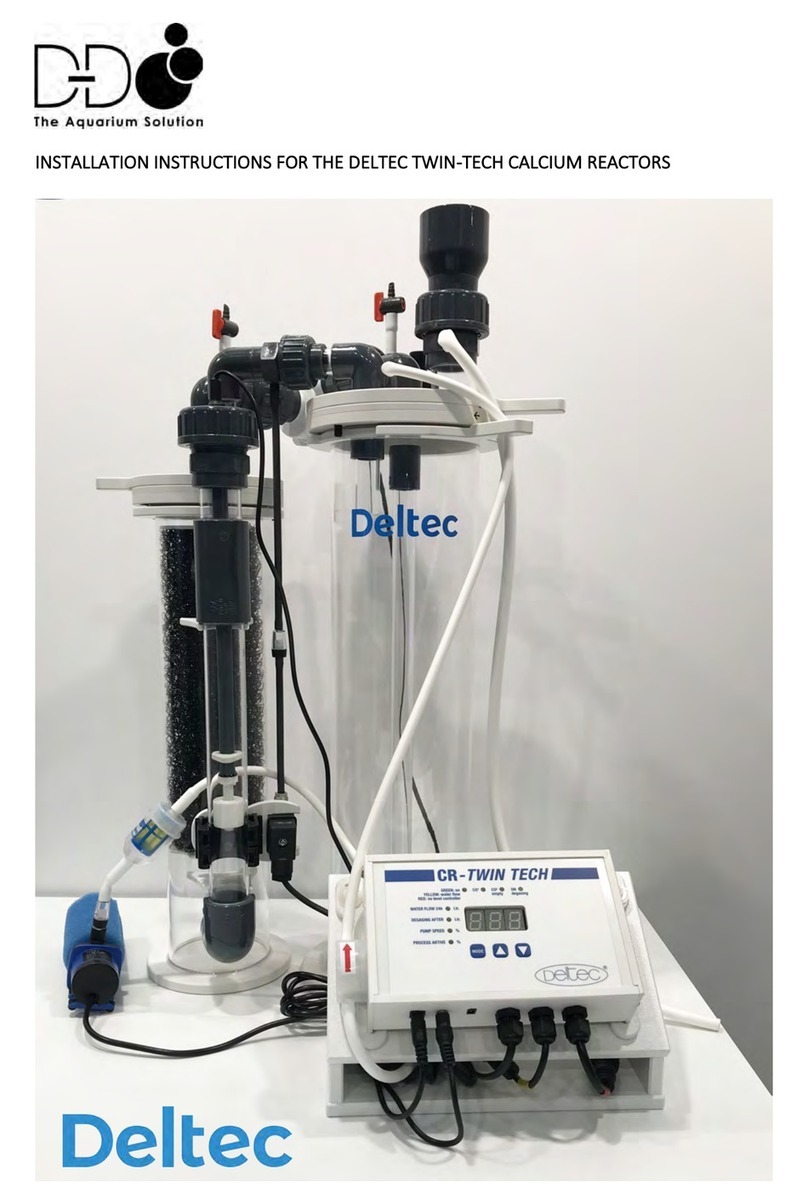

Deltec 1500 Series User manual

- 1 -

Skimmer 1500 Series

Operating instructions

- 2 -

IMPORTANT SAFETY INSTRUCTIONS

WARNING To guard against injury, basic safety precautions should be observed, including the

following.

1) READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

2) DANGER – To avoid possible electric shock, special care should be taken since water is

employed in the use of aquarium equipment. For each of the following situations, do not

attempt repairs by yourself; return the appliance to an authorized service facility for service

or discard the appliance.

a) Do not operate any appliance if it has a damaged cord or plug, or if it is malfunctioning or

has been dropped or damaged in any manner.

b) For added safety, all electric devices must be connected to an RCD (Residual Current

Device).

c) To avoid the possibility of the appliance plug or receptacle getting wet, position aquarium

stand and tank to one side of a wall-mounted receptacle to prevent water from dripping

onto the receptacle or plug.

A “drip-loop”, shown in the figure below, should be arranged by the user for each cord

connecting an aquarium appliance to a receptacle. The “drip-loop” is that part of the cord

below the level of the receptacle, or the connector if an extension cord is used, to prevent

water travelling along the cord and coming in contact with the receptacle.

If the plug or socket does get wet, DON´T unplug the cord. Disconnect the fuse or circuit

breaker that supplies power to the appliance. Then unplug and examine for presence of

water in the receptacle.

3) Close supervision is necessary when any appliance is used by or near children.

4) Do not use an appliance for other than intended use. The use of attachments not

recommended or sold by the appliance manufacturer may cause an unsafe condition.

5) Make sure an appliance mounted on a tank is securely installed before operating it.

6) Read and observe all the important notices on the appliance.

7) If an extension cord is necessary, a cord with a proper rating should be used. A cord rated for

less amperes or watts than the appliance rating may overheat. Care should be taken to

arrange the cord so that it will not be tripped over or pulled.

8) This appliance has a polarized plug (one blade is wider than the other). As safety feature, this

plug will fit in a polarized outlet only one way. If the plug does not fit, contact a qualified

electrician. Never use with an extension cord unless plug can be fully inserted. Do not attempt

to defeat this safety feature.

Exception: This instruction may be omitted for an appliance that is not provided with a

polarized attachment plug.

Removing of the plug invalidates the warranty!

- 3 -

SAVE THESE INSTRUCTIONS

Deltec Skimmer Series

Skimmer of the Deltec Skimmer Series are designed to operate only in external filter

sumps.

Installation

Please refer to the technical data for the recommended water level in the sump (Fig. 1).

A prerequisite for continuous efficient performance is a constant water level in which the

skimmer operates. Ideally, a water level top up system should be used or better still a

separate skimmer compartment in the sump (picture 2).

The water level in the skimmer compartment should be higher than in the rest of the sump,

but within the levels recommended for the skimmer model. (6 inches to 10” inches

This compartment can be supplied with water from a bypass of the aquarium overflow.

- 4 -

Safety Overflow

Skimmers of the “i” and “ix” series have a safety overflow and a regulator tube. These are

not glued to the footplate and can be interchanged as required (pictures 3,4 and 5). It must

be ensured that the outlet of the regulator tube points inwards, as if the skimmer is

removed too quickly from the filter chamber, water can be forced over the edge of the filter

sump.

If the safety overflow is not desired, the emergency overflow pipe can be removed and the

opening can be closed with the supplied plug, (picture6).

- 5 -

Starting the skimmer

-position the skimmer in the sump

-Remove the suction pipe above the safety overflow or turn to the side (picture 5).

-feed water into the skimmer compartment (if applicable)

-open the water level adjuster (picture 7) fully by turning it anti-clockwise

-start the skimmer pump

-Only for 400i - 2000i: Set the pump controller to the lowest level.

-close the water level adjuster until fine bubbles are visible between the bayonet and

the bottom of the skimmer cup (picture 8)

-initially keep the foam level in the skimmer cup low to avoid over skimming and

possible flooding of the cup.

-wait a minimum of 48 hours before the final adjustment, only then adjust the

controller up and down.

-The specified at the safety overflow pipe min and max. Values for the water level are

not to be considered in the start-up phase.

-Only for 400i - 2000i: After the start-up phase, set the controller to level 7 (400i)

level 5 (600i), level 7 (1000i), level 7 (1500i) or level 8 (2000i), optimal for most

aquariums.

-turn the water level adjuster in or out until the fine air bubbles start bursting

approximately halfway up the cup riser tube

-Set the water level between min. and max.

-Position the suction pipe above the safety overflow pipe.

-If the safety overflow pipe is not used, adjust the water level in the area of the upper

edge of the pipe, lower edge of the bayonet (picture. 8). The suction tube can be

removed.

-for dry foam turn the water level adjuster anti-clockwise, for wet foam clockwise

-Important: Never allow the pump to run dry.

Only for 400i - 2000i: When pressing the feed timer button on the controller, the pump

will stop for 10 minutes and will resume automatically.

Picture 7 Picture 8 Picture 9

Water level adjuster Skimmer cup Ozonizer

- 6 -

Operation with ozone

Ozone is an extremely aggressive gas which - if not used properly - can damage one's

health. For this reason, ozone should never be breathed in directly.

In addition, at high doses ozone can damage the skimmer.

The dosing of ozone must be set so that no free ozone can be discerned on the skimmer lid.

Deltec skimmers can be operated with 50 mg/h of ozone per pump. An ozone-resistant T-

piece (Glass) should be fitted in the air hose above the skimmer pump. The free end of the

T-piece is connected to the ozonizer by means of an ozone-resistant hose.

In addition, if necessary (depending on the skimmer) an air valve must be installed.

It must be throttled until air is independently sucked through the ozonizer. The skimmer

can be operated with ozone up to max. 50 mg/h per pump. The air connection of the

ozonizer should be connected via a suitable silicon hose to the protein skimmer pump. The

air is automatically sucked in the ozonizer by the skimmer pump. Should the skimmer

performance deteriorate please check the ozonizer for blockage.

Safety information:

-The maximum ozone quantity of 50mg/hour per pump must not be exceeded.

-The air passage can be reduced as a result of dust deposits in the ozonizer. This can

result in an increase in the water level in the skimmer, which - in extreme cases - can

overflow. To avoid this, check the ozonizer regularly to make sure that there are no

deposits of dust. If necessary, clean it.

-Never breathe in free ozone.

-The ozonizer may not be directly connected to the air valve.

-In order to avoid water damage, the ozonizer must be placed high enough to ensure

that no water can penetrate it when the skimmer pump is switched off.

Fresh saltwater

If the skimmer is used with new saltwater on an aquarium it is common for find an

excessive quantity of small bubbles and often the skimmer cup fills with a clear liquid. This

is due to the high surface tension of the new seawater which prevents the bubbles from

bursting. Once the water matures this effect will go away but can take up to 2-3 weeks. The

effect is different on different salt brands and is often dependent on levels of conditioning

agents added to the salt. Once these are skimmed out then the skimmer will act normally.

Heavier feeding in the initial stages will give the chemically pure water something to react

with and allow it to mature and assist with normal protein skimming.

- 7 -

Technical data

Technical Data

Skimmer

400i

Skimmer

600i

Skimmer

600ix

Skimmer

1000i

Skimmer

1000ix

Skimmer

1500i

Skimmer

1500ix

Skimmer

2000i

Footprint (l/w) mm

205x120

220x140

220x140

235x155

235x155

270x185

270x185

300x225

Height mm*

510*

510*

510*

520*

520*

565*

565*

560**

Aquarium size / litre

100-400

200-600

200-600

600-1000

600-1000

1000-1500

1000-1500

1500-2000

Water level mm

150-250

150-250

150-250

150-250

150-250

160-260

160-260

160-260

Power consumption Watt

5 - 12

9 - 21

9

9 - 21

11

10 - 28

27

10 - 28

Power AC/DC Volt

DC / 24V

DC / 24V

AC / 230V

DC / 24V

AC / 230V

DC / 24V

AC / 230V

DC / 24V

Air litre/h max.

450

900

450

900

600

1200

1200

1450

Air litre/h optimal / Cont.

stage

300 / 7

500 / 5

450 / --

650 / 7

600 / --

1000 / 7

1000 / --

1300 / 8

Body diameter mm

110

125

125

140

140

160

160

200

Cup diameter inner tube

mm

60

76

76

90

90

110

110

125

Pump

DCC 1

DCC 2

DCS 400

DCC 2

DCS 600

DCC 3

DCS 1200

DCC 4

Controller

SWC 1

SWC 2

-

SWC 2

-

SWC 3

-

SWC 3

Double Base Anti-Flood

●

●

●

●

●

●

●

●

Safety overflow

●

●

●

●

●

●

●

●

Drain Skimmer cup

-

-

-

●

●

●

●

●

Cleaning system manual

-

CSM 600

CSM 600

CSM 1000

CSM 1000

CSM 1500

CSM 1500

CSM 2000

Cleaning system

automatically

-

-

-

-

-

CS 1500**

CS 1500**

CS 2000**

*+15 mm to remove the cup ** without siphon

Fault finding

malfunction

cause

remedy

Pump produces

insufficient air

airline or venturi blocked

clean

airline kinked

remove kink

ozonizer blocked

clean

excessive air bubbles in

aquarium water

caused by additives in certain sea

salts and water conditioners

Use different salt or feed heavily

for a period, empty skimmer cup

frequently. This condition may

last for several weeks.

Pump does not start

Bearing of the impeller stuck. When

the pump (after having been used in

marine water) has been stored dry for

a period of time, the bearing can "dry

out".

Remove impeller and loosen the

bearing by moving the bearing plate

around and along the ceramic shaft in

tap water.

Impeller incorrectly fitted

See service hints

- 8 -

Maintenance

The Deltec skimmer range should need very little adjustment and maintenance once set

correctly however due to the high levels of calcium in marine aquariums it is common for

deposits to build up on moving parts requiring periodical cleaning. It is recommended every

6 months, or when required, that the pumps are removed from the skimmer having first

drained the body of Water.

Check and clean the impeller of debris. Soak the neck of the pump housing in white vinegar

or lime scale remover to dissolve any calcium carbonate deposits. A build up of calcium,

dust and salt can restrict or block the venturi inlet on the connecting pipe work and reduce

the skimming efficiency. This should be checked and carefully cleaned with a toothpick or

fine drill rotated between the fingertips.

It is advisable to stop the pump for approximately 15 minutes once every week in order to

dissolve any dust or salt crystals that may have collected in the venture tube.

Please observe: The water level adjuster must be checked at regular intervals (at least

once a week) for accumulation of dirt or other substances with may inhibit or interfere with

its proper function. If required please clean. For this purpose the water level adjuster can be

simply removed by pulling it upwards. After reinstallation of the water level adjuster please

make sure it is correctly set. Any foreign bodies, limestone build up ect. can cause the

skimmer water level to raise, in extreme cases the skimmer may get flooded.

- 19 -

Skimmer 1500i

- 20 -

1500i Parts List

No

Art. Nô.

Skimmer 1500i

Description

No

Art. No.

Skimmer 1500i

Description

1

81165100

Body only

15

81165200

Foot plate top

2

81160300

Skimmer cup

16

81165500

Water level adjuster

3

80500110

O-Ring Skimmer cup

17

29008000

Controller DCC3/4

4

81160400

Lid skimmer cup

18

61701000

Silikone foot

5

81160500

Silencer

19

81165110

Regulator tube

6

61760000

Silicone hose white 5/8

20

80600000

Knurled head screw short

7

81160700

Air inlet adapter

21

81165120

Safety overflow tube

8

29087000

Pump housing

22

81165210

Foot plate bottom

9

26088100

O-Ring Pump DCC3

23

81135140

Plug for safety overflow

10

26088000

Stator DCC3

24

81135130

Suction tube safety overflow

11

81208000

Defuser

25

93419000

Shut-off-valve

12

27088000

Impeller DCC3

26

61760000

Silicone hose white 7/10

13

37086000

Adaptor 1,75A

14

80601000

Knurled head screw long

- 21 -

Skimmer 1500ix

- 22 -

1500ix Parts List

No

Art. Nô.

Skimmer 1500ix

Description

No

Art. No.

Skimmer 1500ix

Description

1

81165100

Body only

15

81166200

Foot plate top

2

81160300

Skimmer cup

16

81165500

Water level adjuster

3

80500110

O-Ring Skimmer cup

17

80018000

Cap nut Pump

4

81160400

Lid skimmer cup

18

61701000

Silikone foot

5

81160500

Silencer

19

81165110

Regulator tube

6

61760000

Silicone hose white 5/8

20

80600000

Knurled head screw short

7

81166700

Air inlet adapter

21

81165120

Safety overflow tube

8

80017000

Bearing plate

22

81166210

Foot plate bottom

9

80016000

O-Ring DCS 1200

23

81135140

Plug for safety overflow

10

26089000

Stator DCS 1200 ix

24

81135130

Suction tube safety overflow

11

81208000

Defuser

25

93419000

Shut-off-valve

12

27089000

Impeller DCS 1200

26

61760000

Silicone hose white 7/10

13

80020000

Extracter for Impeller

14

80601000

Knurled head screw long

-25 -

Disassembly 400i, 600i, 1000i, 1500i, 2000i

-28 -

Disassembly1500ix

This manual suits for next models

15

Table of contents

Other Deltec Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Owen Mumford

Owen Mumford AutoDrop OP6000 instructions

Keysight

Keysight M8195A Getting started guide

Grant-bio

Grant-bio Vortexer PV1 operating instructions

IKA

IKA Topolino Mobil operating instructions

Sartorius stedim

Sartorius stedim Sartobind Phenyl nano 3 ml operating instructions

Westlab

Westlab 664-315 product manual

Agilent Technologies

Agilent Technologies G2747A installation guide

REPLIGEN

REPLIGEN TangenX PRO Compatibility guide

Endress+Hauser

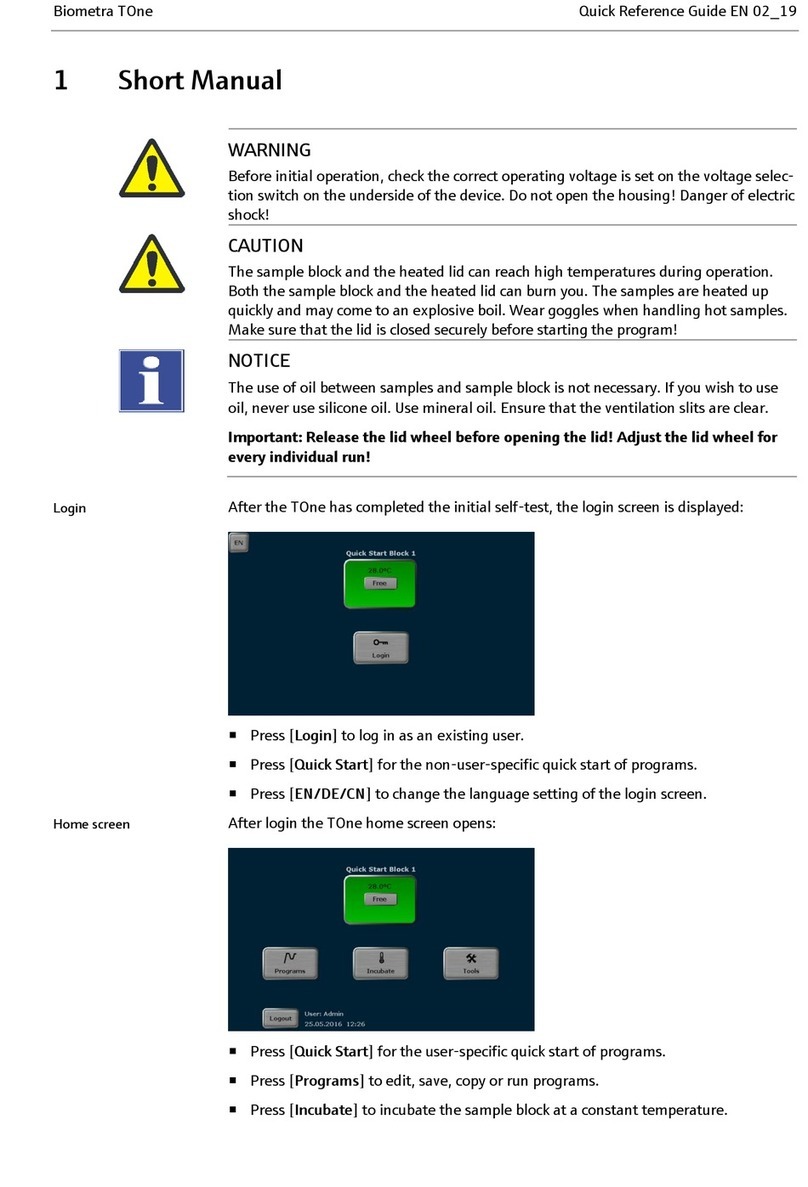

Endress+Hauser Analytik Jena Biometra TOne Short manual

Agilent Technologies

Agilent Technologies G1289 operating manual

Basler

Basler BE1-25A instruction manual

MedKlinn

MedKlinn PRO AS3 operating manual