997-417, Issue 2 June 2002

EE

FFDDGG

GG

GG

GG

CCGG

BB

FF

DD

EE

AA

Check Your Equipment....Check Your Equipment....

The NOTIFIER IDR-MD Mimic Driver kit (PN: 020-574) is provided as part of a versatile system to provide effective mimic display

solutions. The installer is responsible for the correct assembly and electrical interconnection of the various components of the IDR Mimic

system. The kit is simple to install providing the instructions described below are followed.

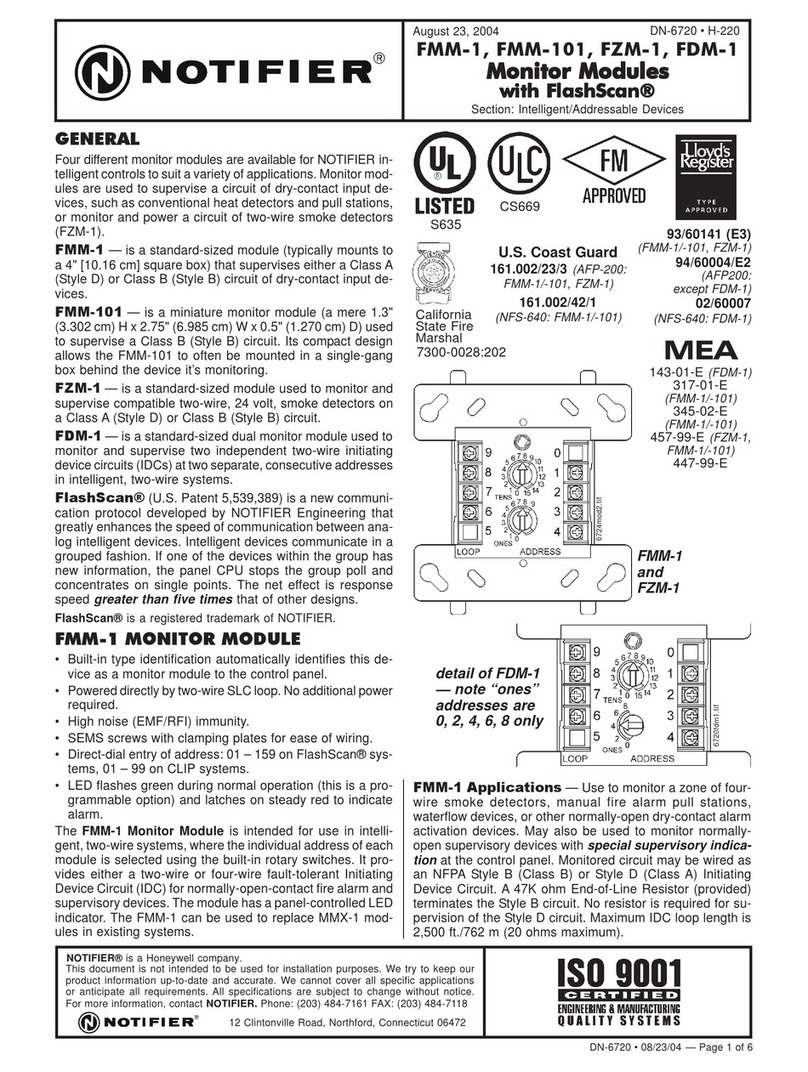

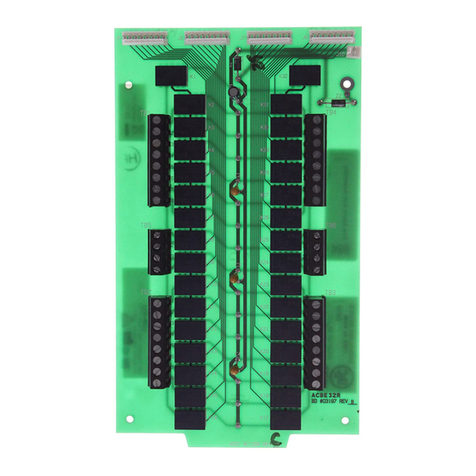

The kit comprises one mimic driver PCB and two mimic driver termination PCBs mounted on separate chassis. One ribbon cable is

provided for interconnection between the mimic driver PCB and the mimic control PCB (provided in kit PN: 020-573) or the previous mimic

driver PCB. Up to eight driver PCBs can be driven by one mimic control PCB. Two ribbon cables are provided for interconnection between

the mimic driver PCB and the two driver termination PCBs. Each driver termination PCB can support the connection of up to 32 LEDs or

relays (selected by jumper links) and also has 8 I/O lines. The IDR-MD mimic driver kit is designed for installation either using a third-party-

provided chassis/enclosure or the NOTIFIER ID/NFXXXX Adapter Mimic Kit (PN: 020-597) for 19” rack mounting applications. The

installation must meet the Environmental specifications defined in the IDR-M Mimic Control Board manual (ref. 997-412).

The NOTIFIER IDR-MD Mimic Driver kit (PN: 020-574) is provided as part of a versatile system to provide effective mimic display

solutions. The installer is responsible for the correct assembly and electrical interconnection of the various components of the IDR Mimic

system. The kit is simple to install providing the instructions described below are followed.

The kit comprises one mimic driver PCB and two mimic driver termination PCBs mounted on separate chassis. One ribbon cable is

provided for interconnection between the mimic driver PCB and the mimic control PCB (provided in kit PN: 020-573) or the previous mimic

driver PCB. Up to eight driver PCBs can be driven by one mimic control PCB. Two ribbon cables are provided for interconnection between

the mimic driver PCB and the two driver termination PCBs. Each driver termination PCB can support the connection of up to 32 LEDs or

relays (selected by jumper links) and also has 8 I/O lines. The IDR-MD mimic driver kit is designed for installation either using a third-party-

provided chassis/enclosure or the NOTIFIER ID/NFXXXX Adapter Mimic Kit (PN: 020-597) for 19” rack mounting applications. The

installation must meet the Environmental specifications defined in the IDR-M Mimic Control Board manual (ref. 997-412).

Taking suitable precautions, before proceeding with the installation, remove all

packaging and inspect for any damage that may have occurred during transit. If

no damage is evident, proceed using the instructions below. In the unlikely

event that damage has occurred, or any items are missing, DO NOT

PROCEED, contact your supplier and refer to the panel Installation &

Commissioning Manual.

Observing all necessary precautions, proceed with the installation of the IDR-

MD Mimic Driver Kit.

Taking suitable precautions, before proceeding with the installation, remove all

packaging and inspect for any damage that may have occurred during transit. If

no damage is evident, proceed using the instructions below. In the unlikely

event that damage has occurred, or any items are missing, DO NOT

PROCEED, contact your supplier and refer to the panel Installation &

Commissioning Manual.

Observing all necessary precautions, proceed with the installation of the IDR-

MD Mimic Driver Kit.

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE

DEVICES

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE

DEVICES

ATTENTIONATTENTION

997-417, Issue 2 June 2002

EE

FFDDGG

GG

GG

GG

CCGG

BB

FF

DD

EE

AA

Check Your Equipment....Check Your Equipment....

The NOTIFIER IDR-MD Mimic Driver kit (PN: 020-574) is provided as part of a versatile system to provide effective mimic display

solutions. The installer is responsible for the correct assembly and electrical interconnection of the various components of the IDR Mimic

system. The kit is simple to install providing the instructions described below are followed.

The kit comprises one mimic driver PCB and two mimic driver termination PCBs mounted on separate chassis. One ribbon cable is

provided for interconnection between the mimic driver PCB and the mimic control PCB (provided in kit PN: 020-573) or the previous mimic

driver PCB. Up to eight driver PCBs can be driven by one mimic control PCB. Two ribbon cables are provided for interconnection between

the mimic driver PCB and the two driver termination PCBs. Each driver termination PCB can support the connection of up to 32 LEDs or

relays (selected by jumper links) and also has 8 I/O lines. The IDR-MD mimic driver kit is designed for installation either using a third-party-

provided chassis/enclosure or the NOTIFIER ID/NFXXXX Adapter Mimic Kit (PN: 020-597) for 19” rack mounting applications. The

installation must meet the Environmental specifications defined in the IDR-M Mimic Control Board manual (ref. 997-412).

The NOTIFIER IDR-MD Mimic Driver kit (PN: 020-574) is provided as part of a versatile system to provide effective mimic display

solutions. The installer is responsible for the correct assembly and electrical interconnection of the various components of the IDR Mimic

system. The kit is simple to install providing the instructions described below are followed.

The kit comprises one mimic driver PCB and two mimic driver termination PCBs mounted on separate chassis. One ribbon cable is

provided for interconnection between the mimic driver PCB and the mimic control PCB (provided in kit PN: 020-573) or the previous mimic

driver PCB. Up to eight driver PCBs can be driven by one mimic control PCB. Two ribbon cables are provided for interconnection between

the mimic driver PCB and the two driver termination PCBs. Each driver termination PCB can support the connection of up to 32 LEDs or

relays (selected by jumper links) and also has 8 I/O lines. The IDR-MD mimic driver kit is designed for installation either using a third-party-

provided chassis/enclosure or the NOTIFIER ID/NFXXXX Adapter Mimic Kit (PN: 020-597) for 19” rack mounting applications. The

installation must meet the Environmental specifications defined in the IDR-M Mimic Control Board manual (ref. 997-412).

Taking suitable precautions, before proceeding with the installation, remove all

packaging and inspect for any damage that may have occurred during transit. If

no damage is evident, proceed using the instructions below. In the unlikely

event that damage has occurred, or any items are missing, DO NOT

PROCEED, contact your supplier and refer to the panel Installation &

Commissioning Manual.

Observing all necessary precautions, proceed with the installation of the IDR-

MD Mimic Driver Kit.

Taking suitable precautions, before proceeding with the installation, remove all

packaging and inspect for any damage that may have occurred during transit. If

no damage is evident, proceed using the instructions below. In the unlikely

event that damage has occurred, or any items are missing, DO NOT

PROCEED, contact your supplier and refer to the panel Installation &

Commissioning Manual.

Observing all necessary precautions, proceed with the installation of the IDR-

MD Mimic Driver Kit.

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE

DEVICES

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE

DEVICES

ATTENTIONATTENTION

Your kit PN: 020-574 should contain:

Mimic Driver Assembly PN: 004-096

Mimic Driver TerminationAssemblies (2 off) PN: 004-097

Ribbon Cable, 10-way PN: 082-171-004

Ribbon cable, 40-way (2 off) PN: 082-220

Plug, 8-way screw terminating (2 off) PN: 610-169

M4 x Nyloc locking nuts (2 off) PN: 750-058

Fuse, 500mA (T) PN: 570-105

8-way Jumper Block (8 off) PN: 542-340

Anti-Static Warning instructions PN: 997-180

Your kit PN: 020-574 should contain:

Mimic Driver Assembly PN: 004-096

Mimic Driver TerminationAssemblies (2 off) PN: 004-097

Ribbon Cable, 10-way PN: 082-171-004

Ribbon cable, 40-way (2 off) PN: 082-220

Plug, 8-way screw terminating (2 off) PN: 610-169

M4 x Nyloc locking nuts (2 off) PN: 750-058

Fuse, 500mA (T) PN: 570-105

8-way Jumper Block (8 off) PN: 542-340

Anti-Static Warning instructions PN: 997-180

The mimic driver assemblies are designed to interlock using the provided

studs and corresponding holes of each metal chassis and the supplied M4

Nyloc locking nuts.

Procedure

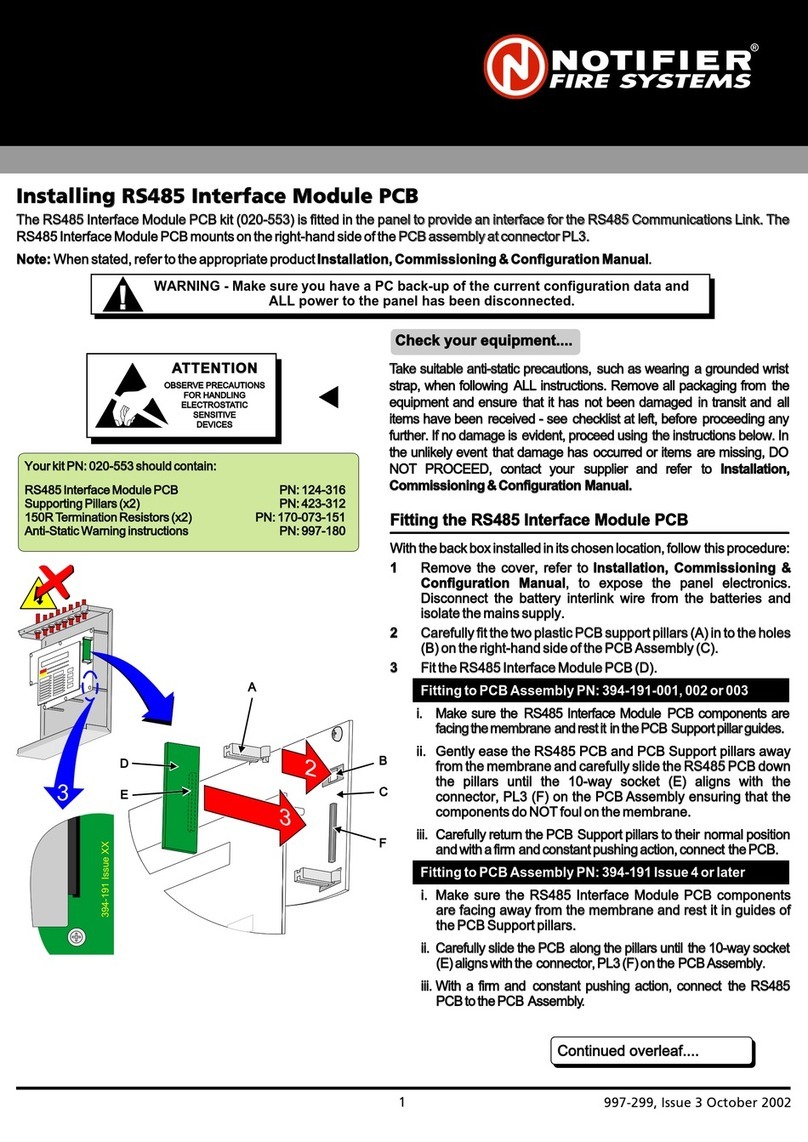

Position the mimic driver assemblies (A) as shown below so that each

joggled (cranked) long-sided edge (B) is adjacent to the non-joggled long-

sided edge (C) of the next assembly. Pass the two studs (D) through the

holes (E) of the next assembly. Secure together using the supplied M4

Nyloc nuts (F). DO NOT over-tighten!

Repeat procedure as required. When all assemblies are connected

together, secure the assembly within its enclosure using the provided

4mm holes (G).

The mimic driver assemblies are designed to interlock using the provided

studs and corresponding holes of each metal chassis and the supplied M4

Nyloc locking nuts.

Position the mimic driver assemblies (A) as shown below so that each

joggled (cranked) long-sided edge (B) is adjacent to the non-joggled long-

sided edge (C) of the next assembly. Pass the two studs (D) through the

holes (E) of the next assembly. Secure together using the supplied M4

Nyloc nuts (F). DO NOT over-tighten!

Repeat procedure as required. When all assemblies are connected

together, secure the assembly within its enclosure using the provided

4mm holes (G).

Procedure

Fixing Multiple Mimic Driver Assemblies Together

to Form an Interlocking Module

Fixing Multiple Mimic Driver Assemblies Together

to Form an Interlocking Module

For clarity, only the middle Mimic Display board is shown in detail.For clarity, only the middle Mimic Display board is shown in detail.

!!

CAUTION!

To ensure EMC requirements are

met, ALWAYS install the IDR-MD

Mimic Driver Kit PCBs in an

enclosure. NEVER REMOVE the

PCBs from their metal chassis

plates, which MUST be earthed.

Route external wiring away from

SPI bus cables.

CAUTION!

To ensure EMC requirements are

met, ALWAYS install the IDR-MD

Mimic Driver Kit PCBs in an

enclosure. NEVER REMOVE the

PCBs from their metal chassis

plates, which MUST be earthed.

Route external wiring away from

SPI bus cables.

1

Installing the IDR-MD Mimic Driver KitInstalling the IDR-MD Mimic Driver Kit