HEX060PA Heat Exchanger Instruction Manual

Page 7

Quarterly

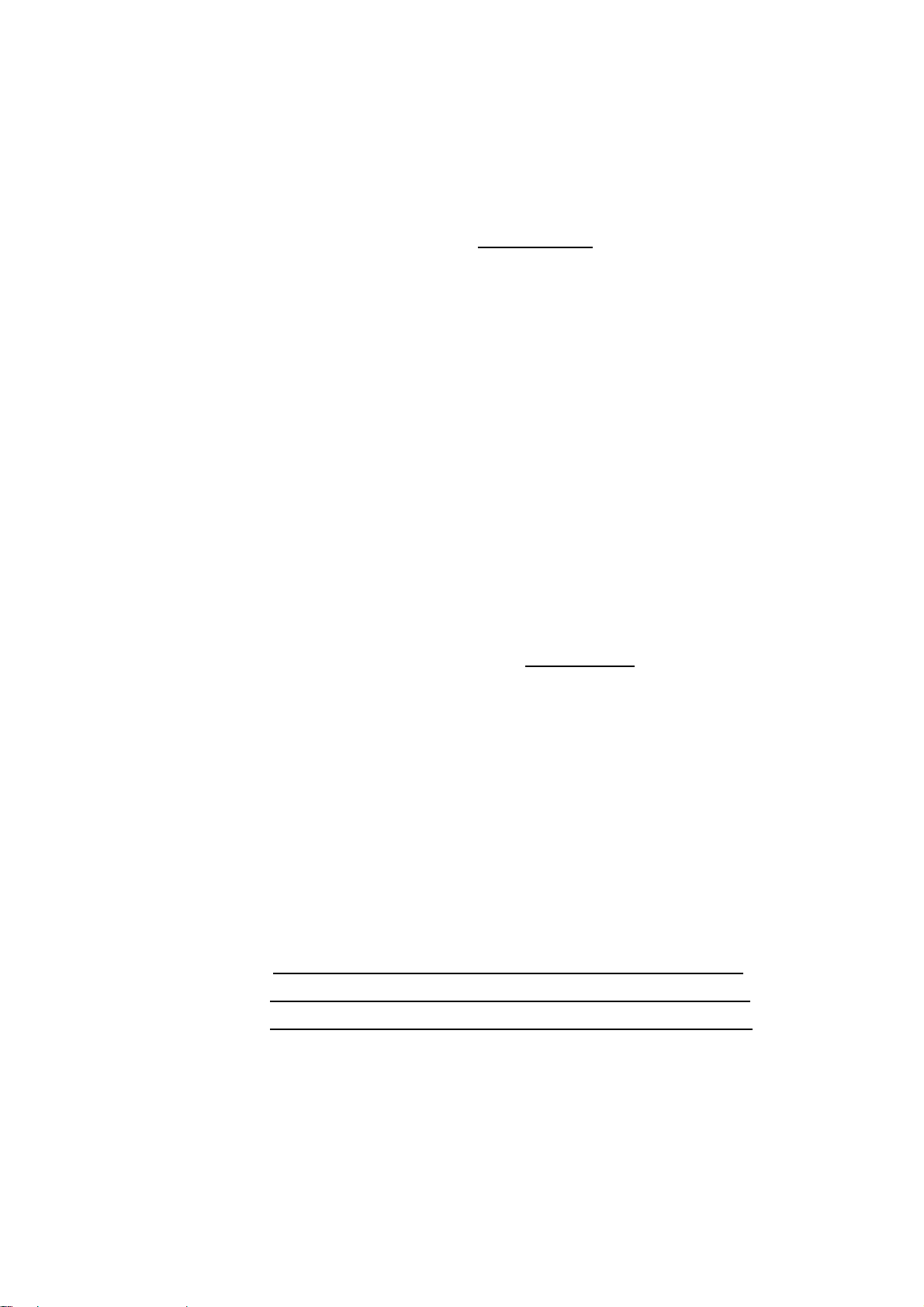

User can follow below sequence to proceed the maintenance .

Internal loop maintenance :

* The maintenance is from internal side .

* Use screw driver to remove the secured screw on upper

portion of chassis assy (Item 1) .

* Disassemble the internal plate assy (Item 7) and disconnect

fan from controller (Item 3) , Note to record the connection

location .

* Use brush and low pressure air to remove dust on

internal plate assy (Item 7) , internal fan (item 4) & heat

exchange CORE opening .

* Hold internal plate assy (Item 7) and connect fan to

controller (Item 3) .

* Re-attach internal plate assy back (Item 7) and use screw

driver to secure screw with chassis assy (Item 1) .

External loop maintenance :

* The maintenance is from from internal side .

* Use screw driver to remove the secured screw on upper

portion of chassis assy (Item 1) .

* Disassemble the internal plate assy (Item 7) and disconnect

fan from controller (Item 3) . Note to record the connection

location .

* Remove frame assy (Item 2) carefully to avoid waterproof

foam between around fame assy (Item 2) and chassis assy

(Item 1) to be damaged .

* Use brush and low pressure air to remove the dust on

external fan (Item 5) & heat exchange CORE opening .

* Please check waterproof foam whether had damaged

before secure frame assy (Item 2) back , if yes , please

remove damaged and stick new waterproof foam first .

* Hold internal plate assy (Item 7) and connect fan to

controller (Item 3) .

* Re-attach internal plate assy back (Item 7) and use screw

driver to secure screw with chassis assy (Item 1) .