SAFETY INSTRUCTIONS

PLEASE NOTE FOLLOWING CONDITIONS BEFORE USING DRFF-500R

◎For a normal performance, please install this machine on a flat and stable

working table, do not slant or pad, otherwise machine function might be

affected.

◎Turn off the power switch and unplug the AC adaptor when this machine is

not being used for a period of time.

◎To avoid damage and malfunction, use the AC adaptor supplied with this

machine only.

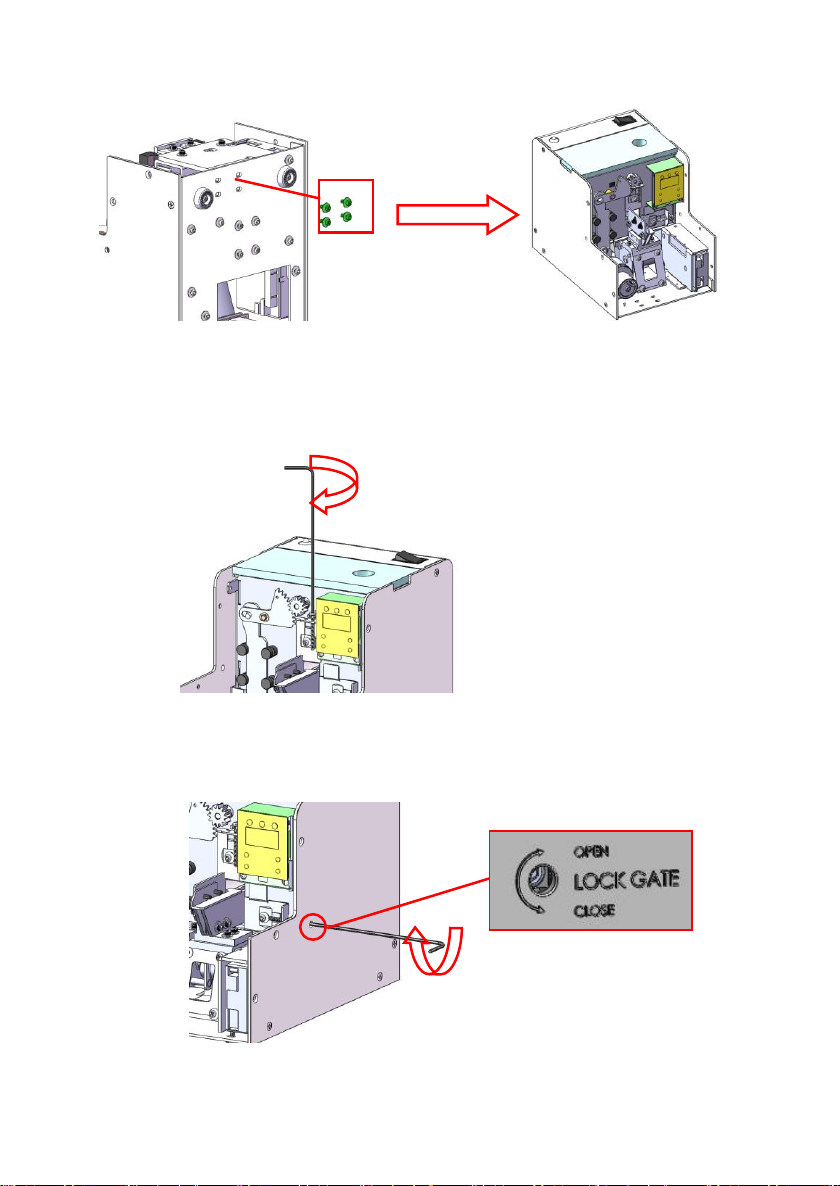

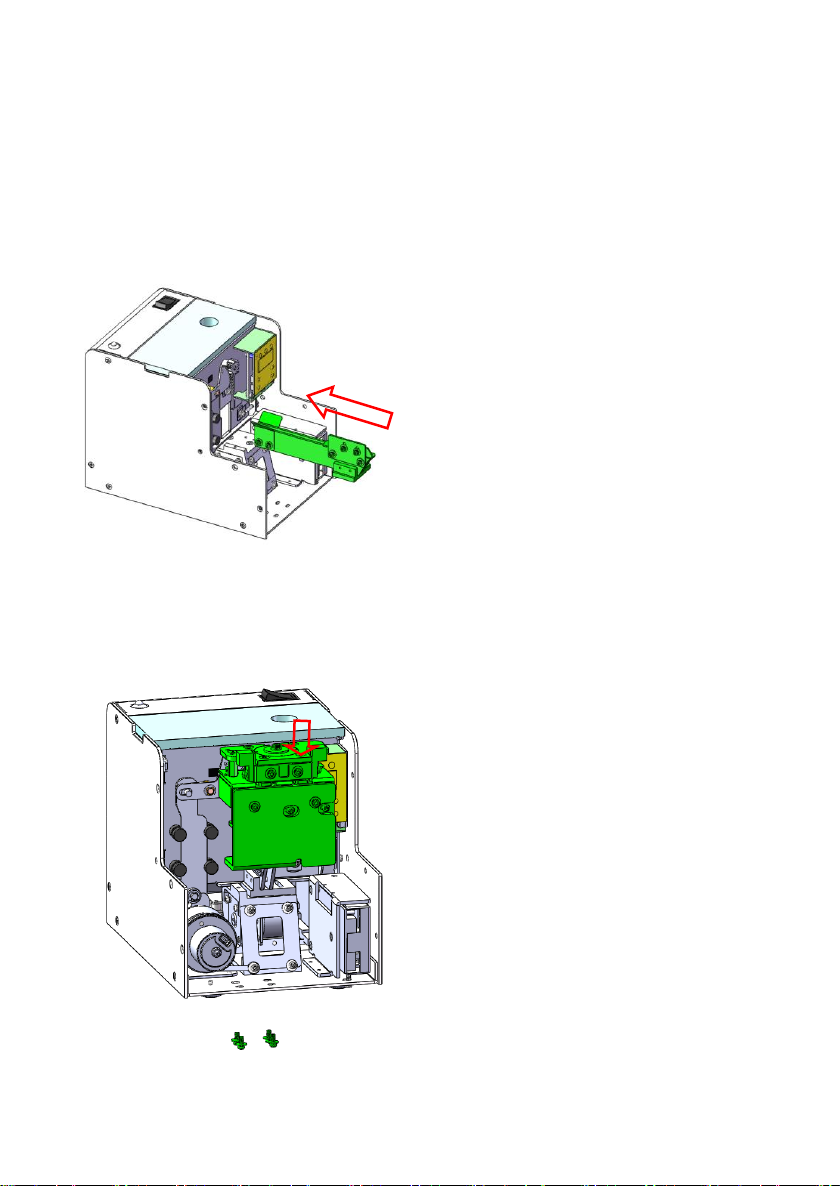

◎Keep the surface of the rail groove clean and free from dust and oil.

Failure to keep the rail groove clean could result in damage to the

machine.

◎The applied screws must be clean without grease or dust, and screw size

is within specified range as machine rail.

◎Handle screws on rails with care, do not use excess force to remove them

or the rails may be damaged.

◎When scooping chamber is turning, do not put fingers or objects other

than screws into the chamber.

◎Do not turn ON the power switch before the rails are set properly for

operation.

◎In case of malfunction during operation, please turn off the power and

unplug the AC adaptor. Contact your supplier at on

Whenever this machine requires service, please contact your supplier for

assistance, or go to our website & e-mail us your contact detail and

requirement, we will respond ASAP.