Warning

This Instruction Sheet only provides descriptions for installation, wiring and trial run. For further infromation,

please refer to special module of PLC Application Manual.

DO NOT touch terminals when power on. Please must power OFF before wiring.

This is an OPEN TYPE PLC. The PLC should be kept in an enclosure away from airborne dust, humidity, electric

shock risk and vibration. Also, it is equipped with protective methods such as some special tools or keys to open the

enclosure in order to prevent hazard to users or damage the PLC.

DO NOT connect the AC input power to any of the input/output terminals, or it may damage the PLC. Check all the

wiring prior to power up.

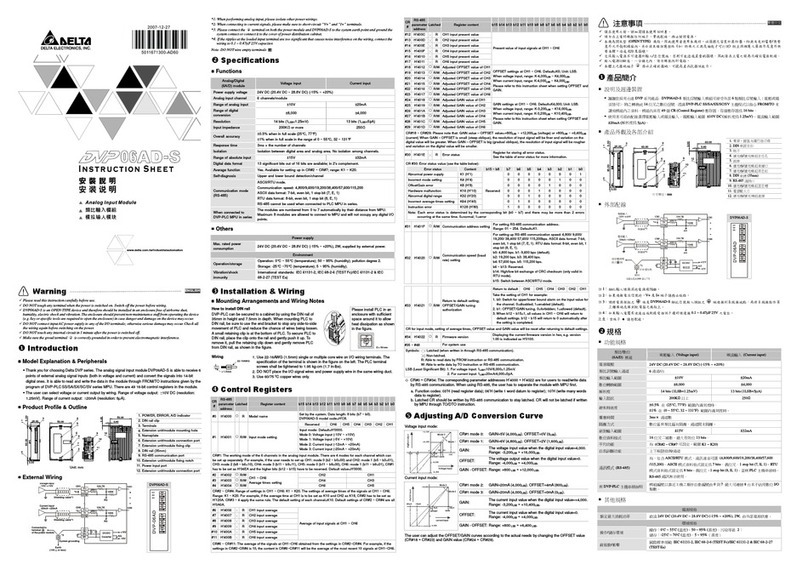

Introduction

Model Explanation & and Peripherals

DVP01PU-S (positioning unit) is mainly applied to the speed/position control of step/servo driven system. The maximum

output pulse ca n be up to 200 kPPS, and built-in various route control modes. The DVP-PLC SS/SA/SC/SX/SV series can

read/write DVP01 PU-S via FROM/TO instrucitons. T here are 49 CRs (Control Register) with 16-bit for each register in

DVP01PU-S. The 32-bits data is composed of 2 continuous CR number.

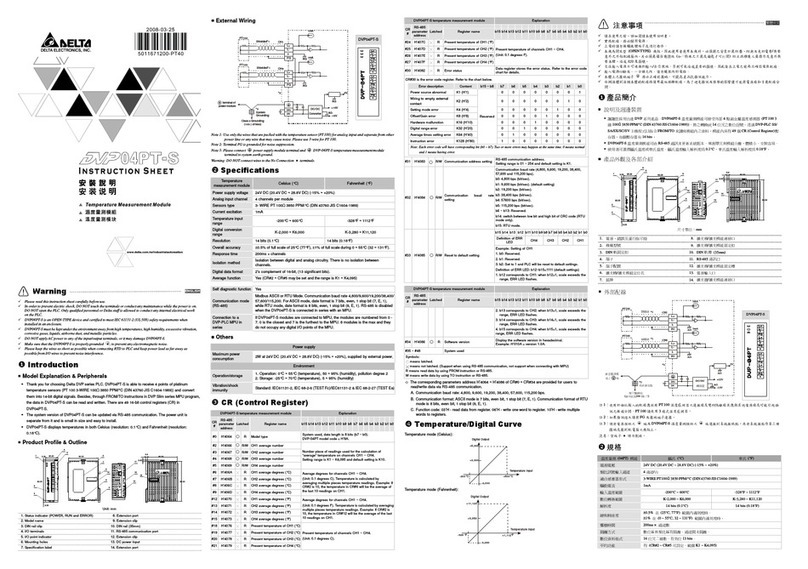

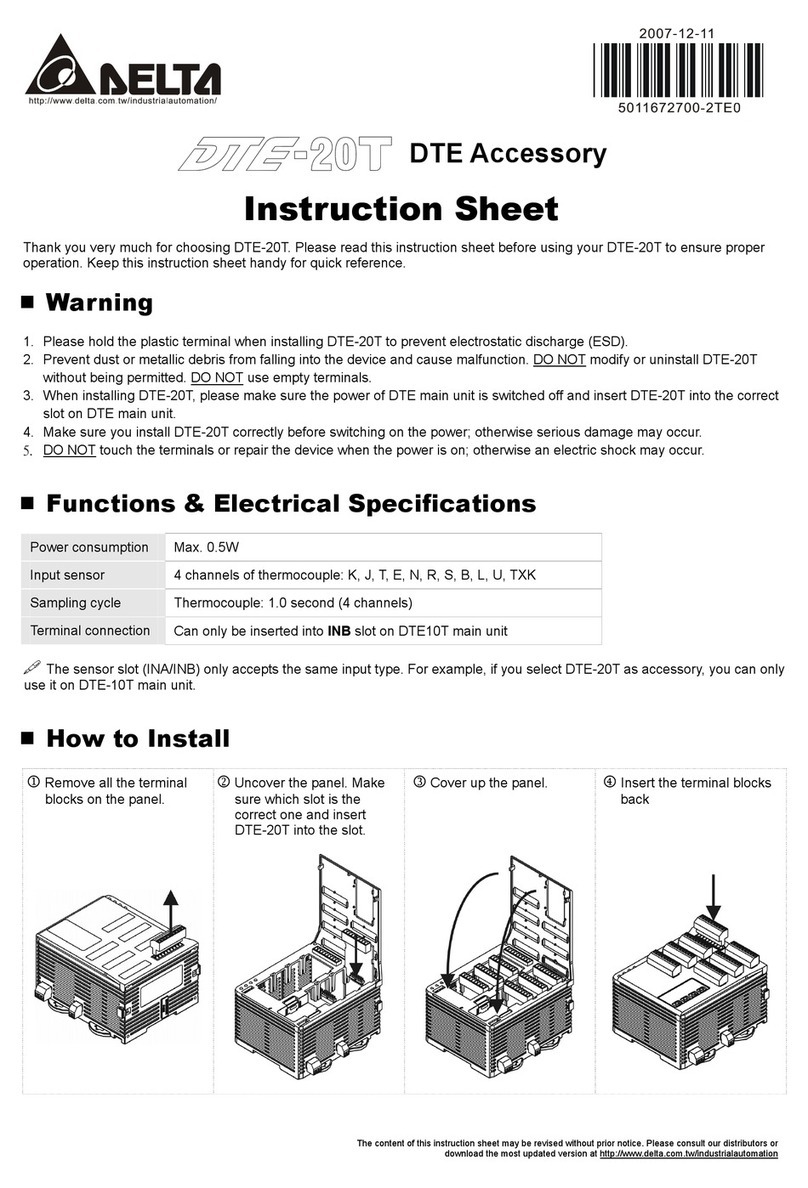

Product Profile & Outline (LED Indicator and Terminal Block)

Upper Row

S/S A-

START B+

STOP B-

DOG CLR+

LSP CLR-

LSN FP+

PG0+ FP-

PG0- RP+

●

RP

FP

CLR

●

●

●

●

DVP-01PU

START

PG0

A

B

LSN

LSP

DOG

STOP

ERROR

L.V

ss

POWER

090.00

3.00

25.20 60.00 3.40

1

2

3

14

4

5

6

8

10

15

16

Unit: mm A+ RP-

1. Status Indicator (Power, LV and ERROR) 2. Model name 3. DIN rail clip

4. Terminal 5. Terminal indicator 6. Mounting hole

7. Nameplate 8. Extension p ort to connect extension module

9. Extension unit/module clip 10. DIN rail track (35mm)

11. RS-485 communication port 12. Clip for combining extension modules

13. Power input 14. Extension port to connect extension module

15. Upper row terminals 16. Lower row terminals

LED Display

POWER : Power indicator, +5V internal power START : Start input

LV : Low voltage indicator STOP

: Stop input

lit when external input power is lower than 19.5V DOG : DOG (near point signal) input

ERROR

: Error indicator (ON/OFF blinking). FP : CW pulse output

It will blink when CR#3 9 is not 0 . RP : CCW pulse output

LSP : Right limit input indicator ΦA : A-phase input of manual pulse generator

LSN : Left limit input indicator ΦB : B-phase input of manual pulse generator

PG0 : Zero signal input indicator CLR : Output clear signal

Input/Output Terminal

Description Terminal name

+24V, 0V Power input/24V DC (-15 ~ +20%)

Current consumption 70

±

10mA; Startup peak current 1.3 A -

Description Terminal name

START Start input terminal 4ms/12ms

STOP Stop input terminal 4ms

LSP/LSN Limit Stroke of right/left limit 1ms

ΦA+, ΦA- A-phase terminal (+, -) of manual pulse generator input (line driver input) 200kHz

ΦB+, ΦB- B-phase terminal (+, -) of manual pulse generator input (line driver input) 200kHz

PG0+, PG0- Zero signal input terminal +, - (line driver input) 4ms

DOG

Offers two different functions depending on operation mode.

(1) It is near-point signal in zero return mode.

(2) It is start signal on interrupt 1st or in terrupt 2nd speed mode.

1ms

Input

S/S Signal common terminal of these Inputs (START, STOP, DOG, LSP, LSN) -

CLR+, CLR- Clear signal (clear sig nal of internal error counter for Servo drive) 4ms

FP+, FP- FP/RP mode: CW pulse output I/O mode: Output pulse

AB-phase mode: A-phase output 200kHz

Output

RP+, RP- FP/RP mode: CCW pulse o utput I/O mode: direction output

AB-phase mode: B-phase output 200kHz

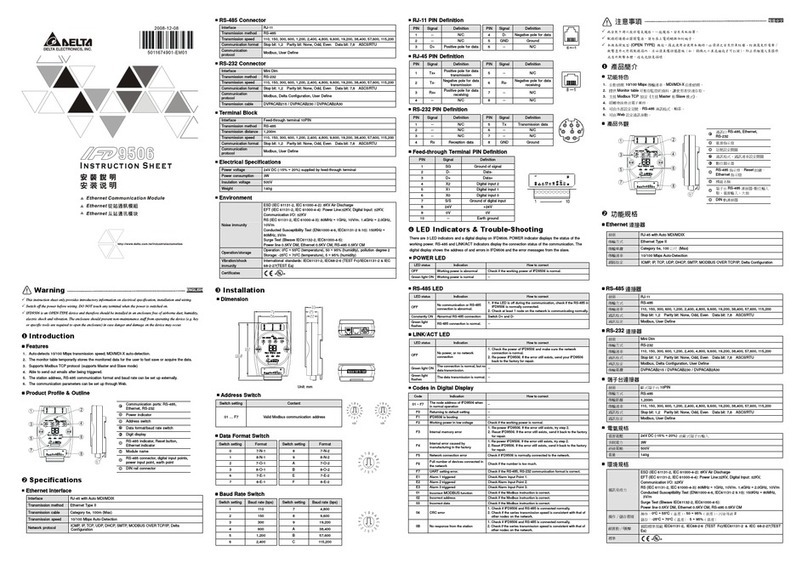

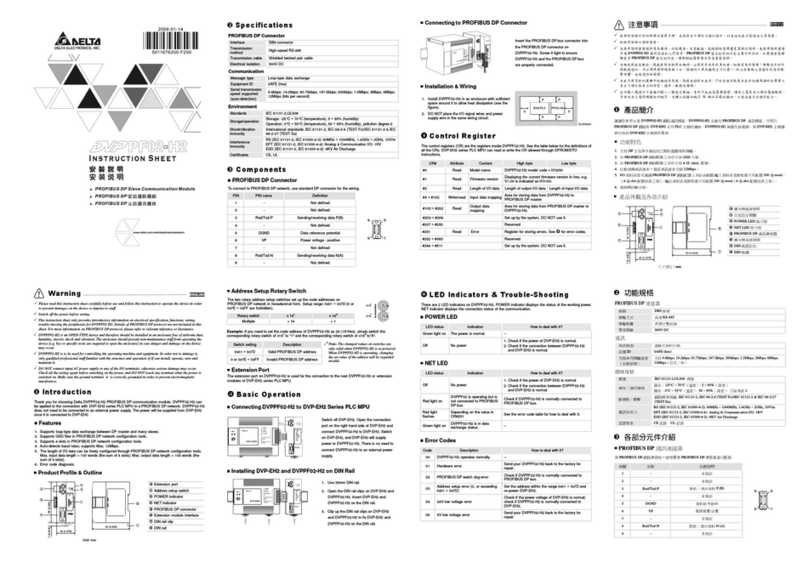

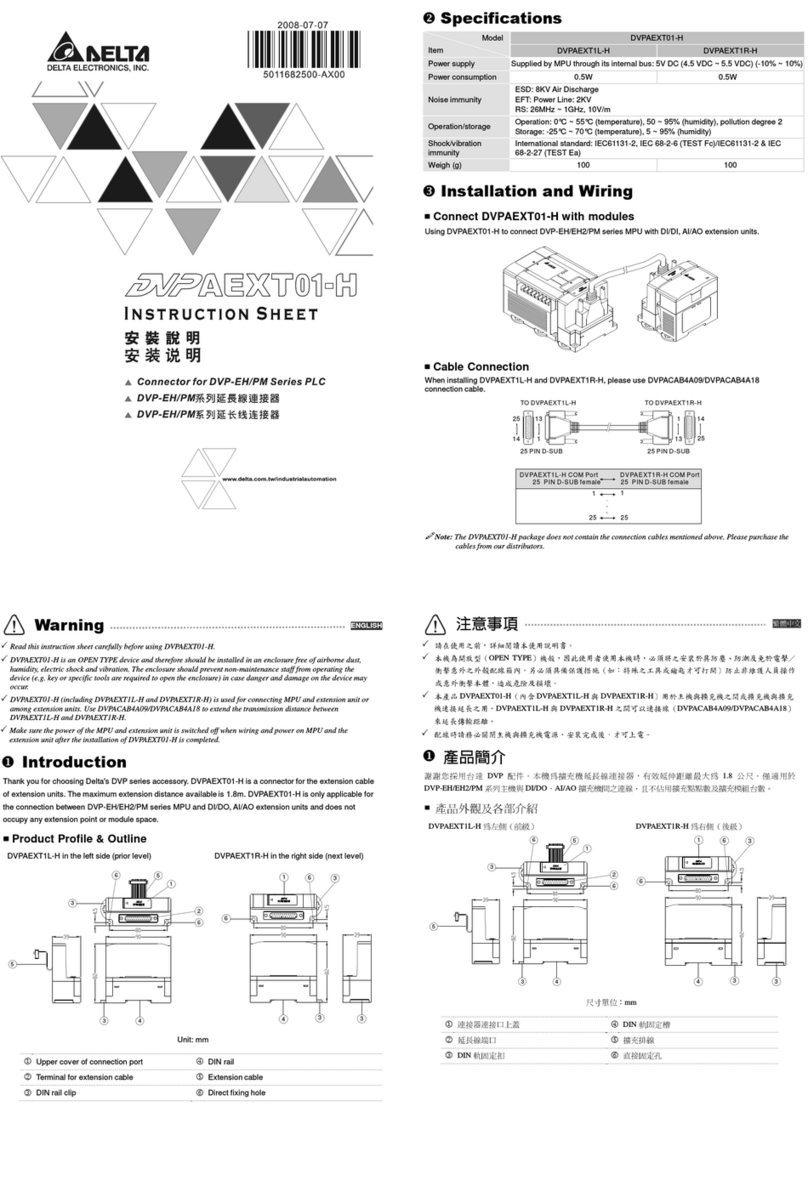

Input/Output Circuit

STA RT

STO P

LSP

LS N

DO G

S/S

+2 4V

5-2 4V D C

24V

0V

FP +

FP -

RP +

RP -

CL R+

CL R-

A-p ha se

Φ

A+

Φ

A-

Φ

B+

PG 0+

PG 0-

5-2 4 VD C

PLS

/P LS

SI GN

/S IG N

DI2

CO M-

Ma nual p uls e gen era tor

Sh ield ed cab le

1. Please use 22-16AWG (1.5mm)

wiring (either single or multiple core)

for I/O wiring terminals. PLC

terminal screws should be tightened

to 1.95 kg-cm (1.7in-lbs). Use

copper conductors only, 60/75oC.

2. DO NOT arrange the wiring of I/O

signal wires or power supply in the

same wiring duct.

3. Make sure the terminals of

power module and DVP01PU-S are

properly grounded or connected to

the cover of power distribution

cabinet.

4. DO NOT wire to null terminal .

5. Use only 60/75°C copper conductors.

Specifications

Functions

Item Content

Power supply 24V DC (-15% ~ +20%) ; Current consumption 70±10m A; Startup peak current 1.3 A

Max. number of

connected axes

8 units; (SS/SA/SX/SC/SV series MPU can connect up to 8 extension modules without occupying any

I/O)

Distance

instruction

Distance value is set by CR

1. Setting range: -2,147,483,648 ~ +2,147,483,647; 2. Selectable unit: um, mdeg, 10

-4

inch, Pulse;

3. Selectable rate: 10

0

, 10

1

, 10

2

, 10

3

;

4. Selectable position: absolute and relative position instruction

Speed

instruction

Speed value is set by CR

1. Setting range: -2,147,483,64 8 ~ +2,147,483,647 (conversion value of 10 ~ 200 kPPS pulse)

2. Selectable unit: pulse/s, cm/min, 10deg/min, inch/m in

External output

Photo coupler is for insulation and there are LED indications for all output/input signals

Outputs: FP and RP (line driver output 5V)

Output: CLR is the type of NPN open collector transistor output (5 ~ 24V DC, less than 20mA)

External input

Photo coupler is for insulation and there are LED ind ications for all output/input signals.

Input point: START, STOP, LSP, LSN, DOG(contact or open collector transistor, 24V DC±10%, 5±1mA)

Inputs: ΦA, ΦB (line driver or open collector transistor, 5 ~ 24V DC, 6 ~15mA)

Input: PG0 (line driver or open collector transistor, 5 ~ 24V DC, 6 ~ 15mA)

Pulse output

format Three selectable modes: Pulse/Dir, FP (CW)/RP (CCW), A/B (all modes are line driver output).

Position

program & data

transmission

CR data can be read/write via FROM/TO intruction of PLC MPU. The 32-bit data is composed of 2

continuous CR number. The range of 16-bit CR is CR #0 ~ CR#48.

Connect to

DVP-PLC

series

Modules are numbered from 0 ~ 7 with 0 closet a nd 7 farthest to the M PU. Up to 8 modules can be

connected without occupying an y digital I/O.

Others

Environmental specifications

Operation

/Storage

1. Operation: 0°C~ 55°C (Temperature), 50 ~ 95% (Humidity), pollution degree 2

2. Storage: -25°C~ 70°C (Temperature), 5 ~ 95%

(

Humidity

)

Vibration /Shock

immunity Standard: IEC 61131-2, IEC 68-2-6 (TEST Fc)/IEC 61131-2 & IEC 68-2-27 (T EST Ea)

Approvals

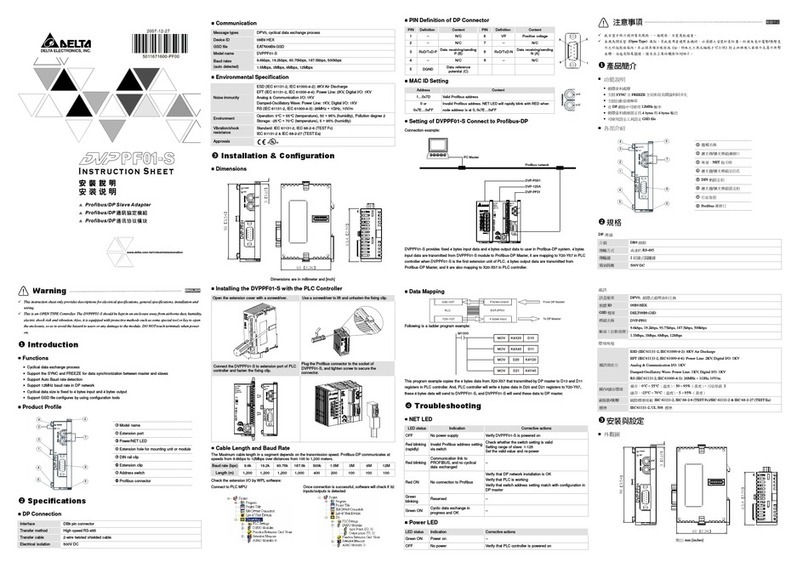

CR (Control Register)

CR No.

HM LW

Address

Attribute

Content Setting Range

#0

Model No. System setting, Read-only (T he model number of DVP01PU-S is H’0110.)

#2

Pulse rate (A) Range: 1 ~ +2,147,483,6 47 PPS/REV, factory setting: 2,000

Pulse/Revolution (PLS/REV)

#4

Feed rate (B) Range: 1 ~ +2,147,483,647 unit/REV, factory setting: 1,000 (unit*1/REV)

b15

Parameter

setting

Factory setting:

H’0000

STOP

input polarity

START input polarity

START response

time

Acceleration curve

options

DOG

polarity

DOG trigger time

Pulse direction

Zero return direction

LSN input polarity

LSP input polarity

Pulse output format

Position rate setting

Unit setting

#7 #6 H’4196

○

Maximum

speed V

max

Range: 0 ~ +2,147,483,647 unit*1 (10 ~ 200 kPPS) *2

Factory setting: 200,000 unit*1

#9

Bias speed

V

bias

Range: 0 ~ +2,147,483,647 unit*1 (0 ~ 200 kPPS pulse transfer value) *2

Factory setting: 0 unit*1

#11

JOG speed

V

JOG

Range: 0 ~ +2,147,483,647 uni t*1 (10 ~ 200 kPPS pulse transfer value) *2

Factory setting: 5,000 unit*1

#13

Zero return

speed V

RT

Range: 0 ~ +2,147,483,647 unit*1 (10 ~ 200 kPPS pulse transfer value) *2

Factory setting: 50,000 unit*1

#15

Zero return

deceleration

speed V

CR

Range: 0 ~ +2,147,483,647 unit*1 (10 ~ 200 kPPS pulse transfer value) *2

Factory setting: 1,000 unit*1

#16

PG0 in zero

return mode N

Range: 0 ~ +32,767 PLS

Factory setting: 0 PLS

#17

The number of

pulse in zero

return mode P

Range: -32,768 ~ +32,767 PLS

Factory setting: 0 PLS

#18

Zero return

mode H Mode

b0: zero return mode,

b1: detect DOG falling-edge in zero return mode

#20

Zero point

setting (HP)

Range: 0 ~

±

999,999 unit*1

Factory setting: 0 unit*1

#21

Acceleration

time T

acc

Range: 10 ~ +32,767 ms

Factory setting: 100 ms

CR No.

HM

Attribute

Content Setting Range

#22

Deceleration time

T

dec

Range: 10 ~ +32,767 ms

;

factory setting: 100 ms

#24

Range: -2,147,483,648 ~ +2,147,483,647 unit*1 (-2,147,483,648 ~

+2,147,483,647 pulse tra nsfer value) *2; factory setting: 0 unit*1

#26

Running

speed (I) V(I)

Range: -2,147,483,648 ~ +2,147,483,6 47 unit*1 (10 ~ 200 kPPS pulse

transfer value) *2; factory setting: 1,000 unit*1

#28

Target

position (II)

P(II)

Range: -2,147,483,648 ~ +2,147,483,647 unit*1 (-2,147,483,648 ~

+2,147,483,647 pulse tra nsfer value) *2, factory setting: 0 unit*1

#30

Running

speed (II) V(II)

Range: 0 ~ +2,147,483,647 unit*1 (10 ~ 200 kPPS pulse transfer value) *2

Factory setting: 2,000 unit*1

b15

Running

instruction

factory setting:

H’0000

-

-

CLR output

CLR signal

output mode

-

Current

position

= 0

Zero return

start

JOG-

JOG+

Work mode

Factory setting:

H’0001

-

-

Current position: CR34, 33; current

speed: CR36, 35;

display unit: 0

pulse, 1

unit

Return to

factory

setting

MASK setting

LSP/LSN stop mode

Manual pulse generator range limitation

STOP mode

Manual pulse generator input operation

Variable speed operation mode start

Interrupt 2

nd

-speed position mode start

2

nd

-speed position mode start

Interrupt 1

st

-speed position

mode start

1

st

-speed position mode start

#34

CP (PLS)

Range display: -2,147,483,648 ~ +2,147,483 ,647 PLS

Factory setting: 0 PLS

#36

Current speed

CS (PPS)

Range display: 0 ~ +2,147,483,647 PPS

Factory setting: 0 PPS

#37

Communication

address and

Baud rate

setting

RS-485 communication address setting: setting range 01 ~ 254

Factory setting: K1. Baud rate setting: 4,800, 9, 600, 19,200, 38,400, 57,600,

and 115,200 bps. ASCII mode data format is 7Bit, even bit and 1 stop bit (7 E

1). RTU mode data format is 8Bit, e ven bit and 1 stop bit (8 E 1)

b0: 4,800 bps (bit/sec.), b1: 9,600 bps (bit/sec.) (factory setting)

b2: 19,200 bps (bit/sec.), b3: 38,400 bps (bit/sec.)

b4: 57,600 bps (bit/sec.), b5: 115,200 bps (bit/sec.)

b6: reserved, b7: 0 for RTU, 1 for ASCII mode,

b8 ~ b15: communication address

b15

Execution

status

factory setting:

H’XXXX

-

-

-

-

-

MPG input downward

MPG input upward

-

Route paused

indication

Position completed

indication

Error occurred flag

CP value overflow

Zero return is done

CCW pulse is

outputting

CW pulse is

outputting

Status indication

#39

R Error code Please refer to “Error Code & Troubleshooting” for detail.

Factory setting: H’0000

#40

Electronic

gearing number

of MPG input

Please refer to the following explanation

Factory setting: H’1

#41

Electronic

gearing

denominator of

MPG input

Please refer to the following explanation

Factory setting: H’1

#43

Input frequency

of manual

pulse generator

The input frequency of manual pulse ge nerator

Factory setting: 0

#45

Accumulated

pulse input no.

of manual

The count value of CW manual pulse input is “ +” symbol, on the contrary, the

CCW manual pulse input is “-“symbol. And the count value is nothing to do

with the ratio setting of m anual electronic gear ing (CR#40, #41). Factory

setting: 0.

Value

Response speed

≧

5 4ms (factory setting)

4 32ms

3 108ms

2 256ms

#46

Response

speed of

manual pulse

generator

1 or 0

500ms

When response speed setting is faster, the

instructions of pulse output and manual

pulse generator input will be m ore

synchronous. W hen

is slower, the instruction of pulse output is

slower than the instruction of manual pulse

generator input. Factory setting: 5

bit #

Status Description

b0 START input When START input is On , b0 is On.

b1 STOP input When STOP input is On, b1 is On.

b2 DOG input When DOG input is On, b2 is On.

b3 PG0 input When PG0 input is On, b3 is On.

b4 LSP input When LSP input is On, b4 is On.

b5 LSN input When LSN input is On, b5 is On.

b6 A phase input When A phase input is On, b6 is On.

b7 B phase input When B phase input is On, b7 is On.

#47

b8 CLR output When CLR output is On, b8 is On.

#48

System version is in hexadecimal. e.g. software V1.00 is for H’0100.

*1: Unit setting varies based on b0 and b1 setting of CR#5.

*2: Use max. Pulse output if upper limit is exceeded. Use min. pulse output if lower limit is exceeded.

※

CR#0 ~ CR48: user can use the corresponding addresses H

’

4190 ~ 41C0 to read/write data via RS-485

communication.

1. Baud rate supportive: 4,800, 9,600, 38,400, 57,600, and 115,200 bps.

2. Modbus ASCII/RTU: ASCII mode is 7 bits, even bit and 1 stop bit (7, E, 1). RTU mode is 8 bits, even bit

and 1 stop bit (8, E, 1).

3. Function code: 03’H for read data from CR; 06’H for write one word in CR; 10’H for write many words in

CR. It indicates DVP01PU-S hardware malfunction or error parameter setting when error LED flashes.

ERR code is recorded in CR#39.

Error Code & Troubleshooting

Error code Description Error code Description

H’0000 No error H’0014 JOG speed (V

JOG

) setting error

H’0001 Target position (I) setting error H’0020 CW pulse is forbidden

H’0002 Target address ( II) setting error H’0021 CCW pulse is forbidden

H’0010 Running speed (I) setting error H’0030 Low voltage

H’0011 Running speed (II) setting error H’0080 Hardware error in internal m emory

H’0012 Zero return deceleration (V

CR

) setting error H’0081 Data write in error in internal memory

H’0013 Zero return (V

RT

) setting error

注意事項

本手冊主要提供

DVP01PU-S

定位模組安裝、配線回路及試機之參考,有關進一步 使用說明,請參考

DVP-PLC

應用技術手冊

【特殊模組篇】

。

請勿在上電時觸摸任何端子。實施配線,務必關閉電源。

本機為開放型

(Open Type)

機殼,因此使用者使用本機時,必須將之安裝於具防塵、防潮及免於電擊

/

衝擊意

外之外殼配線箱內。另必須具備保護措施

(

如

:

特殊之工具或鑰匙才可打開

)

防止非維護人員操作或意外衝擊

本體,造成危險及損壞。

交流輸入電源不可連接於輸入

/

出信號端,否則將造成嚴重 損壞,請在上電之前再次確認電源配線。

產品簡介

說明及週邊裝置

DVP01PU-S

脈波產生單元主要可應用于步進或伺服驅動系統之速度或位置控制,最

200 kPPS

脈波輸出,內建

多種行程控制模式。透過

DVP-PLC SS/SA/SX/SC/SV

系列主機程式以指令

FROM/TO

來讀寫模組內之資料,模組

內具有

49

個

CR

暫存器,每個暫存器為

16

位。

32

位

元

數值參數由兩個連續編號的

CR

所組成。

產品外觀與各部介紹

(

((

(

指示燈、端子台

)

))

)

上排端子

下排端子

S/S A-

START B+

STOP B-

DOG CLR+

LSP CLR-

LSN FP+

PG0+ FP-

PG0- RP+

●

RP

FP

CLR

●

●

●

●

DVP-01PU

STAR T

PG0

A

B

LSN

LSP

DOG

STOP

ERRO R

L.V

ss

POW ER

3

90.00

3.00

25. 20 60.00 3. 40

1

2

3

14

4

5

6

8

10

3

7

9

12

11

15

16

尺寸單位:

mm

A+ RP-

1.

電源、低電壓及運行指示燈

9.

擴充機

/

擴充模組固定扣

2.

機種型號

10. DIN

軌糟

(35mm)

3. DIN

軌固定扣

11. RS-485

通訊口

4.

端子

12.

擴展機

/

擴展模組固定槽

5.

端子指示燈

13.

電源輸入口

6.

擴充機

/

擴充模組定位孔

14.

擴充機

/

擴充模組連接口

7.

銘牌

15.

上排端子

8.

擴充機

/

擴充模組連接口

16.

下排端子

面板指示燈

POWER

:電源指示燈,內部

+5V

電源正常

START

:啟動輸入指示燈

LV

:低電壓指示燈,外部電源輸入小於

STOP

:停止輸入指示燈

19.5V

,該指示燈亮

DOG

:近點信號輸入指示燈

ERROR

:錯誤指示燈(

On/Off

閃爍),當

CR#39 FP

:正轉方向輸出指示燈

錯誤編號不為零時動作

RP

:反轉方向輸出指示燈

LSP

:右極限輸入指示燈

ΦA

:手搖輪

A

相輸入指示燈

LSN

:左極限輸入指示燈

ΦB

:手搖輪

B

相輸入指示燈

PG0

:零點信號輸入指示燈

CLR

:清除信號輸出指示燈

繁體中文

輸入輸出端子信號

種

類

端

子

說

明

回應特性

電源輸入供應

+24V, 0V,

輸入電源

24V DC (-15 ~ +20%)

消耗電流

70±10mA

開機電流

1.3 A -

START

啟動輸入

4ms/12ms

STOP

停止輸入

4ms

LSP/LSN

右極限輸入左極限輸入

1ms

ΦA+, ΦA-

手搖輪

A

相輸入

+, -

(差動信號輸入)

200kHz

ΦB+, ΦB-

手搖輪

B

相輸入

+, -

(差動信號輸入)

200kHz

PG0+, PG0-

零點信號輸入

+, -

(差動信號輸入)

4ms

DOG

依照運行模式不同有下列

2

種變化:

1.

原點復歸時為近點信號。

2.

一段速或二段速

插入啟動信號

1ms

輸入

S/S

輸入點

(START, STOP, DOG, LSP, LSN)

信號共用端

-

CLR+, CLR-

清除信號(

Servo

驅動器內部偏差計數器清除信號)

4ms

FP+, FP-

正

/

反轉模式:正轉方向脈波輸出;脈波

/

方向:脈波輸出端;

AB

相模式:

A

相輸出

200kHz

輸出

RP+, RP-

正

/

反轉模式:反轉方向脈波輸出;脈波

/

方向:方向輸出端;

AB

相模式:

B

相輸出

200kHz

輸入

/

輸出回 配線

START

STOP

LSP

LSN

DOG

S/S

+24V

5-24 VDC

輸入

24V

0V

FP+

FP-

RP+

RP-

CLR+

CLR-

台達伺服驅動器

隔離線

手搖輪脈波

A

相

Φ

A+

Φ

A-

Φ

B+

PG0+

PG0-

5-24 VDC

PLS

/PLS

SIGN

/SIG N

DI2

COM-

ASD A 列系

VDD

COM+

17

11

41

B

相

Φ

B-

1.

輸出

/

入配線端請使用

22-16AWG (1.5mm)

單蕊祼線

或多蕊線。

PLC

端子鏍絲扭力

為

1.95 kg-cm (1.7lb-in)

。

2.

在配線時請勿將輸入點信號線

與輸出點或電源等動力線置於

同一線糟內。

3.

請將電源模組之

端及

DVP01PU-S

定位控制模組之

端連接到系統接地點,再

將系統接點作第三種接地或接

到配電箱之機殼上。

4.

空端子

請勿配線。

5.

只能使用

60/75°C

的銅導線。

規格

功能規格

項

目

說

明

電源輸入

24V DC (-15% ~ +20%)

消耗電流

70 ±10mA

開機電流

1.3 A

最大連接台

(

軸

)

數

8

台(軸);(不占任何

I/O

點數

SS/SA/SX/SC/SV

系列主機所能連接特殊擴充機台數總和為

8

台)

距離值

距離設定值由控制暫存器

(CR)

來設定

1.

設定值:

-2,147,483,648 ~ +2,147,483,647

;

2.

單位可選擇:

um, mdeg, 10

-4

inch, Pulse

;

3.

可選擇倍率:

10

0

, 10

1

, 10

2

, 10

3

;

4.

可選擇絕對位置或相對移動量

速度值

速度設定值由控制暫存器

(CR)

來設定

1.

設定值:

-2,147,483,648 ~ +2,147,483,647 (10 ~ 200kPPS

的脈波轉換值

)

;

2.

單位可選擇:

Pulse/s, cm/min, 10deg/min, inch/min

外部輸出點

全部採用光耦合作隔離 輸出

/

入信號皆附

LED

作為信號及致能的指示

輸出點:

FP, RP

輸出差動驅動信號

5V

輸出點:

CLR

為電晶體

NPN

開集極

5 ~ 24V DC, 20mA

以下