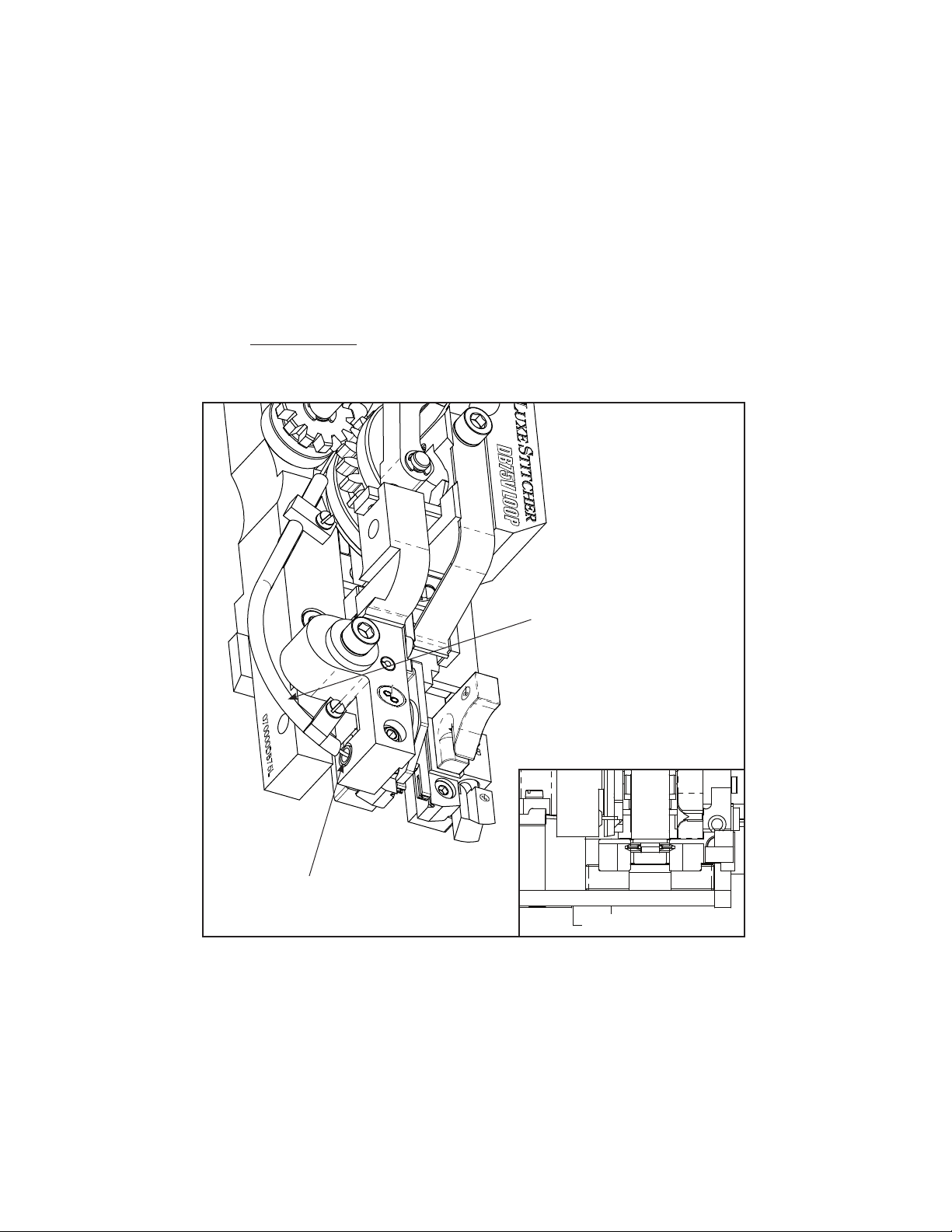

Attaching the Feed Release Handle (Figure 2)

From out of the box, secure the Feed Release Handle

[070119] to the stitcher head by slipping the handle over the

Feed Release Cam Assembly [070118] and securing it with

the provided screw, inserting it through the spring. Make sure

the handle is angled toward the outside of the head when the

screw is tightened.

Carefully inspect the condition of the shipping container before unpacking your replacement Head

for Müller-Martini Stitchers. If the container is broken or damaged and there is evidence that the

stitcher head may be damaged, immediately

notify the carrier who delivered the head and the

DeLuxe Stitcher Graphic Arts Representative

from whom the head was purchased.

Installation

6

Pre-Inspection

As you carefully unpack the replacement

head, check to make sure all components

were delivered and are in good working

order. Use Figure 1 in this manual for refer-

ence to the following pieces:

• Replacement head for Müller Martini

Stitchers: DB75HD, DB75VHD or

DB75VSHD

• Wire guide spring [070286]

• Clincher plate assembly [077030 or

077030C]

• Feed release handle [070119]

• 2.5, 3, 4 and 5 mm hex key wrenches

[G20361, G20360, G20373 and G20362]

• Stitch samples

Inspection (Figure 1)

Figure 1 - Inspection

070286

077030 (DB75) or

077030C (DB75V/VS)

070119

G20360

(3 mm)

G20362

(5 mm)

G20361

(2.5 mm)

G20373

(4 mm)

Mounting & Assembly (Figure 2-6)

Figure 2- Feed Release Handle

Screw

Spring

Handle