Paul B. Zimmerman DS-15 User manual

by PBZ

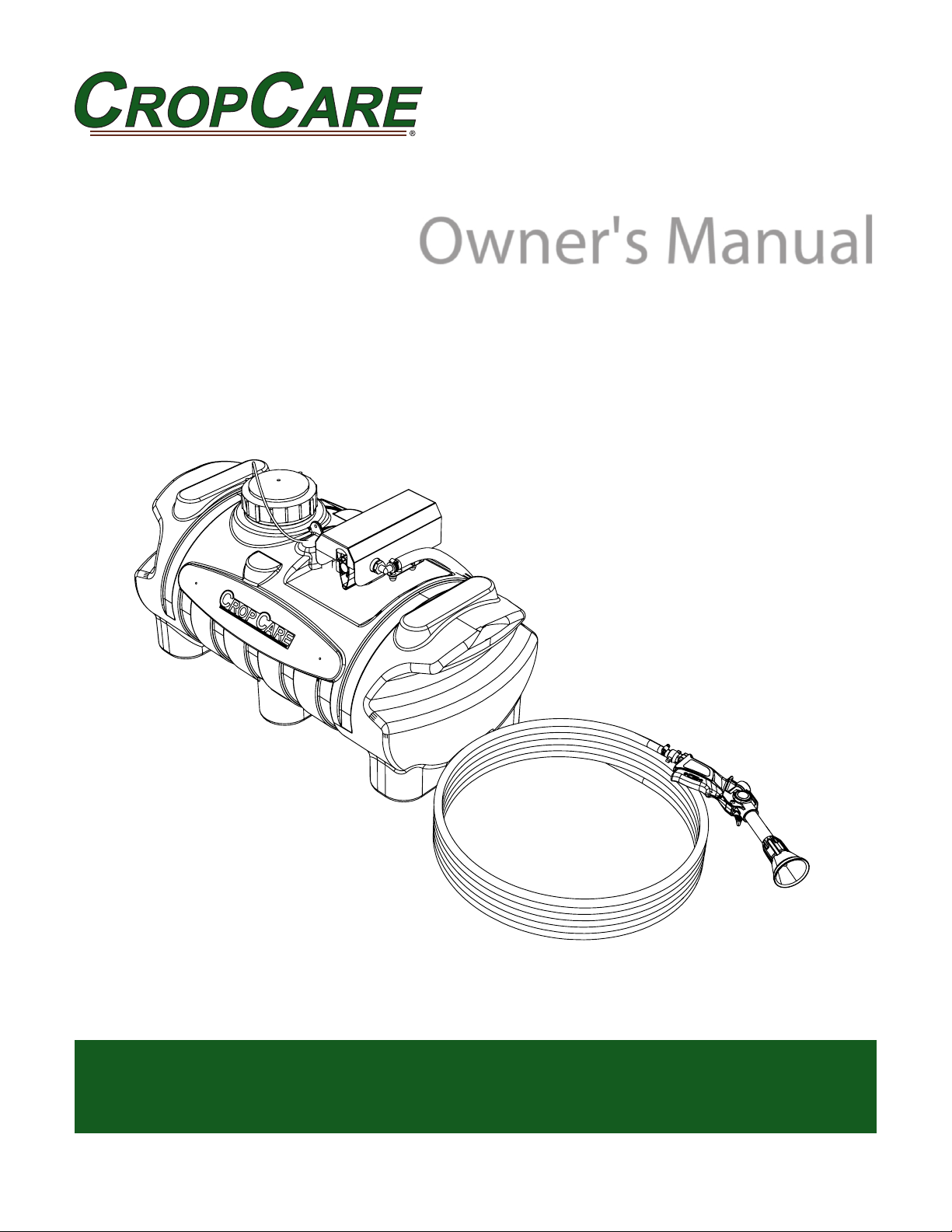

15 & 25 Gallon Disinfect Sprayer

Model DS-15 & DS-25

Form: DS25OM

Rev: B.1 Date: 05/19

PBZ LLC | 295 Wood Corner Rd | Lititz PA 17543

www.CropCareEquipment.com | (717)-738-7365

A Paul B Zimmerman Inc. Company

Owner's Manual

3

Table Of Contents

Before You Begin....................................................................................3

Identication Of Machine...................................................................3

Safety Precautions.................................................................................4

General Guideline...................................................................... 4

Before Operation.........................................................................4

During Operation........................................................................5

Following Operation..................................................................5

Pump Safety Precautions..........................................................5

Breakdowns & Parts List......................................................................6

DS-15 & DS-25 Breakdown.......................................................6

DS-15 & DS-25 Parts List............................................................7

DS101 Breakdown & Parts List................................................8

DS102 Breakdown & Parts List................................................9

DS103 Breakdown & Parts List..............................................10

DS104 Breakdown & Parts List..............................................11

DS106 Breakdown & Parts List..............................................12

GK50DS Breakdown & Parts List...........................................13

Disinfect System Plumbing Schematic..............................14

Installing the Sprayer........................................................................15

Base Unit Installation (DS-15 & DS-25)...............................15

Filter Unit Assembly..................................................................16

Thank you for purchasing this CropCare product. This owners manual contains helpful information regarding the installation,

operation and maintenance of your product. For parts and service please contact your local CropCare dealer.

Trailer/Drive Axle Nozzle Assembly & Mounting............16

Steering Axle Nozzle Assembly & Installation.................17

Diaphragm Check Valve Assembly & Installation...........18

Bulk Head/Quick Disconnect Assembly & Install...........18

Spray gun Assembly & Installation..... ...............................18

Maintenance & Winterizing Instructions.....................................19

Routine Maintenance...............................................................19

Winterizing Your Sprayer........................................................19

CropCare Limited Warranty .............................................................20

Notes................................................................................................. 21-22

Contact Us..............................................................................................23

• Please read and understand this manual and its instructions and warnings completely before operating the sprayer.

• Be aware of all safety guidelines, warnings, and cautions.

• Completely assemble the sprayer according to the directions supplied in this manual.

• Read and understand the chemical manufacturer’s labels, warnings, and instructions.

• Familiarize yourself and other operators with the sprayer’s components and how all parts are operated.

Before You Begin

Please read and understand this manual and its instructions and warnings completely before operating.

Identication of Machine

• Model #’s: DS-15 & DS-25

• The model number and revision identication decal is located on top of the pump cover.

4

• Carefully study and understand this owner’s manual.

• Read and follow the inoculant or chemical manufacturer’s labels, warnings, and instructions! A material safety data sheet

(MSDS) should be provided by the chemical manufacturer.

• To avoid injury from chemical hazards, wear the proper protective clothing. Each chemical manufacturer’s clothing

requirements are listed under the “Personal Protective Equipment” (PPE) section in the chemical instructions.

• Do not wear loose-tting clothing which may catch in moving parts.

• It is also recommended that operators wear suitable hearing and eye protection.

• Inspect the sprayer for worn parts, loose bolts, or other visible problems, and make the necessary repairs. See the

maintenance section.

• Make sure the area is clear of any people or obstructions before using the sprayer.

• Have all operators practice operating the sprayer and its attachments until all persons are completely capable of safe

operation.

General Guidelines

• The operator should be a responsible adult. Do not allow persons

to operate this liquid applicator until they have displayed a

thorough understanding of applicator safety precautions and

operational use!

• The best defense against accidents is a careful and responsible

operator.

• A chemical warning decal and an owner’s manual warning decal

are located on the applicator’s tank. Be aware of their location. See

Figure 1 and Figure 2.

• Always replace any warning decals that aren’t legible or are missing.

• When transporting the sprayer on public roads, always follow

state and local regulations regarding safety and transportation

requirements.

• If there is any portion of this manual that you do not fully

understand, please contact PBZ LLC.

Safety Precautions

Before Operation

Figure 1: Chemical Warning Decal(# DEMT3980)

Figure 2: Owner's Manual Decal(# DE39)

Every year many unnecessary accidents occur due to improper equipment handling and a disregard for safety precautions. You, the

operator, can avoid accidents by observing the precautions in this section.

5

During Operation

• Always be aware of bystanders, particularly children!

• Keep hands and body parts clear of all moving parts!

• Never leave running equipment unattended.

• Never leave running equipment, including the liquid applicator, unattended!

• Remember that accidents can even happen to seasoned operators. Always take your time and follow all safety instructions.

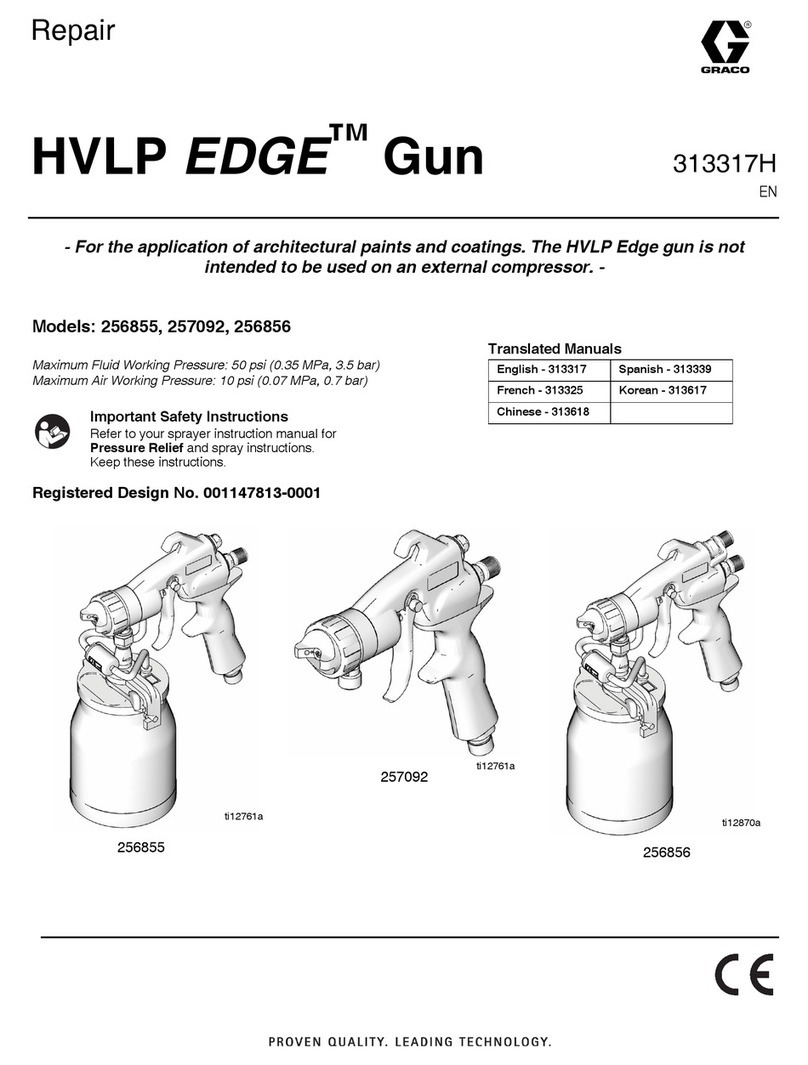

Pump Safety Precautions

Safety Precautions

• Never pump ammable, explosive, petroleum-based, or any other non-compatible products such as gasoline, fuel oil,

kerosene, etc. Such practices will void the manufacturer’s warranty.

• DO NOT allow the pump to get wet or to be exposed to the elements. Allowing the pump to get wet or to be exposed to the

elements voids the manufacturer’s warranty.

• Note: The pump may be run dry for limited periods without resulting in damage.

• Always disconnect the power to the pump when working on the pump. Failure to do this could result in electrical shock.

Following Operation

• After operation, store the sprayer away from human and livestock activity.

• Do not permit children to play on or around the sprayer.

6

Breakdowns & Parts Lists

Disinfect Sprayer Breakdown

DS-15 & DS-25, Disinfect System Base Assembly

1

2

3

4

5

6

5

7

8

9

10

11

11

12

13

13

18

19

14

16

15

17

2

20

7

Breakdowns & Parts Lists

Disinfect Sprayer Parts List

DS-15 & DS-25, Disinfect System Base

Ref # Qty. Part Numbers Description

1 1.67’ 1208 Hose, EPDM Rubber 1/2”200 PSI

2 2 62606 Hose Clamp, Narrow 5/16”-7/8” SS

3 1 10416D Strainer, Suction 3/8”FPT 40 Mesh

4 1 3A3812 Fitting, Hose 3/8” MPT x 1/2” HB

5 2 3EL1212 Hose adapter, 90°, 1/2” MPT x 1/2” barb

6 1 5537-1G1-63B Pump, Diaphragm 12V 5.3 GPM Demand 75 PSI Viton Santo, Heavy Duty Motor

7 2 DE46 Decal, CropCare logo, 1.9”x 8.8”

8 1 DS106 Filter/Valve Assembly, Disinfect System

9 2 HSS10*12 Screw, Hex TEK #10 x 1/2” SS

10 1 SB25WP-DR + Tank, 25 Gal White Poly w/Lid Lanyard Outlet Cap Gasket&Tether

11 4 SBT316*1 Bolt, Stove Truss Head 10-24 x 1”

12 1 T744 Pump cover, stainless steel

13 2 T743 ATX pump cover, tab

14 1 11042 Gasket, EPDM for 5”Lid

15 1 10035* Lid, Tank 5" w/ out Lanyard

16 1 10873* Lanyard, 12"

17 1 10960* Gasket, Tank Outlet Cap for Den Hartog Applicator Tank

18 1 19024* Cap, Tank Outlet for Den Hartog Applicator Tank

19 1 19025* Tether, Cap Tank Outlet for Den Hartog Applicator Tank

20 1 DE184 Decal, DS-25 Model and Revision

* Components are available as part of the tank (Item 10).

+Shown for DS-25 (25 gallon), use part # SB00015SW with DS-15 (15 gallon).

8

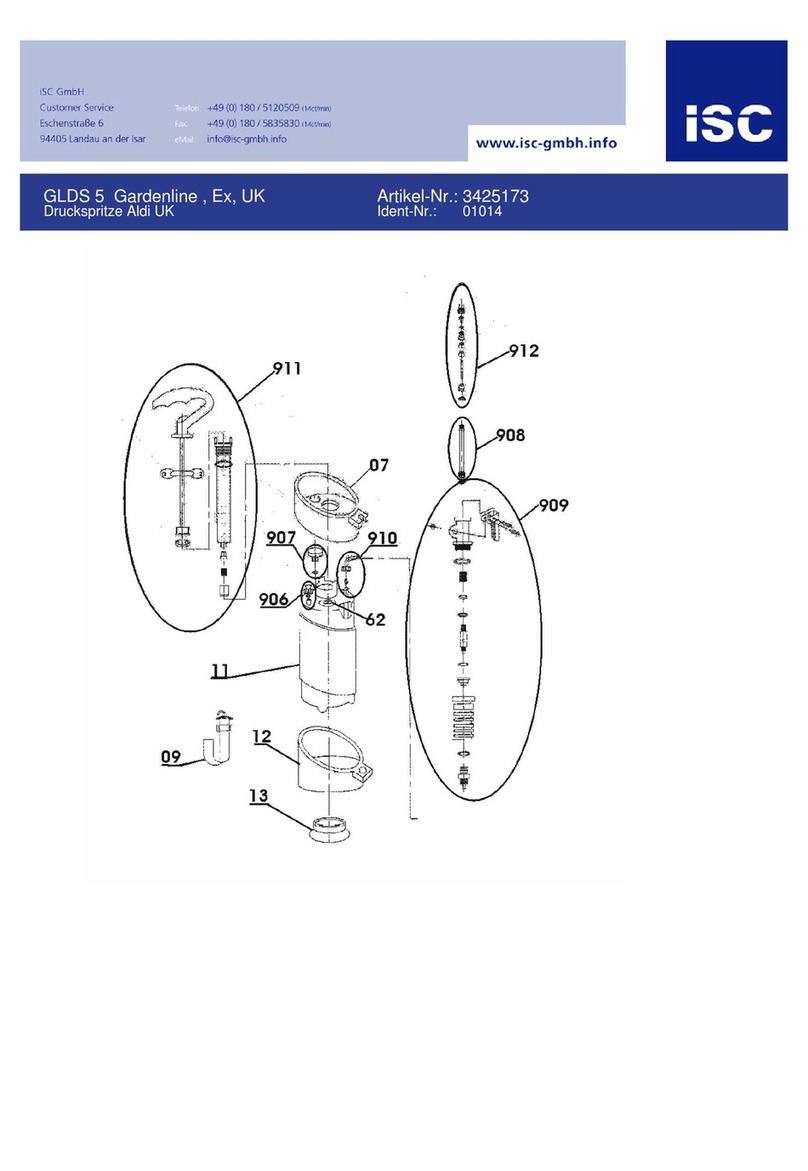

Breakdowns & Parts Lists

Disinfect Sprayer Breakdown & Parts List

DS101, Nozzle Assembly

Ref # Qty. Part Numbers Description

1 1 62606 Hose Clamp, Narrow 5/16"-7/8" SS

2 2 22674-14-NYB Adapter, Nozzle 45° 1/4”NPT

3 2 256003NYR Cap & Gasket, Quick TeeJet Red

4 1 3AF1438 Adapter, Hose 1/4” FPT x 3/8” HB

5 2 8079PP50 Strainer, Tip 50 Mesh Red Poly Body SS Screen

6 2 H5C14*1 Bolt, Hex 1/4-20 x 1”Gr 5

7 2 LW14 Washer, Lock 1/4”

8 2 NC14 Nut, Hex 1/4-20

9 1 T14S Tee, 1/4”NPT SS

10 1 T533 Gauge mount nipple, 1/4” MPT x 1 1/2”, stainless

11 2 TFVP2 Tip, Turbo FloodJet Polymer Red

1

2

2

3

3

4

5

5

6

7

8

9

10

11

11

9

Breakdowns & Parts Lists

Disinfect Sprayer Breakdown & Parts List

DS102, Nozzle Assembly

Ref # Qty. Part Numbers Description

1 1 62606 Hose Clamp, Narrow 5/16”-7/8” SS

2 1 22674-14-NYB Adapter, Nozzle 45° 1/4" NPT

3 1 256003NYR Cap & Gasket, Quick TeeJet Red

4 1 3AF1438 Adapter, Hose 1/4” FPT x 3/8” HB

5 1 8079PP50 Strainer, Tip 50 Mesh Red Poly Body SS Screen

6 2 H5C14*1 Bolt, Hex 1/4-20 x 1”Gr 5

7 1 L14S Elbow, 90° 1/4”NPT SS

8 2 LW14 Washer, Lock 1/4"

9 2 NC14 Nut, Hex 1/4-20

10 1 T533 Gauge mount nipple, 1/4” MPT x 1 1/2”, stainless

11 1 TFVP2 Tip, Turbo FloodJet Polymer Red

1

2

3

4

5

6

7

8

9

10

11

10

Breakdowns & Parts Lists

Disinfect Sprayer Breakdown & Parts List

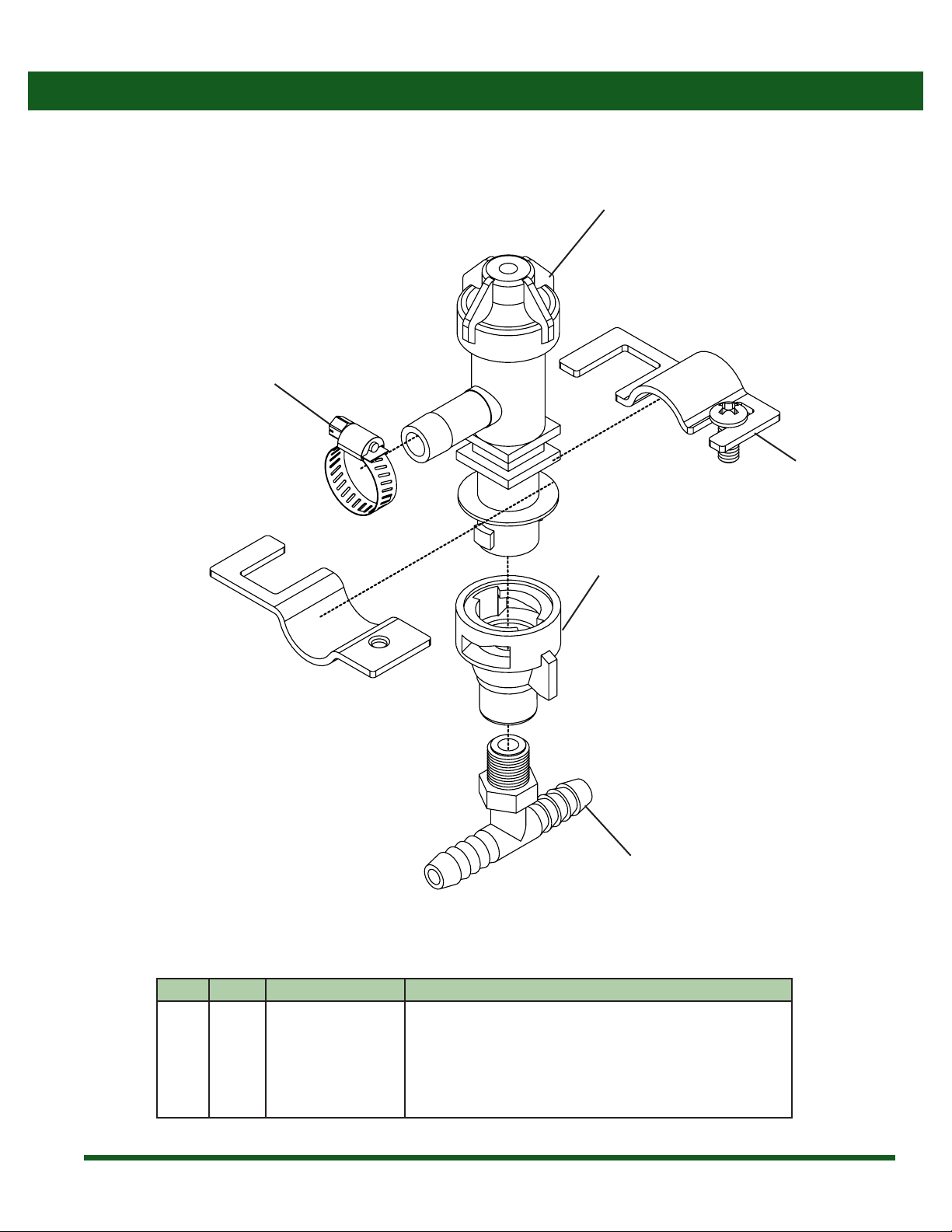

DS103, Disinfect System Check Valve

Ref # Qty. Part Numbers Description

1 1 22251311500NYB Body, Nozzle Elbow 1/2”QJ300

2 1 3T1438T Tee, Fitting 1/4" MPT x 3/8" HB Run Poly

3 3 62606 Hose Clamp, Narrow 5/16”-7/8” SSd

4 1 QJ11112 Clamp, Nozzle Body 1/2" Pipe

5 1 QJ467614NYR Adapter, Cap QJ To 1/4” FPT

1

2

4

5

3

11

Breakdowns & Parts Lists

Disinfect Sprayer Breakdown & Parts List

DS104, Disinfect System Quick Disconnect

Ref # Qty. Part Numbers Description

1 2 62606 Hose Clamp, Narrow 5/16”-7/8” SS

2 1 207-08-08 Fitting, Bulkhead Brass 1/2” NPT

3 1 3A1212 Adapter, Hose 1/2” MPT x 1/2” HB

4 1 3EL1212 Hose adapter, 90°, 1/2” MPT x 1/2” barb

5 1 BST4M Quick Disconnect, Brass, 1/2" MNPT

6 1 BSTN4 Plug, Quick Coupler 1/2” NPT Brass

7 1 SE12S Elbow, Street 90° Stainless 1/2”NPT

1 2

1

3

4

5

6

7

12

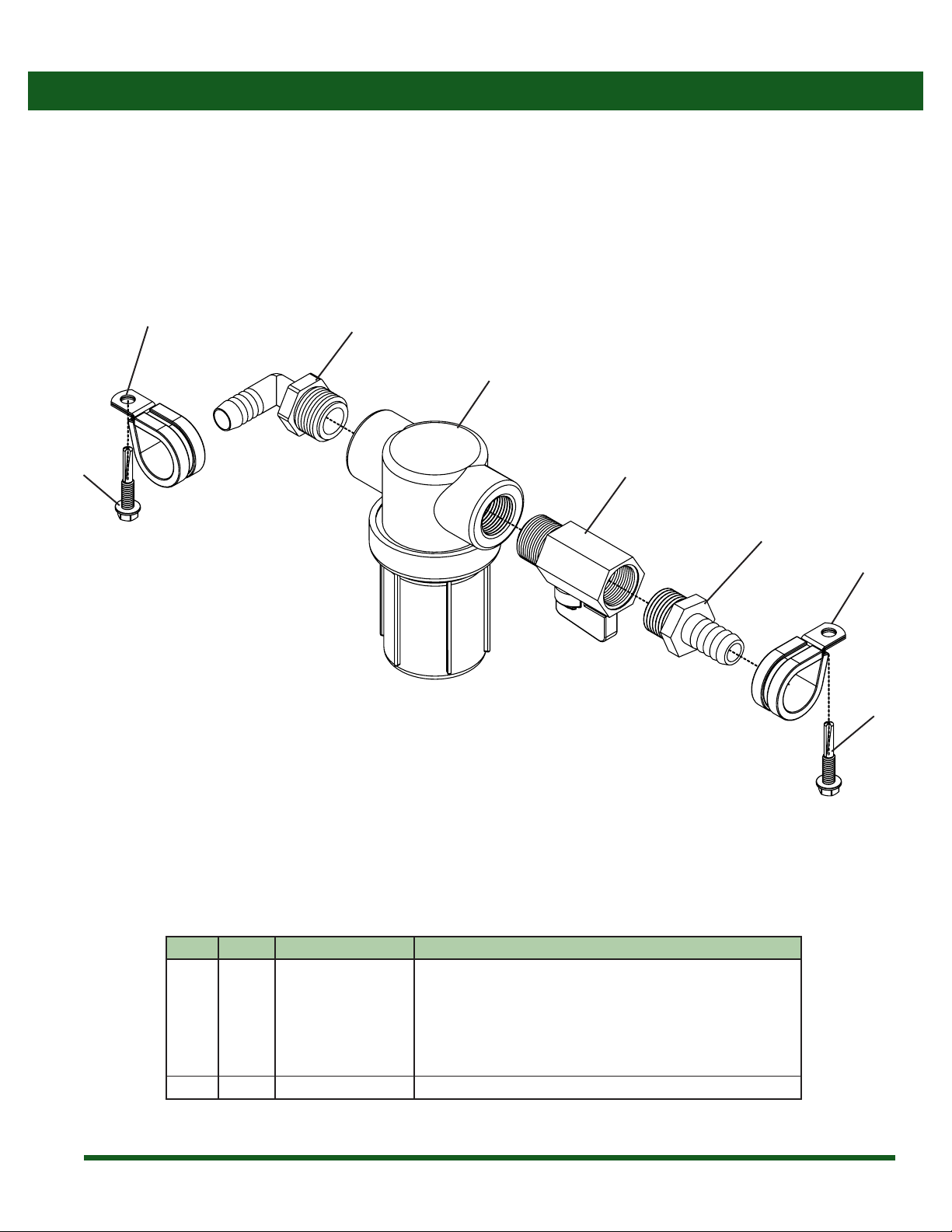

Breakdowns & Parts Lists

Disinfect Sprayer Breakdown & Parts List

DS106, Disinfect System Filter/Valve Assembly

Ref # Qty. Part Numbers Description

1 1 3A1212 Adapter, Hose 1/2” MPT x 1/2” HB

2 1 3EL1212 Hose adapter, 90°, 1/2" MPT x 1/2" barb

3 1 90FMB12 Valve, Ball 1/2" FPT x 1/2" MPT 300PSI

4 1 AA12212PP50 Strainer, Line 1/2” FPT 50 mesh screen

5 2 DC2014 Clamp, Loom Steel 7/8”

6 2 TK12*114H5 Screw, Tek Hex Head 12-24 x 1-1/4”

1

2

3

4

5

5

6

6

13

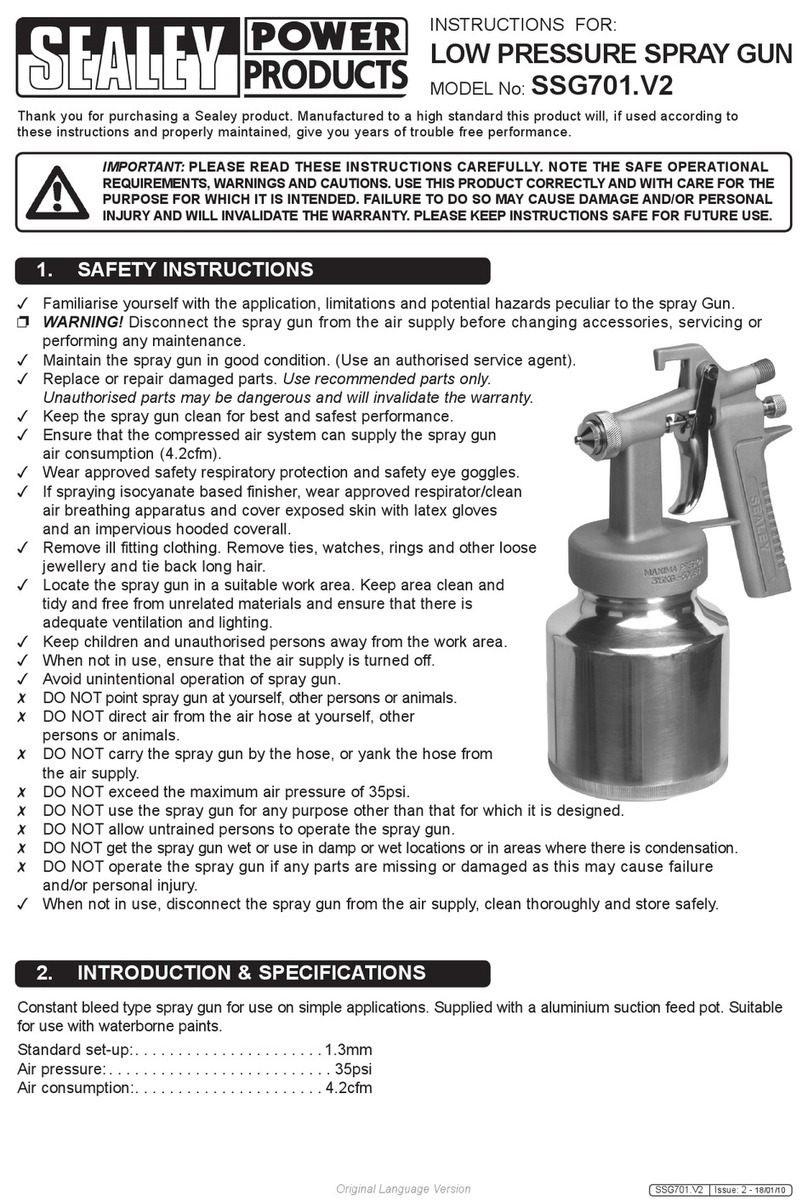

Breakdowns & Parts Lists

Disinfect Sprayer Breakdown & Parts List

GK50DS, Disinfect System Filter/Valve Assembly

Ref # Qty. Part Numbers Description

1 50’ 1206 Hose, EPDM Rubber 3/8”200 PSI

2 4 62606 Hose Clamp, Narrow 5/16”-7/8” SS

3 1 9910110131 Adapter, 3/8” HB x 1/2” BSP Wing Nut Assy

4 1 3AF1238 Adapter, Hose 1/2 FPT x 3/8 HB

5 1 3T12T Tee, Fitting 1/2" MPT x 1/2" HB Run Poly

6 1 5062410F Spray Gun, 700 PSI

7 2 DC2014 Clamp, Loom Steel 7/8”

8 2 TK12*114H5 Screw, Tek Hex Head 12-24 x 1-1/4”

12

2

2

3

4

5

6

7

8

14

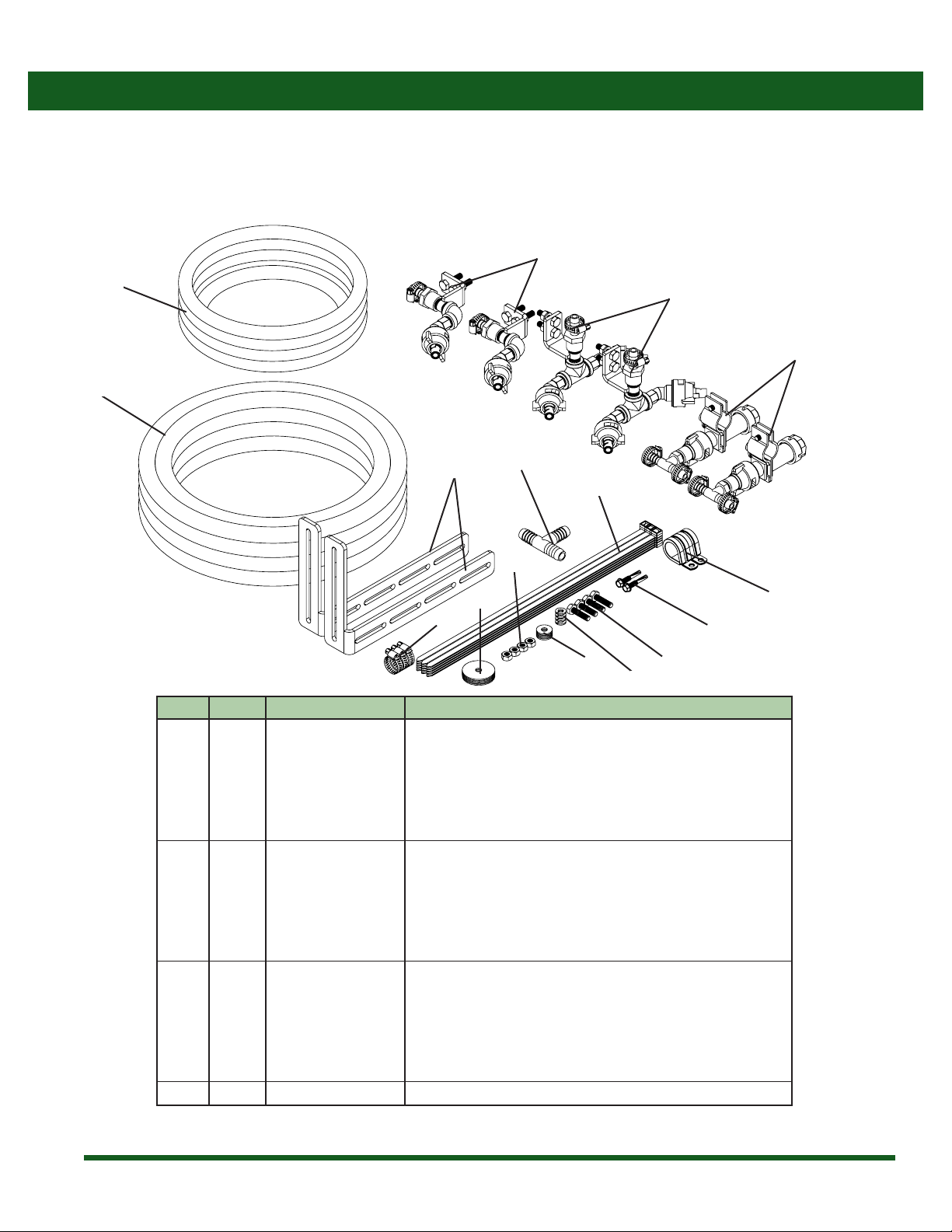

Breakdowns & Parts Lists

Disinfect Sprayer Breakdown & Parts List

DS-TK, Disinfect System, Tractor/Straight Truck Plumbing Kit

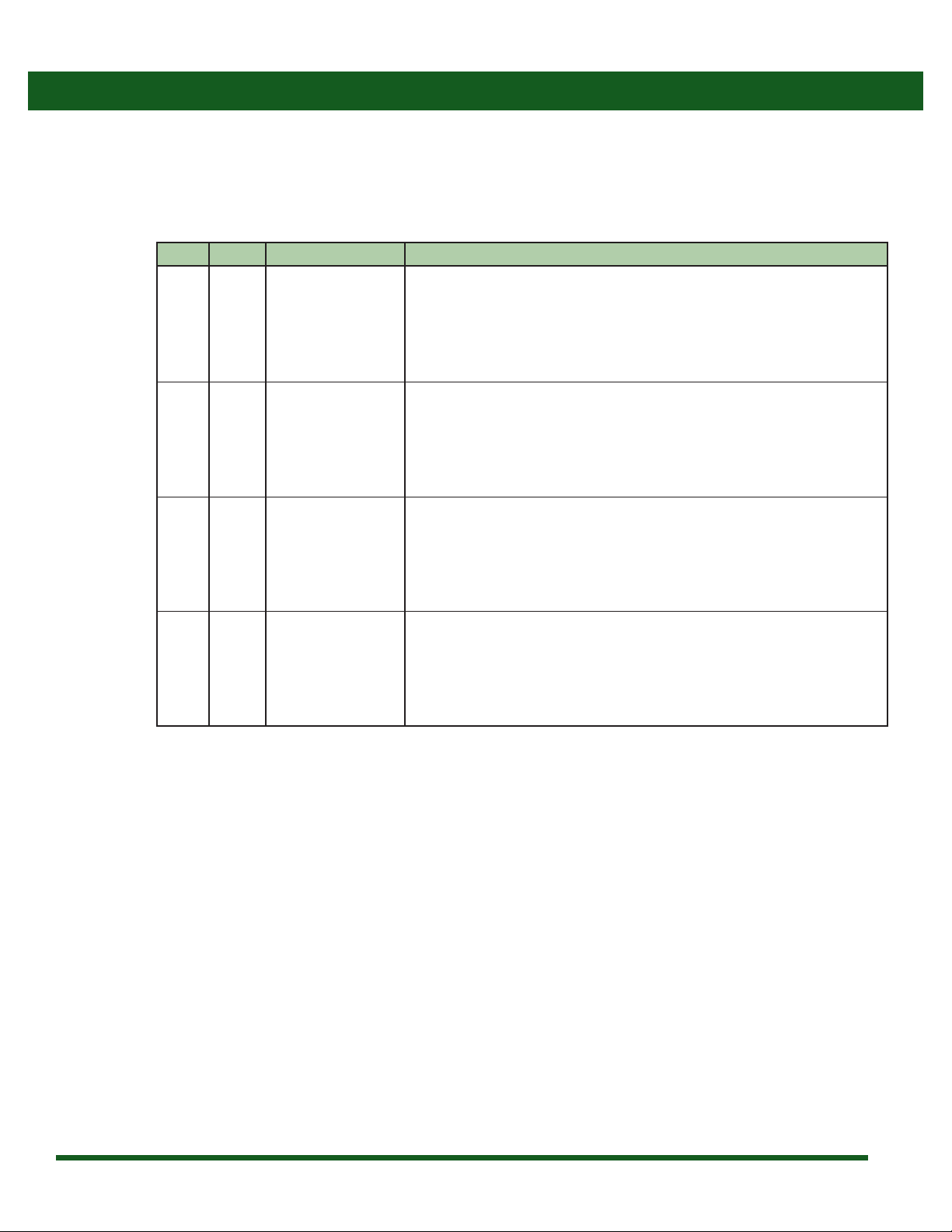

Ref # Qty. Part Numbers Description

1 25 FT 1206 Hose, EPDM Rubber 3/8" 200 PSI

2 55 FT 1208 Hose, EPDM Rubber 1/2" 200 PSI

3 15 1475UV Cable Tie, 14" 75 Lb UV Black

4 3 62606 Hose Clamp, Narrow 5/16"-7/8" SS

5 2 DC2014 Clamp, Loom 7/8" Steel

6 2 DS101 * Disinfect System Nozzle Assembly (Drives and Trailer)

7 2 DS102 * Disinfect System Nozzle Assembly (Steering)

8 2 DS103 * Disinfect System Check Valve

9 4 FDW14*112 Washer, Fender 1/4" ID x 1-1/2" OD

10 4 FW14 Washer, Flat 1/4"

11 4 H5C14*1 Bolt, Hex 1/4-20 x 1" Gr 5

12 4 LW14 Washer, Lock 1/4"

13 4 NC14 Nut, Hex 1/4-20

14 1 T12 Tee, 1/2" Hose Barbs Nylon

15 2 T533BKT Extension Bracket for T533

16 2 TK12*114H5 Screw, Tek Hex Head 12-24 x 1-1/4"

* These items are shown assembled, but will come in individual bags. See individual breakdowns for assembly.

3

4

59

10 11

12

13

14

15

16

2

6

7

8

1

15

Breakdowns & Parts Lists

Disinfect Sprayer Breakdown & Parts List

DS-TR, Disinfect System Trailer Plumbing Kit

Ref # Qty. Part Numbers Description

1 25 FT 1206 Hose, EPDM Rubber 3/8" 200 PSI

2 65 FT 1208 Hose, EPDM Rubber 1/2" 200 PSI

3 50 1475UV Cable Tie, 14" 75 Lb UV Black

4 3 62606 Hose Clamp, Narrow 5/16"-7/8" SS

5 10 DC2014 Clamp, Loom 7/8" Steel

6 2 DS101 * Disinfect System Nozzle Assembly (Drives and Trailer)

7 1 DS103 * Disinfect System Check Valve

8 1 DS104 * Disinfect System Quick Disconnect

9 4 FDW14*112 Washer, Fender 1/4" ID x 1-1/2" OD

10 4 FW14 Washer, Flat 1/4"

11 4 H5C14*1 Bolt, Hex 1/4-20 x 1" Gr 5

12 4 LW14 Washer, Lock 1/4"

13 4 NC14 Nut, Hex 1/4-20

14 1 T12 Tee, 1/2" Hose Barbs Nylon

15 2 T533BKT Extension Bracket for T533

16 10 TK12*114H5 Screw, Tek Hex Head 12-24 x 1-1/4"

* These items are shown assembled, but will come in individual bags. See individual breakdowns for assembly.

4

5

9

10

11

12

13

14

15

16

2

6

7

8

1

3

16

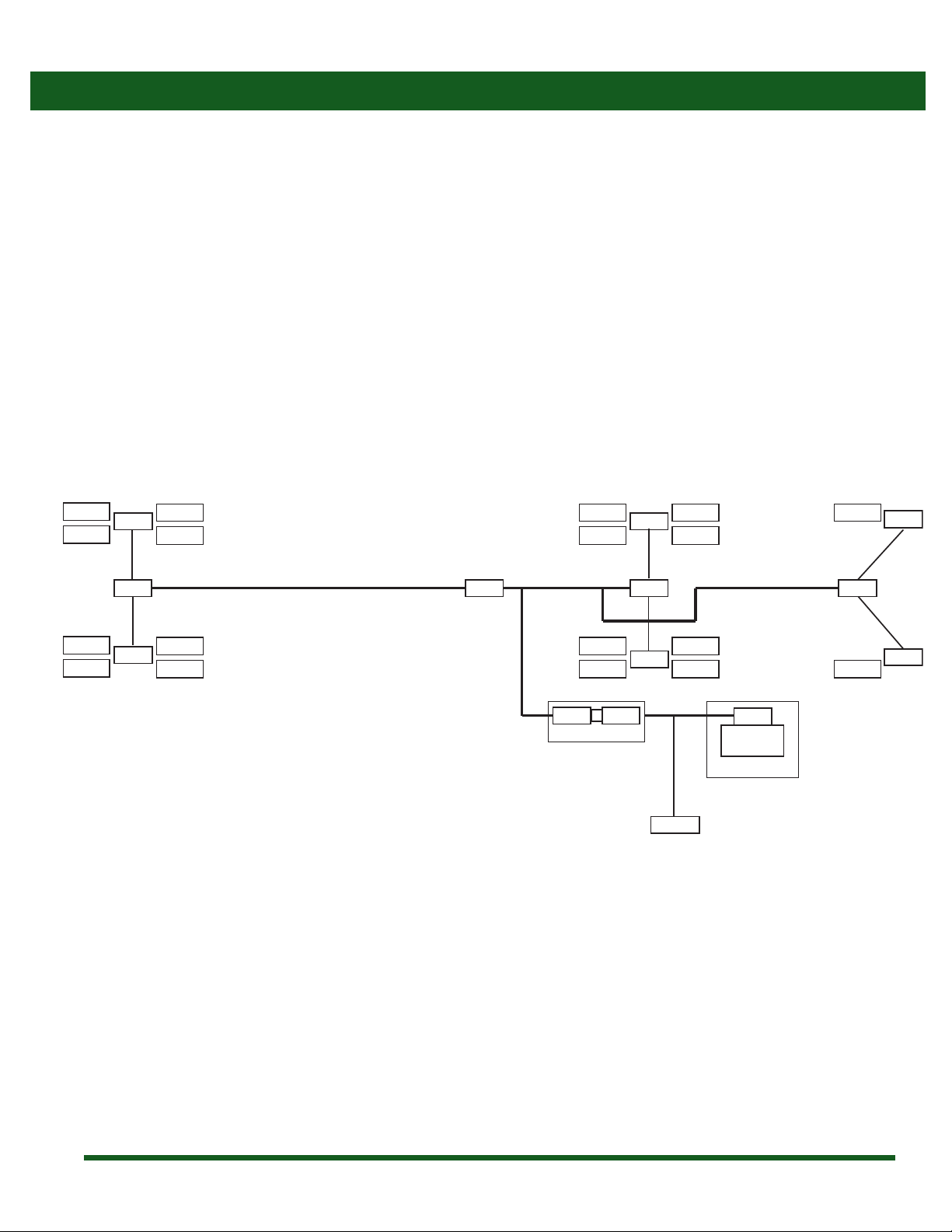

Disinfect Sprayer Schematic

Disinfect Sprayer Plumbing Schematic

DS103 DS103DS103

DS101

DS101

DS101

DS101

DS104

TRAILER DRIVES STEERING

DS102

DS102

“T”“T”

1/2” 1/2”

3/8”

3/8”

3/8”

3/8”

3/8”

3/8”

FILTER VALVE

DS106

DS-25

TANK

PUMP

“T”

GK50DS

3/8”

1/2”

1/2”

NOTE: This is a typical tractor trailer conguration for a DS25.

17

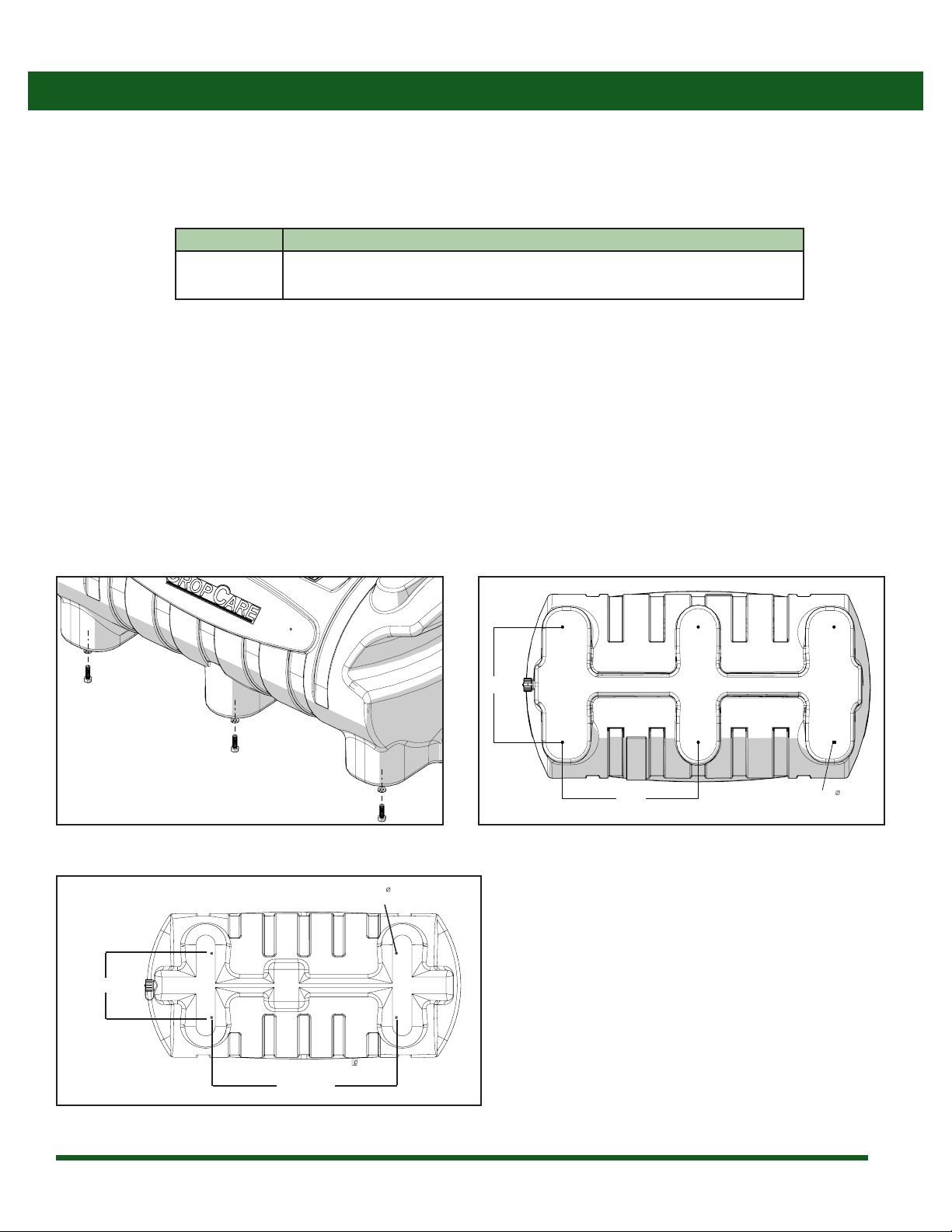

Installing the Sprayer

1. Select a mounting surface for the base unit. Mount the tank on the truck in a location that can withstand the weight of the base

unit with a full tank (approximately 250 lbs).

2. The location of the tank should not cause interference with the operation of the equipment it is mounted on.

3. For optimal stability, mount the liquid applicator with bolts using the six threaded holes in the bottom of the tank.

14”

11 1/8”

5/16

Figure 3: Applicator Unit Mounting Figure 4: Bottom Hole Dimensions (DS-25)

Base Unit Installation (DS-15 & DS-25)

Qty. Description

1 Assembled Base Unit

1 Parts bag with lter assembly components

Base Unit Box Contains:

• NOTE: Measure the distance between the bottom mounting holes because tank measurements can vary up to 1/4”.

• Attach the tank to the desired mounting surface using 5/16-18 bolts.

• IMPORTANT: Make sure that the bolts do not extend more than 1/2”into the tank. Use the shortest bolts possible and spacing

washers as needed to ensure that excess bolt length does not puncture the tank. Do not over-tighten bolts.

6 15/16”

19 3/4”

14”

11 1/8”

5/16

Figure 5: Bottom Hole Dimensions (DS-15)

18

Installing the Sprayer

Filter Unit Assembly and Installation (DS106)

1. Assemble components from lter unit package as shown on

page 12. Use Teon tape and/or thread sealant paste to seal

threaded connections. Do not over-tighten plastic ttings or

damage will occur.

2. Secure the lter unit to a solid surface using the supplied

loom clamps and self-drilling hex head screws.

3. Connect the pump outlet to the lter assembly inlet with

the required length of 1/2” hose and secure the hose with

hose clamps. Reference plumbing schematic on page 14.

Trailer/Drive Axle Nozzle Assembly and Mounting (DS101)

1. Assemble components from nozzle unit package as

shown on page 8. Use Teon tape and/or thread sealant

paste to seal threaded connections. Do not over-tighten

plastic ttings or damage will occur.

2. Nozzle should be approximately 13” from the tire and

centered between the dual wheels or centered on the

single tire to ensure complete and thorough coverage of

the tire(s). Use the supplied universal mounting bracket

to ensure that you can achieve the desired coverage.

Nozzles Mounted with Bracket

Nozzles Mounted without Bracket

19

Installing the Sprayer

Steering Axle Nozzle Assembly and Installation (DS102)

1. Assemble components from nozzle unit package. Use Teon tape and/or thread sealant paste to seal threaded connections

as shown on page 9. Do not over-tighten plastic ttings or damage will occur.

2. Nozzle should be approximately 8” from the tire and centered on the tire to ensure complete coverage.

20

Installing the Sprayer

Diaphragm Check Valve Assembly and Installation

1. Assemble components from nozzle unit package as shown on page 10. Use teon tape and/or thread sealant paste to seal

threaded connections. Do not over-tighten plastic ttings or damage will occur.

2. Secure the check valve unit near the axle with the supplied universal mounting bracket (reference 4, page 10).

3. Connect the 3/8” hose to the “T” (reference 2, page 10) on the check valve unit and route hose to the nozzle unit.

4. Connect ½” hose to the check valve inlet and route hose from the check valve to the outlet of the lter assembly.

5. Use one check valve assembly for every axle. Connect the 1/2” hoses from all check valve assemblies together using 1/2” tees

(reference plumbing schematic, page 14)

Bulkhead/Quick Disconnect Assembly and Installation

1. Drill a 1-3/16” hole in the desired location for the quick disconnect coupler. It should be located near the air and/or electrical

connections between the tractor and trailer.

2. Place the bulkhead adapter tting through the hole and secure with the external locking washer and nut.

3. Assemble the remaining components from the quick disconnect assembly package onto the bulkhead as shown on page 11.

4. Connect ½” supply hose from lter assembly to the xed end of the quick disconnect and the tractor supply hose to the plug

end of the quick disconnect (reference plumbing schematic, page 14).

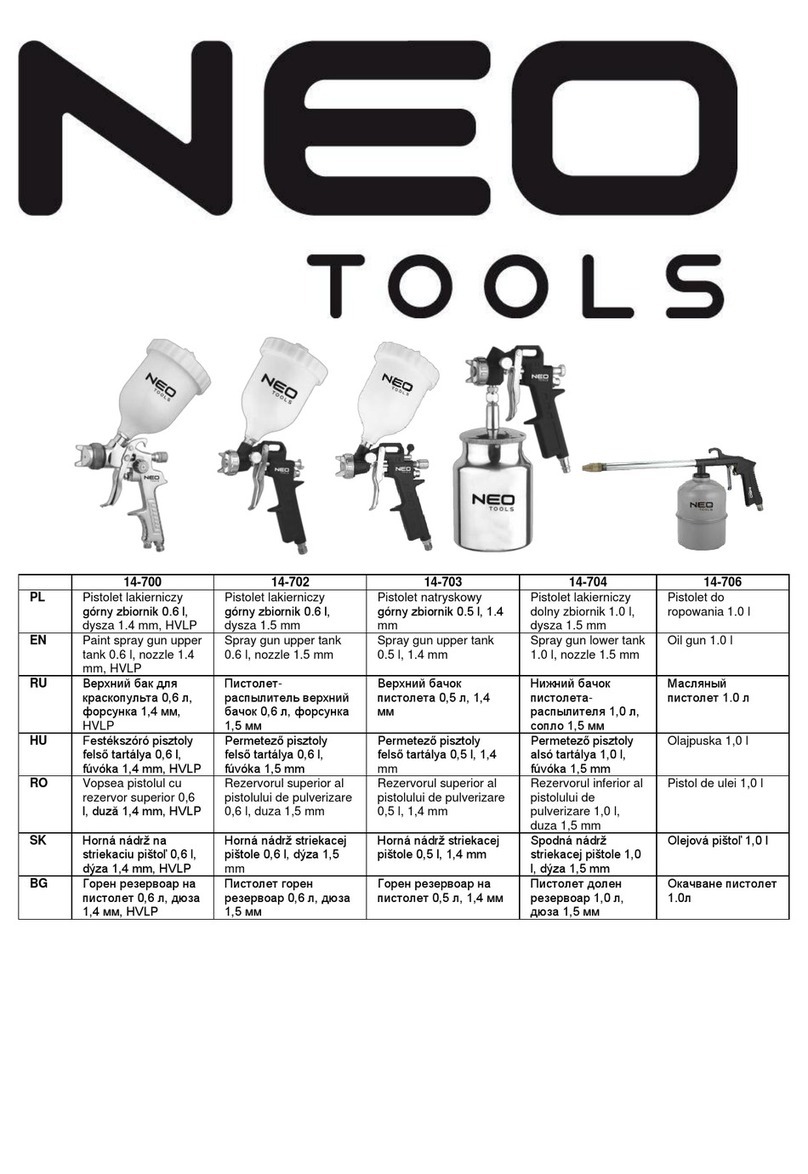

Spray Gun Assembly and Installation

1. Cut the ½” supply line between the pump outlet and the lter assembly. Install the adapter “T” (reference 5, page 13) into the

supply line and secure with hose clamps (reference plumbing schematic, page 14).

2. Connect the 3/8”spray hose to the adapter“T” (reference 4, page 13) and to the swivel spray gun adapter (reference 3, page 13)

and secure the hose with a hose clamp (reference 2, page 13).

3. Thread the swivel adapter (reference 3, page 13) onto the spray gun inlet.

4. Coil the 3/8”spray hose and securely fasten to the truck with bungee straps (not included) or alternative method.

This manual suits for next models

1

Table of contents

Other Paul B. Zimmerman Paint Sprayer manuals