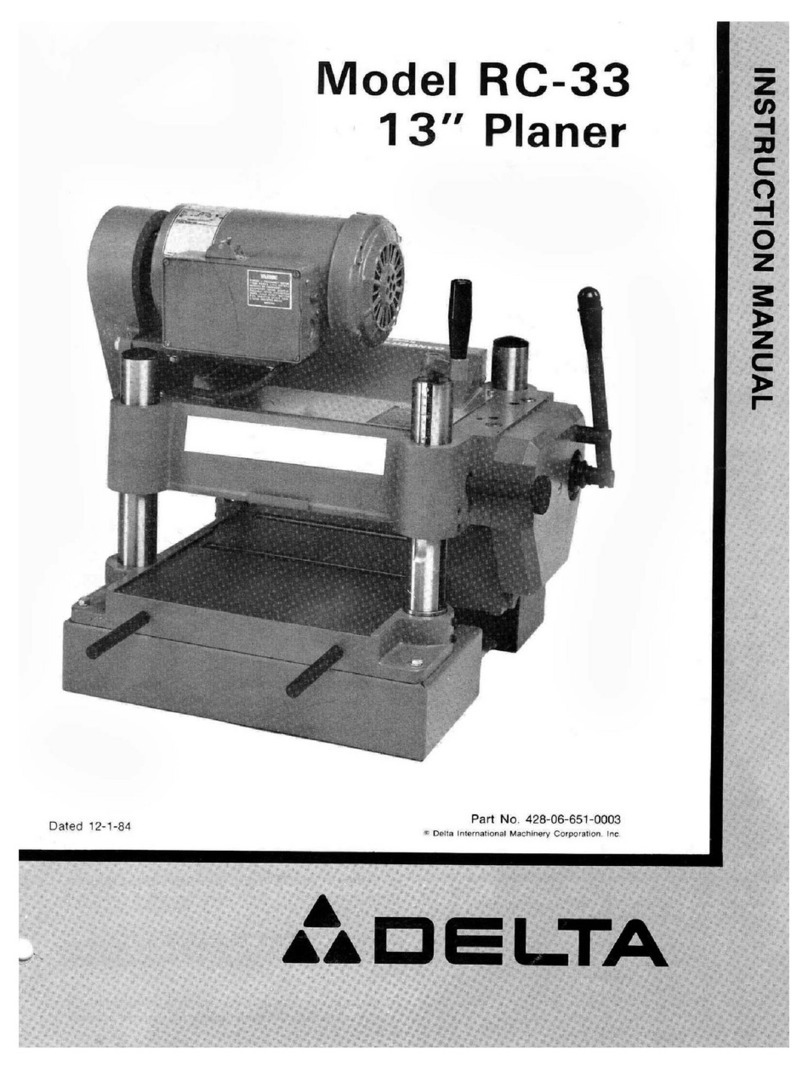

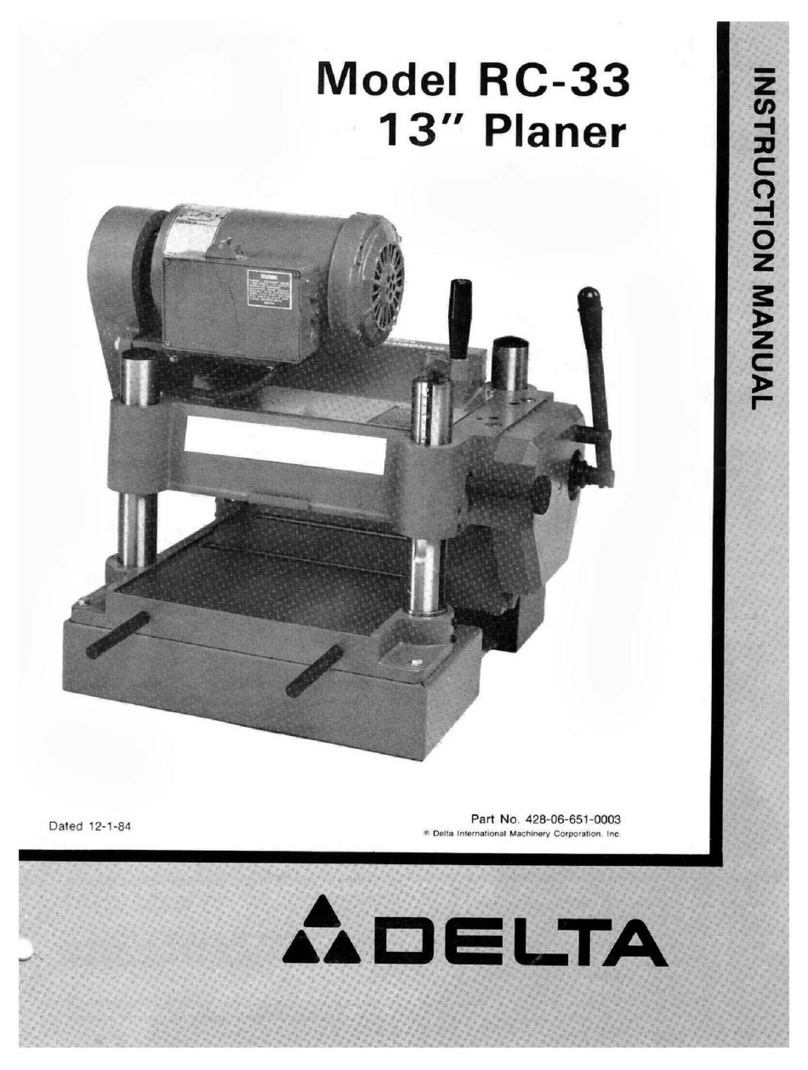

Delta RC-33 User manual

Other Delta Planer manuals

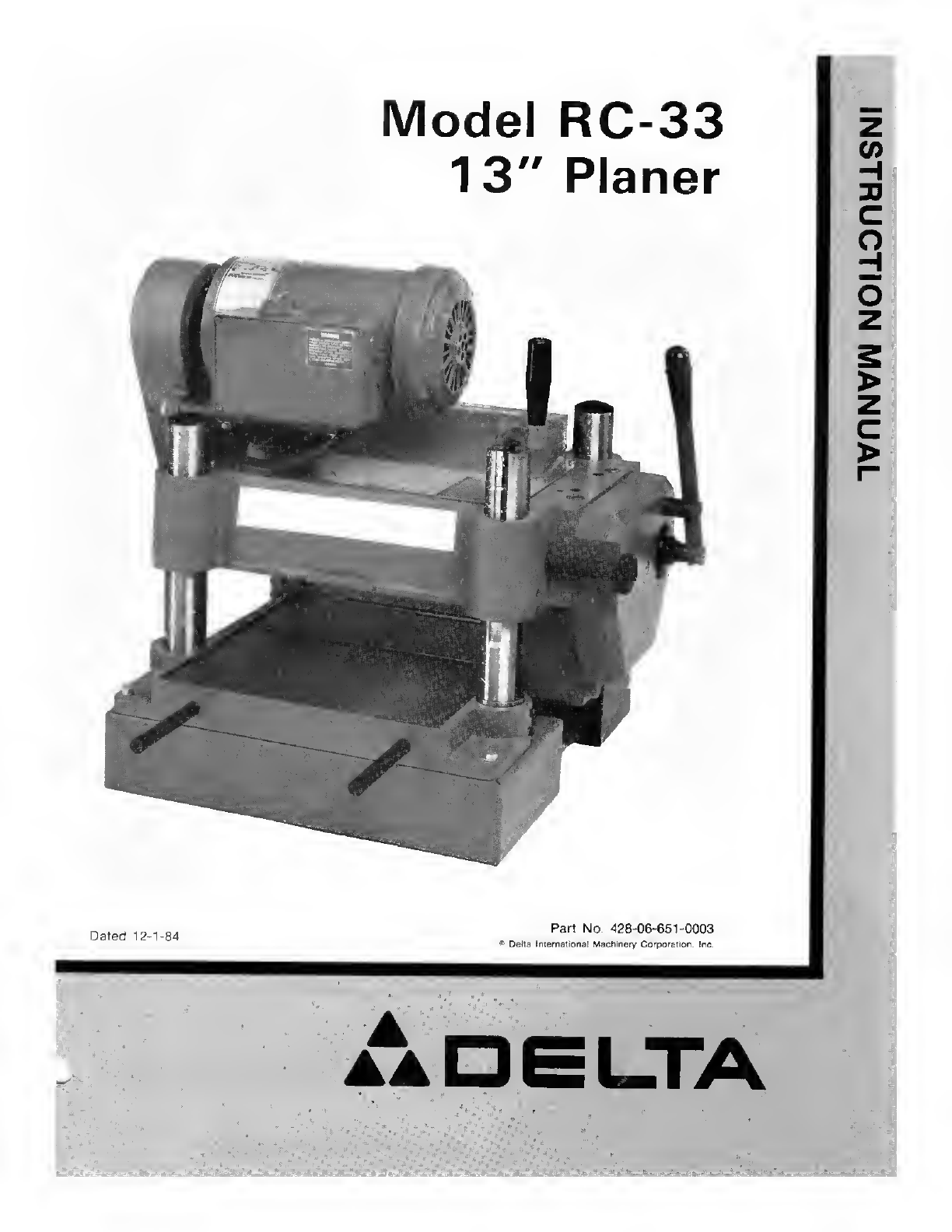

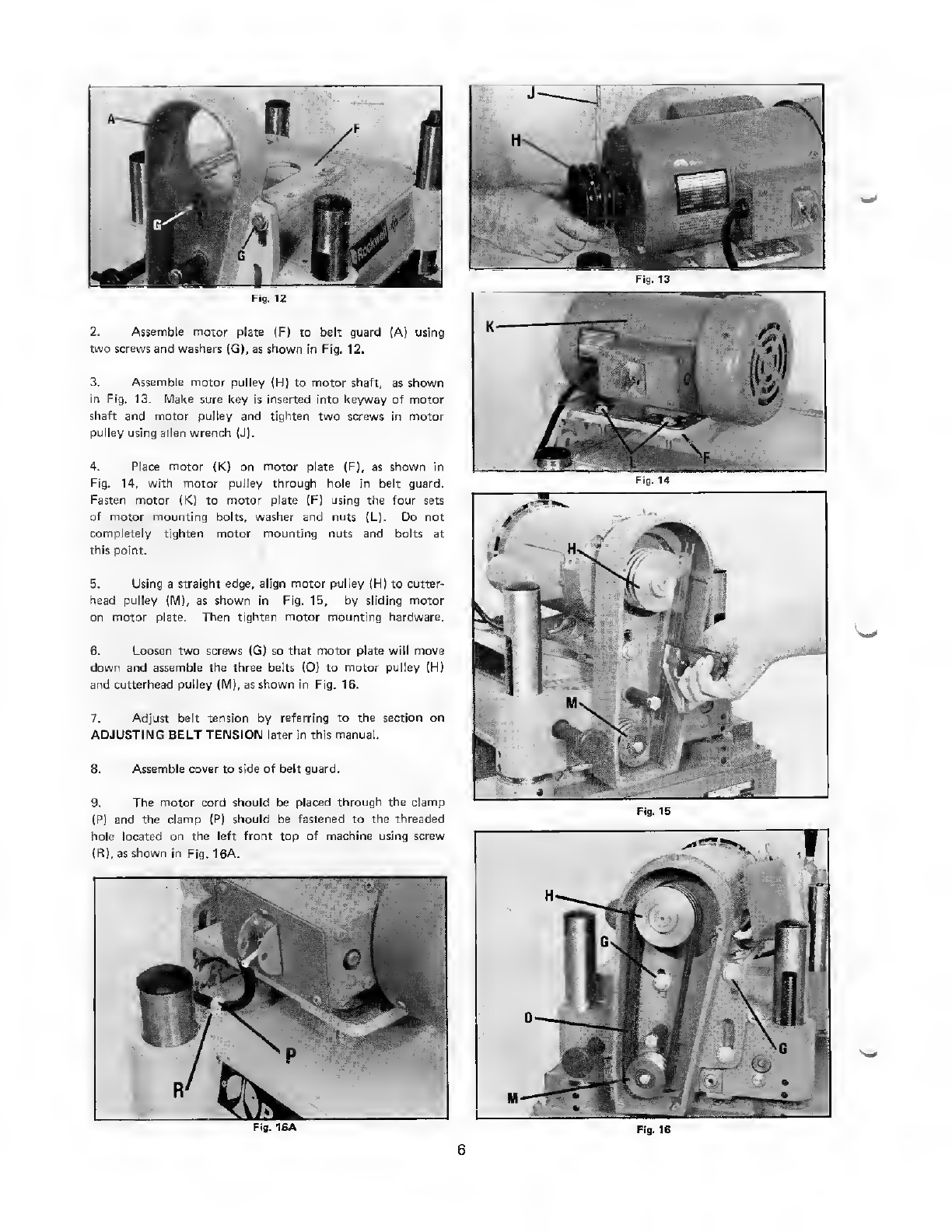

Delta

Delta ShopMaster TP300 User manual

Delta

Delta TP305 User manual

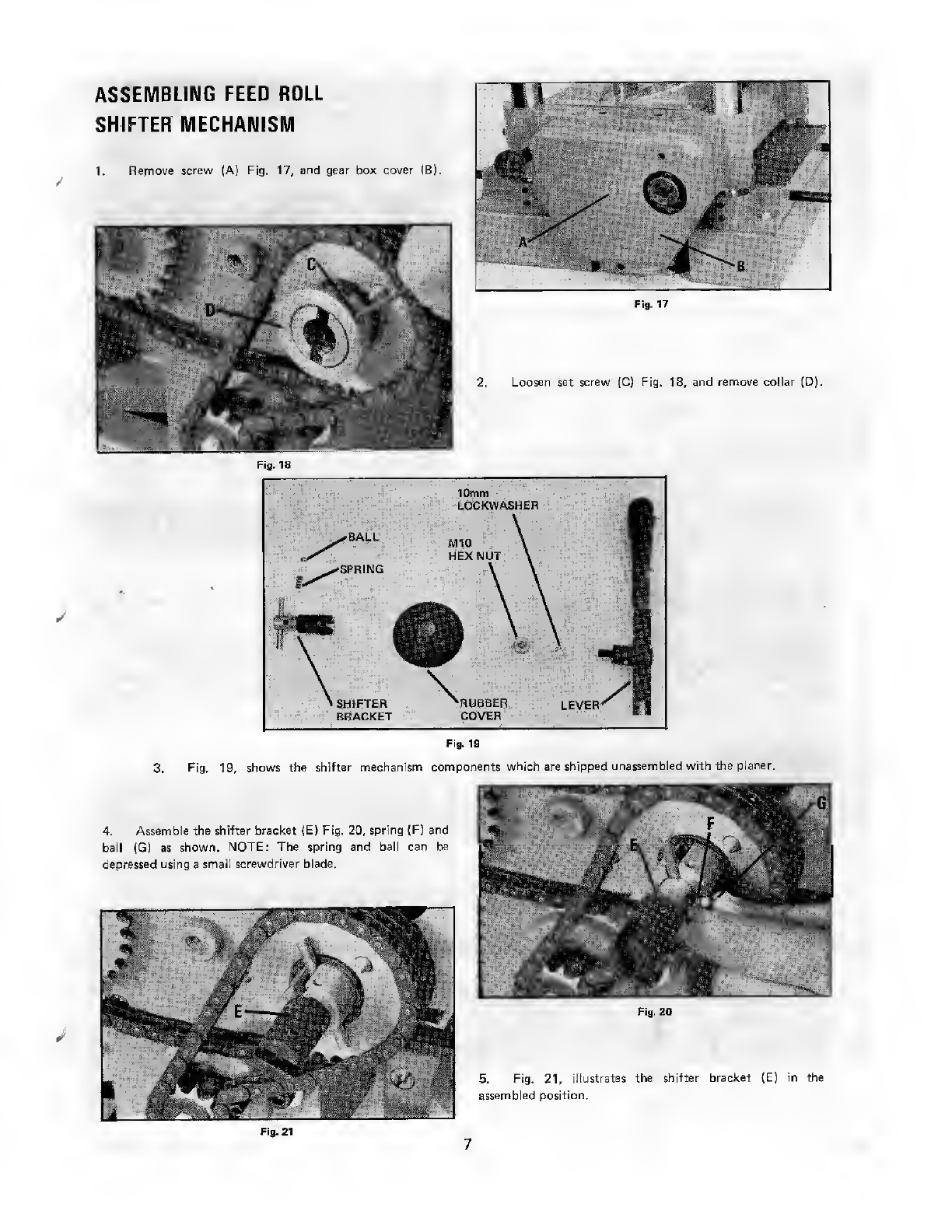

Delta

Delta 22-790X User manual

Delta

Delta 22-785 User manual

Delta

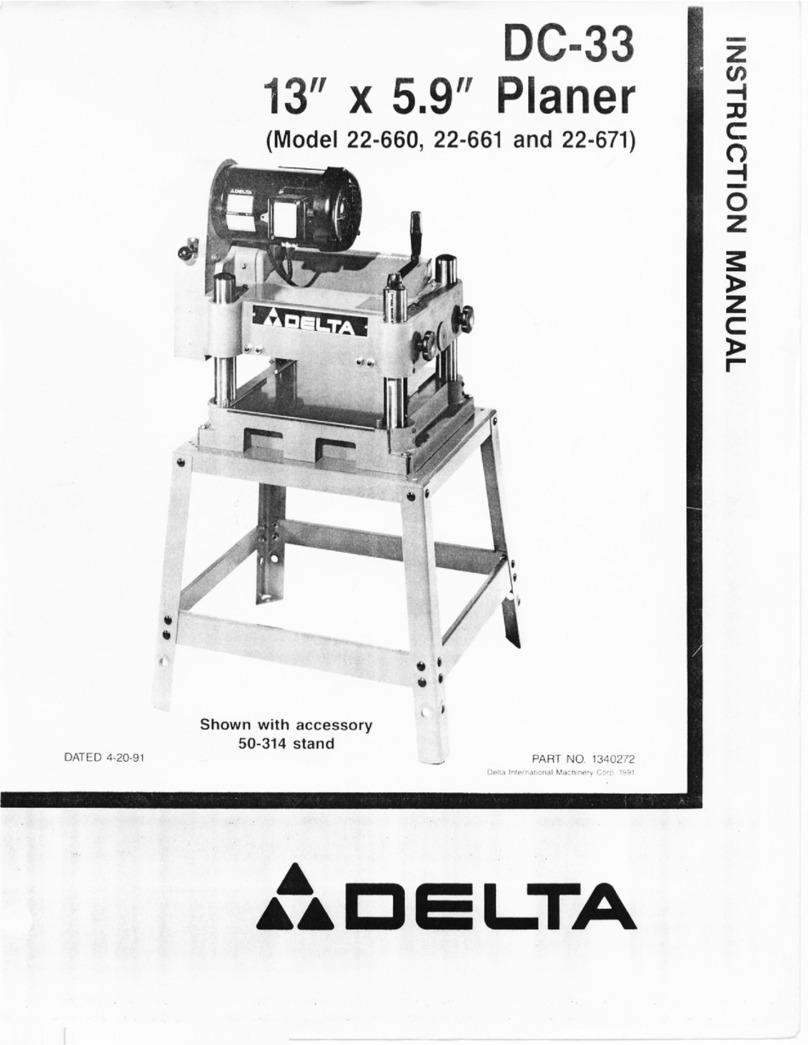

Delta 22-660 User manual

Delta

Delta ShopMaster TP400LS User manual

Delta

Delta RC-33 User manual

Delta

Delta 22-560 User manual

Delta

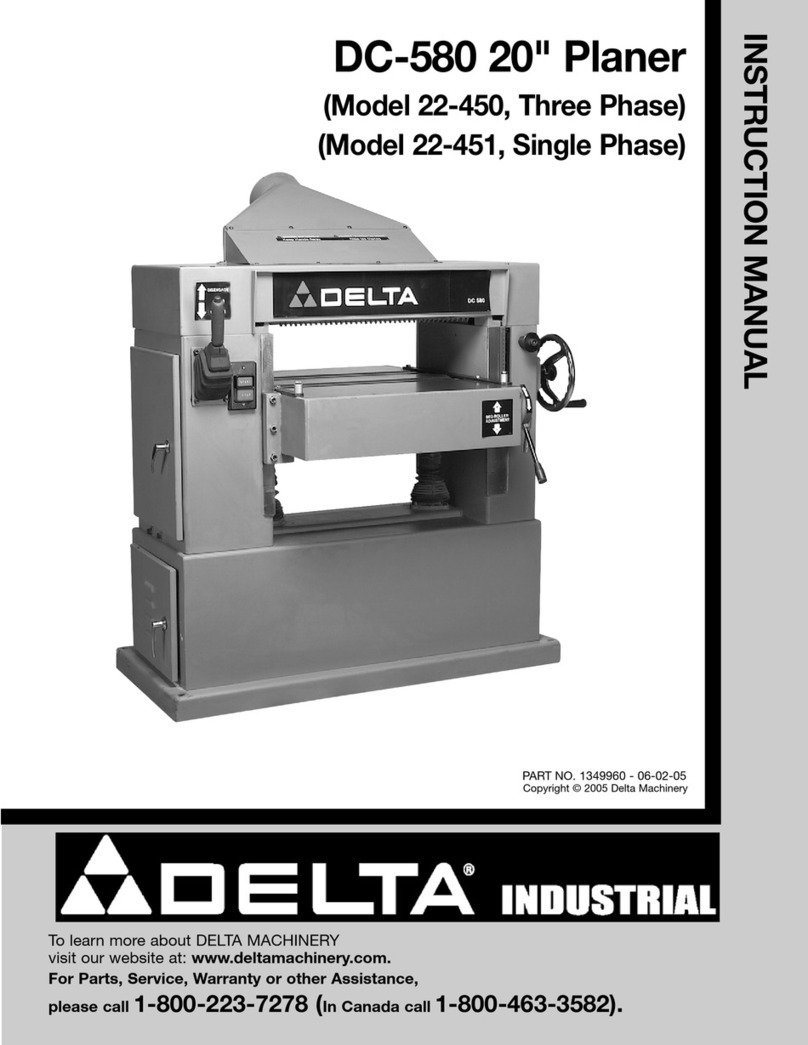

Delta DC-580 20" PLANER 22-450 User manual

Delta

Delta 22-555 User manual

Delta

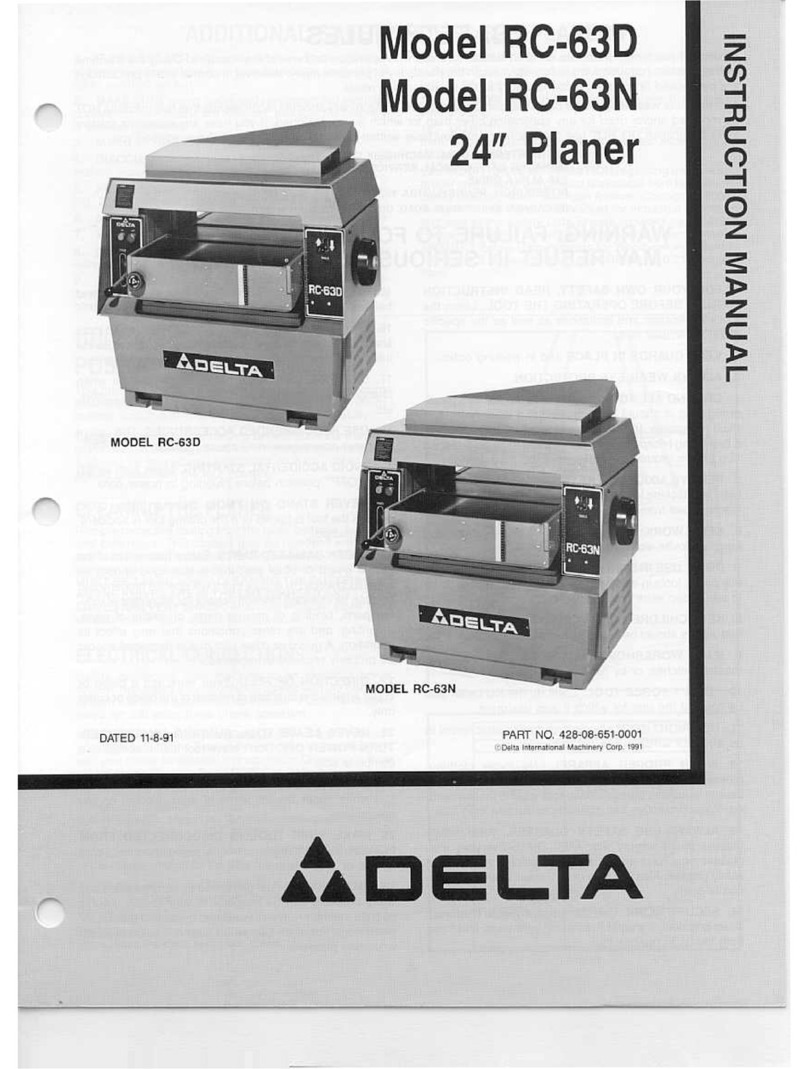

Delta RC-63D User manual

Delta

Delta RC-33 User manual

Delta

Delta 22-470 User manual

Delta

Delta 22-540 User manual

Delta

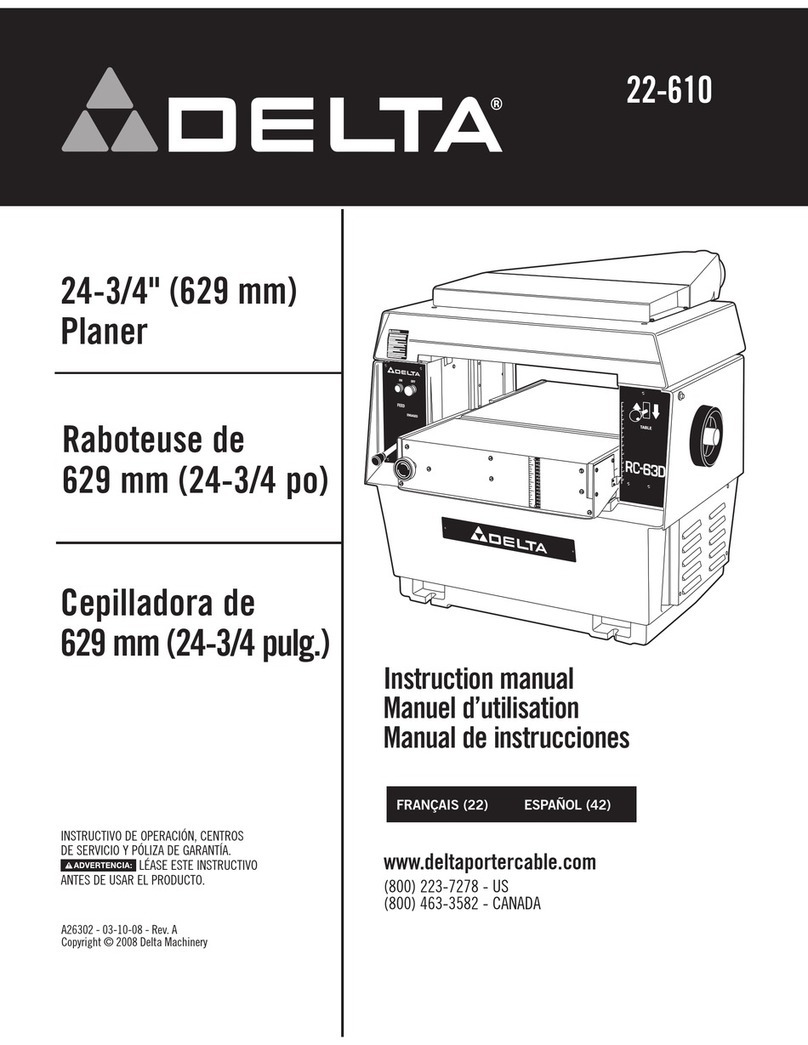

Delta 22-610 User manual

Delta

Delta RC-51 User manual

Delta

Delta 13" PORTABLE PLANER 22-590 User manual

Delta

Delta 22-560 User manual

Delta

Delta Milwaukee PM-1738 Manual

Delta

Delta 18657 User manual

Popular Planer manuals by other brands

Felisatti

Felisatti PF180/1500 operating instructions

DeWalt

DeWalt DW 1150 Operation, adjustmants, maintenance, spare parts

Triton

Triton TRP UL Operating and safety instructions

Melbourne

Melbourne MTC-49407 owner's manual

VARO

VARO POWERplus POW1520 manual

Powermatic

Powermatic 209 Operating instructions and parts manual