Table of Contents

Check before Use................................................................................................................................1

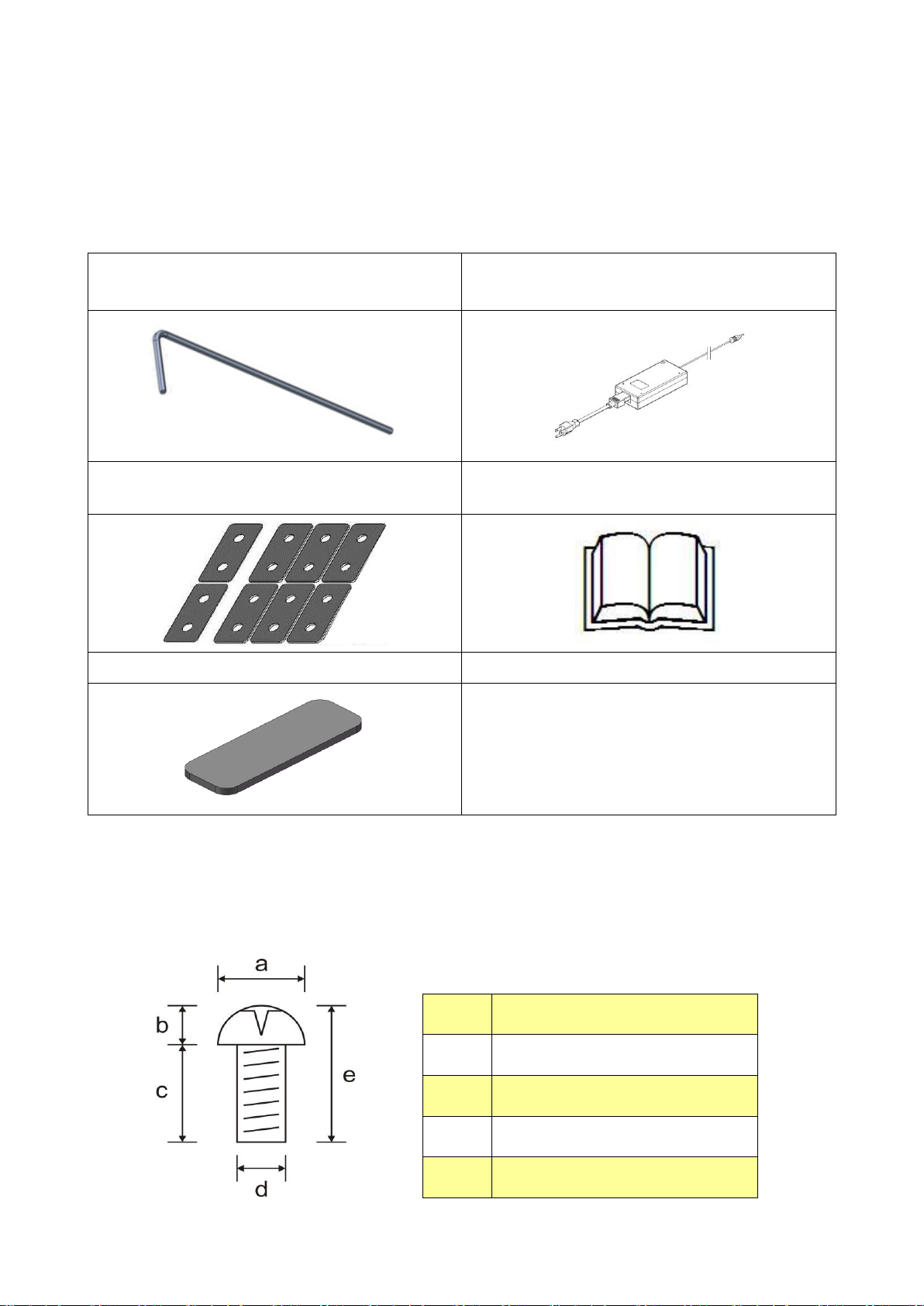

Equipped Accessories ..................................................................................................................1

Check Screw Dimension..............................................................................................................1

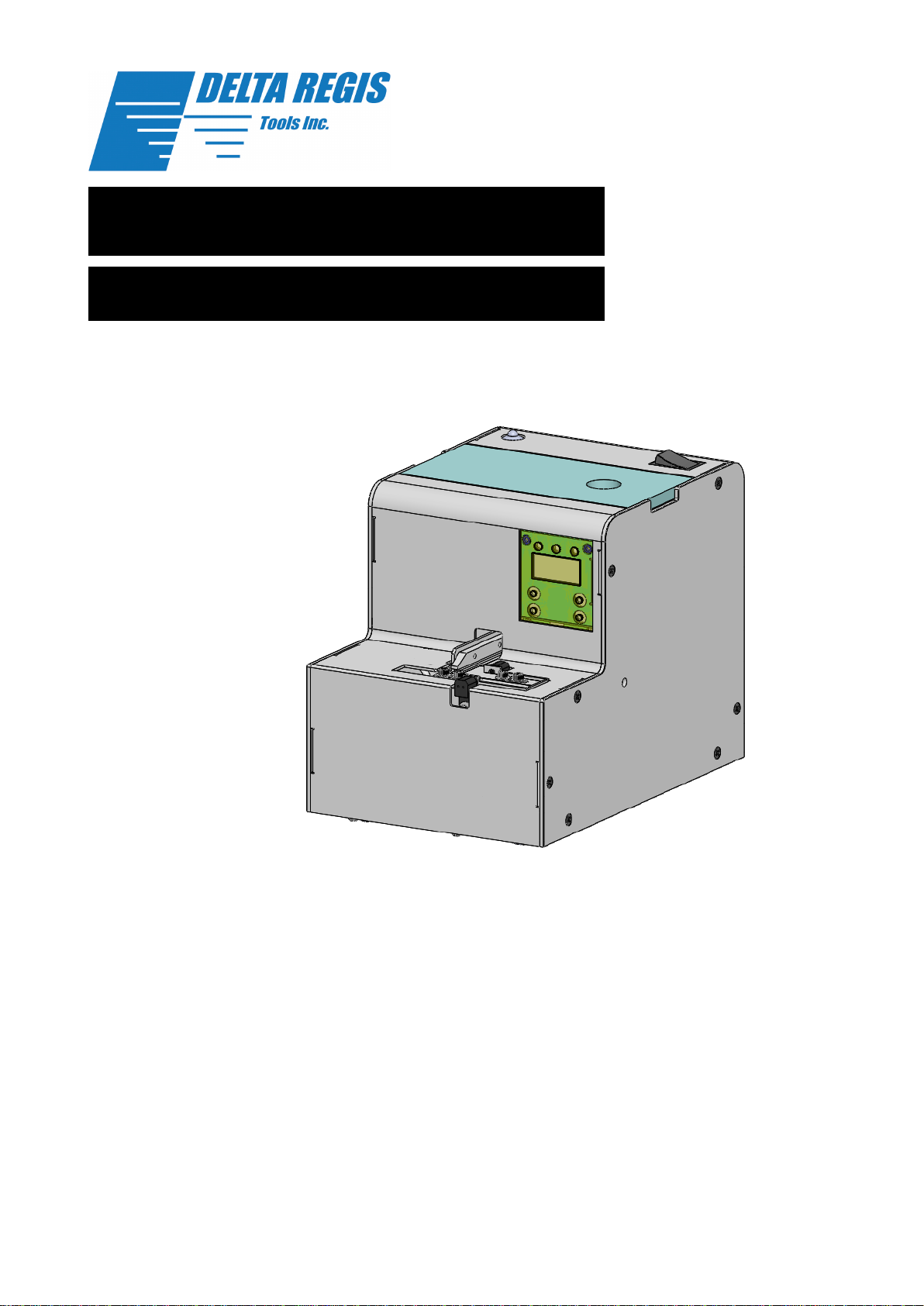

Description of Machine & PCB Function and Panel Hole Locations ...........................................2

Adjustment .........................................................................................................................................3

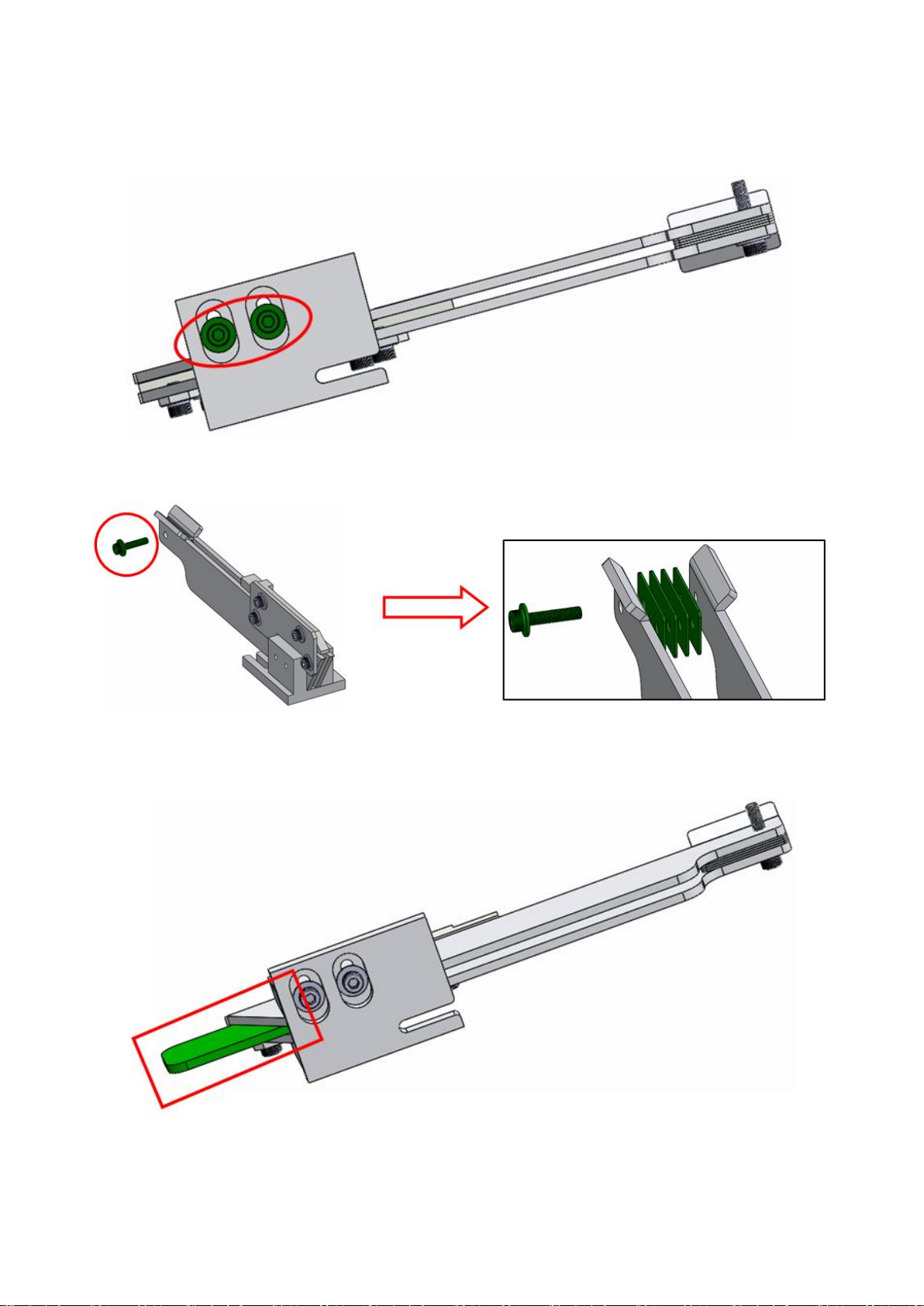

Track Adjustment.........................................................................................................................3

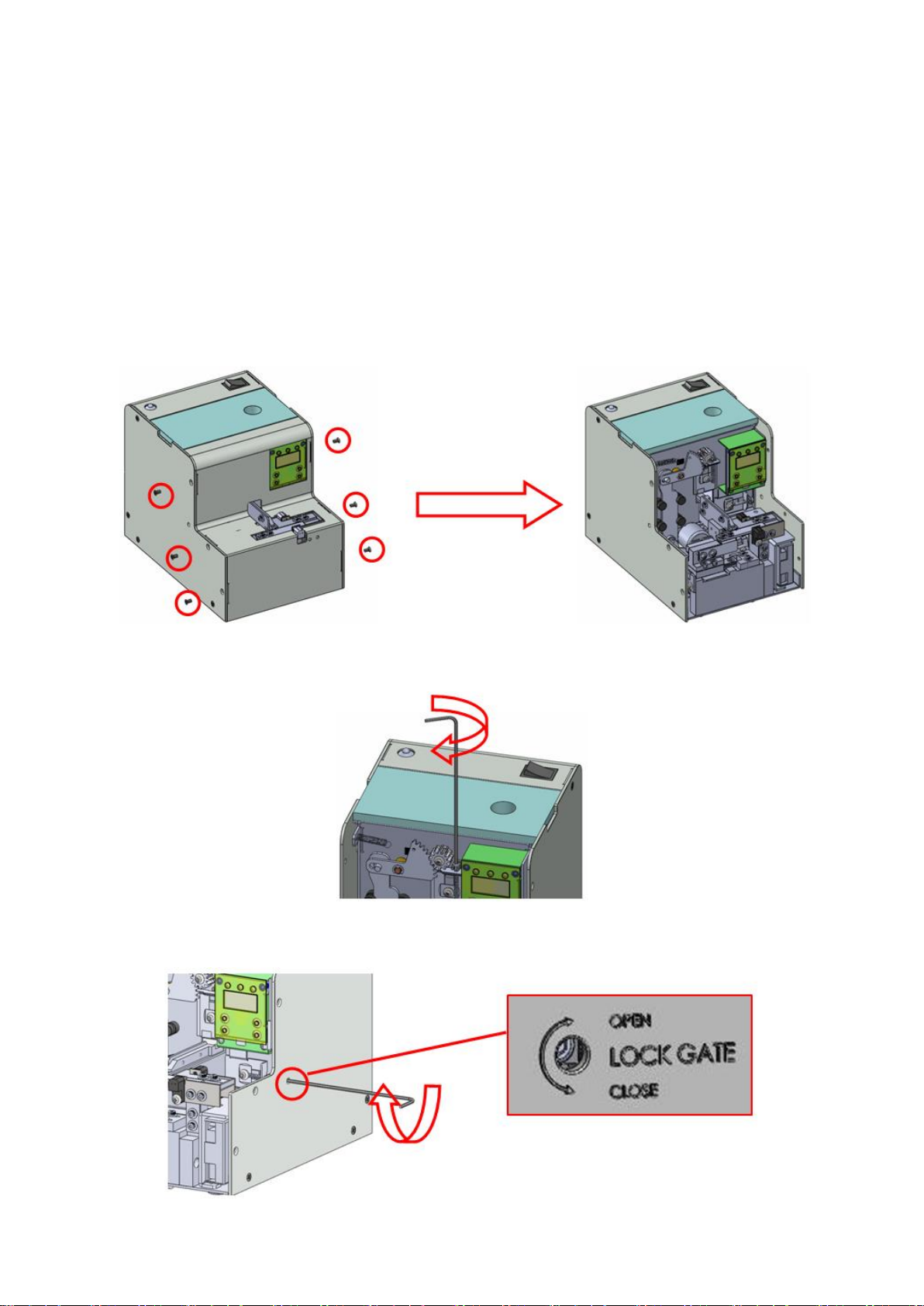

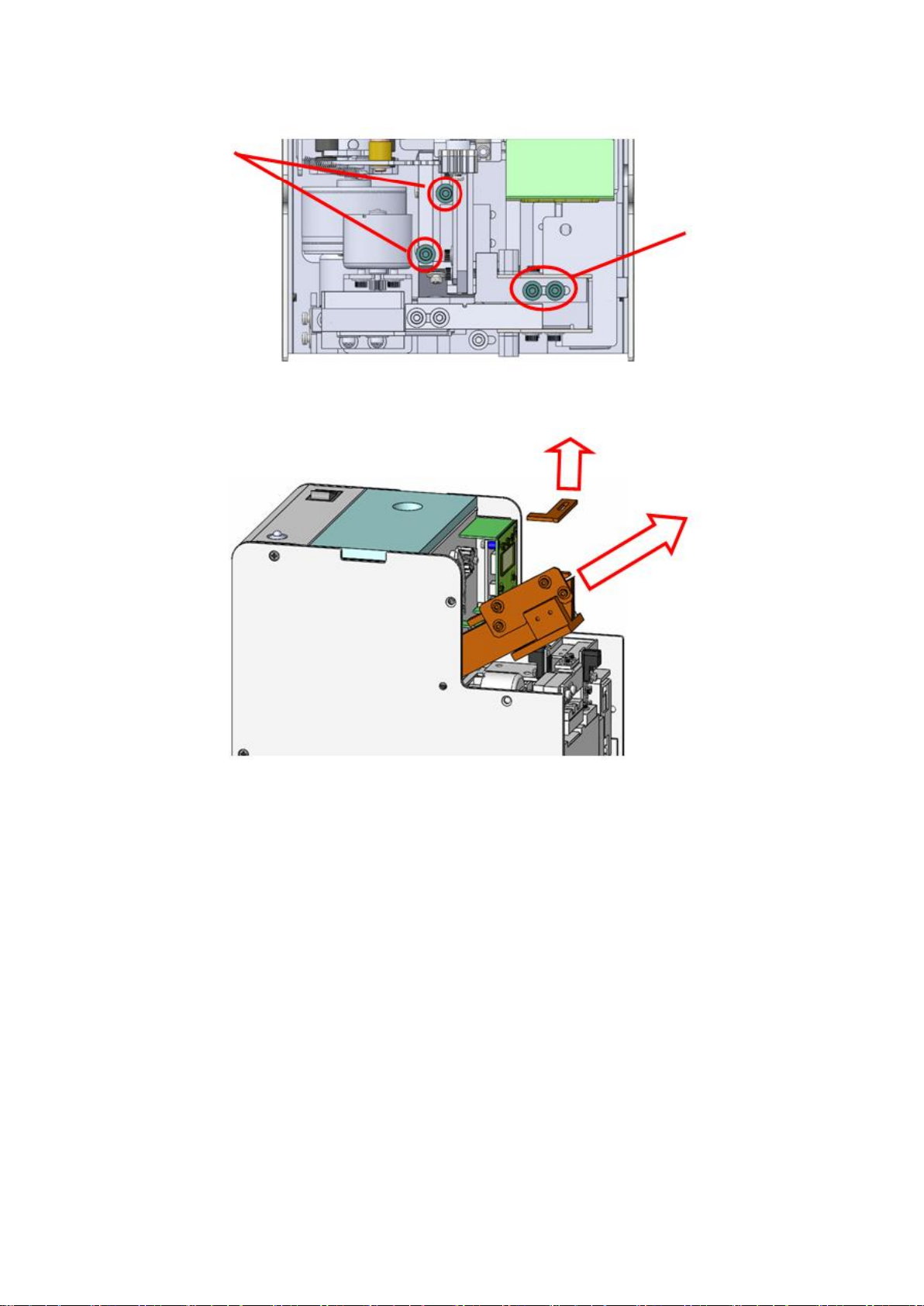

Track Removal.....................................................................................................................3

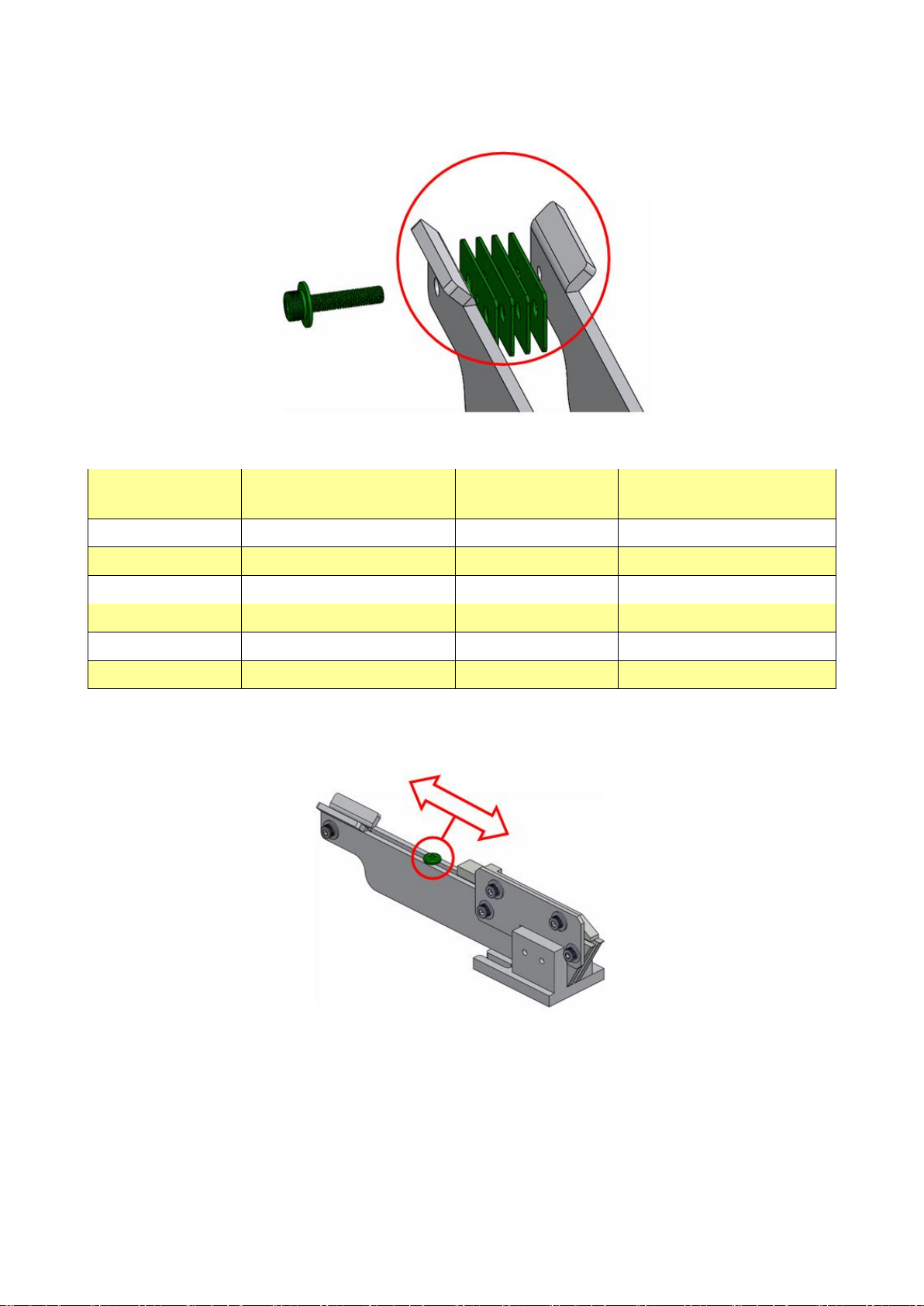

Adjust Track Width..............................................................................................................5

Track Installation .................................................................................................................7

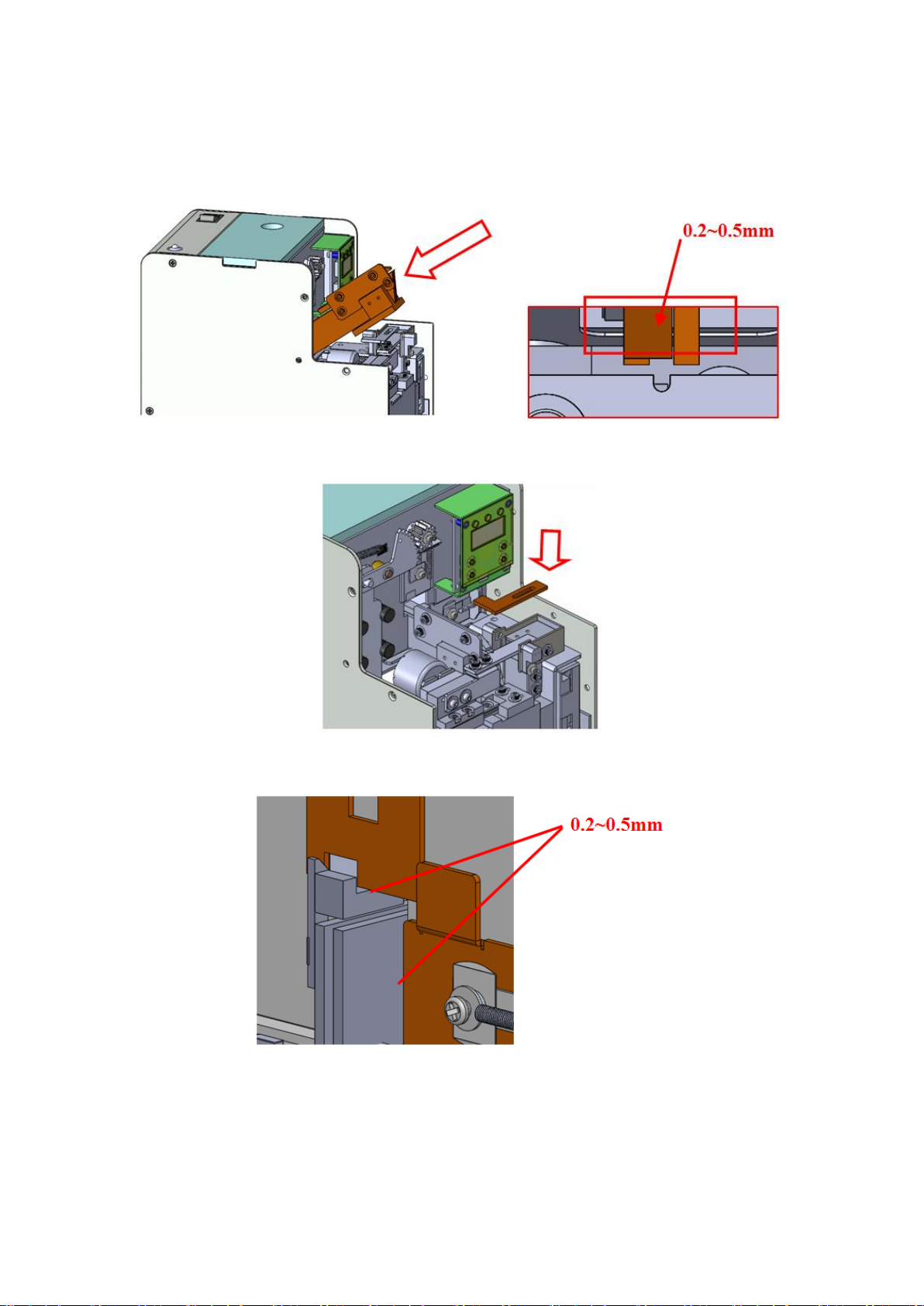

Adjustment of Keep Board ..........................................................................................................8

Adjustment of Infrared Device ....................................................................................................9

Adjustment of Dispensing Mechanism......................................................................................10

Adjustment of Container Funnel Inside Cylinder......................................................................13

Adjustment of Brush..................................................................................................................14

Method of Use...................................................................................................................................16

Quantity of Screws Placed In.....................................................................................................16

Signal Board Connection...........................................................................................................17

Counter Interface Operation.......................................................................................................18

Common Malfunction and Simple Resolution ..............................................................................21

Maintenance and Cleaning..............................................................................................................22

Warranty Clause..............................................................................................................................23