Delta United Instrument DU-330 Series User manual

P

P

Pr

r

ro

o

og

g

gr

r

ra

a

am

m

mm

m

ma

a

ab

b

bl

l

le

e

e

H

H

Hi

i

i-

-

-P

P

Po

o

ot

t

t

T

T

Te

e

es

s

st

t

te

e

er

r

r

DU–331/332

Operation Manual

** CAUTION - HIGH VOLTAGE **

※This tester generates high voltage up to

5 KV AC (DU-331 & DU-332)

6 KV DC (DU-332 only)

※Any incorrect operation may cause serious

damage and fatal electric shock

※In order to avoid any accident please read the

section 1 “Safety Steps Before Operation”

******* GUARANTEE *******

This tester has been under thorough testing, inspection and quality control before shipments.

Tester’s specification and performance have been under intensive burn-in testing such that

it performs all functions with guarantee specifications as specified. We provide free

warranty of 12 months from date of purchase for defects due to manufacturing poor

workman-ship and the tester is under normal usage. Should tester is malfunction under the

following causes of damage, repair charges will be imposed:

1. Operation under which operator does not follow instructions described in the manual or

damages caused by careless operations.

2. Damages caused by incorrect modifications, settings, or repairing by unauthorized

personals, and

3. Damages caused by human errors, natural disasters and fire.

Should there be any requirements for repair services, operation problems, please contact the

manufacturer or our sales distributors.

INCORRECT & DANGEROUS OPERATION

Do not touch the following spots on which high potential may be imposed when the tester is in

operation mode such that high voltage may be generated. Hazardous or fatal damage maybe

caused by electric shock. Operator must watch out the followings:

* Do not touch voltage output terminals.

* Do not touch wires connected to the output terminals.

* Do not touch device under test (DUT).

* Do not touch any electronic parts connecting to the output terminals.

* Do not touch DUT immediately after the tester has just completed the testing procedure or

output voltage has been just cut off.

*UNPACK CARTON BOX & INSPECTION *

This tester has been under thorough quality inspection both electrical and mechanical. Should

there be any damages or malfunction due to mechanical shock during transportation, please

inform manufacturer or distributor for inspection.

STANDARD ACCESSORIES

Item Accessories P/N Qty Nature

1. AC Power Cord 1 Power cord for AC power

2. AC Power Fuse 1 4.0 A Fast for 120V

3. AC Power Fuse 1 2.0 A Fast for 240V

4. Voltage Test Lead

(Red) 1

Insulated Voltage Test Lead

for HIGH Output Terminal

5. Voltage Test Lead

(Black) 1

Insulated Voltage Test Lead

for LOW Output Terminal

6. Input Voltage Selection

Switch

3P-

2P 1 Selection of Input Voltage

7. Operation Manual 1 English Version

OPTIONAL ACCESSORIES

Item Accessories P/N Qty Nature

1. High Voltage Test Gun 1High Voltage Output with

Remote Control

2. SCAN BOX 1 Scan Box for multi-point test

OPTIONS

Item Descriptions P/N Qty Nature

1. SCAN Interface 1 Interface for Scanner Box

2. RS-232 Interface 1 Interface to computer

3. I R 1 Insulation Resistance

Measurement

INDEX

Page

1. Safety Steps Before Operation 1 - 4

2. Overview 5 - 6

3. Specification 7 - 8

4. Panel Layout 9- 11

Front Panel Layout 9 - 10

Rear Panel Layout 10 - 11

5. Operation Instructions 12 - 25

5.1 Caution - Before Operation 12

5.2 Test Datum Setting Operation 12 -15

5.3 Test Operation Procedure 16 - 17

5.4 “INITIAL” Operation Instruction 17 - 19

5.4.1 INTERFACE 17 - 18

5.4.2 UTILITY 18

5.4.3 INITIAL VALUE 19

5.4.4 CALIBRATION 19

5.5 Step Mode Test Selection 20 - 21

5.6 VI - ADJ. Operation 21

5.7 FREQ Adjustment 22

5.8 OFFSET Function Operation 22

5.9 RECALL / STORE Function 23

5.10 Remote Control (RMT) Operation 24

5.11 Signal Output 25

6. Calibration 26 - 30

6.1 List of equipments required for calibration 26

6.2 Precaution Before Calibration 26

6.3 Calibration Procedure 26

6.4 Calibration Procedure and Method 26 – 31

Section 1

1. Safety Steps Before Operation

This tester can generate up to 5 KV AC (for DU-331) and 6 KV DC as well (for DU-332) at output

terminals. Make sure that the tester is properly used as instructed otherwise there is a danger to

encounter electric shock that can cause fatal accident of any damage.

1.1 Electric Shock

To prevent any electric shock it is recommended to wear plastic glove before operating the

tester.

1.2 Earth

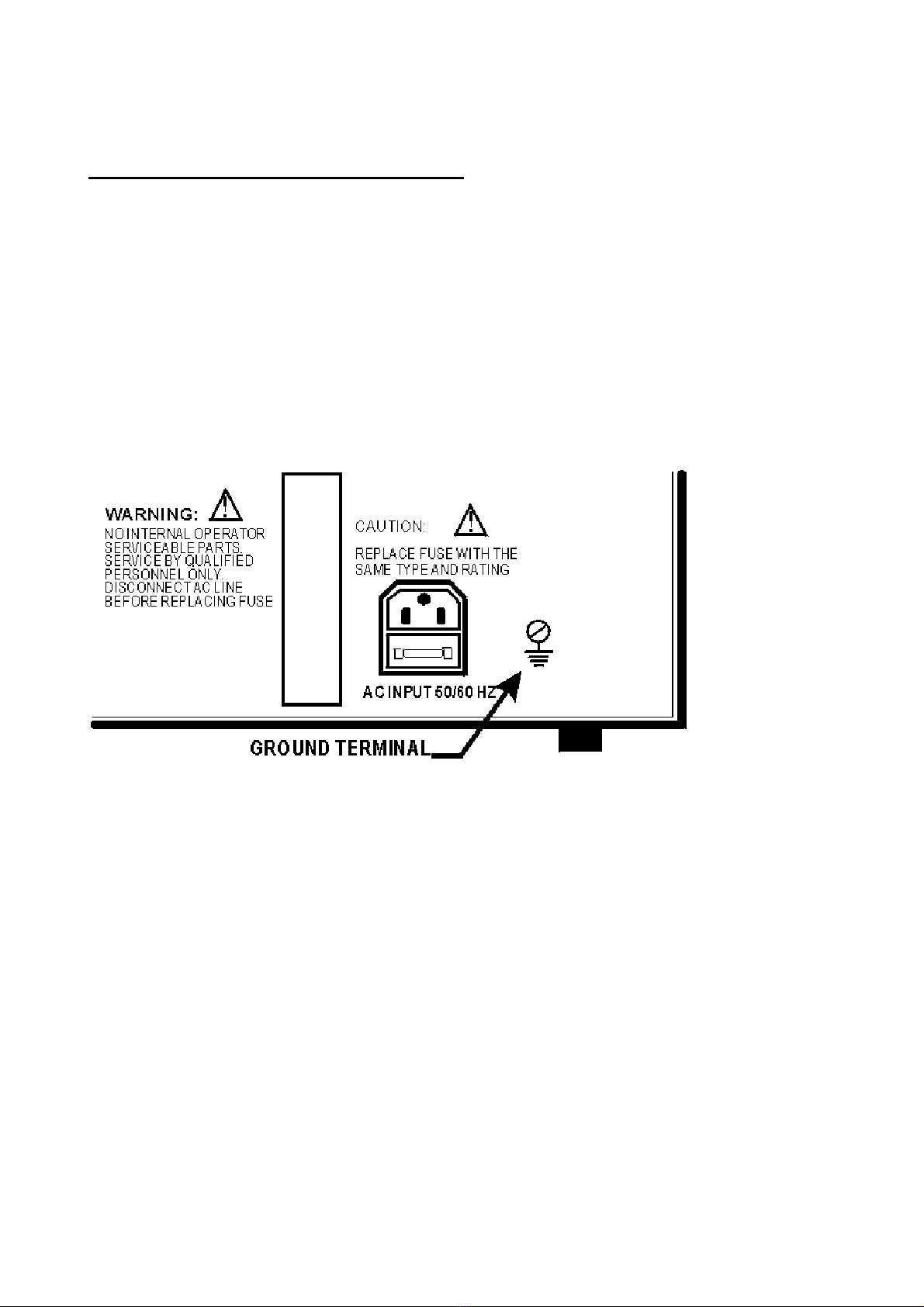

There is a “GROUND TERMINAL” at the rear panel of the tester (Diagram. 1). Make sure this

terminal is properly grounded otherwise electric shock may occur to operator when the tester

is malfunction or high potential may accidentally in contact to the chassis.

Diagram. 1

Page 1

1.3 Connecting Voltage Test Lead (Black) to “LOW” Output Terminal

Always connecting Voltage Test Lead (Black) to “LOW” Output Terminal when the tester is

under operation as shown in (Diag.2). Also always check if the test lead is properly

connected to the “LOW” Output Terminal without loosen or fallen off. When tester is under

operation connect the “LOW” Output Terminal to the device under test through the Voltage

Test Lead (Black). Should the “LOW” Output Terminal is not properly connected, the device

under test may have been charged at high voltage that may cause serious electric shock

accident.

MAKE SURE THIS TERMINAL

IS IN GOOD CONTACT WITH

VOLTAGE TEST LEAD (BLACK)

Diagram 2

1.4 Connecting Voltage Test Lead (Red) to “HIGH” Output Terminal.

When the Voltage Test Lead (Black) has been well connected and secured to the “LOW”

Voltage Output Terminal, operator can connect the Voltage Test Lead (Red) to the “HIGH”

Voltage Terminal according to the following steps:

* Press [RESET] button.

* Assure [OUTPUT HIGH VOLTAGE INDICATOR] LED is “OFF”.

* Short the Voltage Test Lead (Black), which is connected to the “LOW”, output terminal to

the “HIGH” output terminal so to make sure that no voltage exists at the “HIGH” output

terminal.

* Insert and connect the “HIGH” Voltage Test Lead (RED) to the “HIGH” output terminal.

* Lastly connect both the Voltage Test Lead (Black) and (RED) to the DUT “Device under

test” for testing.

1.5 End of Test

When test has been finished either temporary or completely, or the tester is not under

operation, make sure the tester is power OFF.

Page 2

(WARNING)

DO NOT TOUCH VOLTAGE TEST LEAD (RED), “HIGH” OUTPUT

TERMINAL, AND DEVICE UNDER TEST DURING OPERATION.

***** When High Voltage Output is “OFF” *****

1.6 Should there be any necessity to make modification in test lead connection, such that

touching the device under test, voltage output test leads, or “HIGH” voltage output terminal is

a must watch out the followings:

* AC Power “OFF”.

* Short circuit between the “LOW” and “HIGH” voltage output terminals.

1.7 AC Power “ON” / “OFF”.

Beware not to switch on AC Power “ON” immediately after turning off the AC Power of the

tester. Operator should wait for a few second to re-switch on the AC Power.

********** Under Emergency Situation **********

1.8 Immediate Actions

Under emergency situations such as en-counting electric shock, device under test or main

tester is burning, in order not to cause any more and serious damage please follows the

following steps:

* Turn off the AC Power immediately.

* Unplug the AC Power from the main source.

*********** Solution To Problems ***********

1.9 Problems

Situation is very dangerous when the following happens:

* The OUTPUT indication light still blinks when [RESET] switch is activated.

* The OUTPUT indication light still blinks when the output voltage meter indicates no voltage

value.

When the above situations happen, the Voltage Output Terminal may have certain amount

of high voltage. In such cases, operator should turn OFF the AC power, unplug the AC

Power from the main source and stop using the tester. Consult the manufacturer or

distributor, and/or return the tester for repair.

* When [START] switch is activated, output voltage value indicates on the display, but

OUTPUT indicator is “OFF”, it shows that the voltage indication lamp may be malfunction.

Please contact the manufacturer or distributor for repair.

Page 3

1.10. The DU-330 Series Tester has 4 selections on AC Input Voltage Range (Pls. see Table 1).

Check the AC power line and select the correct useable voltage range from the “Voltage

Selection Panel” located at the rear panel. There are two types of fuse provided.

Use correct fuse according to Table 1 as shown.

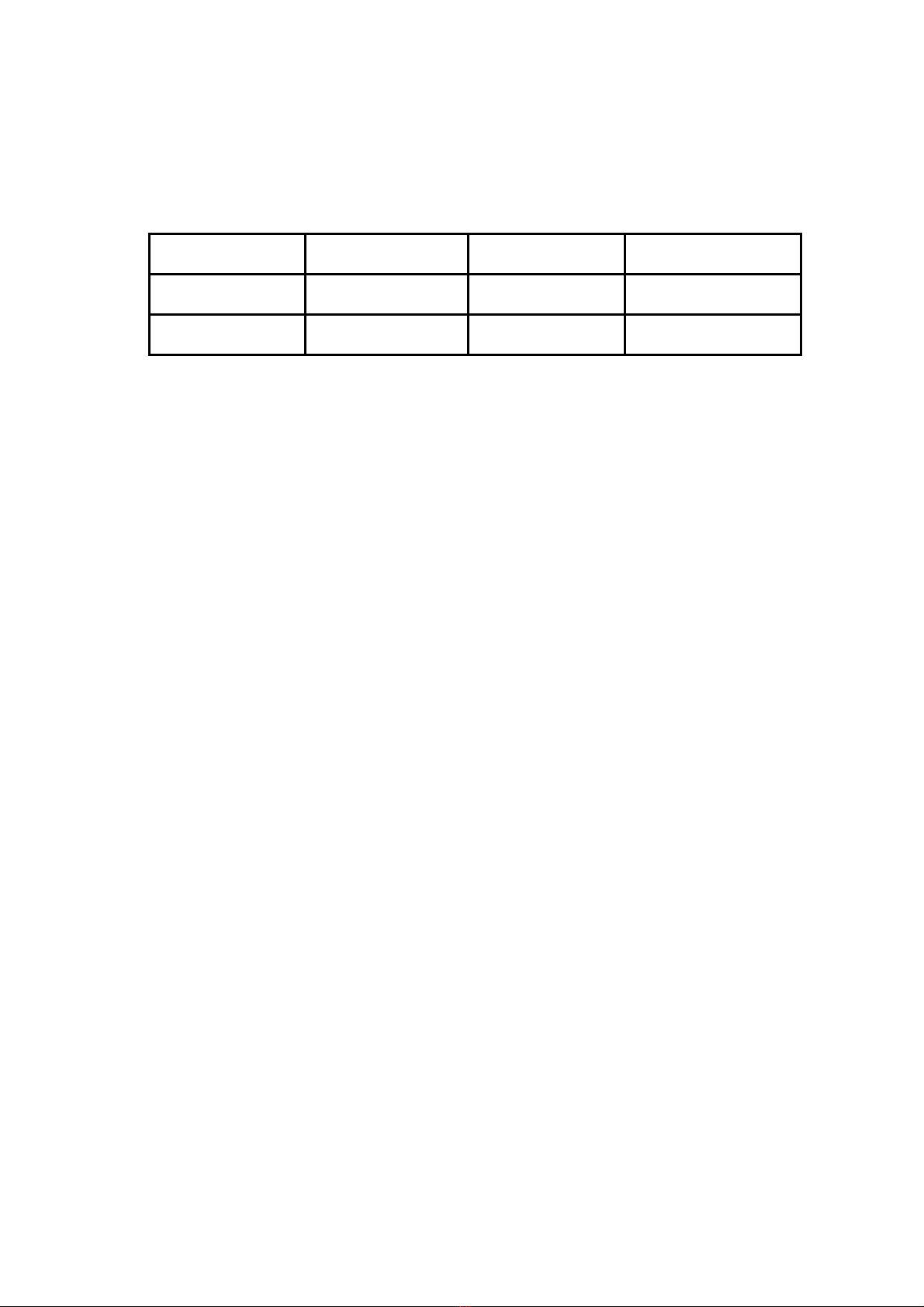

Voltage

Indication Nominal Value Voltage Range Type of Fuse

100

120

100V

115V

90V ~ 110V

104V ~ 125V

4A Fast

4A Fast

220

240

215V

230V

194V ~ 236V

207V ~ 250V

2A Fast

2A Fast

Table 1

Make sure to turn the power switch “OFF” and unplug the input power cord before replacing

the fuses. Open up the fuse storage cabinet located inside the power input socket at the

rear panel of the tester. Remove the burnt fuse and replace it with a new suitable rating

fuse by inserting it into the fuse holder.

(WARNING)

TO AVOID ANY ACCIDENT MAKE SURE TO USE CORRECT SUITABLE

FUSES.

1.11 This tester will perform properly when applied with a clean AC power source. Should the

AC power source fluctuates it is recommended to use an AC Regulator.

1.12. Storage

The tester functions normally under the working environment of 5 °C ∼40 °C, 80% RH., and

is recommended to put into storage at condition of -20 °C ∼70 °C, 80% RH. Do not expose

the tester under sunlight, high temperature, humid, dusty and under vibration environments.

1.13 Warm-up

It is recommended to allow 15 min warm-up time before the tester is put into operation

mode so the tester can perform functionally and accurately according to specified

specifications.

Page 4

2. Overview

2.1 Highlight Features

The DU-330 Series programmable auto withstanding voltage/insulation tester is designed for

automatic, fast, efficient and accurate testing for electrical and electronic products.

Withstanding Voltage Measurement: The DU-331 can generate up to 5KV AC / 15 mA output

whereas the DU-332 can generate up 6KV DC / 7.5 mA as well.

Insulation Measurement: With option IR, the tester can measure insulation resistance ranging

from 1~ 9999 MΩat test voltage which can be set at any value ranging from 100 VDC~ 1000

VDC.

The DU-330 Series has a large LCD display which displays all setting parameters such as

ramp up time, test time, output test voltage, leakage current, high/low leakage current limits,

insulation resistance value, Hi-Lo IR resistance limits, steps, and memory numbers etc. Test

parameters can be recalled from memory that provides efficient and easy way to perform tests

at different parameter setting conditions.

The DU-330 Series equips with comparator for Go/No Go function. Test result is indicated by

both visual “PASS/FAIL” and audio alarm. Signal of test result can be fed externally through its

remote signal output terminals for remote control. With optional RS-232 interface and Scanner

interface one can hook up to an Automatic Handler or a Scanner Box for fast multi-points

testing.

2.2 Product Features

2.2.1 Multi-step Test Mode

DU-330 Series tester provides capability of multi-step test selection. Under single step test

mode, it can be set to perform single Hi-Pot test (AC only for DU-331, and AC or DC for DU-

332), or single IR test with IR Option only. It also can perform multi-step test in specified

sequence at any different setting test steps e.g. (Step 1) AC Hi-Pot Test →(Step 2) Insulation

Resistance Test →(Step 3) DC Hi-Pot Test →any other set of test steps provided test steps

can be recalled from the memory.

2.2.2 Large LED Display

DU-330 Series tester uses a large LCD display. With it’s well display format design, it can

display all setting parameters, test results, step numbers, memory numbers etc.

simultaneously in one display area. This allows the operator to see in the most convenient way

all necessary testing parameters under setting mode, and test results.

2.2.3 Efficient and Convenient Method of Setting

DU-330 Series is designed to provide easy Manu-driven setting method. After one parameter

has been set; it will simply jump to the next setting step automatically. That allows the operator

to start changing or setting the parameters for the next setting step.

Page 5

2.2.4 Saving and Recall Setting Parameter

DU-330 Series has internal memory for storage of setting parameters. It provides 9 groups of

memories and each group has 99 steps of setting parameters. Any of these 9 groups and 99

steps of memory can be recalled for usage or change of parameters. This feature can save

time and effort to set testing parameters whenever is required.

2.2.5 Temporary Saving Memory

Under “SET” mode DU-330 Series tester will store all settings or changes in parameters to

temporary memory. Same setting datum or parameters before tester is power down will be

resumed automatically when power is up again.

2.2.6 Hi-Lo Measure Value Limit Setting and Comparison Testing Function

DU-330 Series provides internal Hi-Lo measure value limits setting and comparison testing

function (both on Hi-Pot test and IR test). This particular function is designed to compare the

tested value of the device under test with both the High and Low limit values. With this function

one can detect if there is any bad contact or test leads that have been accidentally drop off

causing a miss-leading test results, and distinguish good or bad DUT automatically.

2.2.7 Remote Control

DU-330 Series testers provide two “TEST” and “RESET” control signal inputs used to connect

externally to a foot switch or a control box that can control and activate the output signal.

2.2.8 Test Result Signal Output

Test result status such as “PASS”, “FAIL” and “TEST” can be obtained through RELAY

contacts located at the rear panel of the tester for external control.

2.2.9 Key Lock

Key lock function is provided. Under test condition, if Key Lock function is activated, all

function and data entry keys have been locked except the [RESET]and [∆][∇] keys. This can

prevent, under test condition, any sudden changes of test condition such as the output voltage

and leakage current that may cause dangerous accident.

2.2.10 Change of Voltage Rising Time

DU-330 Series testers provide a [RAMP]function which is used to change the time required

for the output voltage to ramp from zero to the preset voltage level.

2.2.11 OFFSET Function

DU-330 Series testers provide an [OFFSET]function which can sample any residual leakage

current occur between the two output terminals under any test mode. This leakage current will

be stored into the memory and its value will be offset or deducted in every test automatically

so to provide a better accurate test result.

2.2.12 Data Hold Function

Under test mode, tested value will be held and displayed on the LED display temporary when

preset test time has reached.

Page 6

3. SPECIFICTIONS.

Model DU-331 DU-332 DU-333

Scan Test 8 ports ± phase

Withstanding Voltage Test (DU331 AC, DU332, 333 AC/DC)

Output Voltage AC: 0~5000V / DC: 0~6000V. Digital setting (4 digits), 10V/ step,

adjustable with^/ ﹀keys.

Voltage Regulation ≤1%+5V

Waveform & Frequency Sine Wave 50Hz/60Hz selectable

Voltmeter Accuracy 4 digits, ±1% of reading +5 digits

Output Current AC: 0.01mA~15.00mA, DC: 0.01mA~7.5mA

Current Meter Accuracy 4 digits, ±(1.5% of reading +5 digits)

Arc Detection Function 0.5mA~15mA(DC0.5mA~7.5mA) 0.01mA/Steps. (0.0mA is OFF)

Test Time 0.5~999.9 Sec (±20mS), 0.1sec/Steps. (0.0 sec is OFF)

Ramp up Time 0.1~999.9 Sec (±20mS), 0.1sec/Steps. (0.0 sec is OFF)

PASS/FAIL Judgment

Windows comparator system

HI-Limit: 0.10~15.00mA, Digital setting (4digits), 0.01mA/Steps.

LO-Limit: 0.05~7.5.00mA, Digital setting (4digits), 0.01mA/Steps.

Arc Detection 0.5mA~15mA(DC 0.5mA ~ 7.5mA) 0.01mA/Steps. (LO-

Limit & Arc Detection setting 0.0mA is OFF)

Judgment Accuracy ±(1% of setting+50uA)

Insulation Resistance Test (Option of DU332/333 only)

Measuring Voltage DC: 100~1000V, Digital setting, 10V/steps.

Voltmeter Accuracy 4 digits, ±(1% of setting +5 digits)

Measuring Range 1~9999MΩ

Measuring Accuracy

≥500V: 1~1000MΩ: ±5% of reading

≥500V: 1001~9999MΩ: ±15% of reading

< 500V: 1~ 200MΩ: ±10% of reading,

< 500V: 201~1000Ω: ±15% of reading

Test Time 0.5~999.9 Sec (±20mS), 0.1sec/Steps. 0.0sec is off

Judgment Waiting time 0.1-999.9 Sec (±20mS), 0.1sec/Steps

PASS/FAIL Judgment

Windows comparator system.

Both HI and LO limit values can be set with the measuring range.

Note: When the lower limit value is greater than 2000 MΩ, a Judgment

wait time of 1.0second or more is necessary.

Judgment Accuracy Same as measurement accuracy.

Test Time 0.5 to 999.9 sec. (±20ms), 0.1sec/Steps. (0.0 sec is OFF.)

Judgment Waiting Time 0.1 to 999.9 sec. (±20ms), 0.1sec/Steps

Test Modes

Auto Test Up to 9 test steps with different test parameters.

Single Test Execution withstanding voltage test or insulation resistance test.

Auto Scanning Test

Link with Model DU330 Scan Box, it performs auto test for objects

having two or more points (Optional Scanner Interface and Box are

required)

Page 7

Source Protection Function

Fast Output Cut off < 0.4ms

Fast Discharge < 0.2s

Panel Operation Lock YES

Power On Data Rally YES

Reset Protection Key YES

Other Function

Display 240x64 Dot Graphic LCM, CFL back light.

Signal Output PASS, FAIL, and TEST with relay contact signal.

Data Hold YES

Judgment Result Display PASS/ FAIL and Alarm.

Memory Storage 01 to 99, 99 groups of memory, each memory include 9 steps.

Remote Control 9 Pins D-type connector, TEST/RESET/RMT ENABLE.

Interlock Function The test voltage cannot be generated unless the interlock input terminal

is short-circuited

Ambient Temperature and Relative Humidity

Specifications range 5 to 35℃(41 to 95℉), 20 to 80﹪RH.

Operable 0 to 40℃(32 to 104℉), 20 to 80﹪RH.

Storage range 20 to 70℃(4 to 158℉), ≦80﹪RH.

Power Requirements

Line Voltage A: 90~110V, B: 104~125V,

C: 194~236V, D: 207~250V.

Frequency 50 or 60 Hz

Power Consumption When no-load: < 70VA

When with Rated Load: >300VA

Insulation Resistance ≧30MΩ, with 500V DC.

Withstanding Voltage 1000V AC, for 1 minute.

Dimension

DU-331/332 365W x 105H x 350D mm.

DU-333 365W x 160H x 350D mm.

Weight

DU-331: Approx.10kg. DU-331: Approx.11kg. DU-331: Approx.15kg.

Accessories

Operation Manual, Power cord set, 3P-2P AC adapter plug,

High voltage test lead wire (1 meter long), 2A fast blow Fuse (in fuse holder), Certificate of

Calibration

Options

Accessory High Voltage Test Bat

Function

Insulation test function (DU 332/333 only)

Analysis Graph: Graph of Measuring amount,

GO/NG counts, Date, Time… for Analysis

Interface RS-232 interface, GP-IB interface, Printer interface,

Scan interface for Scan box DU-330S/380S

Page 8

4. Panel Layout

4.1 FRONT PANEL LAYOUTS.

1. POWER ON/OFF SWITCH

This is an On/Off switch for AC power source. Please refer to Section 1 “Safety Steps Before

Operation” for detail.

2. PROG. /EXIT

This allows tester-entering program set up mode. When this button is pressed LED display

screen will show all set up parameters. A “STEP” sign is shown in reverse video that enables

the tester entering into program set up mode. Operator can key in new or changes of testing

parameters. Also tester can exit programming set up mode by pressing this key once again.

3. ∆∇

Up and Down key. These two keys are being used to change the value of corresponding

highlighted parameters during set up mode. They perform differently under different mode of

operation.

4. ENTEER

This key is used to confirm data set or changed of parameters in set up mode.

5. RECALL/BACK

This key can recall steps and program from the memory or to return to previous set up stage.

Under “RESET” state, pressing this key it will enter into memory management mode under

which operator can call up parameters from the memory. If under set up mode, pressing this

it can return to previous set up parameter.

6. LCD DISPLAY

This is a 240 x 64 LCD display, which enables displaying all setting parameters, test and

comparison results in a comprehensive way.

7. FREQ.

This is to set the test frequency under STANDBY MODE selectively between 50Hz and 60Hz.

8. INITIAL

This is a System Setup Initializing Key. When this key is pressed the System Setup page is

displayed. Under this mode, one can change the interface, all special set up parameters,

default values, and calibration values.

9. STEP MODE

This key enables to set test steps mode and test sequence used.

10. V.ADJ

Under ‘TEST’ mode when pressing this key the output voltage value can be adjusted by

pressing the ∆up and ∇down keys.

Page 9

11. OFFSET

This switch enables the tester to offset any residual leakage current occurs on test leads or

test fixture in used.

12. TEST

When this switch is activated the tester will enter into test mode such that the output

terminals will experience high voltage. All measurement and comparison functions are in

operation.

13. RESET

When activating this switch the tester returns to STANDBY mode. Any output voltage at

output terminals will be cut-off. All comparison test results will be erased too.

14. OUTPUT LED

When this LED blinks it indicates the tester is under test mode. High voltage potential exists

across the output terminals, which should not be touched at all time.

15. OUTPUT TERMINAL

H.V. TERMINAL: A high voltage to a maximum of 6KV DC may be existed at this terminal.

Do not touch it at all time. LOW TERMINAL: This is a low voltage terminal and usually is

grounded with the case.

4.2 REAR PANEL LAYOUTS

1. AC INPUT

This AC power input socket is equipped with a fuse holder containing a fuse suitable for

correct AC voltage range indicated in the AC voltage selection switch.

2. STATUS SIGNAL OUTPUT

There are 4 test result conditional ON/OFF terminals as listed

PASS -- These terminals are in NO condition and are short-circuited when the DUT has been

checked and determined to be good. The short circuit specification is 115VAC at <

0.3A or 24V DC at <1A. Contact duration will be app. 0.5 sec.

FAIL ---- These terminals are always open and short circuited when the DUT fails to meet

with test parameters. The short circuit specification is same as ‘PASS’ mentioned

above. The short circuit state stays until RESET switch is activated.

TEST -- These terminals will be short circuited when tester is under test mode. This allows

control of external signals. The contact specification is same as above, and the

contact state will change until RESET switch is activated.

INTERNAL -- This is a double safety-locking device. TEST can only be operated when LOCK and

only when these terminals are short circuit. The tester cannot activate TEST when

these terminals are open.

Page 10

3. VOLTAGE SELECTOR

These are input voltage range selection switches, which enable the tester for global usage

are 4 different voltage ranges for selection as listed:

a. 90 ∼110 V AC

b. 104 ∼125 V AC

c. 194 ∼236 V AC

d. 207 ∼250 V AC

When correct voltage is selected make sure corresponding fuse used is correct before

turning ON the AC power.

4. FAN

This DC motor fan is used to circulate the air inside in order to prevent the components from

being overheated.

5. GND TERMINAL

This is the ground terminal. Electric shock may occur to operator if this has not been properly

connected to the ground.

6. REMOTE CONNECTOR

A remote control socket is installed for receiving remote control signals for “TEST”, “RESET”

and “RMT-ENABLE” functions. Operation is described in detail in “REMOTE” section of

CHAPTER 5.

7. RS-232 CONNECTOR (OPTION)

A standard RS-232 interface is offered as an option. With the interface the tester can be

communicated with PC for remote control operation.

8. SCAN CONNECTOR (OPTION)

This connector can link up a built-in optional “SCAN INTERFACE CARD” to an optional

scanner, which performs tests for multi-points.

Page 11

5. Operation Instruction

5.1 CAUTIONS - BEFORE OPERATION

1. Make sure the AC power line supply matching the selected voltage range before turning on

the AC power switch.

2. The tester has self-calibration function which performs right after the power switch is “ON”

Should there be any extra-ordinary situation happened turn off the in power switch and un-

plug the AC power source.

5.2 Test Datum Setting Operation

5.2.1 Range of Datum Setting

All datum can be set by pressing the front panel switches and is shown clearly on the

LCD display. Range of datum listed as follow:

1. Test Steps: 1 ∼9

2. Test Mode: AC / DC / IR

3. Hi-Pot Test: 100 ∼5000 VAC (6000 VDC)

4. Insulation Test Voltage: 100 ∼1000 VDC

5. Leakage Current High Limit : 0.10 ∼15.00 AC mA (7.50 DC mA)

6. Leakage Current Lo Limit : 0.05 ∼½ of High Limit or 0.00 mA (OFF)

7. Insulation Resistant High Limit : 0 ∼9999 MΩ(0 MΩ= OFF)

8. Insulation Resistant Lo Limit : 1 ∼9999 MΩ( must be lower than Hi Limit)

9. Test Time : 0.5 ∼99.9 Sec.

10. Ramp up Time : 0.0 ∼99.9 Sec.or 0.0 Sec. (OFF)

11. ARC Test Current : 0.50 ∼15.00 mA (DC 7.50mA) or 0.00 mA

(OFF)

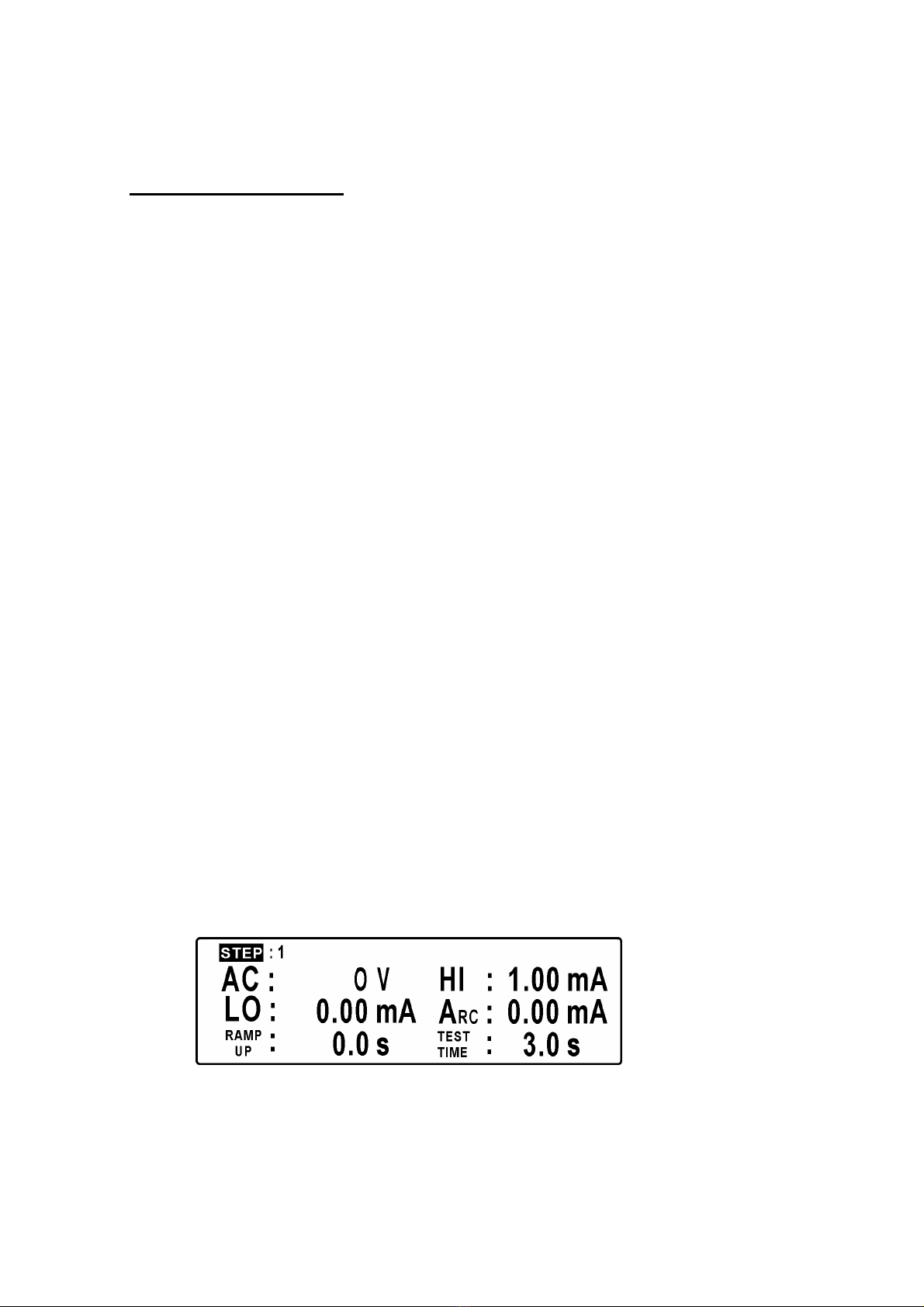

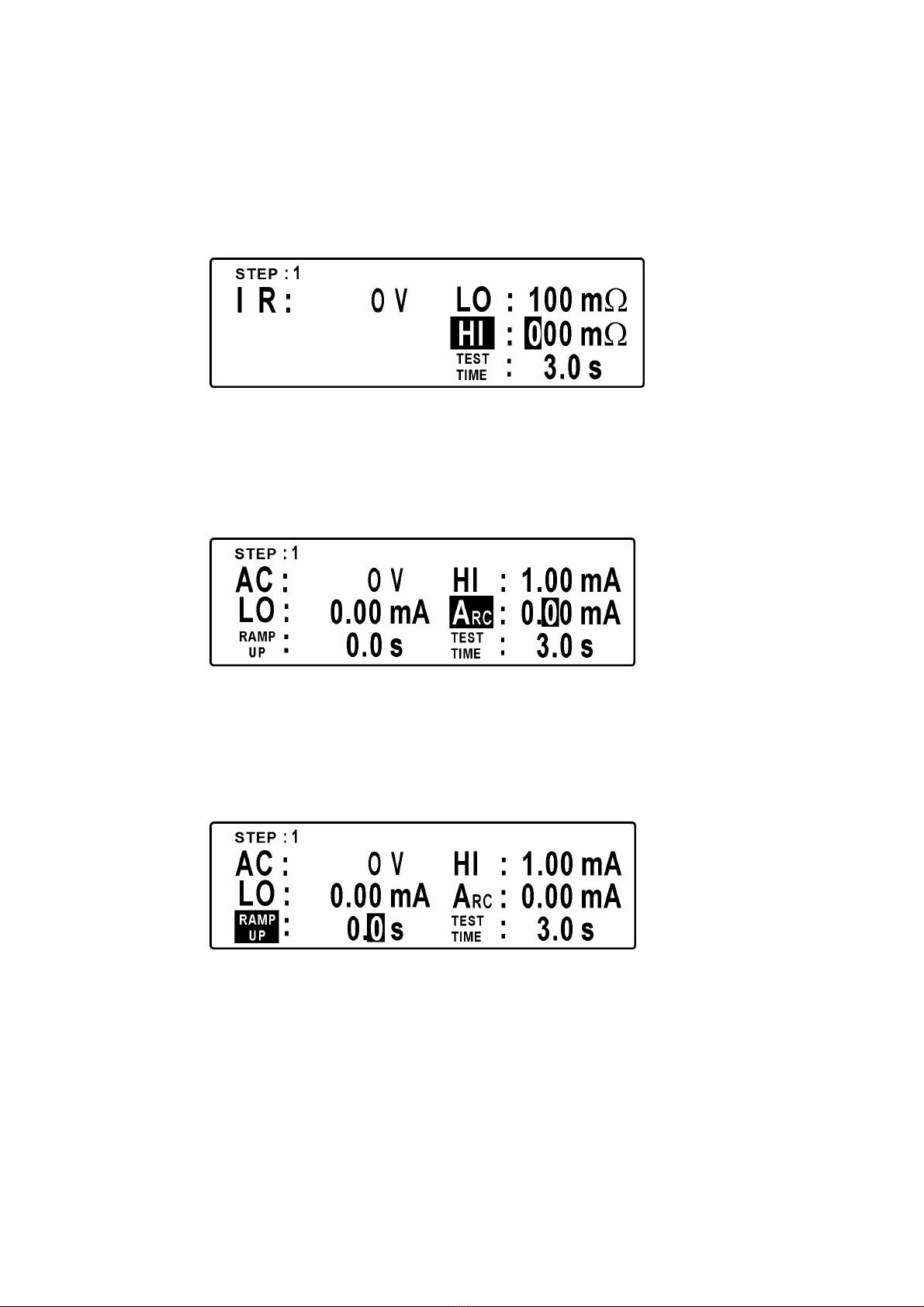

5.2.2 Parameter Setting Procedure

1. Step Setting: 1 to 9

A program page as follow is displayed when [PROG. /EXIT] key is pressed and the

word “STEP” in reverse video appears immediately. Step number 1 to 9 can be

assigned by pressing ∆or ∇. Set data is memorized by pressing [ENTER], and the

cursor automatically jumps to next setting parameter.

Page 12

2. Test Mode Set Up: AC / DC / IR

Test mode can be assigned by pressing ∆or ∇. Setting can be confirmed by

pressing [ENTER] and the cursor automatically jumps to next setting parameter.

3. Leakage Current Hi Limit: 0.10 ∼15.00 mA (DC 7.50mA)

Value of current can be set by pressing the ∆or ∇key and stored into memory after

pressing the [ENTER] and the cursor jumps to next setting parameter.

If test mode has been selected as IR, the set up page will be shown as follows. The

reverse video cursor is at Insulation Resistance Lo Limit position. Its value can also

be adjusted by pressing the ∆or ∇key. Set value is also stored into the memory

and the cursor goes to the setting parameter in the next page after pressing

[ENTER].

4. Leakage Current Lo Limit: 0.05 mA ∼½ of the High Limit

The reverse video cursor is now at the Lo Limit position. The current value can be

adjusted as above and can also be set to 0.00mA. This means the low limit

comparison function is not used. The adjusted value is completed and confirmed by

pressing the [ENTER] and the cursor jumps to the next page.

Page 13

If test mode has been selected as IR, the cursor is highlighted at the position of the

value of Insulation Resistance for High Limit. Press the ∆or ∇key to change the

value and confirmed by pressing [ENTER], thus position of the cursor will jump to

next page.

5. ARC Setting: 0.50 ∼15 mA AC (0.50 ∼5.00 mA DC) or (OFF)

The cursor is now in the position of ARC current limit. The value can be

adjusted and set by pressing ∆or ∇key. If the ARC current limit function is

not used enter value of 0.00 mA and press [ENTER]. The cursor will jump to

the next page.

6. Ramp-Up Time Setting: 0.00 ∼99.9 Sec or 0 (OFF)

Ramp-up time is the time required that the output voltage reached to the set

value which can be adjusted or set by pressing the ∆or ∇key. If ramp-up

time control function is not required set the value to 0.00S and press [ENTER]

to store the value, exit and jump to the next page.

Page 14

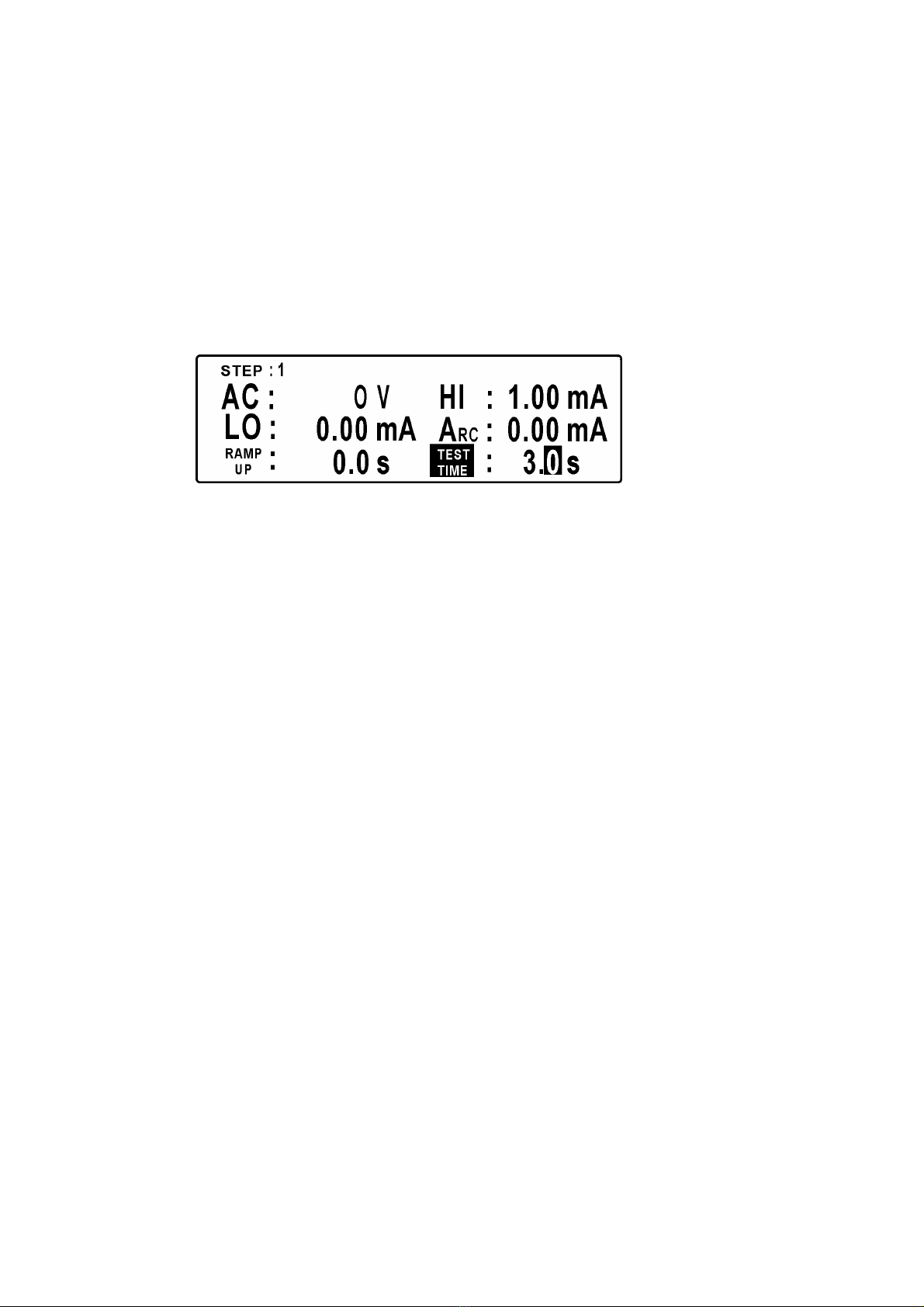

7. Test Time Setting: 0.00 ∼99.9 Sec. or 0.00 Sec. for continuous test

“Test Time” is high-lighted by the reverse video cursor. The assigned length

of test time can be changed by pressing the ∆or ∇key. If 0.00 Sec.is set, the

test will perform continuously until [RESET] is key in. When setting is

completed confirmation is assured by pressing [ENTER]. New setting is

stored into the memory, and setting returns to original ‘Step Setting’ page. To

exit the program press the [PRO/EXIT] key and the reverse video cursor

disappears.

Page 15

This manual suits for next models

3

Table of contents

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started