CHIAROSCURO WH25 User manual

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.1 di 20

USE AND MAINTENANCE MANUAL

English version

This user manual is an integral part of the machine and must be kept in an appropriate manner to maintain

its integrity and allow it to be consulted during the life of the equipment.

Read this manual carefully before proceeding with any intervention on the equipment

The manufacturer has the right to make changes to the production and to the manual, without this

entailing the obligation to update the production and previous manuals.

ACTUATOR FOR SWING BLINDS

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.2 di 20

PREFACE

Dear Customer,

In thanking you for the preference given to us in choosing our equipment which will surely prove to be

important, especially over time, we invite you to strictly follow the instructions given in this manual, this

will be of great help for optimal use and to keep it unchanged over time. the characteristics of your

equipment.

CHIAROSCURO SAS by Girelli Marco & C.

1. GENERAL INFORMATION

This user manual is an integral part of the equipment supplied and constitutes the indispensable support

for installation and correct use. Read it with particular attention and completely before proceeding with

the installation and use of the equipment. The manual must accompany the equipment in case of resale.

Partial and total reproduction of this document is prohibited without the written authorization of

CHIAROSCURO SAS.

1.1 DEFINITIONS AND SYMBOLS

The paragraphs below contain a series of definitions, terminologies and symbols used in the drafting of this

manual.

SYMBOL

DESCRIPRION

User: (U.) operator without specific skills, able to use the equipment in normal operating

conditions and for simple maintenance interventions.

Electromechanical operator: (E.O.) technician able to install mechanical - hydraulic -

pneumatic parts and to carry out adjustments, maintenance or repairs and to operate in

the presence of voltage inside cabinets, junction boxes and electrical systems.

Manufacturer's technician:(M.T.) qualified technician made available by the

manufacturer to carry out complex operations in particular situations or, in any case, as

agreed with the user. The skills are, depending on the case, of a mechanical and / or

electrical and / or electronic and / or software type.

Note: It contains the important information or information contained in the manual to be

read, with particular attention, for the best use of the equipment.

Danger: Indicates a situation that can cause injury, even death, or serious damage to

health.

Attention: Indicates a situation that could cause, even indirectly, damage to people,

property and the environment with consequences also of an economic nature.

Warning: Indicates that the directions must be followed with particular attention. Failure

to observe the warning could cause malfunctions or dangerous conditions or damage.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.3 di 20

2. IDENTIFICATION OF THE MANUFACTURER

The plate fixed in the upper part of the actuator contains all the identification data of the WH25 actuator.

Fig.3.1 Example of label (the data shown are purely indicative, the real values are shown on the label of the

equipment placed on the automation itself).

2.1 INFORMATION ON TECHNICAL ASSISTANCE AND MAINTENANCE

To report faults, contact the Assistance Center:

CHIAROSCURO SAS di Girelli Marco & C.

C.so General A. Cantore 23 - 38068 Ala (TN) Italia

Tel : +39 0464 424715 fax : +39 0464 712027

Email : info@chiaroscuro.eu site: www.chiaroscuro.eu

For communications, requests for information or any orders for accessories or spare parts, send your

requests to the email info@chiaroscuro.eu

3. SALE INFORMATION

The label, applied to all motorizations, shows

information relating to the automation model used,

the power supply voltages, the absorption, the

movement speed, the degree of electrical protection,

the operating temperatures, the lot number and the

year of production of the automation and

compatibility with the European marking .

During the warranty period, the customer must strictly follow the instructions indicated in

this manual. Otherwise the Warranty is void, we will not be held responsible for any

problems or malfunctions of the appliance (in this regard, carefully read the validity

conditions of the Warranty attached to the manual).

The manufacturer, in order to adapt the equipment to technological progress and specific

production needs, may decide, without prior notice, to make changes to it without this

entailing the obligation to update the production and previous manuals. Furthermore, if the

illustrations in this manual differ slightly from the equipment in your possession, the safety

and operating indications of the same are always guaranteed.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.4 di 20

4. CHARACTERISTICS AND TECHNICAL INFORMATION

MODEL

W25.2A.60

WH25.1A.30

L/R

NUMBER OF DOORS

2

1 sx / 1 dx

MIN-MAX WIDTH

60 - 150 cm - 2 doors

30 - 80 cm. - 1 doors

MAX. SURFACE

3,00 mq - 2 doors

1,5 mq. - 1 doors

MAX WEIGHT 1 DOOR

50 kg

ELECTRONIC BOARD POWER SUPPLY

110 ÷ 230 VAC

MAX CURRENT CONSUMPTION

~ 0,3 A

IMPACT FORCE OBSTACLE DETECTION

< 150 N

MAX TORQUE

25 Nm

ENGINE CERTIFICATION DEGREE

IP X4

MANEUVER TIME 180 °

30 sec.

20 sec.

WORKING CYCLE

20 cycles/hour

END OF STROKE ADJUSTMENT

Position self-determination

SEPARATE CONTROL UNIT LXHXP

in box PT5 160x130x70

IRREVERSIBLE BLOCK

Standard

PIN DIAMETER

12 o 14 mm

ENGINE COLOR

Black Ral 9006 opaque

MAX CABLE LENGTH FROM CONTROL UNIT

5 meter

ELECTRO BLOCK

on request

RADIOR RECEIVER

on request

The blind develops a maximum torque of 25 Nm. With WH25 and 50 Nm. With WH50. In the

presence of obstacles or wind that opposes the movement of the door, the automation blocks

the operation of the motor for safety. The data of compartment size, door size, weight and

surface may vary depending on the conditions (wind, condition and assembly of the hinges,

etc.)

4.1 REGULATORY REFERENCES

The legislative references applied and the national and harmonized technical standards applied for

compliance with the above legislative references are:

The legislative references are: The international technical standards are:

2004/108 / EC EMC Directive

2006/95 / EC LVD directive

2006/42 / EC machinery directive

2011/65 / EC RoHS2 Directive EN 55014-2 (1998_10) /

A1 (2002_09) / A2 (2009_09)

EN 60335-1 (2008_07)

EN 60335-2-103 (2003_08) / A11 (2009_07).

EN 55014-1 (2008_01) / A1 (2010_10) / A2 (2012_02)

EN 55014-2 (1998_10) / A1 (2002_09) / A2 (2009_09)

On request of the customer, a version of the WH25 / WH50 system is available equipped with

a radio receiver module and transmitters operating in the 433MHz band that meet the

requirements of Directive 1999/95 / EC (radio equipment and telecommunications equipment)

and subsequent amendments.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.5 di 20

5. GENERAL DESCRIPTIONS

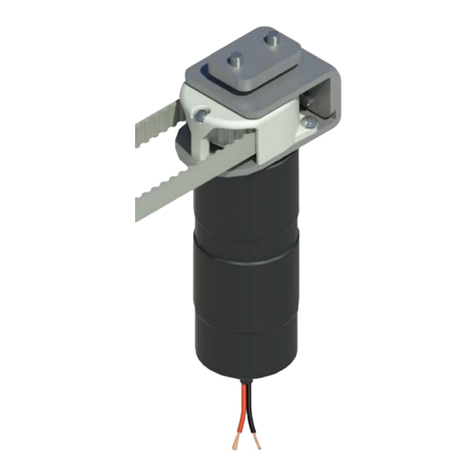

The WH25 / WH50 equipment is an automation for opening / closing swing shutters (windows). It consists

of a high performance non-reversible automation coupled with high resistance metal gears. The possibility

of closing or opening with simple manual controls placed in remote positions (remote control) or with

automation systems (home automation) allows the user to make the most of the protection offered by the

blinds in the different environmental conditions present (e.g. hot, cold, sheltered from insects etc.)

6. RECEIPT AND STORAGE

6.1 CHECK UPON RECEIPT OF THE EQUIPMENT

Upon receipt of the equipment, remove the packaging and

ensure the integrity of the content.

6.2 BOX CONTENTS:

Pz.1

Engine 1 DX internal view

Pz.1

Engine 2 SX internal view

Pz.1

Control unit in PT5 box

Pz.1

Template for coring center

Pz.4

Strap fixing pins

Pz.2

Flanges

Pz.2

Gasket to be interposed between the engine block and the cap

Pz.4

Motor connection terminals

In the event that the product, upon receipt, is damaged and / or with missing parts and / or defects /

malfunctions are detected, do not try to repair the equipment but contact the service center

indicating the model, code and serial number of the equipment.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.6 di 20

6.3 STORAGE

7. INSTRUCTRIONS FOR MECHANICAL ASSEMBLY

Electromechanical operator: (E.O.) technician able to install mechanical - hydraulic -

pneumatic parts and to carry out adjustments, maintenance or repairs and to operate in the

presence of voltage inside cabinets, junction boxes and electrical systems.

The automation provided is a product for professional use for free installation. Assembly must

be carried out by a qualified electromechanical operator. CHIAROSCURO SAS is exonerated

from any responsibility in case of bad installation and / or installations made by unauthorized

operators.

7.1 TOOLS REQUIRED FOR ASSEMBLY

To proceed with the installation, the following tools and materials are required:

Drill / Hammer

Cup core drill from Ø 66mm to Ø 70mm

Screwdriver

Wall tip diam. 6.5mm.

Iron tip diam. 4mm.

4x1 power and control cable

Phillips and slotted screwdrivers

# 4 Allen screwdriver

Template cutting scissors

7.2 IDENTIFICATION OF THE TYPE OF APPLICATION

The flaps can be retractable or supported, to be made to measure and to be ordered separately from

the automation.

The minimum thickness must be 4mm, where possible 5mm.

The hinge of the motor is Ø 12mm.

If the equipment is not used for a long time, store the equipment in a dry, clean and dust-

free place.

In the event of material storage for more than 24 months from registration,

CHIAROSCURO SAS provides the Guarantee provided for in the General Conditions of Sale.

The list shown is not supplied with the WH25 / WH50 product, but is necessary for correct

bench installation. D.P.I. or other are edited and evaluated by the O.E. depending on the

installation itself in the field.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.7 di 20

It is denoted that the product WH25 / WH50 is specific for doors and windows with hinged doors. Any

other use is not guaranteed correct operation and compatibility with the CE marking

8. ELECTRICAL PREPARATION

9. PRE INSTALLATION CHECK

If you do not have the recommended space of 30mm between the side of the door and the axis of the

hinge, it will be necessary to change the position of the hinges and reposition all the hinges before

proceeding with the installation of the WH25 / WH50 automation.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.8 di 20

9.1 CHOICE OF THE HINGES TO BE MOTORIZED

For doors that have 2 hinges, you can

choose to motorize the high or low hinges

indifferently.

For the shutters that have 3 hinges it is

recommended to motorize the central

hinge.

Provide for the installation of the opening

stroke stops.

Also install the closing stroke stops, both at

the top and at the bottom.

It is possible to install a closing electro-

piston at th

e top or at the bottom

(optional).

10. PHISICAL INSTALLATION OF THE AUTOMATION

10.1 CHECK OF LEAF MOVEMENT AND FASTENING

The automation you are installing integrates a safety device which, detecting impediments, stops the

movement of the doors. For this reason, it is necessary to check, even before installing the automation,

that the doors have compatible characteristics as per the table on page 4 (in particular the maximum

weight of the door of 50kg / 75Kg and the door that must not exceed 1.5 sq.m. / 2.0 sq.m. for each door).

It is also necessary to check the rotation of the leaves, which must rotate smoothly, free and without

obstacles. We suggest carrying out this check by closing the door and pushing it from the closed position.

With a normal push, the door should open completely until it touches the opposite wall. If the door

exhibits some friction in its movement, it is necessary to suspend the assembly phase of the automation

and intervene on the hinges and elements of the shutter that compromise the fluidity of movement,

making the appropriate changes to the elements that create friction. A door that presents problems will

reduce the life of the automation, which will be unnecessarily fatigued for its entire life of use.

Furthermore, once connected, it will be more complex to identify this type of problem that must therefore

be solved initially.

10.2 ENGINE POSITIONING

Install and lock the doors in the closed position. Use the template supplied by inserting it into the strips to

be motorized and mark the point where to drill with a pencil.

When marking the core drill holes make sure the jigs are snug against the wall

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.9 di 20

10.3 DRILLING THE WALL

Remove the doors and use the hammer drill with the

core drill bit.

Drill the wall with a depth of 150mm making sure to be

perpendicular to the wall both vertically and horizontally

For the passage of the sheath for the electrical

connection, drill with a 16-20mm bit

Thoroughly clean the holes with a vacuum cleaner and wire brush to allow the chemical

sealant to take hold

10.4 ASSEMBLY OF THE AUTOMATION

Unscrew the two screws that hold the motor fixed to the shell and remove the motor from the casing.

Prepare the electrical sheath to allow the passage of the cables and leave a cable length of 200mm outside

the wall, section 2x1.5mmq.

Insert the gaskets and connect the cables following the wiring diagram. The NEGATIVE pole is marked with

a white dot on the rear of the engine. Insert the motor in the cover and fix it with the screws previously

unscrewed.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.10 di 20

Fix the strips to the doors and insert the doors on the hinges.

Pay particular care and attention to the alignment of the manual hinges with the motorized

hinge. Always keep in mind that the reference for alignments is always the motorized hinge. If

it is necessary to protrude further, it is possible to order 10mm extensions to be interposed

between the hood and the motor block.

Use the notches present in the cap to insert the chemical glue into the spaces between the hole in the wall

and the cap. Start clockwise from hole 1 up to number 4 as you gradually use more and more adhesive.

Once finished, go over the outermost part following the entire perimeter, taking care to clean the surplus

of material.

Wait for the chemical adhesive to dry respecting the times and methods recommended by the

manufacturer

Fit the protection flange

The protection flange will be spaced a few mm from the masonry

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.11 di 20

10.5 ASSEMBLY OF THE DOOR ON THE MOTORIZED HINGES

Disassemble the doors and mark the point to be drilled 20mm from the upper edge of the eye of the strip.

Drill the eye of the strip with a 6.5mm metal drill, the hole must be through and perfectly perpendicular or

parallel to the door.

To make the holes in the strips easier, a template (optional) is available that guides the tip

both in height and in direction.

It may be necessary to widen the holes present in the hinge of the motor to allow the passage of the

through pin, or use the supplied dowel. Reassemble the doors, rotate the doors until it is possible to insert

the through pin.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.12 di 20

11. ELECTRICAL INSTALLATION PREPARATION

WARNING

!

The electrical installation must be carried out following the national standards in force, thus for all the

obligations established by law. The electrical connections must be made without voltage, do not power

the work area before completing all assembly operations.

RADIO SPECIFICATIONS

Frequency: 433.92 Mhz Transmitter range: approx: 70m free field

The good propagation of radio waves depends on the nature of the environments to pass through.

The range of radio waves is affected by the type of construction.

12. AUTOMATION OPERATION

The automation operates the doors after pressing the button and continues to move them until the button

is pressed. The operator switches off automatically when the effort is detected, with the leaf completely

open or completely closed. The closing / opening force must be set appropriately by means of a trimmer

(see chapter “Adjustment trimmer”). To stop the leaves at an intermediate point during movement, simply

stop pressing the button.

Make sure that there is a soft pad in the upper corner of the door or a small dark man

without automatic release, so that the door always remains free and can rest without

marking itself. In this way, the motorization will also be able to better determine the “All

Open” position.

These elements are generally charged to the supplier of the shutters, but can be supplied as

accessory elements upon request.

13. ELECRTICAL CONNECTION

Assembly must be carried out by a qualified electromechanical operator. CHIAROSCURO SAS exonerates

itself from any responsibility in case of bad installation and / or installations made by unauthorized

operators. (Minimum card size 145 x 105mm)

The proper functioning of the equipment and compliance with

safety requirements are

guaranteed only if connected to an efficient electrical system built in accordance with the

laws in force (in Italy Legislative Decree 37/2008). The manufacturer assumes no

responsibility for any damage to the equipment or to third

parties caused by the use of a

system that does not comply with current regulations.

If the behavior of the equipment does not reflect the above, do not use the automation and

immediately report the anomaly to the authorized CHIAROSCURO SAS service cent

er. Never

open the enclosure of the equipment unless expressly authorized in writing by

CHIAROSCURO SAS. Failure to comply with this rule results in the immediate forfeiture of

the warranty and consequent liability of CHIAROSCURO SAS for aspects concerning

the

safety and operation of the equipment.

It is the sole responsibility of the electromechanical operator to set up the system.

CHIAROSCURO SAS is in no way responsible for any deficiencies of any natu

re on the

system. All the information necessary fo

r a good system is fully available, it is the buyer's

responsibility to request them formally.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.13 di 20

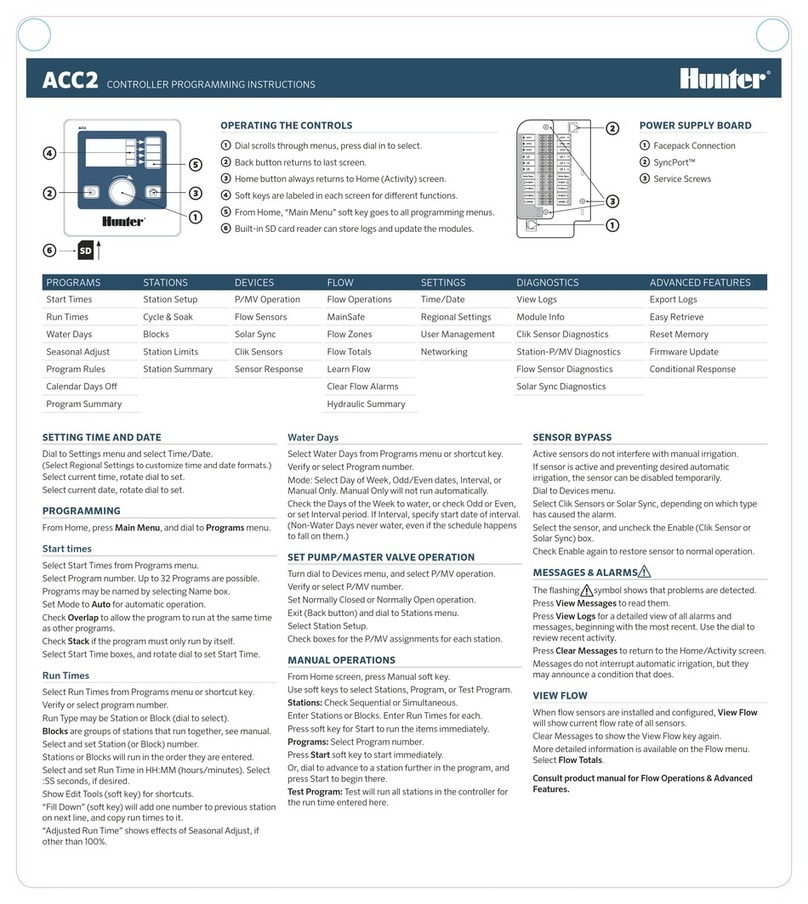

14. TYPE OF CONTROL BUTTON AND CONNECTION TO THE INTEGRATED CONTROL UNIT

TYPE OF CONTROL BUTTON

The switch must necessarily be of the type:

interlocked up and down switch switch

without restraint.

15. WIRING DIAGRAMS

15.1 ELECTRICAL DIAGRAM FOR COMMAND CONNECTION

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.14 di 20

15.2 WIRING DIAGRAM FOR “DEAD MAN”TYPE CONNECTION

15.3 WIRING DIAGRAM FOR “IMPULSIVE”TYPE CONNECTION

15.4 RADIO RECEIVER WIRING DIAGRAM MOD.EWSCE230

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.15 di 20

15.5 ELECTRICAL DIAGRAM FOR ELECTRONIC PISTON CONNECTION

The solenoid lock must be connected by bridging the motor cables corresponding to the first leaf to open.

For further information, refer to the instructions in the solenoid lock package

Check that the electrical setting and all the parameters are respected as indicated in the

previous sheets.

In the event that defects / malfunctions are found, do not try to repair the equipment but

contact the service center indicating the model, code and serial number, data available on

the label applied to the engine.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.16 di 20

16. COMPATIBILITY WITH HOME AUTOMATION SYSTEMS

The automation is compatible with almost all home

automation systems and existing home automation

management modules that manage the opening and closing of

the shutters (modules that can be purchased from specialized

dealers). As for the control of rolling shutters, it is in fact

sufficient to set a retention time of more than 60 seconds

using your favorite application: the automation will perform

the movement and automatically stop when the doors are

opened / closed. The integrated card is in fact able to stop the

motors when the movement is complete, identify any

obstacles or presences during operation, in order to guarantee

maximum safety during operation and to protect the motors

from stress. This simplified use makes automation extremely

easy to manage and configure! We suggest that you check the

compatibility of your home automation module by consulting

your trusted dealer, showing him this type of simplified use

and these wiring diagrams. You can also contact our

technicians who will be happy to provide you with further

technical and functional details.

17. ADJUSTMENT TRIMMER

The board, as standard, is pre-wired and configured with pre-optimized “default”

parameters that are valid for most users and types of common use.

It is not recommended to modify the default parameters of the electronic board, which

must only take place when necessary. The modification of the configuration parameters

must only be made by knowledgeable and qualified operators.

17.1 TRIMMER TEMP:INCREASE OF THE OPENING DOORS DELAY:

Adjusting the TEMP trimmer allows you to set

the opening delay between the leaves.

Clockwise rotation decreases the opening

delay time between the leaves, on the

contrary, anticlockwise rotation increases it.

Carry out some opening and closing tests to

check that the doors in the movement phase

do not have overlapping and jamming.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.17 di 20

17.2 TRIMMER CURR: INCREASE OF THE MOTOR POWER:

Adjusting the CURR trimmer allows you to

set the thrust torque.

By setting a thrust level too low, the leaves

will lock in an anomalous way, while too

much power would lead to a single effort of

the motors when the stroke is complete. We

suggest identifying the minimum operating

point and from that position, increase the

power by ¼ of a turn.

18. SPECIAL PROGRAMMING FUNCTIONS

18.1 REVERSAL OF THE FIRST DOOR

Of Standard, the first door to open is the right. To reverse the first door to open it is necessary to open the

cover and reverse the cable connections to the electronic board.

ATTENTION: To reverse the opening direction of the leaves, as well as swap the motor cables

on terminal blocks M1 and M2, it is also necessary to reverse the polarity by connecting the

RED cable instead of the BLACK cable for each motor.

19. ELECTROPISTON ASSEMBLY

The electric lock is an optional accessory

and must be mounted near the stop of

the main door when closing. On the

door, on the other hand, a small

perforated flange will be mounted

which, when in the closed position, this

hole must coincide with the solenoid

lock.

The electric lock cables must be routed

to the right, usually, or to the left,

providing a duct for their protection,

until they reach the electronic board.

N.B. our system is able to manage elected 24V powered pistons that do not exceed a

current draw of 600mA

20. MAINTENANCE

The operations described in the following paragraphs must always be carried out with the equipment

off (equipment disconnector in the OFF position).

In the event that defects / malfunctions are found, do not try to repair the equipment but contact the

service center indicating the model, code and serial number of the equipment (see Fig.3.1. Plate data

label).

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.18 di 20

20.1 PERIODIC MAINTENANCE

20.2 EXTRAORDINARY MAINTENANCE

21. PROBLEMS AND ANOMALIES

User: Periodically clean the casing of the equipment using a soft cloth moistened with neutral and

non-aggressive detergents and dry with a dry cloth. Keep the movement area of the window frame

clean and well maintained.

Electromechanical operator : Check the correct tightening of the shoe shank, the play of the shoe in

the guide, the wear of the bushings present in the joint,.

Record any settlements of the window or door .

User: Contact the electromechanical operator in case of breakages or malfunctions .

Electromechanical operator: Identify malfunctions and if necessary contact the service center

indicating the model, code and serial number of the equipment. Use the service request form - spare

parts on p. 27

If the proposed intervention has not resolved the anomaly found, interrupt the operations and

request the intervention of the Assistance Center.

Never open the enclosure of the equipment unless expressly authorized in writing by the Chiaroscuro

company. Failure to comply with this rule leads to the immediate forfeiture of the warranty and the

consequent liability of the supplier for aspects concerning safety and operation.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.19 di 20

22. DISPOSAL

INFORMATION FOR USERS

Pursuant to art. 13 of the Legislative Decree 25 July 2005, n. 151

"Implementation of Directives 2002/95 / EC, 2002/96 / EC and 2003/108 / EC,

relating to the reduction of the use of hazardous substances in electrical and

electronic equipment, as well as the disposal of waste"

The crossed-out bin symbol shown on the equipment indicates that the product

at the end of its useful life must be collected separately from other waste. The

user must, therefore, deliver the equipment complete with the essential

components at the end of its life to the appropriate separate collection centers

for electronic and electrotechnical waste, or return it to the retailer when

purchasing new equipment of an equivalent type, at the one by one. Adequate

separate collection for the subsequent start-up of the discarded equipment for

recycling, treatment and environmentally compatible disposal helps to avoid

possible negative effects on the environment and health and favors the

recycling of the materials that make up the equipment. Illegal disposal of the

product by the user involves the application of administrative penalties

provided for by current legislation.

23. Limits of liability

WH25 offers a torque of 25 Nm, WH50 offers a torque of 50 Nm: these are the maximum driving torques

available on the transmission pin which, through the arm and track, impart movement to the leaf or

maintain its position. It is the responsibility of the buyer / installer to determine whether this pair is

adequate for the needs of the required application; the needs depend on various factors mainly: weight

and dimensions of the leaf (the indications given in chap.11.2 are purely indicative and not binding),

friction of the hinges and correct verticality of the rotation axis of the same, and above all the extent of the

opposing force generated by the wind. The intensity and duration of wind stresses are highly variable and

in the absence of complex and expensive measurement and recording procedures they can only be

estimated not in a subjective and approximate way. In the offer, the supplier company expresses an

evaluation of these factors based first of all on data and information made available by the customer and

possibly emerged from the inspection, but such evaluations cannot be considered contractually binding

and binding for the purpose of attributing responsibility to the supplier company in the choice and

adequacy of the supply to the specific case as only with a pilot installation made in the case considered by

the most significant customer can the real needs / problems of the application emerge. The various

mechanical elements are designed to cope with the stresses and normal wear resulting from the torque

generated by the apparatus for a number of 20,000 operating cycles. However, there are stresses and

consequent wear that do not depend on the drive torque but depend on poor installation and above all on

stresses caused by the wind when the intensity or frequency of the gusts / gusts are significant or linked to

consistent atmospheric phenomena.

Precisely because of the unknown entity and type of said stresses, the resistance of the apparatus for this

purpose cannot be guaranteed.

WH25

CSG2 BOARD DEAD MAN

COMMAND

Cod. 220517

CHIAROSCURO SAS

di Girelli Marco & C.

C.so General A. Cantore 23 - 38061 Ala (TN) Italy

P.I. IT01527050221 Pag.20 di 20

24. MARKING COMPATIBILITY CERTIFICATE

CHIAROSCURO SAS di Girelli Marco & C.

C.so General A.Cantore 23 - 38061 Ala (TN) Italy.

Tel: +39 0464 424715 fax: +39 0464 712027

email: info@chiaroscuro.eu sito: www.chiaroscuro.eu

Declares that the electrical product

It complies with the legislative provisions transposing the following directives and subsequent

amendments:

2004/108 EC Directive (EMC Directive) and subsequent amendments 2006/95 / EC EC Directive (Low

Voltage Directive) and subsequent amendments 1999/5 / EC RoHs2 Radio and Telecommunications

Terminal Equipment 2002/95 / EC Restriction of use of certain Hazardous Substances

Compatibility with the CE marking is valid provided that the WH25 / WH50 actuator is used exclusively for

the intended applications and the installation is performed according to the assembly instructions.

ALA, 20/01/2020 _________________________________

Marco Girelli

Legal Representat

25. Warranty

CONDITIONS AND LIMITATIONS:

CHIAROSCURO SAS company guarantees the equipment for a period of 12 months.

The warranty starts from the date of purchase indicated on the fiscal document at the time of delivery of

the equipment. The company undertakes to repair or replace free of charge those parts that show

manufacturing defects within the warranty period. The guarantee does not include any form of

compensation deriving from direct or indirect damage to persons or things. During the warranty period, if

the Customer wishes the repair to be carried out by the CHIAROSCURO SAS technicians, a written request

must be sent to CHIAROSCURO SAS. In this case, the costs relating to travel, food and accommodation will

be fully charged to the customer. For interventions caused by defects or failures not clearly attributable to

the material or manufacturing, all travel, repair and / or replacement costs of all parts will be charged to

the customer. The extension of the guarantee following a repair on the equipment is excluded. In case of

return of parts of the equipment, the Customer will be able to ship them only after receiving written

authorization from the CHIAROSCURO SAS company. Packaging and shipping costs are charged to the

customer (unless otherwise agreed between the parties). In any case, accidental damage due to transport,

neglect, inadequate treatment, use that does not comply with the warnings given in this manual or for all

those phenomena not dependent on the normal operation or use of the appliance are excluded from the

guarantee. The warranty is void if the equipment is repaired by unauthorized third parties or if equipment

or accessories not supplied, recommended or approved by CHIAROSCURO SAS are used or if the serial

number is removed or altered during the warranty period. The guarantee immediately ceases its effects in

the event that the Customer is late or non-payment, even partial. CHIAROSCURO SAS declines all

responsibility for any damage to persons or things caused by misuse or imperfect use of the equipment.

The Court of Rovereto (ITALY) is competent for any dispute.

Template

WH25/WH50

Description

Actuator for the movement of hinged doors

Table of contents

Other CHIAROSCURO Controllers manuals