls

Delta Controls DRP-T0B User manual

Delta Controls

Delta Controls Red5-PLUS/EDGE-6 Series User manual